Angle Bead Roll Forming Machine

KINGREAL angle bead roll forming machine can produce angle beads of different types and sizes, with a maximum production speed of 30m/min.

- KINGREAL

- China

- Information

- Download

Video About Angle Bead Roll Forming Machine

Introduction of Angle Bead Roll Forming Machine

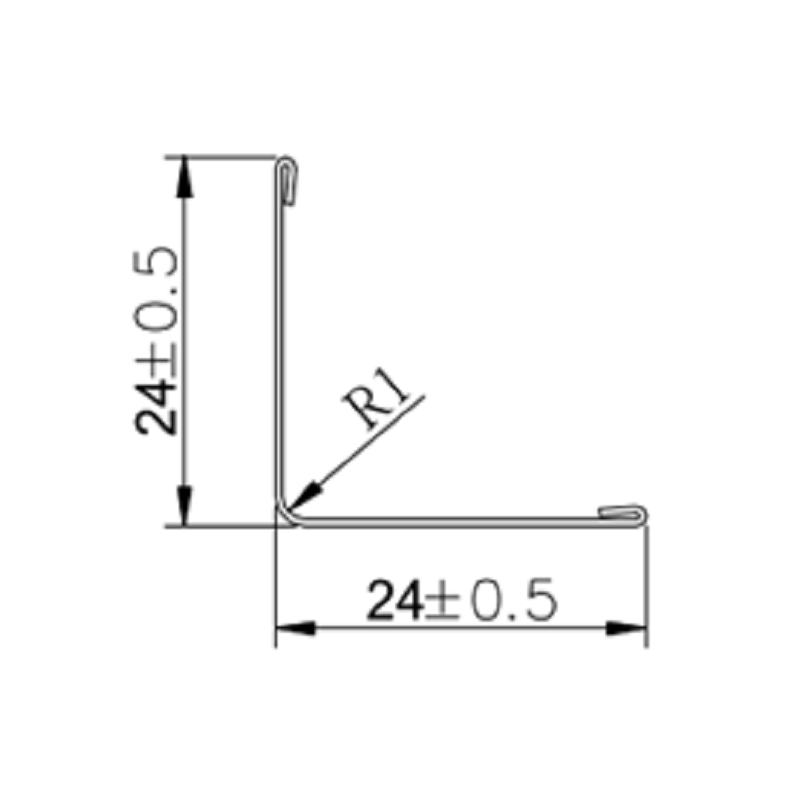

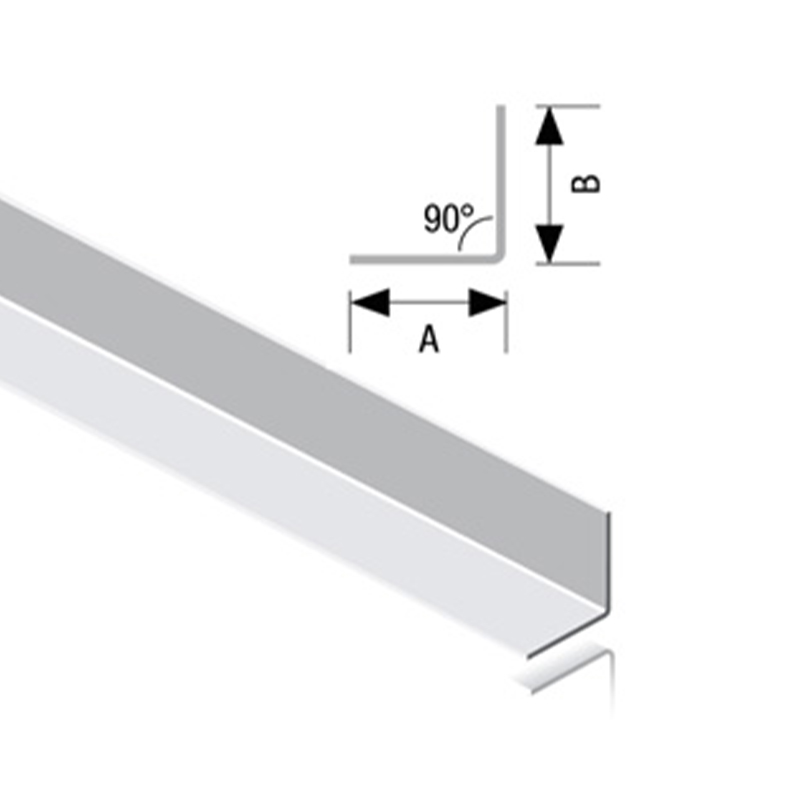

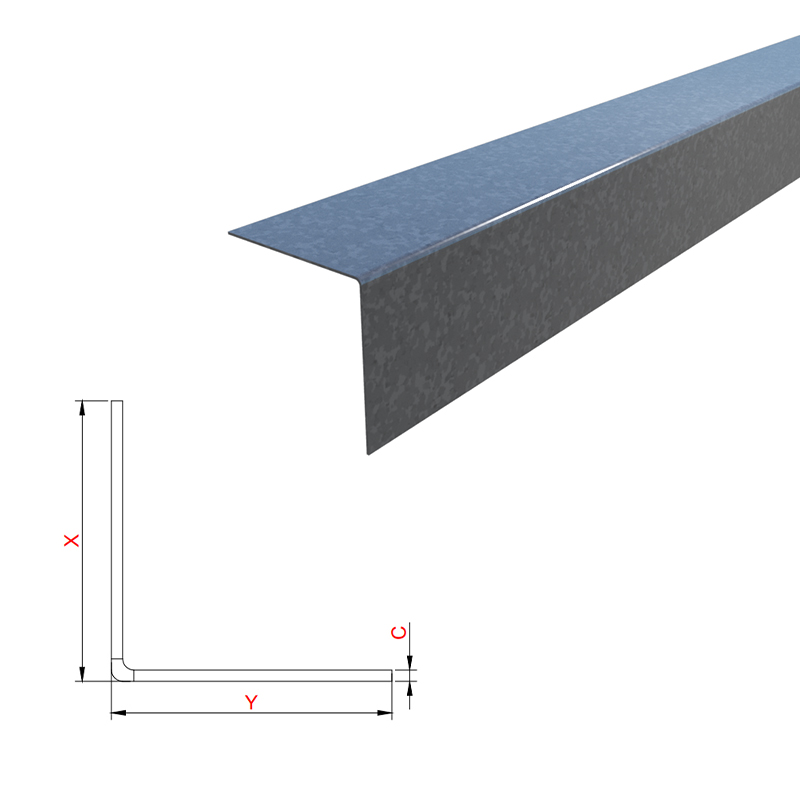

KINGREAL angle bead roll forming machine is designed for producing angle beads of different sizes. It is mainly used to support metal keels, so that a smooth transition between ceiling and wall is formed, and its durability and load-bearing capacity are guaranteed. KINGREAL has equipped the corner bead machine with a numerical control system (NC) for inputting the production program (length and number of workpieces), as well as a shearing station for cutting angle beads at the end of the corner bead machine. The calibration frame can be quickly fine-tuned according to the required thickness and metal type. KINGREAL angle bead roll forming machine can not only produce common corner bead sizes such as 20*20 mm, 25*25 mm, 27*27 mm, 30*30 mm, 40*40 mm, etc., but also customize the corner bead machine according to the customer's needs for special sizes. KINGREAL can provide personalized angle bead roll forming machine customization solutions according to customer drawings. |  |

