Light Steel Keel Machine

1/How Does the Light Steel Keel Making Machine Work?

In the modern construction industry, equipment such as drywall profile machine, metal ceiling channel machine, ceiling t grid machine, and light steel frame machine play a crucial role, collectively forming the support system for modern building structures. The emergence of these steel structure making machines not only responds to market demands but also meets the ever-changing requirements of architectural design. Different light steel keel making machines have their own unique working principles, but they all utilize advanced roll forming technology to produce structural profiles.

The drywall profile machine unfolds the coil material using a decoiler, then the roll forming machine's rollers roll-form the material, and then a fly punching and shearing system punches the required holes and cuts the material precisely to produce studs and tracks of different sizes.

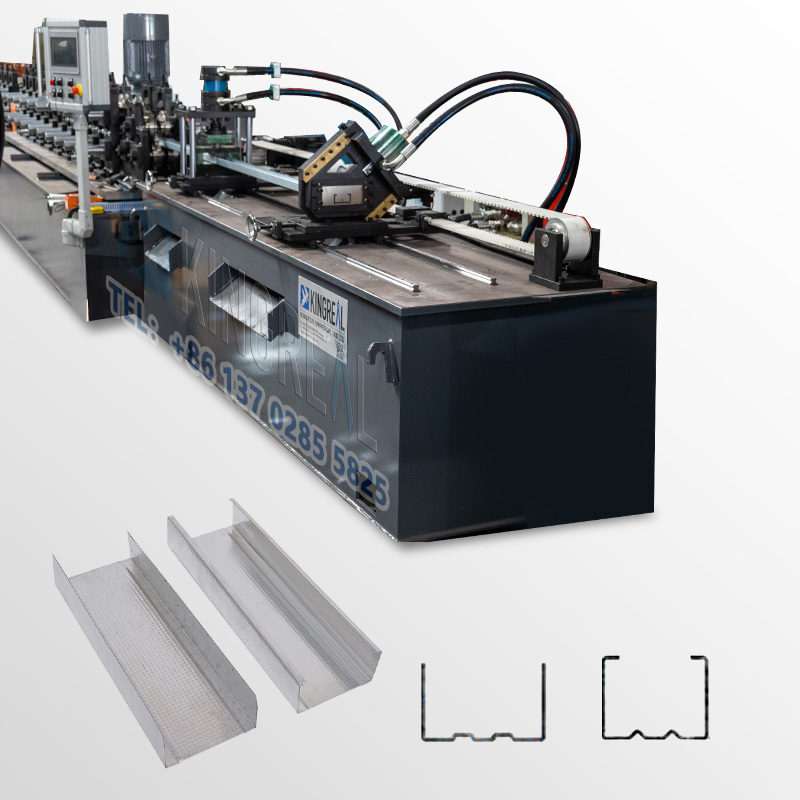

The metal ceiling channel machine can produce three types of profiles (hat channel, u channel, angle bead. It mainly consists of a decoiler, a roll forming machine, and a cutting station, capable of efficient production at 120m/min.

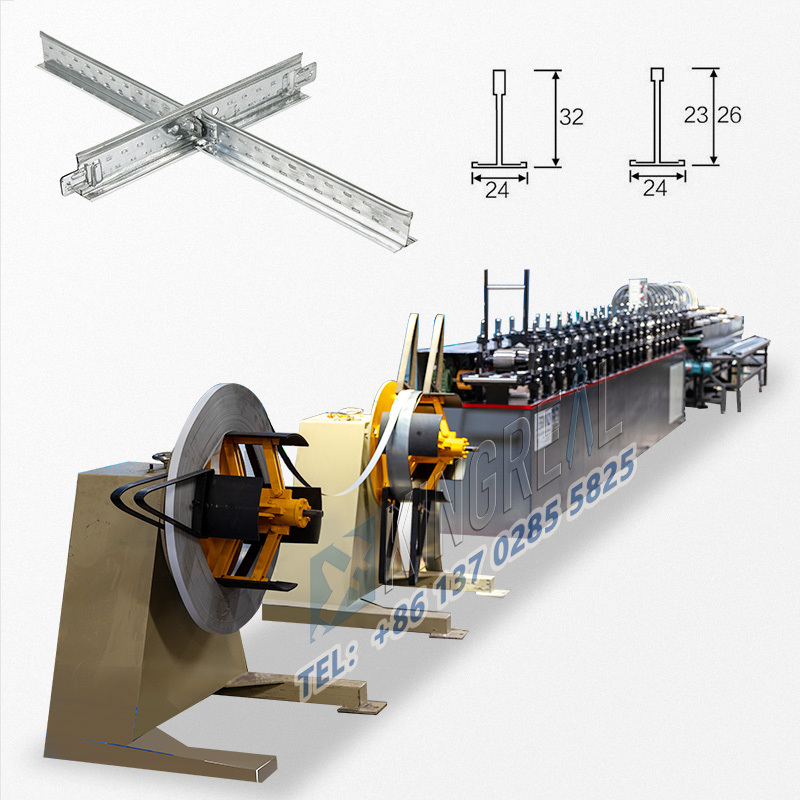

The ceiling t grid machine is known for dual uncoiler and fly punching and shearing system, capable of producing flat ceiling t bar, black line ceiling t bar, groove ceiling t grid, and FUT ceiling t grid.

