How does Solar Channel Roll Forming Machine provide a complete photovoltaic system?

2025-06-19 12:00Solar Channel Roll Forming Machine produces Solar Channels of different sizes to provide safe and reliable support for solar panels, and is a key component in the solar panel installation system. It is favored for its durability and easy installation.

Among them, in a complete photovoltaic system, both the roof tile making machine and the solar channel making machine are indispensable parts. Therefore, only when they are used in combination can a complete photovoltaic system be formed. In this article, KINGREAL will give you a detailed introduction on how the solar channel roll forming machine and the roof tile making machine are used together to provide customers with a complete photovoltaic system.

Solar Channel Roll Forming Machine

◆Definition of solar channel making machine

| KINGREAL high-speed fully automatic solar channel making machine provides an efficient solution for large-scale production. These solar channel roll forming machines are equipped with PLC control systems and servo motors for automatic length measurement, cutting and stacking. High production speed and low maintenance requirements make it an ideal choice for large solar frame manufacturers. |  |

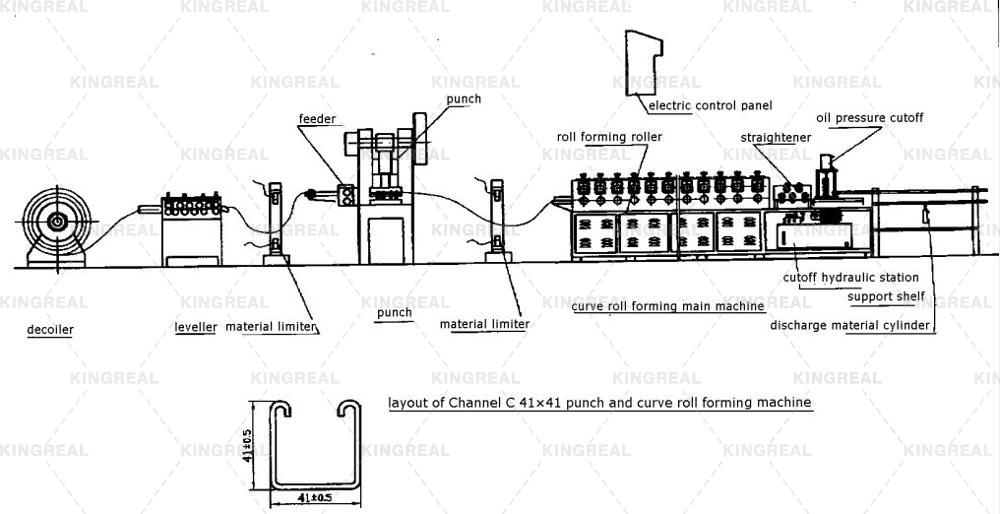

◆Workflow of solar channel making machine

Decoiler - ↓ Servo Feeder- ↓ Punching Press- ↓ Roll forming Machine- ↓ Cutting Station- ↓ Out Table |  |

