HVAC Duct Making Machine

KINGREAL provides complete ductwork system solutions for its customers and customizes a series of roll forming machines, including HVAC duct making machines and flange forming machines, according to customer needs.

- KINGREAL

- Information

- Download

| KINGREAL provides complete ductwork system solutions for its customers and customizes a series of roll forming machines, including HVAC duct making machines and flange forming machines, according to customer needs. This is a very economical option for manufacturing HVAC ductwork. As a professional HVAC duct forming machine manufacturer and supplier, KINGREAL provides customers with expert purchasing advice, helping them to select and combine the appropriate machines more effectively, thereby saving costs and improving work efficiency. At the same time, the HVAC duct making machines can be supplied with corresponding motor power and voltage based on the customer's local power supply environment, ensuring that customers worldwide can safely use KINGREAL HVAC duct forming machines. |

HVAC Duct Making Machine

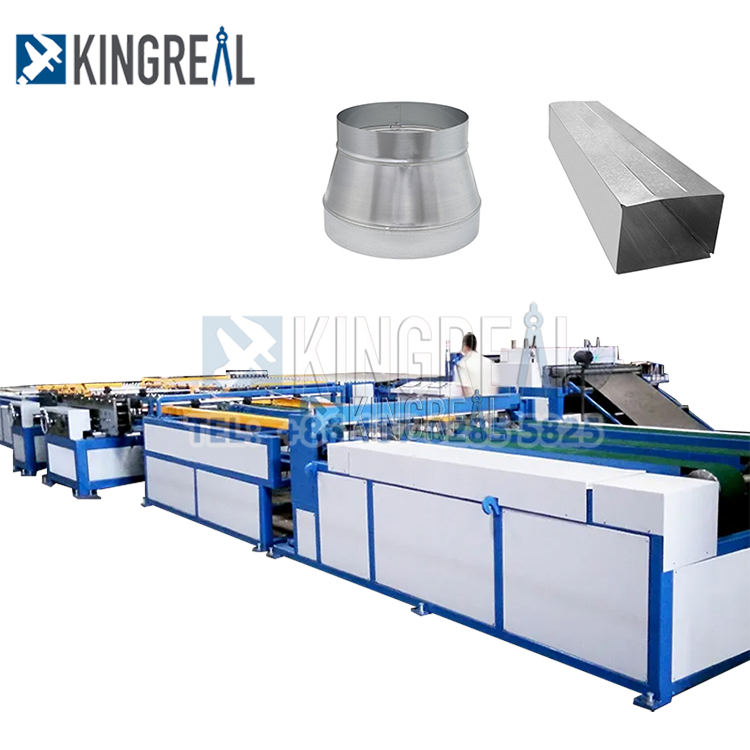

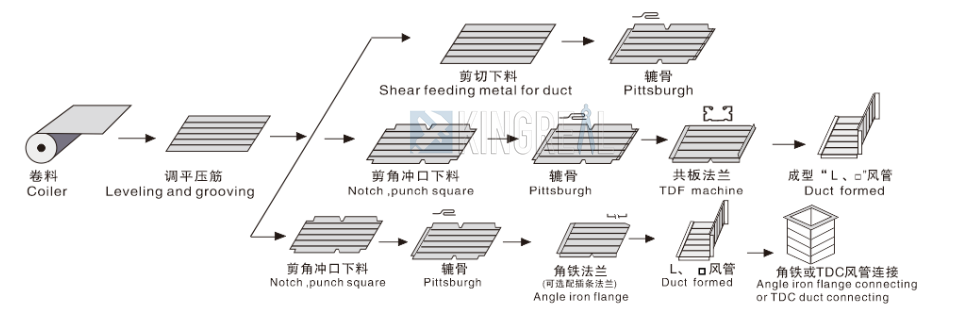

KINGREAL HVAC duct forming machine integrates multiple processes such as straightening, ribbing, notching, shearing, and bending into a single continuous, computer-controlled process, enabling fast and efficient production. This HVAC duct making machine is designed to meet the needs of producing thick-walled ducts, ensuring that the manufactured ducts possess excellent strength and airtightness. Furthermore, the HVAC duct forming machine can quickly switch between different pipe diameters, significantly improving production efficiency. The HVAC duct making machine is also equipped with a synchronous cutting device, ensuring fast processing speed and stable performance.

