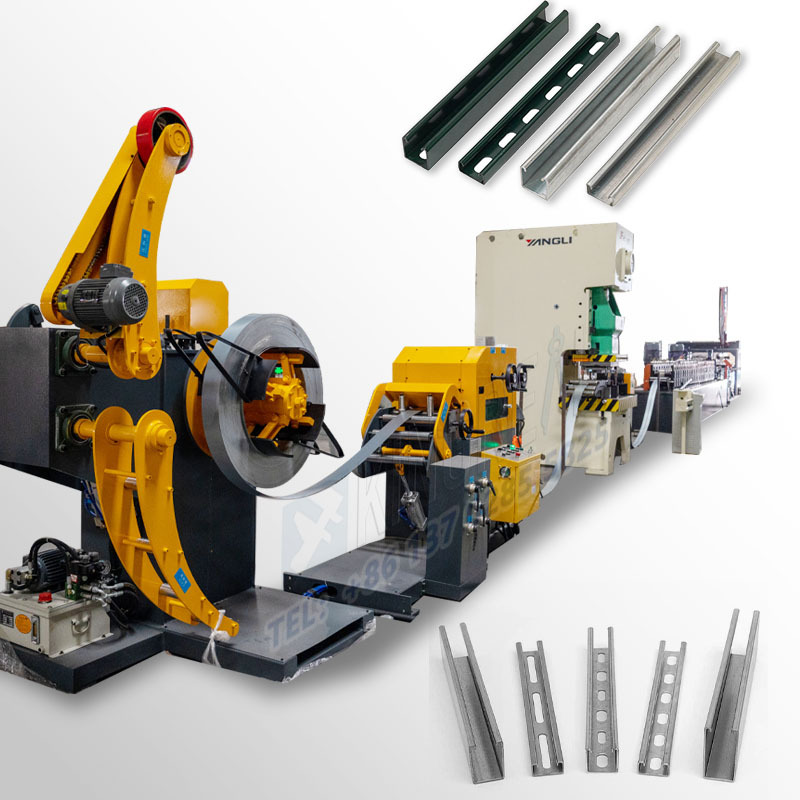

Strut Channel Machine

What is a High Speed Solar Channel Machine?

The solar channel machine is specifically designed for the high-precision, high-consistency, and high-speed production of solar channels. This cu solar channel machine is widely used in solar installation structures, photovoltaic support systems, and industrial frame systems. With the increasing global demand for renewable energy, especially in the solar sector, the importance of high-speed solar channel machines is becoming increasingly prominent.

In modern construction, solar energy, electrical systems, and mechanical support fields, the production of solar channels is a fundamental link. The construction and operation of these industries heavily rely on high-quality strut channels, thus the demand for high-speed solar channel machines continues to rise. KINGREAL high-speed cu solar channel machine, with its advanced technology and precision automation system, can achieve extremely high production speeds while ensuring dimensional accuracy and quality standards. The high-speed operation of this solar channel machine not only significantly shortens the production cycle but also effectively meets the growing market demand. At the same time, KINGREAL cu solar channel machine adopts high-performance servo control systems, automatic punching, and precision cutting, ensuring that every output product achieves the highest quality and reliability. Whether in handling complex production tasks or ensuring production efficiency, KINGREAL solar channel machine performs excellently, providing customers with superior production solutions.

What are the Main Features of KINGREAL Solar Channel Machine?

KINGREAL cu solar channel machine can produce at a high speed of 20m/min, and is equipped with an automated punching and cutting system, ensuring an efficient production process. In addition, the solar channel machine is suitable for the production of various profile sizes. The cu solar channel machine's robust frame design ensures continuous and stable operation throughout the production process, and the optional packaging unit further enhances the automation and efficiency of the production process. Through the packaging unit, finished products can be automatically conveyed, packaged, labeled, and stacked, all of which greatly reduces manual intervention. In practical applications, KINGREAL has successfully collaborated with customers in Mexico and Italy, fully demonstrating KINGREAL professional capabilities in the field of solar channel machines.

Mexico Project: Fully Automated Solar Channel Machine

This Mexican customer desired a fully automated production process to save labor costs and time while improving production quality and efficiency. To this end, KINGREAL specially designed a fully automated cu solar channel machine for this Mexican customer, equipped with a packaging unit. After production, the finished products are automatically transported to the packaging unit for packaging, labeling, and stacking. The packaging unit also features adjustable functions, allowing for adjustment of the number of profiles per bundle according to different needs, ensuring tight bundling and maintaining product integrity during long-distance transportation. This solar channel machine has been running stably in the Mexican customer's factory for several months and has received high praise from the customer, further confirming the reliability and efficiency of KINGREAL cu solar channel machine in practical applications.

Italy Project: Multi-Specification CU Solar Channel Machine

Another Italian customer required high-speed production of multiple profile specifications. After communication, the KINGREAL team designed a multi-specification solar channel machine for the Italian customer. The Italian customer only needs to set the required finished product specifications on the PLC control panel, and the cu solar channel machine's forming roller group will automatically adjust the width, conveniently producing profiles of specifications such as 41 × 21, 41 × 41, 41 × 62, and 41 × 82 mm. This solar channel machine has undergone rigorous testing and has received shipment approval from the Italian customer. Soon, KINGREAL engineers will travel to Italy for cu solar channel machine installation and operation training to ensure that the customer can fully utilize the high efficiency of this solar channel machine.

How Does KINGREAL Ensure Solar Channel Machine Quality?

KINGREAL implements strict quality control in roller manufacturing, machine assembly, and final testing to ensure that every piece of cu solar channel machine meets the highest standards before leaving the factory. Every solar channel machine undergoes actual production testing before delivery to ensure that the cu solar channel machine's quality and performance meet customer needs. KINGREAL always strives to provide customers with durable and high-precision solar channel machines, ensuring that customers have the best experience during the production process. Through rigorous quality control and continuous technological innovation, KINGREAL high-speed cu solar channel machine not only produces high-quality finished products but also maintains stable performance during long-term use, all of which translates into a high return on investment for our customers.

Frequently Asked Questions

1)How many sizes can be made in one solar channel machine?

One solar channel machine could produce one same width with different heights like 41x21, 41x41, 41x62, 41x82.

2)What is the cost of solar channel machine?

Every solar channel machine from KINGREAL is custom-designed, and the price will vary depending on factors such as the machine's components and performance specifications.

3)What materials can the solar channel machine process?

The solar channel machine mainly uses galvanized steel with a thickness of 2.0–2.5 mm as raw materials.

4)Does the solar channel machine include a punching unit?

Yes, KINGREAL can equip solar channel machines with punching stations to create holes according to the needs of solar installation systems.

5)Can the solar channel machine be customized for special profiles?

Of course, please provide the drawings to the KINGREAL team.