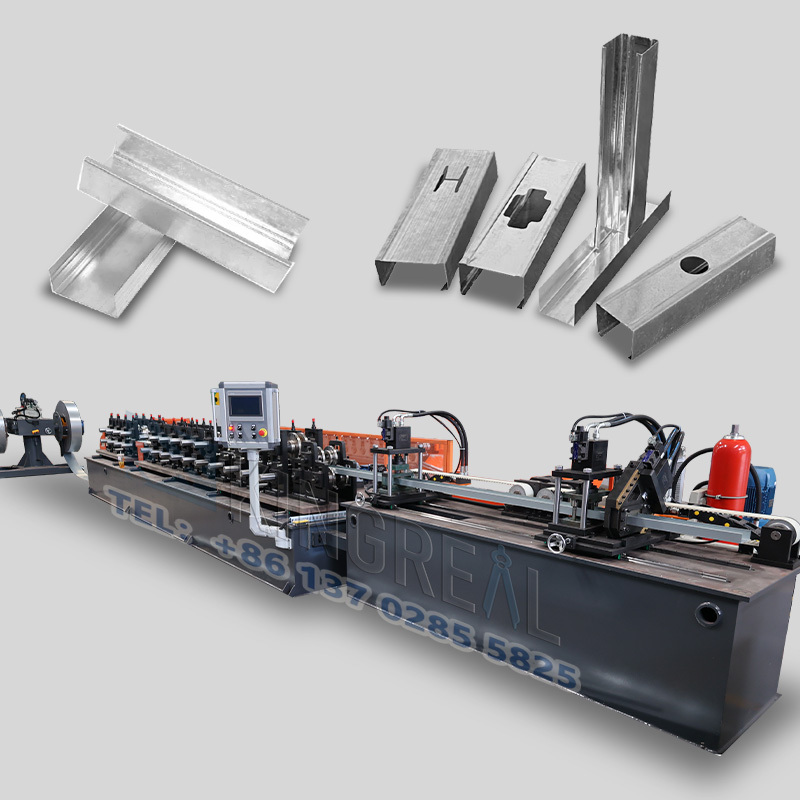

The light steel frame machine has a line speed of up to 2500m/h, with a comprehensive production efficiency of 500-800m/h. It is equipped with a variety of intelligent and precise stamping dies. It mainly produces top hat and c-shaped profiles according to project requirements.

2/ What is the Use of Light Steel Keel?

Various light steel keel making machines serve the steel structure field, mainly including commercial buildings, residential buildings, industrial plants, and public facilities. Each machine is adapted to specific industry needs.

The profiles produced by the drywall profile machine are widely used in building partition wall systems, playing a role in supporting and fixing wall materials. These profiles effectively enhance the stability and durability of the wall, ensuring safety and aesthetics in practical use.

The profiles produced by the metal ceiling channel machine are crucial in ceiling design. They provide a sturdy grid structure to support the installation of materials such as gypsum boards, tiles, or metal panels. On the one hand, these profiles can conceal wires and pipes; on the other hand, they also improve indoor sound insulation and enhance the overall decorative effect of the building.

The profiles produced by the ceiling t grid machine are used for ceiling installation, especially suitable for gypsum board and open cell ceilings. They ensure the stability and aesthetics of the ceiling, becoming an indispensable part of modern interior decoration.

The profiles produced by the light steel frame machine are very popular in projects such as adding floors to old houses and renovations, especially in areas with material shortages or transportation difficulties. Its mobility and high production efficiency allow construction workers to quickly and efficiently meet various project needs.

3/ Technological Breakthroughs in Light Steel Keel Making Machine

KINGREAL continuously innovates in the design and manufacturing of steel structure making machines, striving to meet the growing demands of the market.

Currently, KINGREAL light steel keel making machines achieve a production speed of up to 120m/min, allowing projects to proceed more efficiently. By incorporating a double-head decoiler, downtime due to material shortages is avoided, further improving the stability and efficiency of the steel structure making machine. The modern construction market urgently needs efficient automation. KINGREAL also equips its machines with packaging machines to bundle, stack, and even label the profiles, significantly reducing labor costs and improving the intelligence level of the production process.

Considering the market demand for rapid construction, KINGREAL engineers have specially designed a mobile light steel frame machine. This light steel frame machine can be fixed on a truck and transported directly to the construction site for on-site production, greatly shortening construction time and accelerating project progress.

4/ Can Light Steel Keel Making Machines Produce Parts with Holes or Other Features?

KINGREAL steel structure making machines can be customized according to customers' specific requirements to produce various types of profiles.

The steel structure making machine can be equipped with components of varying performance, enabling it to produce profiles with reinforcing ribs to enhance structural strength and rigidity. In addition, customers can request to add their own logo or model number to the profile surface, making the finished product easier to identify and thus improving its competitiveness in the market.

KINGREAL technological advantage is also reflected in the diversity of profiles. By changing the punching dies, the same light steel keel making machine can produce finished products with different hole types and diameters, adapting to the diverse market demands and optimizing the subsequent installation process, facilitating nail fixing, wiring, and other operations.