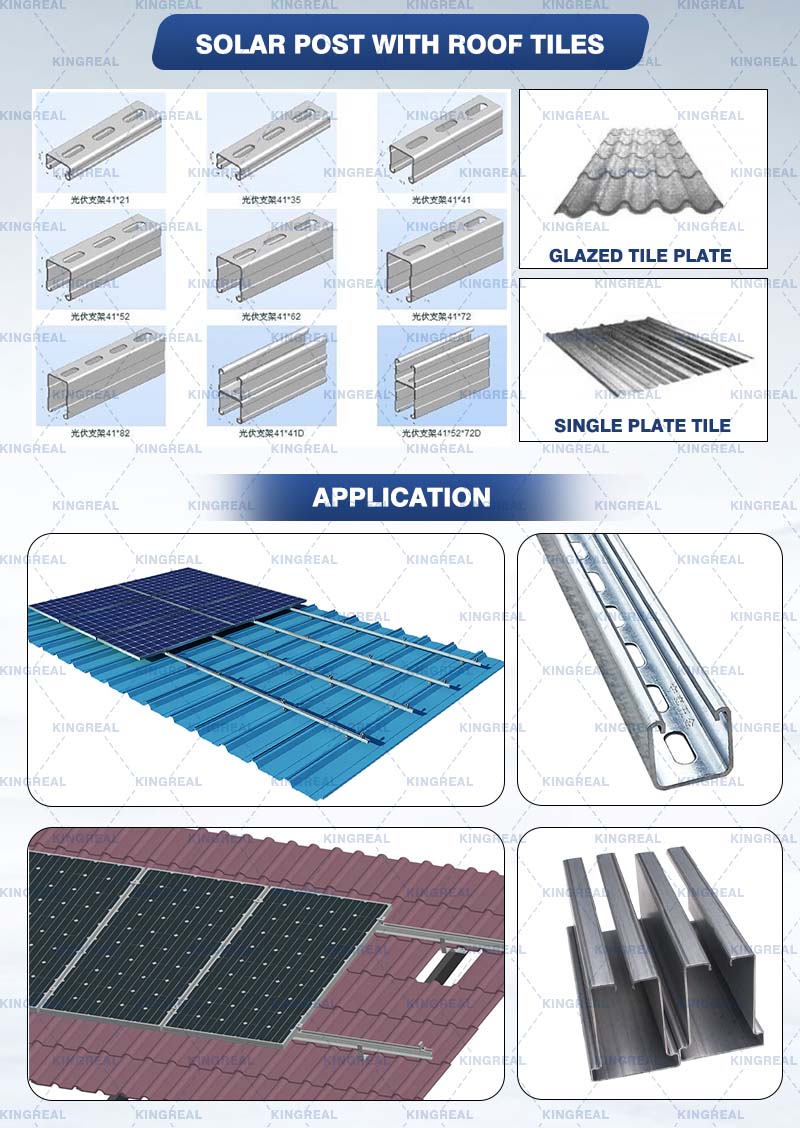

◆Common finished product sizes

41 × 21, 41 × 41, 41 × 62, 41 × 82 mm,etc

◆Parameter of solar channel roll forming machine

| item | value |

| Applicable Industries | Hotels, Shops, Houses, Company...... |

| Production Capacity | 10-15m/min |

| Voltage | 380V 50Hz 3phases or as your requirement |

Dimension(L*W*H) | 8*1.2*1.3 |

| Weight | 5000kg |

| Key Selling Points | Easy to Operate |

Rolling thickness | 0.3-0.8mm |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Core Components | Pressure vessel, Motor, Other, Bearing, Gear, Pump, Gearbox, Engine, PLC |

