Indian Customer Visit: Light Gauge Steel Framing Machine

2025-06-25 12:00| Recently, accompanied by the KINGREAL team, Indian customers visited the KINGREAL factory and visited the company's latest developed light gauge steel framing machine. This visit was not only an understanding of the light steel villa structure machine, but also an in-depth technical exchange. The two sides conducted detailed discussions in various links of light steel villa structure production. |  |

1. Visit Process and Equipment Introduction

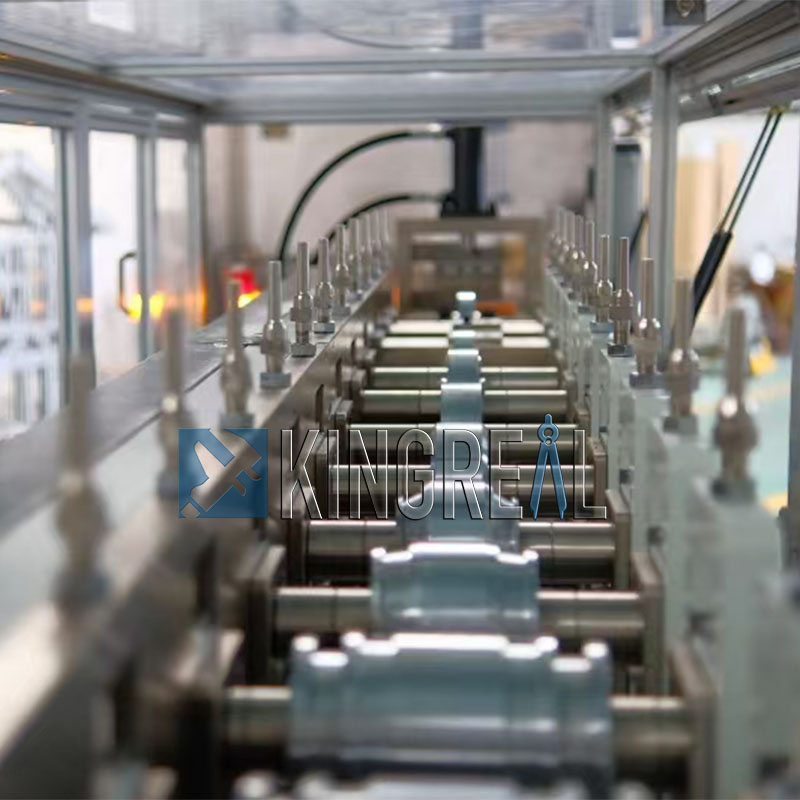

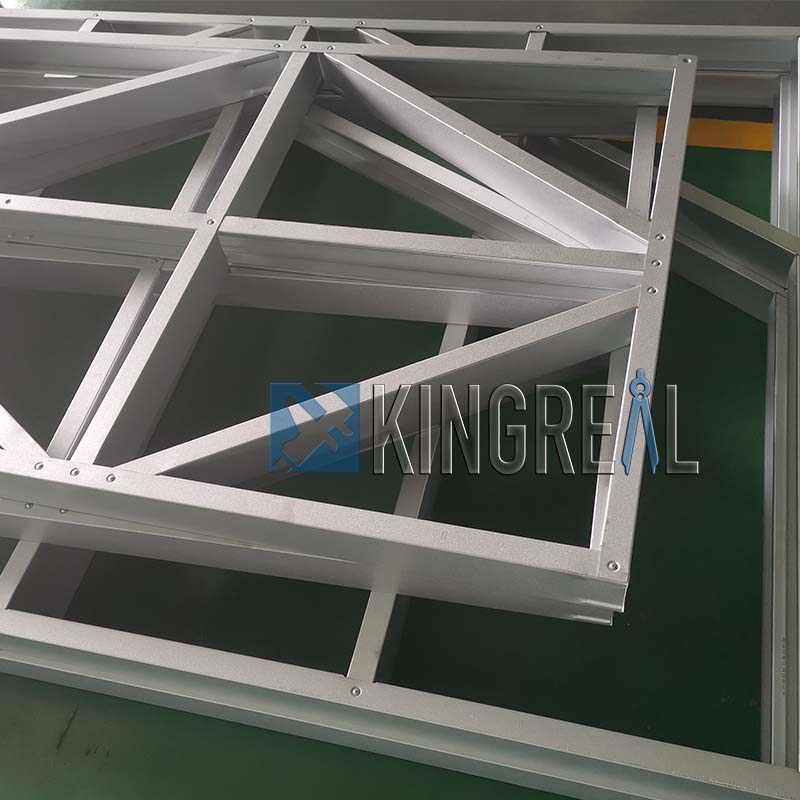

The production process of the light steel villa structure machine mainly includes five important steps: unwinding, leveling, punching, forming and cutting. KINGREAL engineers personally operated the light gauge steel framing machine and demonstrated each production link step by step to Indian customers. During this process, KINGREAL staff explained in detail the technical requirements and precautions of each step, so that customers have a comprehensive understanding of the entire production process.

