What is corner bead making machine?

2025-08-08 12:001/Description of Corner Bead Making Machine

The corner bead making machine is used to produce corner bead of various sizes and types, typically using metal materials with a thickness ranging from 0.2-1.2mm. Punching, logo embossing, and other custom features can be customized to meet specific customer needs. This corner bead machine can be customized to your specific specifications, perfectly matching your project's requirements. Comprehensive safety features ensure peace of mind for operators. Furthermore, the low-noise corner bead making machine offers significant advantages in environments with strict noise requirements. The fully automated design allows for efficient production within the factory. |  |

2/ Workflow of Corner Bead Making Machine

2-in-1 Decoiler & Straightener -- Punching Machine -- Roll Forming Machine -- Cutting Station -- Output Table

3/ Parameters of Corner Bead Machine

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, material is 40Cr |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 4KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear box |

(Corner bead making machine parameters are for reference only. Specific corner bead machine parameters and performance will be adjusted based on customer drawings and actual production conditions.)

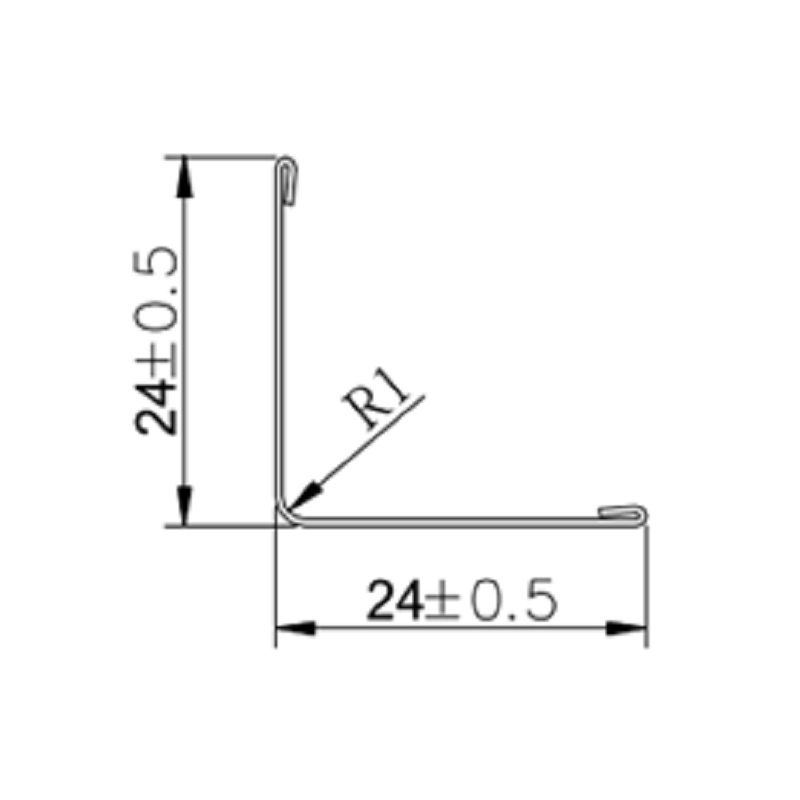

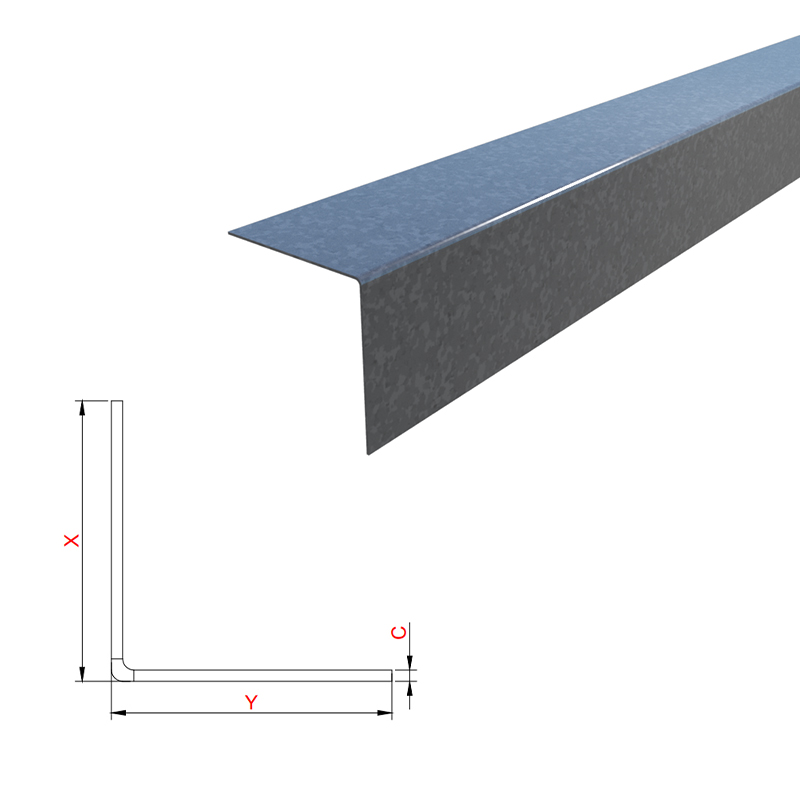

4/ Drawing of Corner Bead Product

5/ Main Components of Corner Bead Machine

1. 2-in-1 decoiler & straightener for corner bead making machine

The corner bead machine's 2-in-1 decoiler & straightener combines the functions of an decoiler and a straightener, achieving efficient space utilization. The decoiler unwinds the metal coil, preparing it for subsequent processing. The straightener ensures that the material remains flat after unwinding, preventing processing problems caused by coil curvature.

The flattening accuracy is exceptionally high, resulting in a smooth, flat surface without indentations, ensuring smooth punching and forming. The efficient mechanical structure of this component reduces surface damage and improves the quality of the finished product.

Furthermore, the 2-in-1 decoiler & straightener design not only saves space but also reduces overall equipment investment and maintenance costs.

2. Punching machine for corner bead making machine

The punching machine is a key component of the corner bead machine. Its function is to punch holes in metal materials according to customer design requirements. This equipment can quickly and accurately produce holes in a variety of hole shapes and diameters. Equipped with high-strength dies, the punch can meet the punching requirements of different materials.

