CEILING T GRID MACHINE

KINGREAL has designed various types of fully automatic ceiling t grid machines, including Black Line Ceiling T Grid Machine, Silhouette Ceiling T Grid Machine, FUT T Grid Machine, Flat Ceiling T Bar Machine and Wall Angle Profile Machine in order to meet market demand, maximize productivity and reduce labor costs for customers.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Ceiling T Grid Machine

Introduction of Ceiling T Grid Machine

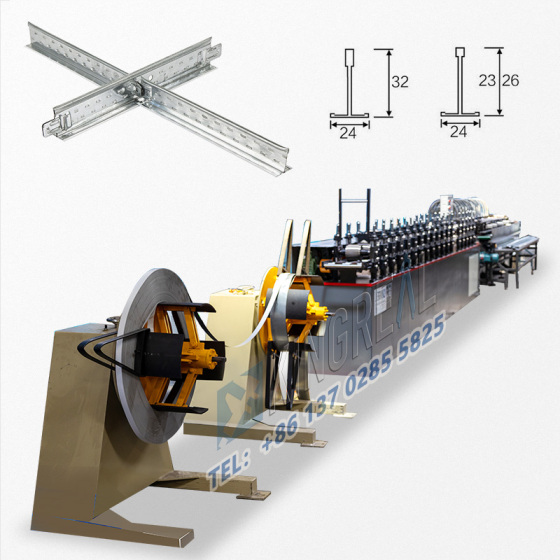

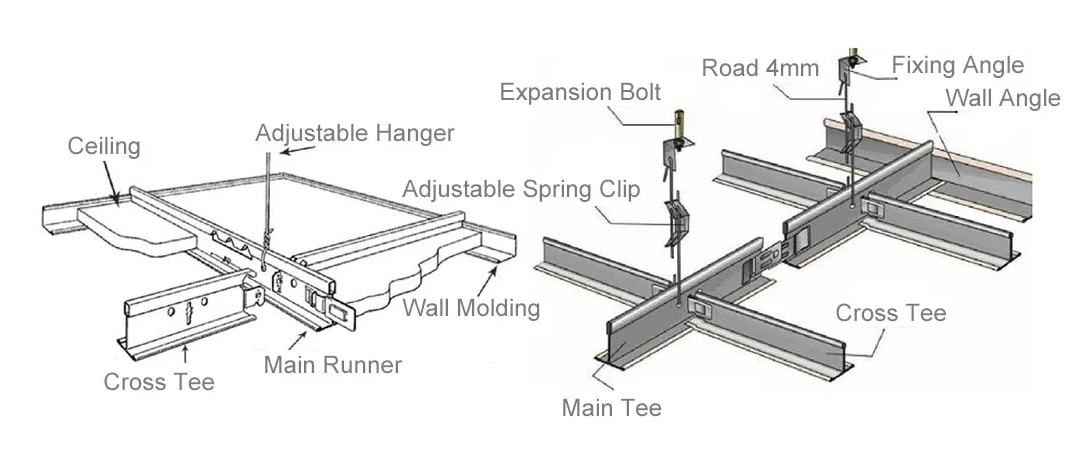

KINGREAL ceiling t grid machine combines galvanized material and fabric through the profiling process to form a T-shape, producing main t, cross t and wall angle, providing stable support for suspended ceilings, and is often used in suspended ceiling decoration. In order to meet market demand, maximize productivity and reduce labor costs for customers, KINGREAL has designed various types of fully automatic tee grid ceiling production lines, including Black Line Ceiling T Grid Machine, Silhouette Ceiling T Grid Machine, FUT T Grid Machine, Flat Ceiling T Bar Machine and Wall Angle Profile Machine. |  |

Installation drawings:

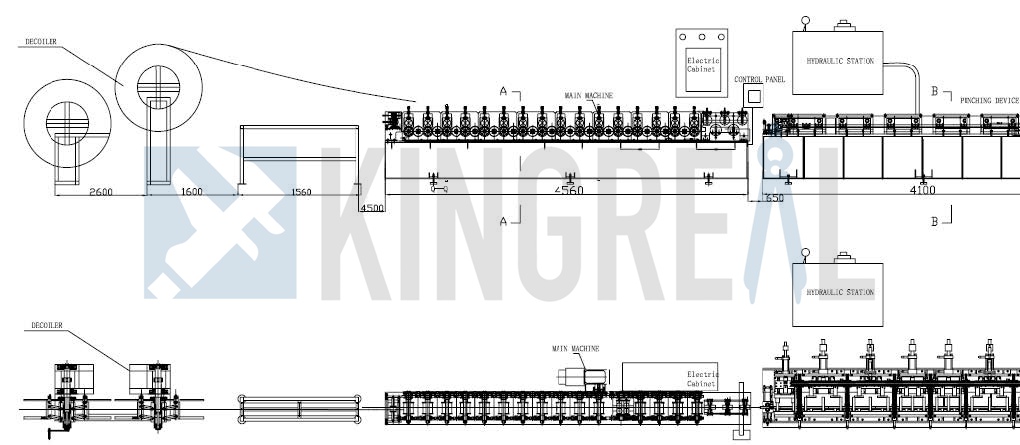

Workflow of Tee Grid Ceiling Production Line

Hydraulic Decoiler ↓ Main Roll Forming Machine ↓ Punching and shearing station ↓ Product table |  |

Advantages of Ceiling T Grid Machine

Fully automated tee grid ceiling production line KINGREAL fully automated ceiling t grid machine is equipped with advanced decoiler, punching station, roll forming machine and shearing station and other key components to achieve full automation of the production process. Users only need to enter the production parameters on the control panel, and the tee grid ceiling production line can be started with one button to automatically complete the entire production process. The ceiling t grid machine can produce up to 33 m/ min and can be flexibly adjusted according to the actual production needs of customers to ensure efficient meeting of customer needs. Whether it is large-scale production or small batch customization, KINGREAL fully automated tee grid ceiling production lines can provide stable and reliable performance. |  |

Multi-specification ceiling t grid machine This tee grid ceiling production line is flexible in design and can produce ceiling t grids of various widths (such as T24 or T15) to meet the needs of different customers. KINGREAL provides the option of changing the hanger or replacing the rollers separately, so that customers no longer need to purchase multiple ceiling t grid machines of different specifications, which greatly saves time and economic expenditure. At the same time, this design also effectively reduces the factory's floor space and human resources investment, which is particularly suitable for customers with multi-specification production needs or companies that plan to expand their production lines in the future. |  |

Customized tee grid ceiling production line KINGREAL is experienced in the manufacture of customized ceiling t grid machines and can provide tailor-made solutions according to the specific needs of customers. KINGREAL can add safety guards and hydraulic oil cooling systems to the tee grid ceiling production line to improve operational safety and efficiency. In addition, KINGREAL engineers can design and manufacture personalized punching dies based on drawings provided by customers. In addition, the color and performance of the ceiling t grid machine can also be adjusted according to the customer's requirements, ensuring that the tee grid ceiling production line fits perfectly with the customer's production environment and brand image. Even with a limited budget, KINGREAL can provide cost-effective customized solutions to make the customer's production process smoother and more efficient. |  |

