The Definitive Guide To Cable Tray Machines

2025-05-30 12:00In modern industry, cable tray machines play a vital role. As a professional cable tray equipment manufacturer, KINGREAL is committed to providing comprehensive information and guidance to customers who have cable tray making machine purchase needs. This article will introduce the different types of cable tray machines on the market in detail to help you make an informed purchase decision. If you are interested in cable tray making machines, please continue reading.

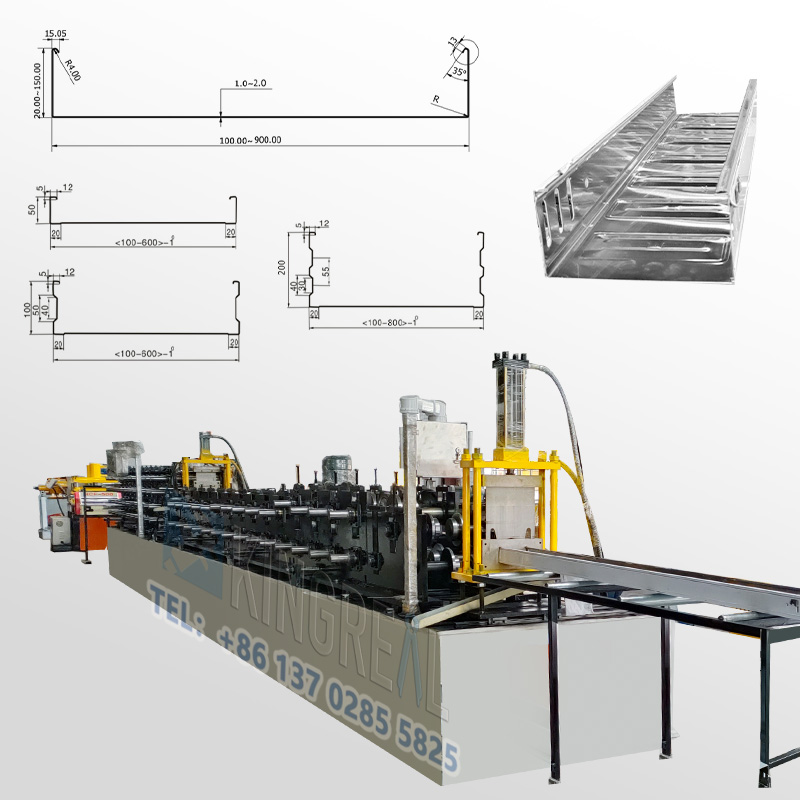

What is a Cable Tray Machine?

A cable tray making machine is an industrial equipment specially used to produce cable trays. It transforms metal raw materials into the required cable tray shape by high-speed roll forming. The main function of a cable tray is to hang and protect cables and signal lines to ensure their safe and reliable use. |  |

Advantages of Using a Cable Tray Making Machine

There are many reasons to choose a cable tray machine. Here are some of the significant advantages:

1. Fast and accurate production The cable tray making machine can produce various types of cable trays extremely quickly to meet the needs of mass production. Its design allows the production process to be efficient and smooth, and a large number of products can usually be manufactured in a short period of time. This efficiency not only saves production time, but also improves overall production efficiency. For example, in the traditional manual production mode, it may take days or even weeks to manufacture the same number of cable trays, but after using the cable tray making machine, the production cycle can be shortened to a few hours. Such improvements enable companies to respond quickly to market demand and meet customer orders, thereby improving market competitiveness. |  |

2. Reduce time and labor costs Through a fully automated production process, the cable tray machine significantly reduces labor costs. Traditional production methods usually require the participation of multiple workers, from the preparation of raw materials to the inspection of the final product, which not only increases labor costs, but is also prone to human errors. The automated design of the cable tray making machine greatly reduces the number of links that operators need to participate in, and many operating processes can be completed independently by the cable tray machine. This means that companies can focus their human resources on other important tasks, such as product design, marketing, etc., further improving overall operational efficiency and profit margins. |  |

3. High degree of automation Modern cable tray machines are usually equipped with advanced control systems that enable automated operation. These control systems not only improve production efficiency, but also reduce the possibility of human error. Through intelligent monitoring and regulation, the cable tray making machine can automatically adjust parameters according to production needs to ensure the quality consistency of each batch of products. In addition, many cable tray machines are also equipped with fault detection and alarm functions, which can monitor the operating status of the equipment in real time and issue alarms in time when problems occur, thereby avoiding production interruptions. This high level of automation brings enterprises higher production safety and stability, reduces downtime, and improves overall production capacity. |  |

How Cable Tray Machines Work?

The working principle of cable tray making machines can be summarized in the following steps: Decoiler for cable tray machine: Unwinds the metal coils and prepares them for subsequent processing. Leveler for cable tray machine for cable tray machine: Ensures that the metal material is flat and ready for punching. Punching station for cable tray making machine: Punches the metal material according to design requirements for subsequent installation and heat dissipation. Roll forming machine for cable tray making machine: Rolls the metal material into the desired shape through a series of rollers. Cutting station for cable tray machine: Cuts the formed cable tray to the specified length. This series of processes ensures efficient and precise production. |  |

Types of Cable Tray Making Machines

KINGREAL provides a variety of types of cable tray making machines according to different usage scenarios and customer needs. Here are some of the main types:

| 1. Cable Tray Ladder Machine | This machine is specially designed to produce ladder-shaped cable trays, suitable for various cable wiring needs. Its structural design allows cables to be better hung and managed. |

| 2. Solid Bottom Cable Tray Machine | It is used to manufacture cable trays with solid bottoms, with strong load-bearing capacity, suitable for heavy-duty occasions. |

| 3. Cable Tray Cover Machine | This machine is used to produce the cover of the cable tray, which can effectively protect the cables from the external environment and extend the service life of the cables. |

| 4. Channel Cable Tray Machine | Channel-type cable trays are suitable for occasions with limited space and can flexibly arrange cables to meet different installation needs. |

| 5. Din Rail Channel Machine | A machine designed specifically for DIN rails, suitable for the wiring needs of electrical control rooms, and supports the installation of a variety of electrical equipment. |

| 6. Perforated Cable Tray Machine | The cable trays produced by this machine have holes for heat dissipation and drainage of cables, suitable for humid environments. |

| 7. Trough Cable Tray Machine | Trough cable trays have strong support and are suitable for centralized management and protection of multiple cables. |

Best Practices for Using Cable Tray Making Machines

To maximize the use of cable tray machines, you need to follow some best practices:

Choose the right machine type

When choosing a cable tray machine, it is crucial to choose the most suitable machine type according to your specific needs. Different types of cable trays have different application scenarios.

Use the right size of metal raw materials

Make sure the size of the metal raw materials used is suitable for the specifications of the cable tray you want to form. Oversized materials may cause difficulty in operation, while undersized materials may not meet the load-bearing requirements.

Follow the manufacturer's instructions

When using a cable tray making machine, be sure to carefully read and follow the operating manual provided by the manufacturer. Any improper operation may cause damage to the cable tray making machine or injury to personnel.

Wear safety equipment

When operating a cable tray making machine, be sure to wear appropriate safety equipment, including masks, gloves, and goggles to ensure safe operation.

Conclusion

Cable tray machines are an ideal solution for improving production efficiency and productivity. By using these cable tray making machines, you can quickly and easily create custom shapes for your products. Its versatile functionality and high level of precision make it an indispensable device in modern cable management systems.

If you are considering increasing your production capacity, a cable tray machine is undoubtedly your ideal choice. KINGREAL looks forward to working with you to provide you with high-quality cable tray making machines and a full range of service support!