In terms of safety, the punching machine is designed with multiple safeguards. If the equipment detects an abnormal or dangerous situation, the operator can quickly stop the punching process using the emergency stop button, significantly reducing safety hazards. Furthermore, the punching machine's speed and efficiency have been optimized to ensure stable performance even during peak production periods, thereby improving overall production efficiency.

3. Roll forming machine for corner bead making machine

The roll forming machine is the core component of the corner bead machine, responsible for forming the punched metal material into the customer's desired corner shape. This unique roll forming machine utilizes high-strength 45# steel and is chrome-plated for wear and corrosion resistance. The roll forming machine's precision roller structure ensures stable pressing and forming of the metal material, ensuring precision and consistency.

4. Cutting station for corner bead machine

The cutting station precisely cuts the corners after forming. Operated via a PLC control panel, it cuts to the user's preset length, ensuring that each corner bead meets the standard dimensions. The shear blades are made of high-strength Cr12 die steel and are hardened for exceptional wear resistance and cutting accuracy.

The cutting station is designed for operational safety and convenience, equipped with safety guards to prevent accidents during the cutting process.

Furthermore, efficient operation of the cutting station significantly reduces production cycle time and improves overall production efficiency.

5. Auto packaging machine for corner bead making machine

Auto packaging machine is an additional device for the corner bead machine, responsible for automatically bundling and stacking completed corner beads.

The introduction of this component significantly improves production line efficiency and frees up manpower.

Through automated control, the packaging machine bundles the trims according to the set quantity and method, ensuring consistent and tight bundling within each bundle.

The packaging unit is also designed for safety during transportation, ensuring that products do not become loose or damaged during long-distance transport. This component not only improves production efficiency, but also ensures the quality of the finished product and reduces labor costs in subsequent operations.

6/ Application of Corner Bead Machine

The corner beads produced by the corner bead making machine, along with other equipment, support the ceiling, forming a complete suspended ceiling system. The strength and stability of the corner beads make them crucial in construction and decoration.

The corner beads produced by the corner bead machine, together with the u channels and omega channels produced by the main channel making machine and omega channel machine, form a perfect suspended ceiling solution that can meet the needs of different customers. |  |