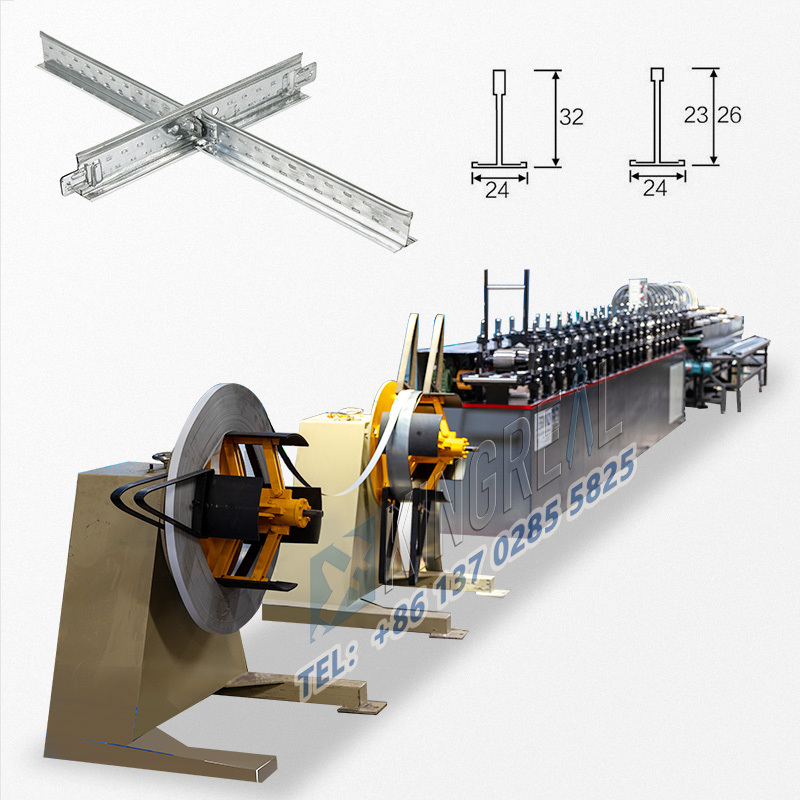

Ceiling T Bar Machine

1/What Does a Ceiling T Bar Machine Do?

A ceiling t bar machine is used to produce ceiling t grid for suspended ceilings. With the continuous development of the construction industry, the demand for suspended ceilings is gradually increasing, and the market application of ceiling t bar machines is becoming more and more widespread. The main function of this ceiling t bar machine is to process galvanized or roll-coated iron coils into main or secondary keels to support suspended ceiling panels. By using a ceiling t bar machine, customers can easily create sturdy and aesthetically pleasing suspended ceilings in various environments.

In the market, there are several types of ceiling t grids available for production, including ceiling flat t grid, ceiling black line t bar, silhouette groove ceiling t grid, and FUT ceiling t bar. Each type of ceiling t bar not only has different functions but can also meet customer needs through different applications and aesthetic combinations. KINGREAL ceiling t bar machines can be customized according to specific customer requirements, producing ceiling t grids of different specifications and types.

2/Successful Project About Ceiling T Bar Machine

KINGREAL ceiling t bar machines are operating smoothly in factories across multiple countries, including Saudi Arabia, India, the Dominican Republic, and Italy. These success stories demonstrate the reliability and efficiency of the ceiling t bar machines, enabling customers to obtain large quantities of high-quality finished products and achieve significant profits.

In addition to providing advanced ceiling t bar machine, KINGREAL also emphasizes after-sales service to ensure customers can smoothly operate the ceiling t bar machines.

●After-sales Installation: KINGREAL professional team will visit the customer's factory to assist with on-site machine installation, ensuring the ceiling t bar machine operates normally.

●Operation Training: Providing comprehensive machine operation training to customers, enabling them to quickly master the operation skills of the ceiling t bar machines and improve production efficiency.

● Spare Parts Supply: Ensuring customers can obtain the necessary spare parts in a timely manner during use, reducing downtime caused by ceiling t bar machine failure.

● Troubleshooting: KINGREAL technical support team is always on standby to resolve any problems encountered by customers during use, enhancing customer satisfaction.

3/Is a Ceiling T Bar Machine Safe to Use?

Regarding the safety of ceiling t bar machines, KINGREAL has implemented multiple measures to provide users with safe and reliable equipment. Firstly, during the manufacturing stage, KINGREAL selects high-quality materials. Careful material selection ensures the ceiling t bar machine's robust and durable structure.

Secondly, KINGREAL manufacturing team comprises workers with over fifteen years of experience. They rigorously control every aspect of the ceiling t bar machine's production to ensure high-quality manufacturing. After production, KINGREAL staff conduct a comprehensive inspection of each ceiling t bar machine, covering its external condition, operational status, and finished product quality, ensuring the ceiling t bar machine withstands rigorous testing before delivery to customers.

To meet customers' high safety demands, KINGREAL also equips ceiling t bar machines with additional safety features. For example, protective shield effectively prevent workers from coming into contact with the rollers during operation, reducing the risk of accidental injury. Furthermore, to prevent malfunctions due to overheating during prolonged operation, KINGREAL offers an optional hydraulic oil cooling system to ensure stable ceiling t bar machine operation.

These safety designs and measures not only give customers peace of mind during use, but also effectively ensure the long-term stable operation of the ceiling t bar machine.

4/FAQ About Ceiling T Bar Machine

Q1:What materials can be roll formed into ceiling t grids?

A1:The material for ceiling t bar is usually galvanized steel (GI) or pre-painted galvanized steel.

Q2:What thickness of coils can be processed?

A2:The ceiling t bar machine typically processes iron sheets with a thickness of 0.23-0.35mm and pre-coated iron sheets with a thickness of 0.3-0.4mm.

Q3:Does the process allow punching of holes for ceiling t grids?

A3:Yes, KINGREAL ceiling t grid machines are equipped with a fly punching system, allowing for rapid punching of materials. The specific hole shape and diameter will be customized according to the customer's drawings to create the appropriate punching dies.

Q4:How many people do you need to run a ceiling t grid machine?

A4:Once the ceiling t bar machine is turned on, only one worker is needed at the output station to organize the finished products.

Q5:What is the typical production rate of these ceiling t grid machines?

A5:Ceiling t bar machine maintenance includes tasks such as lubricating bearings, cleaning debris from the forming stations, and replacing worn parts. Regular training on machine operating procedures for operators is also required.