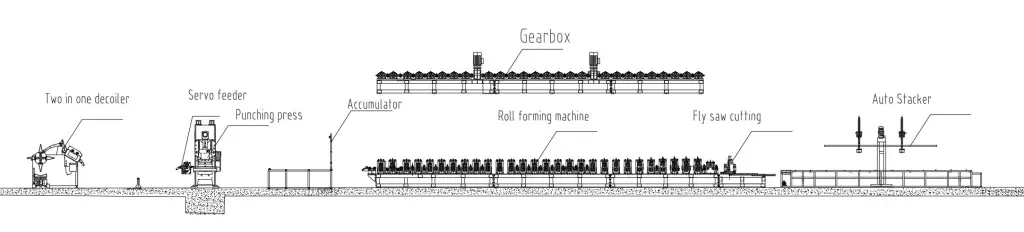

Workflow of Corner Bead Machine

2-in-1 Decoiler and Straightener -- Punching Machine -- Roll Forming Machine --Cutting Station -- Auto Packaging Unit (Optional) |  |

Parameters of Angle Bead Roll Forming Machine

| Angle bead roll forming machine | |

| Raw Material | Gi Steel Strip ISQ230-Z8 |

| Material Thickness | 0.4mm |

| Width | 50mm |

| Length | 2700/3000/3600mm |

| Production Speed | 30m/min |

| Shearing Accuracy | ±1.0mm |

| Straightness | Bending is less than 1‰m Twist is less than 1.3%m |

Features of Corner Bead Machine

2-in-1 Decoiler and Straightener for angle bead roll forming machine 2-in-1 Decoiler and Straightener is specially designed for straightening and leveling various metal coils. Its straightening process adopts a balanced fine-tuning device to ensure that it can handle high-precision products and meet strict production requirements. The rollers of the leveling machine are made of solid shaft steel and are hard chrome-plated to improve wear resistance and service life. Since KINGREAL has equipped the angle bead roll forming machine with this 2-in-1 Decoiler and Straightener , customers can not only save valuable space, but also enjoy high-precision leveling effect. The material leveled by this machine has a smooth surface without indentation, and does not damage the original surface characteristics of the material, ensuring the smooth progress of subsequent processing. |  |

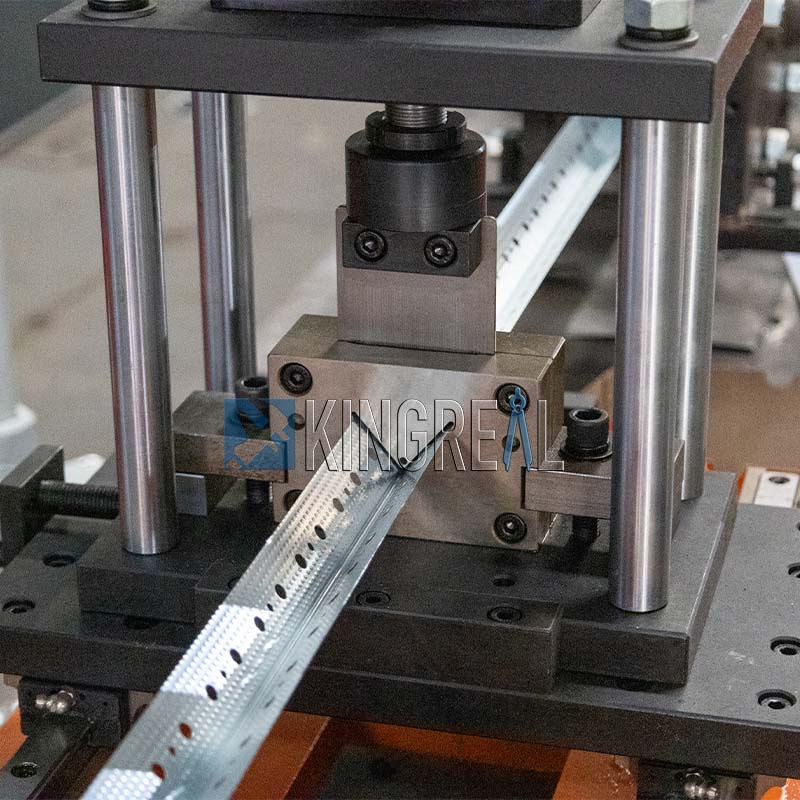

Punching machine for corner bead machine High efficiency is the main feature of the punching machine's design; it is able to punch holes swiftly. To guarantee the punching's accuracy and quality, KINGREAL will modify punching dies of several apertures based on the drawings given by the client. The punching machine can successfully satisfy the requirements of several clients whether it is mass production or custom customizing and so boost manufacturing flexibility. |  |