Main frame | 400 H steel |

Control system | PLC with touch screen |

| Roller material | Gcr15 |

| Material of cutting | Cr12mov with quench HRC58-62° |

Roof Tile Making Machine

◆Definition of roof tile making machine

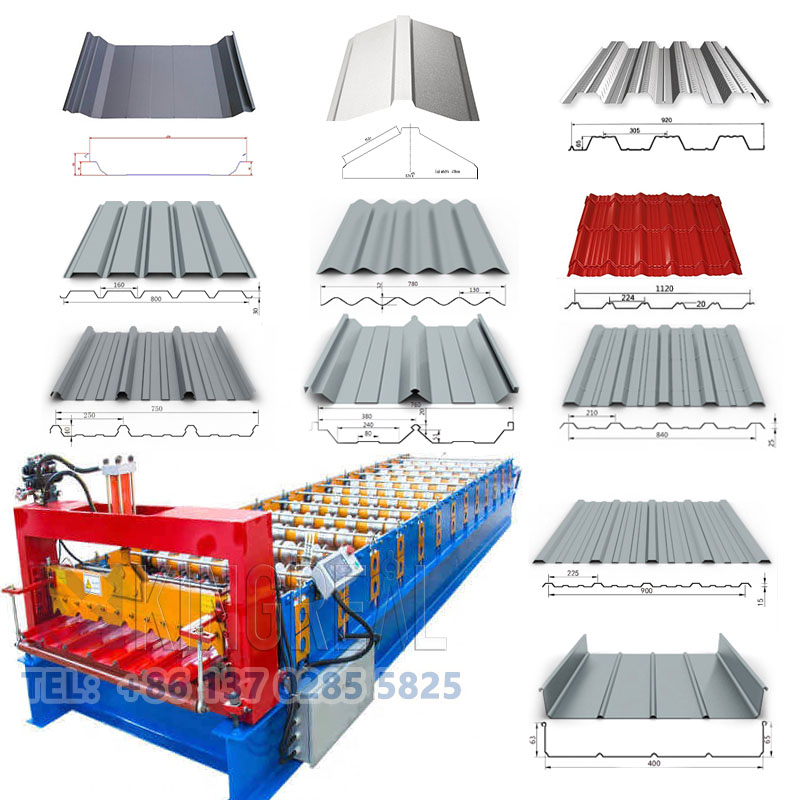

KINGREAL roof tile making machine is specially used to produce metal roof tiles of various types and sizes, with the advantages of fast forming speed, large output, reliable performance, high degree of automation and easy operation. Metal roof tiles are an affordable solution with good high temperature resistance and are in strong demand in many regions. Compared with traditional concrete roof tiles or asphalt roof tiles, metal roof tiles are lighter, more durable and can effectively cope with various climate conditions. |  |

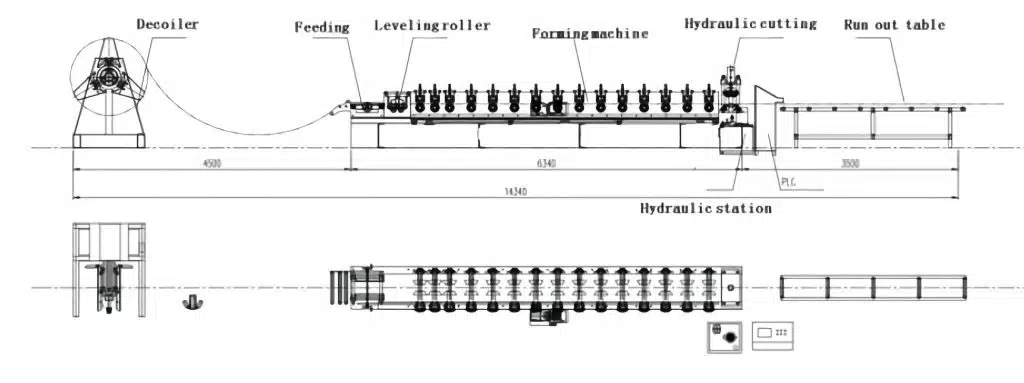

◆Workflow of roof tile making machine

Decoiler ↓ Guiding Device ↓ Roll Forming Machine ↓ Cutting Device ↓ Run Out Table |  |

◆Various types of roof tile making machines

KINGREAL can provide various types of roof tile making machines according to customers' different requirements for finished product materials, characteristics, shapes, applications, etc., including:

glazed tile roll forming machine

corrugated roofing tile machine

double layer roofing sheet machine

standing seam roof panel machine

...

Synergy Between Solar Channel Making Machine & Roof Tile Making Machine

Glazed tile roof photovoltaic brackets provide a safe, beautiful and efficient solution for the installation of solar panels. The design of these photovoltaic brackets is perfectly integrated with the appearance of the tiles, so that the installation of the photovoltaic system will not only not destroy the beauty of the building, but also effectively enhance the overall value of the building. The use of solar channel roll forming machines greatly improves the production efficiency of the brackets and can quickly meet market demand.

