Algerian customer visit - cable tray machine

2025-05-23 12:00Last month, KINGREAL warmly received customers from Algeria. The purpose of the visit of Algerian customers was to inspect KINGREAL cable tray machine to confirm whether it meets the production needs of Algerian customers. As a professional cable tray making machine manufacturer, KINGREAL has always been committed to providing high-quality and efficient cable tray machine solutions to global customers.

Welcome Algerian Customers

| On the day the customers arrived, the KINGREAL team accompanied the Algerian customers throughout the whole process and enthusiastically introduced KINGREAL cable tray machine to them. KINGREAL knows that the performance and quality of the cable tray making machine directly affect the production efficiency and product quality of Algerian customers. Therefore, during the reception process, KINGREAL paid special attention to details to ensure that Algerian customers can fully understand all aspects of the cable tray machine. |  |

Introduction to Various Components of Cable Tray Machine

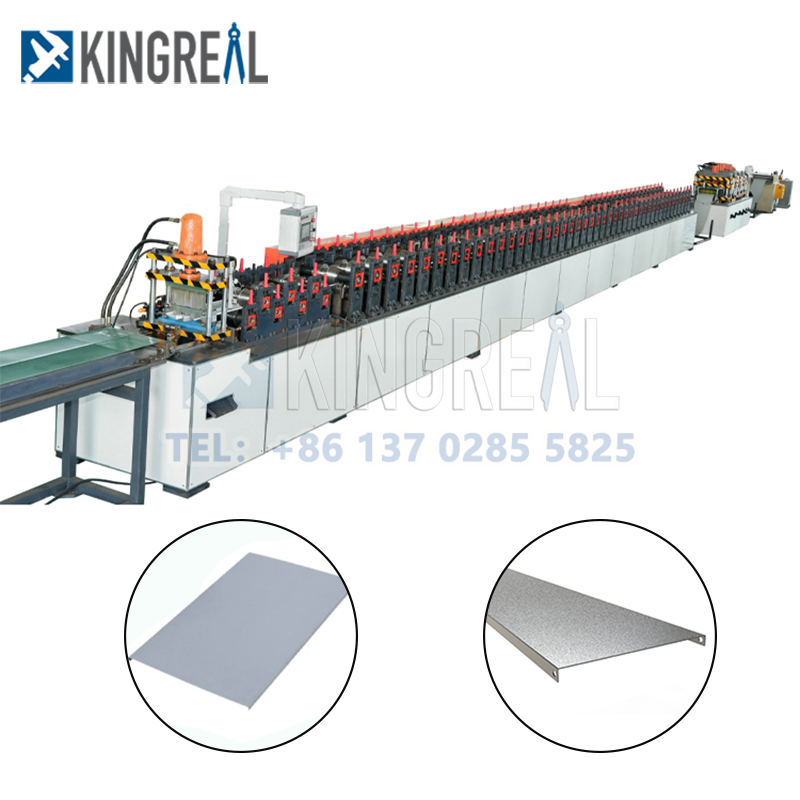

During the visit, the KINGREAL team introduced the key components of the cable tray making machine one by one, including decoiler, precision leveling machine, punching station, shearing station and main roll forming machine, etc.

Decoiler for cable tray making machine The decoiler is the first process of the cable tray machine, which is responsible for smoothly unwinding the coil for subsequent processing. KINGREAL showed the Algerian customer the operation process of the decoiler and emphasized its importance in the production process. A good uncoil effect lays the foundation for the smooth progress of the subsequent steps.

Precision leveler for cable tray machine The precision leveler is responsible for leveling the unrolled coil to eliminate any ripples or irregular shapes. KINGREAL explained to the Algerian customer the working principle of the precision leveler and its impact on product quality to ensure that the Algerian customer can understand the importance of this link. |  |

Punching station for cable tray making machine The punching station is an indispensable part of the cable tray making machine. It is responsible for punching holes in the cable tray for subsequent installation and wiring. KINGREAL introduced the functions of the puncher in detail and demonstrated its application in production.

Cutting station for cable tray machine The cutting station is used to cut the processed cable tray into the required length. KINGREAL emphasized the impact of cutting accuracy on the quality of the final product and demonstrated how to adjust the parameters to achieve different lengths of cutting.