1.1 Unwinding for light steel villa structure machine During the unwinding stage, the raw material coil is installed on the decoiler, and KINGREAL staff demonstrated how to fix and adjust the material to ensure that the coil can be smoothly unfolded in subsequent processes. |  |

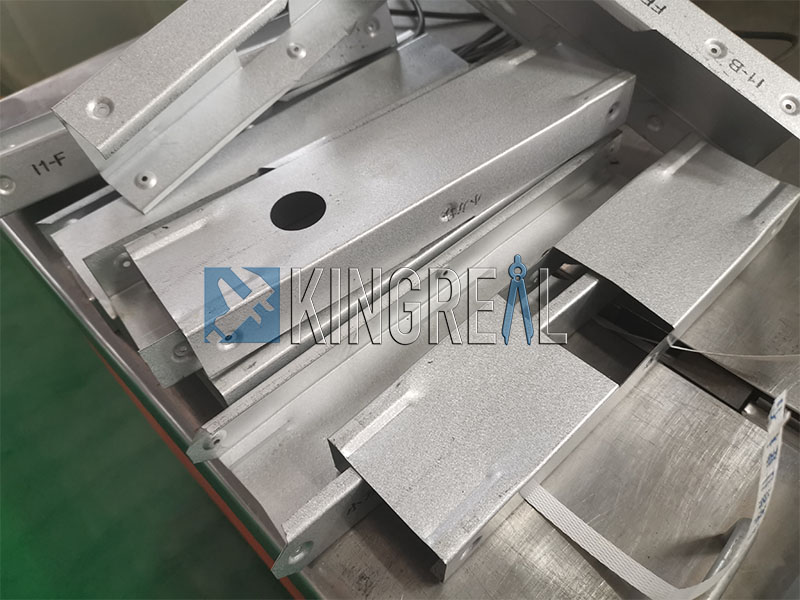

1.2 Punching for light gauge steel framing machine Punching is a key link in the production process of the light steel villa structure machine. The staff introduced to the Indian customers that KINGREAL can customize punching dies according to the drawings provided by the customers to meet the needs of various hole types and hole diameters. The Indian customers expressed great concern about this and asked about the diversity of hole types. KINGREAL staff answered in detail that common hole types include Dimple hole, Web notch, Service hole and Bolt hole. The engineer said that all molds are made of high-quality S45C tool steel, and the mold core uses D2 or SKD11 high-quality steel, and Japanese products are used to ensure the durability and accuracy of the mold. These high-standard material selections make the punching process efficient and accurate, and can meet customers' needs for a variety of hole types on the wall panels. |  |

| 1.3 Forming for light gauge steel framing machine In the forming stage, KINGREAL engineers demonstrated how to use the light steel villa structure machine to form pre-flattened metal materials into light steel components. The design of the roll forming machine uses a steel plate welded frame, which is annealed as a whole to ensure that it will not deform during long-term use. This sturdy structural design provides a reliable foundation for production. |  |

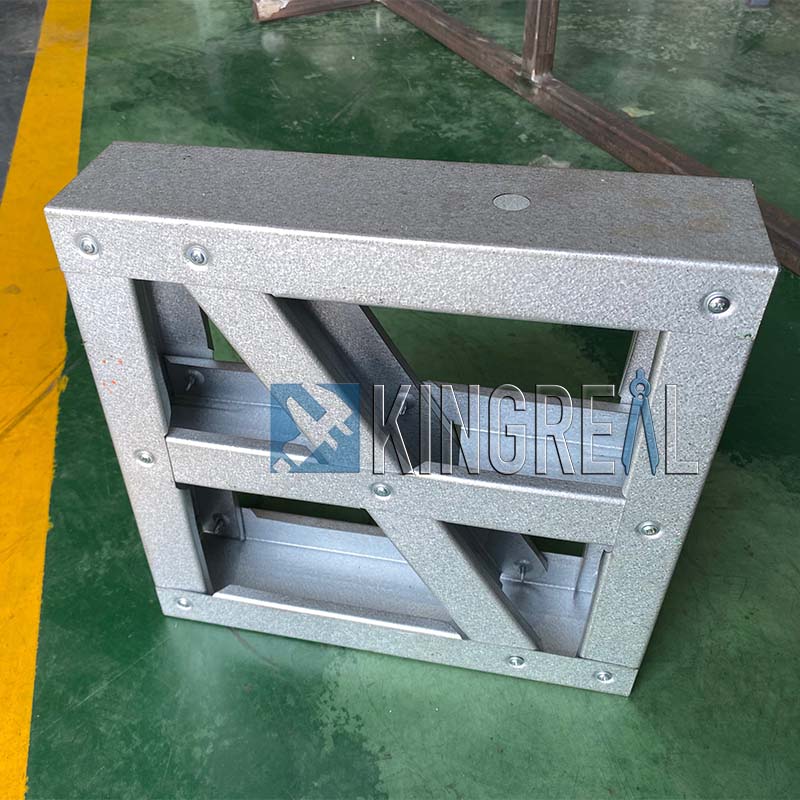

1.4 Cutting for light gauge steel framing machine The cutting stage is to cut the formed metal components according to the length required by the customer. KINGREAL staff specifically mentioned that the production speed of KINGREAL light gauge steel framing machine is very fast, and it can produce up to 1000mm light steel components per second. |  |

2. Advanced Light Steel Villa Structure Machine and Customized Services

During the visit, KINGREAL staff introduced the light gauge steel framing machine's advanced design concept and technical advantages to customers. In particular, relying on internationally advanced design software, KINGREAL can achieve 30 minutes of rapid drawing and enter the production stage, which greatly saves customers' time and resources.