Working Process of HVAC Duct Making Machine

Parameters of HVAC Duct Forming Machine

Plate Thickness | Galvanized Sheet 0.5-1.2mm/Stainless Steel Sheet 0.5-1.2mm | |

| Galvanized Sheet 0.5-1.5mm/Stainless Steel Sheet 0.5-1.2mm | ||

| Width | 1220/1250mm | 1250mm/1500mm |

| Coil Weight | ≤7000kg | |

| Inside Diameter | 508mm | |

| Outside Diameter | ≤1300mm | |

| Work Speed | ≤15m/min | |

| Length Error | ±0.5mm/m | |

| Diagonal Error | ±0.8mm/m | |

| Bending Angle Error | ±5° | |

| Total Power | ≈35kw | |

Advantages of HVAC Duct Forming Machine

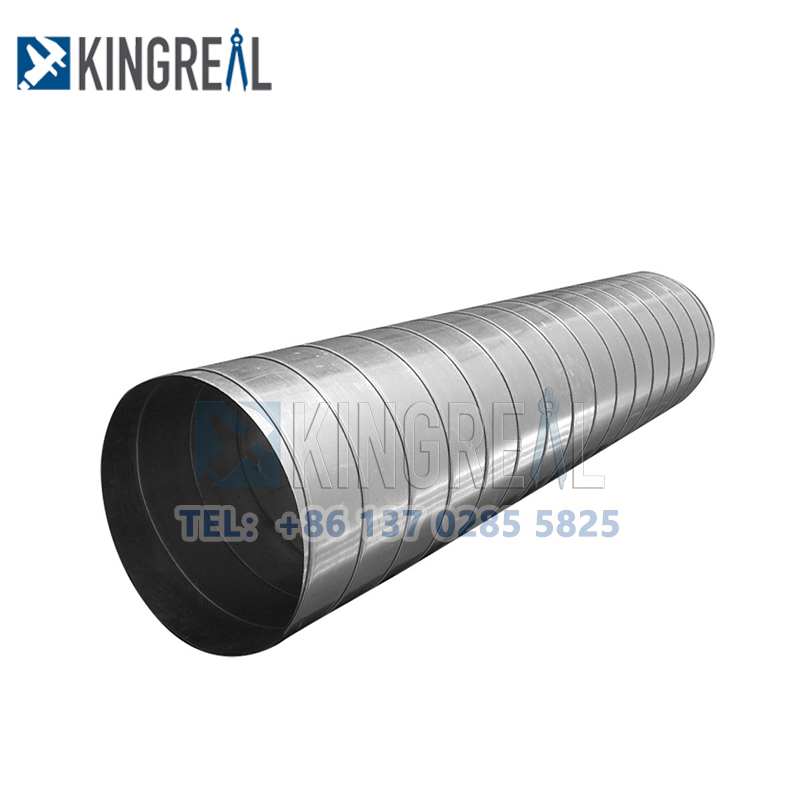

KINGREAL HVAC duct making machines are customized according to the specific project requirements of each customer. They can produce different types of metal pipes, such as square pipes, round pipes, and spiral pipes, based on the drawings provided by the customer. Each HVAC duct forming machine is designed to produce only one shape, but to meet diverse customer needs, KINGREAL also provides parameter adjustment functions, allowing for quick switching between the production of metal pipes of different diameters. This avoids the need for customers to purchase multiple HVAC duct forming machines due to changing requirements, thus saving labor and equipment costs.

To meet the needs of customers of different scales, KINGREAL HVAC duct making machines are available in line No.2, line No.3, line No.5, line No.6, line No.7 and line No.8 configurations. Customers can choose the most suitable model based on their production capacity. Furthermore, if production scale increases in the future, KINGREAL HVAC duct forming machine can be upgraded from the existing base, greatly improving production efficiency and flexibility.

Product Display

KINGREAL HVAC duct making machines can produce finished products of various specifications, including round pipes, square pipes, and spiral pipes, meeting the needs of different application fields. The finished products feature smooth surfaces, burr-free edges, excellent precision, and consistency, making them widely applicable in various projects and an indispensable part of HVAC system installation.