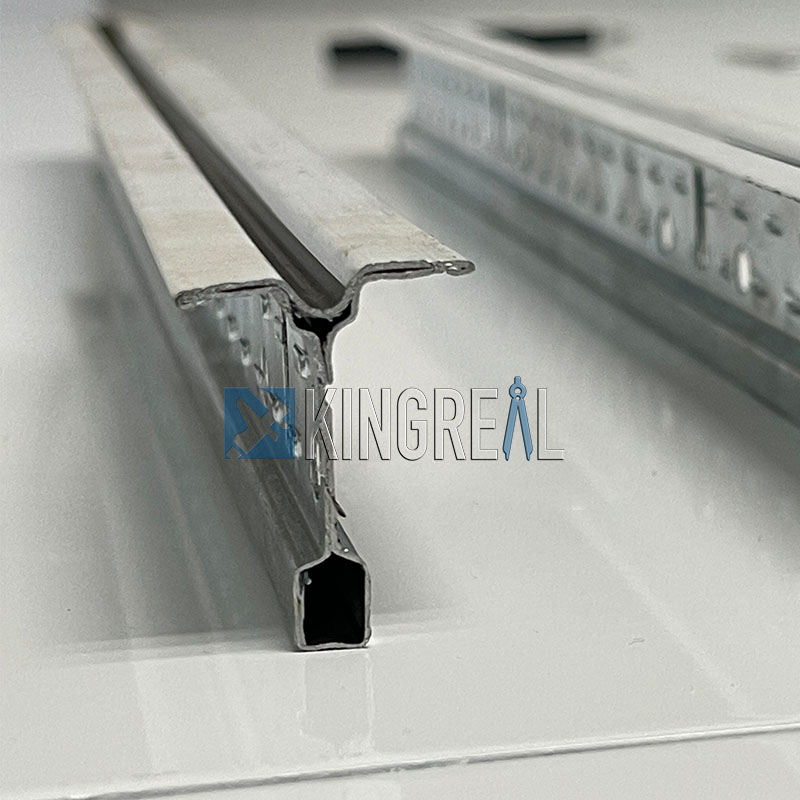

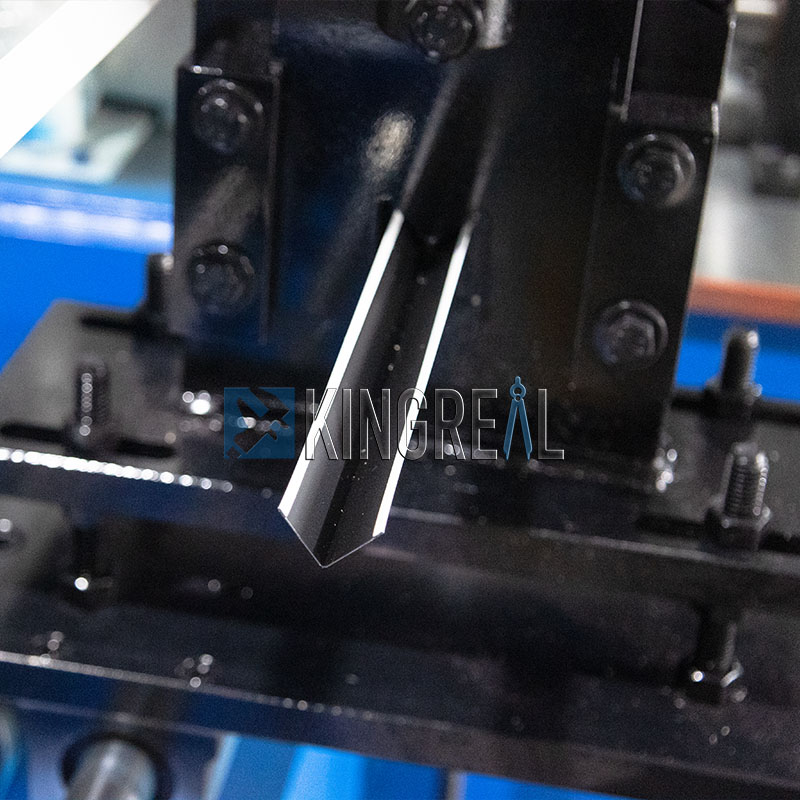

Ceiling t grid machines made of precision components KINGREAL tee grid ceiling production lines use high-quality rollers and precision servo systems to ensure that the produced ceiling t grids have high precision and excellent quality. These high-end components not only improve the stability and durability of the ceiling t grid machine, but also make the production process smoother and reduce the failure rate. Through these precision processes, KINGREAL is committed to providing customers with reliable and durable tee grid ceiling production lines. |

|

Different Ceiling T Grid Machine Manufacturing Solutions

Black Line Ceiling T Grid Machine

The Black Line Ceiling T Grid Machine is an innovative device from KINGREAL, specially designed to add black lines to the surface of the ceiling t bar during the production process. This function is achieved by equipping the roll forming machine with an efficient ink bottle, and the ink dries quickly during the forming process. The quick-drying ink selected by KINGREAL not only dries quickly, avoiding the time waste in the traditional drying process, but also ensures the smoothness of the tee grid ceiling production line and greatly improves production efficiency. In addition, KINGREAL engineers have optimized the ceiling t grid machine structure and adopted a unique arch design, which makes the tee grid ceiling production line more stable during operation, reduces the failure rate, and ensures long-term and efficient production capacity. |  |

Drawing:

