What are advantages of snap lock roof panel machine?

2025-05-21 12:00| Snap Lock Roof Panel Machine is a highly efficient machine designed specifically for producing architectural grade snap lock metal roof panels. Suitable for residential and light commercial use, this type of roof panel has excellent performance and ease of assembly. The snap lock metal roofing machine is able to continuously form metal roof panels for easy installation from eaves to ridges, while its design does not require additional fasteners, greatly improving construction efficiency and safety. The metal panels can be made of steel, aluminum or copper to meet the needs of different customers. |  |

Brief Introduction of Snap Lock Roof Panel Machine

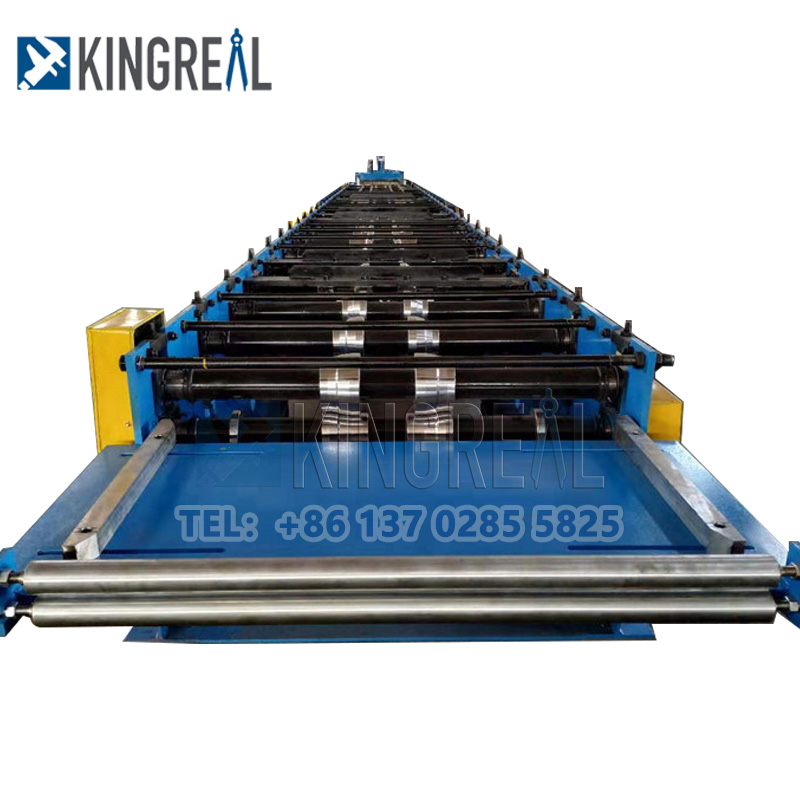

The snap lock metal roofing machine can process snap lock roof panels with a thickness of 0.4-0.8mm, and the production speed reaches 10-15 m/min. This efficient production capacity makes the snap lock roof panel machine an indispensable equipment in the modern construction industry. The produced snap lock roof panels do not need to be fixed with screws, which not only avoids the problem of rust around the screws, but also shortens the installation time and improves the overall efficiency of the construction.

Parameters of Snap Lock Metal Roofing Machine

| Dimension | 7500*1500*1500mm |

| Motor Power | 5.5KW |

| Hydraulic Power | 2.2KW |

| Forming Steps | 17steps |

| Forming Speed | 10-15m/min |

| Voltage | 380V/50HZ/3PH |

| Material Thickness | 0.4-0.8mm |

| Rib Height of Roofing | 51mm |

| Effective Cover Width | 820mm |

| Feeding Material Width | 1000mm |

| Control System | PLC Control |

Advantages of Snap Lock Roof Panel Machine

1

High-quality blades

The blades of the snap lock metal roofing machine are made of high-quality Cr12 die steel and are heat-treated at HRC58-60. Such materials have excellent wear resistance and high temperature resistance, and can remain sharp during long-term use to ensure the quality of forming.

Due to the wear resistance of the blades, the snap lock roof panel machine can maintain excellent cutting and forming effects for a long time, reducing the frequency of blade replacement. This is especially important in large-scale production, because frequent blade replacement not only increases maintenance costs, but may also cause production stagnation and affect overall efficiency. In addition, high temperature resistance ensures that the blade will not lose its effectiveness due to excessive temperature when running at high speed, extending its service life.

In addition, the high durability of the blade has greatly reduced the company's investment in snap lock metal roofing machine maintenance. Using the same set of tools for a long time can reduce material costs and labor costs, thereby improving overall economic benefits. For those companies that pursue efficient production, it would be wise to choose a snap lock roof panel machine equipped with high-quality blades.

2

High-strength forming rollers

The forming rollers of the snap lock metal roofing machine are made of high-quality 45# steel and processed by CNC lathes. Optional hard chrome plating increases the surface hardness and corrosion resistance and extends the service life. This high-strength forming roller ensures the stability and consistency of the forming process.

The stable forming roller can withstand greater pressure during the processing process to ensure the forming quality of each snap lock roof panel. Through precise processing technology, the snap lock roof panel machine can efficiently process metal sheets into the required shape to meet market demand. This consistency is particularly important for the construction industry, because each snap lock roof panel needs to be closely integrated with other parts to ensure the safety of the structure.

