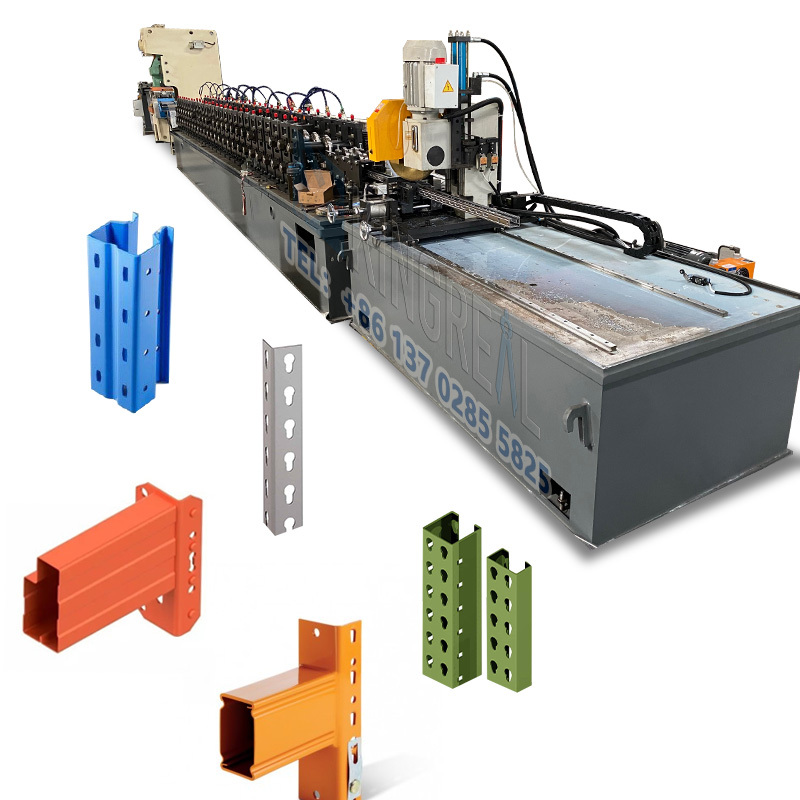

Warehouse Metal Rack Machine

(1)What is a Warehouse Racking System?

Warehouse racking systems are modern storage equipment primarily composed of uprights, beams, and shelves. Through a three-dimensional design, this warehouse racking system is intended to dramatically raise warehouse space utilization by enabling more effective storage and retrieval processes. It helps to guarantee logical and regulated access to products as well as supports the First-In, First-Out (FIFO) rule. An essential component of modern logistics management, warehouse racking systems are used in many different settings including industrial warehouses, logistics hubs, and cold storage facilities.

Design and functionality divide warehouse racking systems into light-duty racks, mid-duty racks, and heavy-duty pallet racks depending on their load-bearing capability. Beam racks and drive-in racks are among among the most popular structural design types. Warehouses can select the best rack type depending on their individual needs thanks to this flexibility. Manufacturing the fundamental elements of these warehouse racking systems, the warehouse pallet rack machine guarantees the racks' sturdiness and great load-bearing capacity, hence maximizing warehouse storage efficiency.

●What is Warehouse Pallet Rack Machine?

Manufacturing the key parts of warehouse racking systems—including shelf panels, uprights, box beams, step beams, and slotted angles—warehouse pallet rack machines are especially built. These warehouse pallet rack machines employ roll forming technology to turn steel coils into sturdy, high-load-bearing metal constructions. Along with a sharp guarantee of product quality, this effective production technique substantially raises the racks more fit for intense warehousing settings by way of greater manufacturing efficiency.

Ranging from supermarket and shopping mall uses to bigger warehousing facilities, these warehouse pallet rack machine applications are rather varied. The racks help to improve the client shopping experience in these locations by not only storing goods but also presenting and organizing items. Warehouse racking systems produced by these warehouse pallet rack machines effectively improve space utilization and allow for the rational arrangement of goods, making them particularly suitable for environments requiring multi-level storage.

(2)How Do Warehouse Pallet Rack Machine Work?

With their sophisticated technology and effective operational methods, warehouse pallet rack machines are very important in the manufacturing process of warehouse shelving. Different sorts of machines, including shelf panel making machine, upright rack making machine, box beam making machine, step beam making machine, and slotted angle rack machine, produce various forms of profiles employed in several components of the warehouse racking system. Although these warehouse pallet rack machines vary in form and purpose, they all use cold roll forming technology.

Every warehouse pallet rack machine is outfitted with high-precision roller sets that shape the raw materials through rolling to meet the ultimate need of the customer. All parts—shelf panels, uprights, box beams, step beams, or slotted angles—go through strict quality testing to satisfy design demands and load-bearing requirements. Advanced warehouse pallet rack machines create these components, which help the whole structure become more stable throughout its installation, hence improving the safety and storage capacity of the warehouse.

(3)Is There Quality Control When Producing Warehouse Pallet Rack Machine?

In the manufacturing process of warehouse pallet rack machines, quality control is of paramount importance. Supervising the whole manufacturing process, KINGREAL has a professional quality control staff.The quality control team guarantees rigorous compliance with quality standards at every step, from raw material preparation to processing, assembly, and testing of rollers and other parts. Moreover, the roller surfaces and shafts are thoroughly checked during packaging to make sure the finished warehouse pallet rack machine arrives perfectly.

Customers are cordially invited by the KINGREAL team to come to the factory and see every aspect of the warehouse pallet rack machine manufacturing process. This open approach not only builds customer trust but also enables them to more clearly appreciate the manufacturing process and quality control criteria. By means of this transparent communication, KINGREAL intends to show its dedication and accountability in after-sales service as well as equipment manufacture, therefore improving customer happiness.

(4)FAQ About Warehouse Pallet Rack Machine

1/How long do warehouse pallet rack machine service lifespans tend to be?

If the warehouse pallet rack machine is properly maintained regularly, it can last for an average of about 15 years or even longer.

2/What materials can this warehouse pallet rack machine process?

This warehouse pallet rack machine is designed to work with various steel materials, including mild steel, galvanized steel, and pre-painted steel coils, ensuring versatility for different storage system requirements.

3/Is the warehouse pallet rack machine adjustable sizes in one machine?

Yes, if the customer keeps the profile height same, it can adjust the different width in one warehouse pallet rack machine automatically.

4/What thickness of metal can the warehouse pallet rack machine handle?

Typically, the warehouse pallet rack machine can process metal coils with thicknesses ranging from 1.5mm to 3.0mm.

5/Can the warehouse pallet rack machine be customized for specific customer needs?

Yes, KINGREAL offer custom warehouse pallet rack machine manufacturing solutions to meet unique production requirements, including special hole patterns or profile shapes.