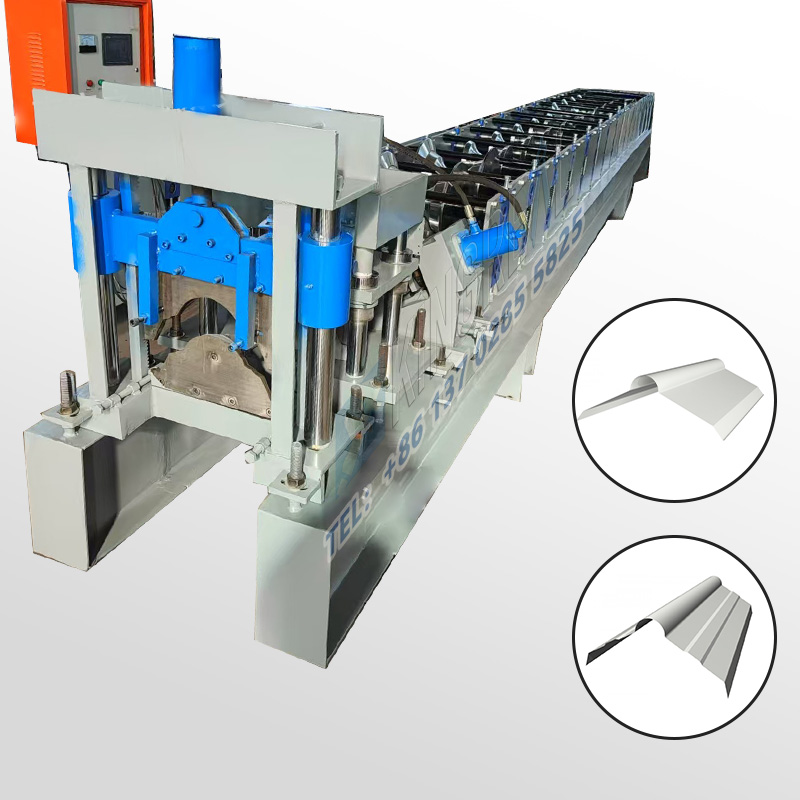

In most cases, the installation of photovoltaic brackets is carried out on the tile surface, so the coordination of solar channel making machines and roof tile making machines is particularly important. Solar channel making machines focus on the production and installation of brackets, while roof tile making machines play a key role in the production of roof tiles. KINGREAL is able to provide a range of specially designed solar channel roll forming machines and roof tile making machines to meet the needs of different roof types, including solar channels for glazed tile roofs, color steel tile roofs and flat roofs.

| ◆Photovoltaic support for roofs of glazed tiles Many people see glazed tile roofs as a premium choice for high-end properties; they are noted for both their beauty and their lifespan. The shape and weight of the tiles must be completely considered when erecting a photovoltaic system on such a roof in the design of the photovoltaic bracket. The relevant solar channel making machine creates appropriate brackets based on the properties of glazed tiles, which can be easily integrated with tiles to guarantee the beauty and operation of the whole system. Besides the necessary support, the photovoltaic bracket for the glazed tile roof serves a waterproof function that guarantees the long-term and stable performance of the photovoltaic system. Ensuring roof tile quality and giving a basis for photovoltaic bracket stability, the roof tile making machine also has a significant part in this procedure. The bracket's installation is rather easy, therefore it can significantly reduce building time and boost work efficiency.

◆Photovoltaic brackets for color steel tile roofs The arrangement of the photovoltaic brackets is also quite important for color steel tile roofs. The installation of the brackets calls for a particular adjustment mechanism to guarantee that the photovoltaic panels can be securely affixed on the smooth surface of the color steel tile. Our brackets for color steel tile roofs offer secure and customizable mounting options to guarantee the system's stability and long performance under various weather conditions. The photovoltaic brackets for color steel tile roofing can provide excellent performance in many settings because they are oxidationresistant and corrosionresistant. This bracket's flexible construction also lets it fit photovoltaic panels of many sizes and types, therefore increasing the compatibility and adaptability of the system. During the production of color steel tiles, the roof tile making machine guarantees the quality of the metal roof tiles by exact control, therefore offering a warranty for the stability of the photovoltaic brackets.

◆Photovoltaic brackets designed for flat roofs Especially crafted to address the challenges of installing photovoltaic panels on flat roofs, the photovoltaic brackets for flat roofs help. Flat roofs typically have problems including rainwater buildup and severe winds. Therefore, the design of the photovoltaic brackets must consider these elements to guarantee that the photovoltaic panels can be securely fastened on the surface of the flat roof. In this procedure, the solar channel roll forming machine is very important; it may swiftly create brackets that meet demands. Emphasizing stability and durability, the flat roof photovoltaic bracket's structural design not only enables the system to withstand the effects of the outside environment but also guarantees the long-term efficient power generation of the photovoltaic installation. The exact manufacturing of theroof tile making machine guarantees the ideal mix of metal roof tiles in the flat roof photovoltaic system, therefore increasing the dependability of the whole system both during installation and in operation. |