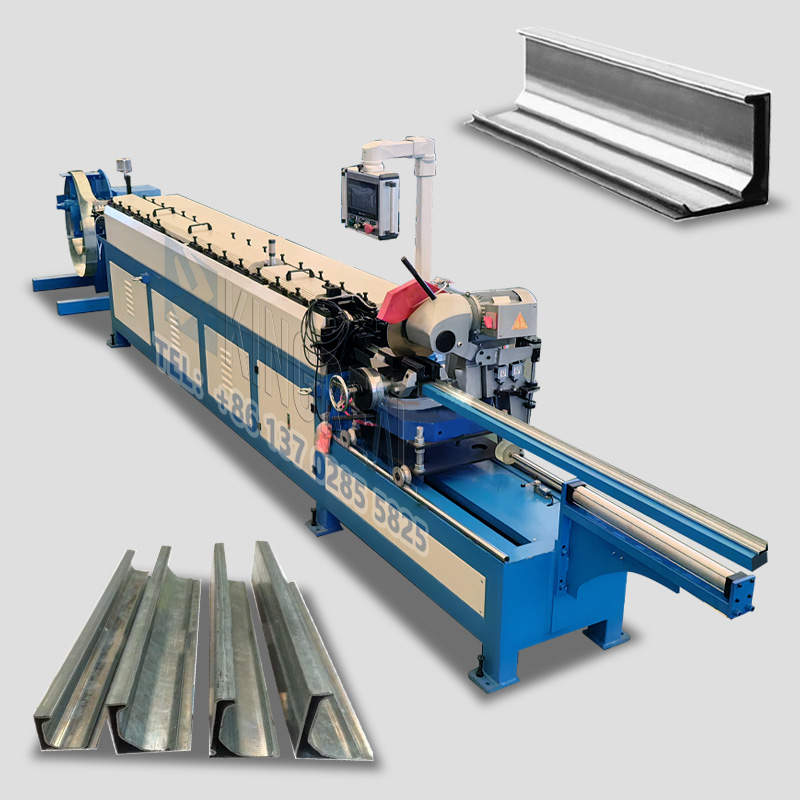

Flange Forming Machine

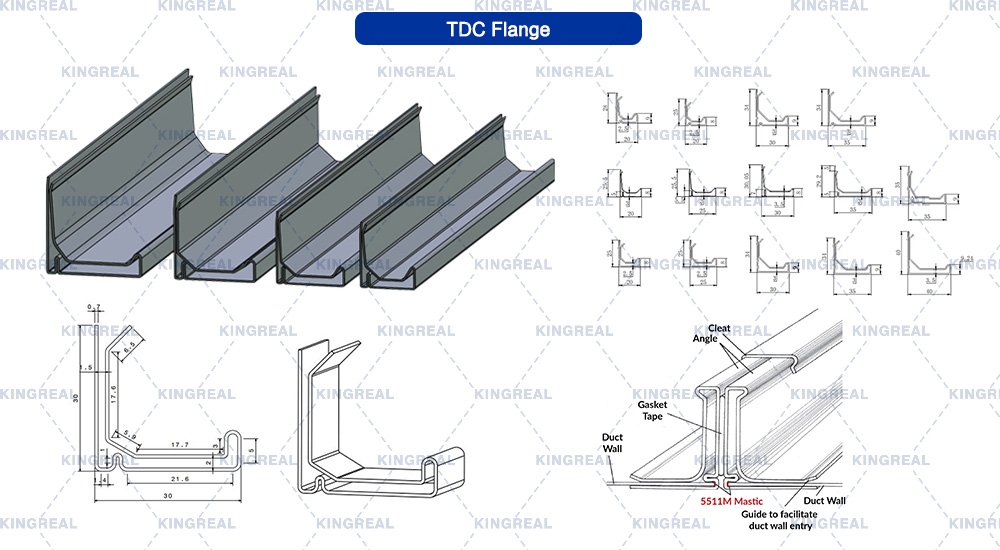

In HVAC systems, the connection of round and rectangular ducts requires high-quality flanges, and KINGREAL automatic flange forming machine is designed precisely for this purpose. KINGREAL flange forming machines include TDC flange forming machines and TDF flange forming machines, mainly composed of a decoiler, a roll forming machine, and a shearing station. Customers only need to input the required flange circumference and quantity on the operation screen, and the flange forming machine will operate automatically. The number of perforations can also be flexibly set according to requirements, supporting fixed-length cutting with minimal burrs, achieving fully automated production.