|  |  |

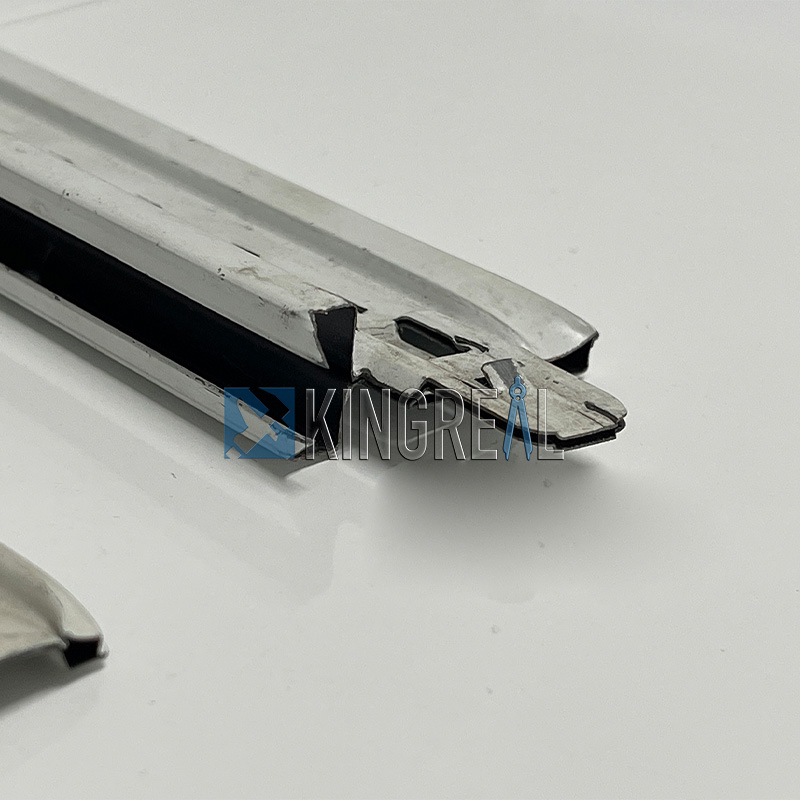

Silhouette Ceiling T Grid Machine

Customers can choose chain drive or gearbox drive for the Silhouette Ceiling T Grid Machine according to specific needs. KINGREAL engineers will deeply analyze the characteristics of the customer's market, actual production conditions and product requirements, and provide tailored rationalization suggestions. The shearing station of this Silhouette Ceiling T Grid Machine is equipped with high-hardness, wear-resistant blades to ensure accurate shearing of the ceiling t bar, making each cut smooth and burr-free. At the same time, the design of the Silhouette Ceiling T Grid Machine takes into account the consistency of production, ensuring that each batch of products can maintain the same high standards. |  |

Drawing:

|  |  |

KINGREAL Flat Ceiling T Bar Machine is equipped with an intelligent PLC control panel that supports multi-language conversion, including English, Russian, Arabic, French, Spanish and German. This function makes it easy for customers from different countries and regions to operate, improving the adaptability of the international market. In addition, the configuration of the heavy-duty decoiler enables the Flat Ceiling T Bar Machine to carry heavy and large rolls of metal coils to meet high-intensity production needs. Whether it is small batch customization or large-scale production, KINGREAL Flat Ceiling T Bar Machine can maintain efficient and stable operation, ensuring production flexibility and reliability. |  |

Drawing:

|  |  |

KINGREAL FUT T Grid Machine can achieve perfect forming effects through the application of high-quality rollers. This FUT T Grid Machine is specially designed with punching dies that meet customer needs to ensure accurate punching while forming and produce high-precision ceiling t grids. Whether it is the requirements for forming shape or hole position, the FUT T Grid Machine can easily meet them. |  |

Drawing:

|  |  |

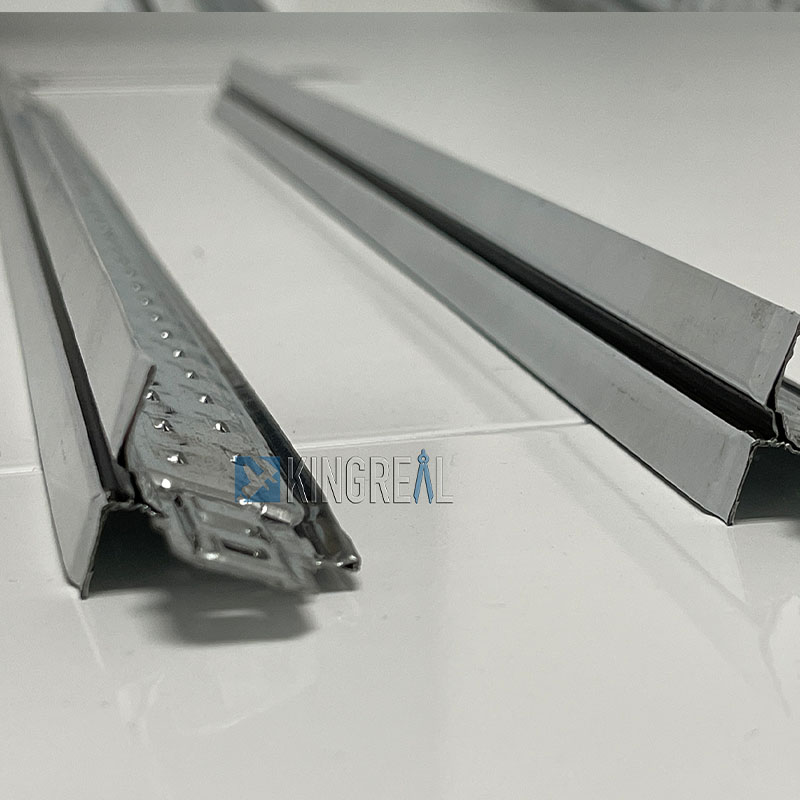

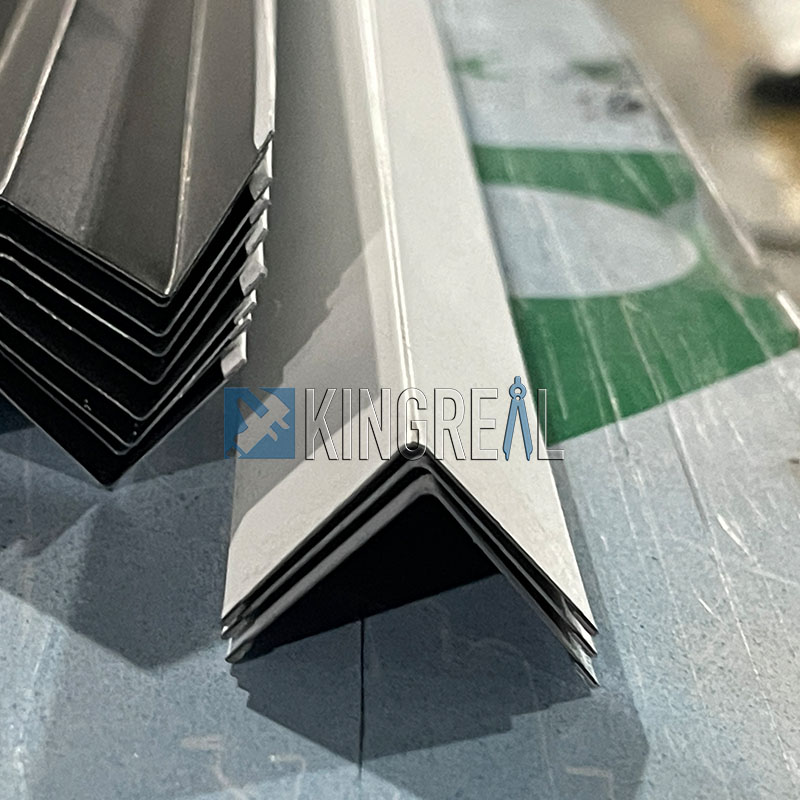

KINGREAL Wall Angle Profile Machine is designed to produce beautiful and uniform wall angles, which can provide a smooth surface for ceiling installation and perfectly connect walls and ceilings. At the same time, in order to meet the market demand for perforated wall angles, KINGREAL has equipped this Wall Angle Profile Machine with an efficient punching machine. In this way, customers only need one machine to realize the full process production from metal coils to perforated wall angles. This integrated design not only improves production efficiency and reduces labor costs, but also effectively reduces equipment investment and floor space, providing customers with great convenience and flexibility. |  |

Drawing:

|  |  |

Common Ceiling T Bar Size Chart

Type | Material | Item | AxB(mm) | Thickness(mm) | Length(mm) |

Flat System (24/15mm width) | Hot Dipped Galvanized Steel | Main T | 38x24 32x24 38x15 32x15 | 0.23/0.26 0.3/0.35 | 3660/3600 3050/3000 |

| Cross T | 26x24 24x24 38x15 32x15 | 0.23/0.26 0.3/0.35 | 1220/1200 610/600 | ||

Groove System (24/15mm width) | Hot Dipped Galvanized Steel | Main T | 32x24 30x24 32x15 | 0.23/0.26 0.3/0.35 | 3660/3600 3050/3000 |

| Cross T | 32x24 30x24 32x15 | 0.23/0.26 0.3/0.35 | 1220/1200 610/600 | ||

FUT (15mm width) | Hot Dipped Galvanized Steel | Main T | 38x24 32x24 | 0.3 | 3660/3600 3050/3000 |

| Cross T | 32x24 26x24 | 0.3 | 1220/1200 610/600 | ||

Expose System (15mm width) | Hot Dipped Galvanized Steel | Main T | 38x15 32x15 | 0.3 | 3660/3600 3050/3000 |

| Cross T | 38x15 32x15 | 0.3 | 1220/1200 610/600 | ||

Wall Angle | Hot Dipped Galvanized Steel | Main T | 20x20 20x14.5 22x22 30x30 | 0.3/0.35 0.4/0.5 | 3000 |

| Cross T | 10x10x10x15 15x10x10x20 19x9x13x24 22x9x11x19 24x11x15x19 24x22x22x13 | 0.4 | 3000 |