Roll forming machine for cable tray making machine The roll forming machine is the core of the cable tray machine, which is responsible for processing metal materials into the required shape. KINGREAL showed the Algerian customer the operating process of the roll forming machine and emphasized its flexibility to adjust the forming specifications according to the needs of Algerian customers. |  |

Confirm Algerian Customer Needs

During the introduction, the KINGREAL team had in-depth communication with the Algerian customer to confirm its production needs. KINGREAL learned about the specific requirements of Algerian customers for the width, thickness and height of the cable tray. According to the needs of Algerian customers, KINGREAL is able to provide medium duty cable tray making machines and heavy duty cable tray machines to meet different production loads.

The difference between medium and heavy duty cable tray machines:

Medium duty cable tray making machines are generally suitable for medium-scale production needs, can handle lighter materials, and are suitable for general cable tray production. Heavy duty cable tray making machines are designed to handle thicker and heavier materials, can withstand greater production loads, and are suitable for large-scale production and high-intensity use. According to the specific needs of customers, KINGREAL will recommend the most suitable model for them.

Diverse Types of Cable Tray Machines

In addition to medium and heavy duty cable tray making machines, KINGREAL is also able to provide different types of cable tray machines to meet customer needs in different scenarios. These types include:

Cable Ladder Machine: used to produce ladder-shaped cable trays, suitable for overhead wiring.

Solid Bottom Cable Tray Machine: used to produce solid bottom cable trays, suitable for heavy loads and complex wiring needs.

Cable Tray Cover Machine: used to produce covers for cable trays, providing additional protection.

Din Rail Channel Machine: cable trays designed for DIN rails, suitable for industrial control equipment.

Perforated Cable Tray Machine: used to produce cable trays with holes for ventilation and heat dissipation.

Trough Cable Tray Machine: suitable for the production of trough cable trays, suitable for a variety of wiring applications.

KINGREAL introduced the characteristics of each type and its application scenarios to customers in detail, ensuring that they can choose the cable tray making machine that best suits their needs.

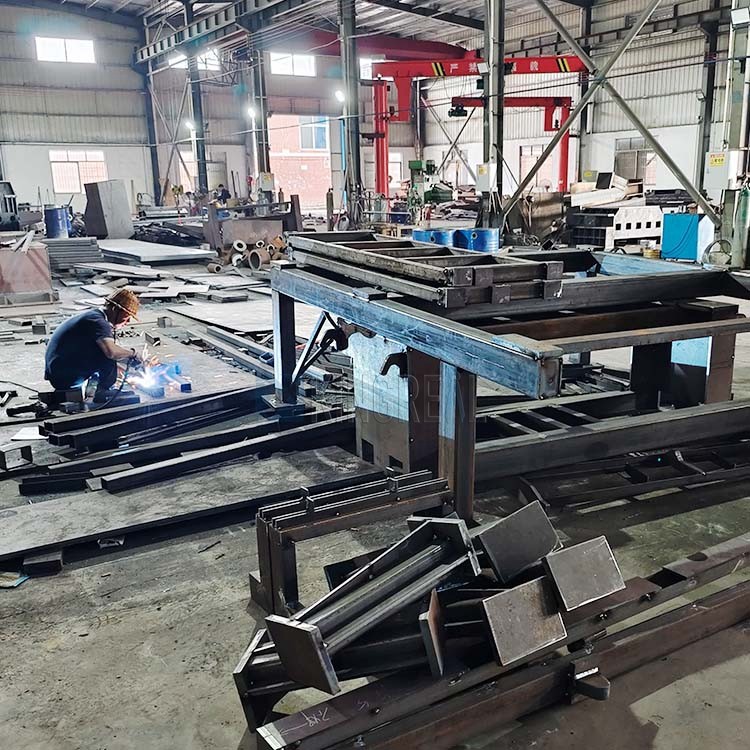

Rigorousness of Manufacturing Process

The KINGREAL team promised Algerian customers that the manufacturing process of the cable tray machine is very rigorous. The materials selected by KINGREAL are all high-quality materials to ensure the quality and durability of the cable tray making machine. KINGREAL took the Algerian customers to visit the raw material selection workshop and showed them KINGREAL strict control of material quality.

During the raw material selection process, Algerian customers can see how KINGREAL screens suitable metal materials and understand KINGREAL strict requirements for material suppliers. Through this transparent process, Algerian customers' trust in KINGREAL has been further deepened.

Feedback from Algerian Customers

At the end of the visit, Algerian customers expressed their satisfaction with KINGREAL cable tray making machine and the entire production process. They highly praised KINGREAL professionalism and the high performance of its cable tray making machine, and look forward to starting cooperation as soon as possible. The feedback from Algerian customers is not only a recognition of KINGREAL work, but also an incentive for us to continuously improve the quality of our products and services.