The flanges produced by these flange forming machines comply with relevant national standards, featuring good sealing, durability, and tight connections. They are suitable for various ventilation ducts with different cross-sectional areas, ensuring the efficient operation of the duct system.

Working Process of Flange Forming Machine

Decoiler--Roll Forming Machine--Cutting Station--Output

Parameters of Flange Forming Machine

| Model | Motor Power(kw) | Processing Thickness(mm) | “a”Size(mm) | Weight(kg) | Dimension(mm) |

| Model 1 | 2.2 | 0.5-1.2 | 35-0.5 | 1500 | 2800x600x1120 |

| Model 2 | 4 | 0.6-1.2 | 34-0.5 | 1800 | 3200x750x1000 |

| Model 3 | 4 | 0.6-1.2(TDF) | 35-0.5 | 3000 | 3200x900x1000 |

| Model 4 | 4 | 0.8-1.0(TDC) | 35-0.5 | 3000 | 3200x900x1000 |

| Model 5 | 5.5 | 0.6-1.2 | 35-0.5 | 3000 | 3200x2700x1100 |

| Model 6 | 5.5 | 0.8-1.0 | 35-0.5 | 3000 | 4500x750x1100 |

Advantages of Flange Forming Machine

●TDC Flange Forming Machine

The TDC flange forming machine is particularly suitable for processing large-section ventilation ducts. It mainly consists of a feeding rack, a cold-rolling forming body, and a cutting section. It uses a high-speed steel circular saw blade non-stop cutting system, cutting to the required length, ensuring minimal burrs, and enabling fully automated operation. Based on working performance, flange strength, and sealing grade, the TDC flange forming machine is available in five models: T-20, T-25, T-30, T-35, and T-40, with corresponding connecting angle models T-20DC, T-25DC, T-30DC, T-35DC, and T-40DC.

●TDF Flange Forming Machine

KINGREAL offers two types of TDF flange forming machines – single-flange forming machines and double-flange forming machines. The single-flange forming machine includes T-12 and T-15 models, capable of forming a flange shape on one side and a snap-lock shape on the other. The double-flange TDF flange forming machine can form flanges on both sides simultaneously, significantly improving work efficiency. The single-flange TDF forming machine is popular due to its moderate weight and ease of movement, making it especially suitable for on-site construction.

What is the Difference Between TDC and TDF Profiles?

TDF flanges are inwardly folded, with the metal sheet edge folded inward to form the flange, making the outer edge of the duct safer and smoother. TDC flanges, on the other hand, are outwardly folded, with the metal sheet edge rolled outward, so the original cut edge is located on the outside of the flange. Both designs have their advantages and disadvantages in terms of sealing and safety, and choosing the appropriate flange type based on the specific application is crucial.