The use of high-strength forming rollers can effectively improve production efficiency. Because it can form stably, it reduces downtime caused by equipment failure, thereby ensuring the smooth operation of the snap lock metal roofing machine. Enterprises can produce more products in a shorter time, which undoubtedly improves market competitiveness.

3

Reliable frame structure

The frame of the snap lock roof panel machine is welded with 400#H-shaped steel, with a sturdy structure that can withstand the operation of the equipment under high load. The sturdy frame structure not only improves the stability of the snap lock metal roofing machine, but also reduces the vibration and noise that may occur during the production process.

The stable frame structure can effectively reduce the risk of deformation during snap lock roof panel machine operation and ensure that the size and shape of each finished product meet the design standards. This high stability is essential to ensure product quality, especially in high-intensity production environments, where the robustness of the frame can avoid damage caused by external forces.

The stability of the snap lock metal roofing machine not only affects product quality, but also the comfort of the operating environment. The sturdy frame structure can significantly reduce noise and vibration during operation, providing operators with a quieter and safer working environment. This humanized design improves employee job satisfaction and thus improves overall work efficiency.

4

Advanced PLC control system

The snap lock roof panel machine is equipped with a PLC control system of well-known domestic and foreign brands, which can be selected according to customer needs. This advanced control system makes the production process more intelligent and automated.

Through the PLC control system, the snap lock metal roofing machine can monitor the production status in real time and automatically adjust parameters to ensure that the snap lock roof panel machine is always in the best working condition. This automated control greatly improves production efficiency and reduces the need for manual intervention. Operators can focus more on the overall operation of the snap lock metal roofing machine without having to pay attention to every detail. The flexibility of the PLC control system enables the snap lock roof panel machine to quickly adapt to different production needs. Whether it is mass production or small batch customization, the system can be quickly adjusted to meet the diverse needs of customers. This adaptability opens up a wider market space for enterprises.

5

Flexible seam clamping force adjustment

The snap lock metal roofing machine can adapt to different metal types and thicknesses by adjusting the seam clamping force through vertical rollers. This flexibility enables the snap lock roof panel machine to handle a variety of metal materials to meet the diverse needs of customers.

This design enables the snap lock metal roofing machine to respond to the ever-changing needs of the market, whether it is small batch production or large-scale manufacturing, and can achieve ideal production results. When customers choose materials, they can adjust the machine settings according to specific needs to ensure the quality and adaptability of the finished product. Flexible seam clamping force adjustment enables rapid switching between different materials, reducing downtime during production switching. This efficient production mode gives the snap lock roof panel machine a significant competitive advantage in the market and can meet customers' needs for product diversification.

6

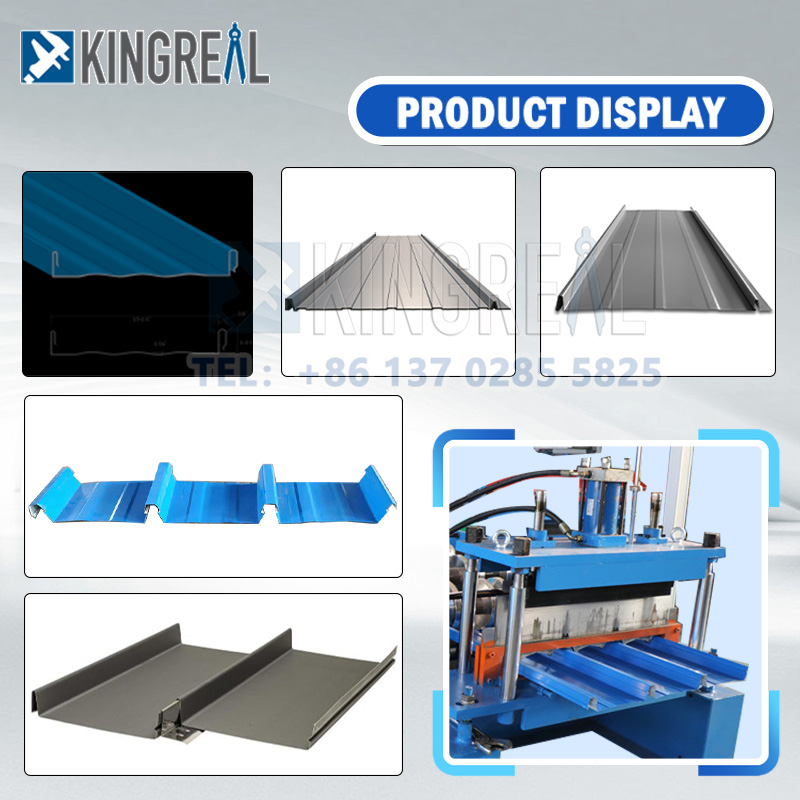

Installation option for additional bead rollers

The snap lock metal roofing machine allows the installation of additional bead rollers for semicircular or trapezoidal ribs. This option enables the machine to produce a more diverse range of roof panels to meet the needs of different architectural styles and functions.

By adding a bead roller, the snap lock roof panel machine is able to expand its product line and provide customers with more diverse solutions. This flexibility allows companies to adapt to different market needs and increase the competitiveness of their products. The market demand for snap lock roof panels is becoming increasingly diverse, and the additional bead roller option of the snap lock metal roofing machine allows companies to flexibly respond to these changes. Whether it is residential, commercial buildings or industrial use, the snap lock roof panel machine can provide corresponding solutions to meet the needs of different customers.