Cr12 Steel Roller for angle bead roll forming machine Used mostly in the manufacture of rollers, particularly for the production of flat steel, round steel, and asymmetrical steel, Cr12 (also known as D3) is a high-carbon and high-chromium alloy steel. Perfect for roll forming machines, this material is renowned for its great abrasion resistance, tensile strength, and toughness. Moreover, the corner bead machine has an embossing roller that may generate particular textures, motifs, or logos on the material surface during the forming process. This treatment not only enhances the visual appeal of the material but also improves its aesthetics. Use of embossing rollers may greatly cut extra processing steps, therefore lowering manufacturing expenses as opposed to post-processing. |  |

Servo cutting system for corner bead machine Using servo motors to manage the cutting action, the servo cutting system is a cutting edge technique. Equipping the servo motor with a sensor gives real-time feedback on the position and mobility of the material being cut, therefore producing precise, quick, and uniform cutting outcomes. This effective cutting technique lowers manufacturing expenses, enhances production efficiency, and lessens material waste. |  |

Advantages of Angle Bead Roll Forming Machine

Manufacture various corner beads based on customer’s need. KINGREAL can adapt to consumer needs whether it is a standard corner bead or a perforated corner bead. For corner beads that need to be punched, KINGREAL can equip the corner bead machine with a dedicated punching machine to ensure that each corner bead produced meets the required aperture and position accuracy. Additionally, KINGREAL offers matching corner bead machines to guarantee product variety and flexibility in the manufacture of common corner beads. |  |

| Automatic packaging machine for angle bead roll forming machine. KINGREAL created an angle bead roll forming machine with an automated packaging unit to increase production efficiency. This creative design improves production process efficiency and smoothness. Once the angle beads are discharged, they may be fast moved to the automatic packaging unit for stacking and packaging, therefore eliminating labor time. The automatic packaging unit has benefits besides speed: its high quality and stability. The number of angle beads in every bundle is the same, therefore guaranteeing that the items will not be dispersed in transit, therefore minimizing losses. |

High speed angle bead roll forming machine. Excellent design on KINGREAL corner bead machine allows it to reach a maximum operating speed of 30 m/min, far beyond the 7-15 m/min of several competing products on the market. This rapid process not only greatly increases production efficiency but also enables clients to rapidly react to market demand when orders are urgent. |  |

Application of Angle Bead Roll Forming Machine

This corner bead machine is designed to produce corner beads of various shapes and sizes. Angle bead is a metal decorative strip used to reinforce the corners of drywall or plaster walls. Corner trim is usually installed at the junction of two walls, or at the junction of a wall and a ceiling or floor. It helps protect the corners from damage and provides a smooth and straight edge for finishing. Corner beads are available in different materials, sizes and shapes, depending on the customer's needs. |  |

Why Choose KINGREAL Corner Bead Machine?

(1) Many successful projects. KINGREAL corner bead machines have worked closely with customers from many countries around the world, including Mexico, Saudi Arabia, Qatar, Turkey, India, Egypt and many other countries. Therefore, KINGREAL engineers have a full understanding of the subtle differences in corner bead machine parameters in each country and can communicate with customers quickly and effectively. |  |

(2) Good quality corner bead machine. KINGREAL is never vague about corner bead machine manufacturing, and the blanking welding, wire cutting and drilling of the angle bead roll forming machine are all done by our factory to ensure the quality of the machine. The electrical components are all well-known domestic and foreign brands. |  |

(3) After-sales service. After the corner bead machine arrives at the customer's factory, KINGREAL will send engineers to the customer's factory for offline installation and provide training to workers on angle bead roll forming machine operation to help customers start production in the shortest possible time. |  |

Drawing About Angle Bead