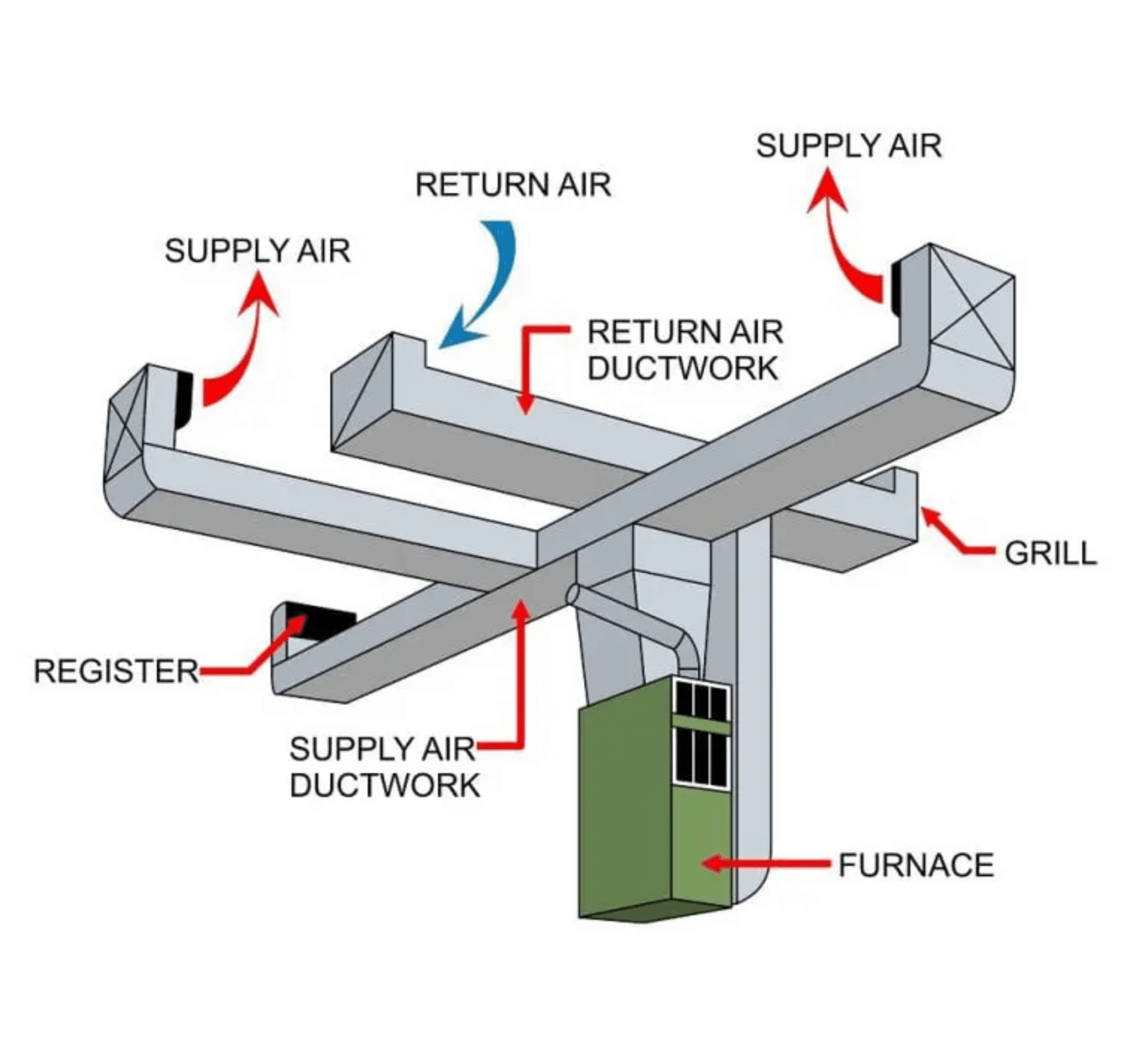

Complete Duct System

The HVAC duct system is like the circulatory system of a building, responsible for transporting the heated and cooled air produced by HVAC equipment to various areas within the building. Its key components include supply ducts responsible for distributing conditioned air, and return ducts that draw back stale air for reprocessing.

In HVAC systems, key components such as vents and grilles are used to control airflow, while proper sealing and sizing are crucial for improving system efficiency and user comfort. KINGREAL HVAC duct making machines and flange forming machines, as essential components in ductwork system installation, provide reliable ventilation solutions for various buildings.

Why Choose KINGREAL?

By choosing KINGREAL, you gain a partner with over 20 years of extensive experience in the roll forming machine manufacturing industry. KINGREAL services cover roll forming machine design, R&D, manufacturing, installation, and troubleshooting, and we have established friendly cooperative relationships with customers in numerous countries, including the UAE, the USA, the UK, Qatar, India, Russia, and Mexico. Continuous technological updates and upgrades ensure that KINGREAL roll forming machine always adapts to the ever-changing market demands. KINGREAL not only provides customized roll forming machine manufacturing solutions but also offers one-stop service, accompanying customers throughout the entire purchase and usage process, including factory visits, professional installation and operation training, spare parts supply, and troubleshooting support. Partnering with KINGREAL is not just about buying a high-quality roll forming machine; it's about establishing a comprehensive support system. KINGREAL commitment to continuous service doesn't end with equipment delivery; customers can rely on KINGREAL professional support at any time to ensure efficient roll forming machine operation and help you achieve greater productivity and business success. Choosing KINGREAL is a step towards future success.