2.1 High-quality inkjet solution for light steel villa structure machine In addition, KINGREAL also equipped the light gauge steel framing machine with an industrial-grade high-quality solvent-based electronic inkjet printer, which can accurately spray the surface of the finished product after the profile is formed. This function makes the printed handwriting clear and firm, which is convenient for subsequent assembly and installation. The surface of the finished product can display information such as type and model, which greatly facilitates customers to identify and manage the finished product |  |

2.2 Flexible component configuration for light steel villa structure machine KINGREAL also provides different components of the light gauge steel framing machine according to customer needs to meet different price and production efficiency requirements. For example, when choosing a decoiler, customers can choose a 1.5-ton hydraulic decoiler or a 2-in-1 decoiler and leveling machine. This flexibility enables KINGREAL to provide customized solutions for customers of different sizes. |  |

3. Quality Assurance Measures

During the customer visit, Indian customers paid attention to the quality of the finished products and asked KINGREAL how to ensure the high quality of the finished products. KINGREAL staff confidently answered that the frame design and material selection of the light steel villa structure machine are the key to ensuring the quality of the machine and the accuracy of the finished product.

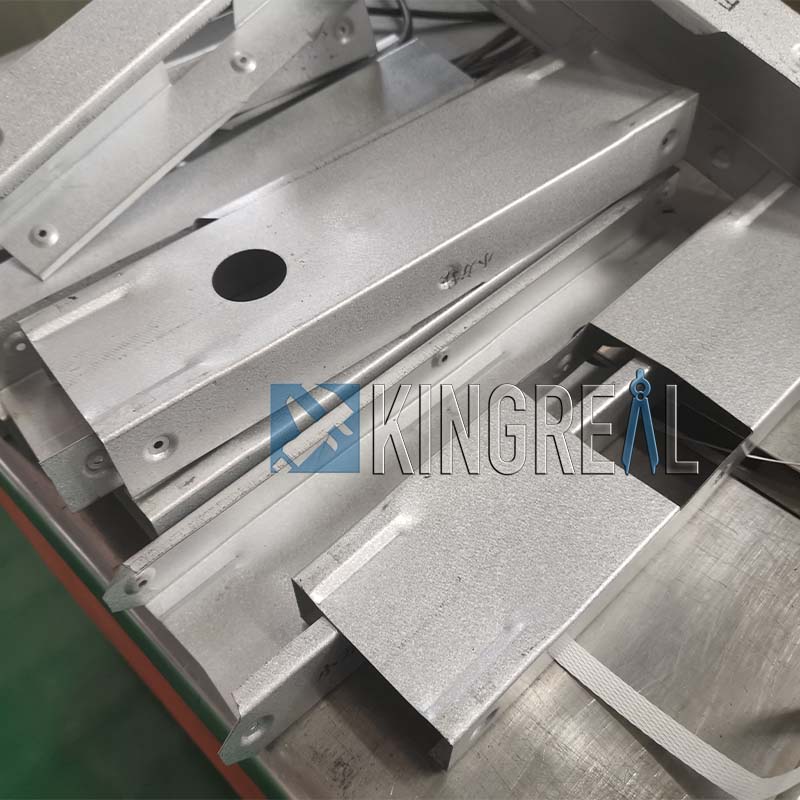

3.1 Frame Design and Materials

The frame of the roll forming machine is welded with steel plates and is subjected to overall annealing and stress relief treatment to ensure that it does not deform during long-term use. The stability of the frame is crucial to the entire production process. KINGREAL processes the frame through a CNC machining center to ensure its dimensional accuracy.

3.2 Molds and Processing Technology

The selection of materials for the forming mold is also very particular. KINGREAL uses Cr12mov mold steel and undergoes vacuum quenching heat treatment to achieve a hardness of HRC60-62°. Such treatment not only enhances the wear resistance of the mold, but also ensures the processing accuracy of the finished product. The inner hole and end face of the mold are finely ground to ensure the high precision and consistency of each hole type.

3.3 Spindle and drive system

The spindle material is 40Cr tool steel, which is quenched and tempered heat treated and finely processed by external cylindrical grinding to improve its durability and precision. The drive mode adopts the linkage of servo motor and reducer to ensure the stability and efficiency of the light steel villa structure machine during operation. The precision hard tooth surface gears are used between the rollers for oil-immersed operation, which can maintain good performance and reduce wear during long-term use.

At the end of the visit, the Indian customer highly appreciated the light gauge steel framing machineand service provided by KINGREAL, and reached a preliminary cooperation intention with KINGREAL.