Metal Ceiling Machine

"In the field of metal ceiling machine, KINGREAL boasts twenty years of manufacturing experience and has consistently focused on the design and production of suspended ceiling machines to meet customer needs for complete ceiling systems. In modern home decoration, suspended ceiling systems not only enhance the aesthetics of the interior but also possess important practical functions. A complete suspended ceiling system typically consists of ceiling panels and other profiles, which need to fit together perfectly during installation to form a sturdy structure. Ensuring a flawless and neat appearance after installation is also crucial."

KINGREAL Metal Ceiling Machines for Suspended Ceilings

KINGREAL offers a variety of metal ceiling machines suitable for different types of ceilings. Customers can choose the most suitable machine based on their site and requirements. KINGREAL suspended ceiling machines are widely used in various fields, such as high-end commercial buildings, public facilities, medical and educational institutions, and even industrial manufacturing, especially suitable for places with strict requirements for fire resistance, moisture resistance, sound absorption and noise reduction, and easy cleaning.

The metal ceiling tile production line mainly uses a notching and shearing press to cut and shear the four corners of the material, ensuring that each corner is precise. Subsequently, the metal ceiling tile production line uses a bending forming press to shape the four corners of the material, ultimately producing various types of metal ceiling panels such as clip-in, lay-in, and tegular. This metal ceiling tile production line design makes the installation process simpler and more convenient. Through a profile support system, modular installation can be achieved, and the use of snap-on connections makes the entire suspended ceiling system stable and aesthetically pleasing.

The baffle ceiling machine, open cell ceiling machine, and linear strip ceiling machine have similar structures, all including precision components such as decoiler, leveling machine, roll forming machine, and cutting station. According to the customer's requirements for the type of suspended ceiling, KINGREAL engineers design the rollers in the forming section, allowing the roller group to gradually roll and shape the profiles. These metal ceiling machines can be used to produce baffle ceilings, open cell ceilings, or linear strip ceilings. They offer advantages in suspended ceiling applications such as enhancing spatial layering, good ventilation, and excellent visual effects. Through splicing with keels or other profiles, these profiles can be firmly fixed to the suspended ceiling panels, providing stronger support for the overall structure.

How Much Does a Metal Ceiling Machine Cost?

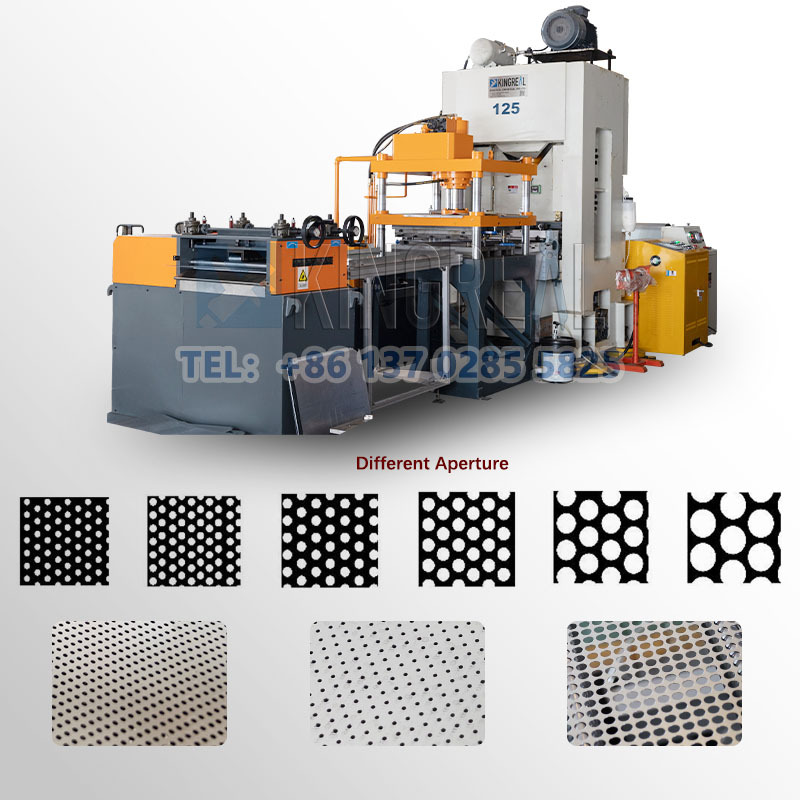

The price of KINGREAL suspended ceiling machines is influenced by various factors, including the technical parameters and performance of the components, the specifications and shape of the finished product, and the customer's production volume requirements. If a customer requires perforated ceiling panels, KINGREAL will customize the corresponding punching dies and add a metal ceiling tile perforation line to the metal ceiling tile making machine. To meet the requirements for material surface cleanliness, KINGREAL can equip the metal ceiling machine with a metal sheet cleaning machine to ensure that the product's appearance remains clean and tidy throughout the production process. For customers with strong noise reduction needs, KINGREAL offers suspended ceiling machines equipped with an acoustical ceiling tile textile stick machine, which can effectively reduce noise and improve the comfort of the living environment. For customers who need to reduce safety hazards, KINGREAL can also equip the suspended ceiling machine with protective shields to enhance safety during use. Driven by these factors, the specifications, types, and performance of the finished products produced by the machine are closely related to the price. KINGREAL is committed to providing customers with the best cost-effective metal ceiling machine manufacturing solutions to meet the specific needs of different projects.

About KINGREAL

01 Extensive Experience: KINGREAL has accumulated extensive experience in the field of suspended ceiling machines and has established close cooperative relationships with customers in many countries (such as Greece, Russia, Italy, UK, Turkey, Ukraine, Vietnam, etc.). KINGREAL team consists of experienced engineers, all of whom have more than 15 years of industry experience and a comprehensive understanding of every detail and working principle of the metal ceiling machines, thereby improving the design and production quality of the metal ceiling machines.

02 Own Factory: KINGREAL owns its own factory, focusing on machine debugging, manufacturing, and shipping. This means that KINGREAL team can control the entire production process of the equipment, ensuring the quality of every metal ceiling machine. At the same time, in the pre-sales stage, KINGREAL welcomes customers to visit the factory in person to observe the suspended ceiling machine's operation and production efficiency for a thorough evaluation, ensuring that the suspended ceiling machine perfectly meets the customer's specific needs.

03 Ensuring High-Quality Metal Ceiling Machines: To ensure the production of the highest quality metal ceiling machines, KINGREAL adopts a series of strict manufacturing standards and inspection procedures. After each metal ceiling machine is completed, KINGREAL conducts a series of machine inspections and debugging to ensure that the machine runs well before leaving the factory and can produce high-precision finished products. Only after meeting strict quality standards will the suspended ceiling machine be prepared for the next step of shipping, ensuring that customers receive satisfactory products quickly.