Drywall Profile Machine

KINGREAL drywall profile making machine can produce CW UW metal stud and track, a frame structure material used in building partition wall systems to support and fix wall materials. This drywall profile making machine usually uses 0.35-1.0MM thick galvanized coils or 0.35-1.0MM thick roll-coated coils as raw materials, and can produce drywall profiles with widths ranging from 40mm to 150mm.

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video About Drywall Profile Machine

Details Information About Drywall Profile Machine

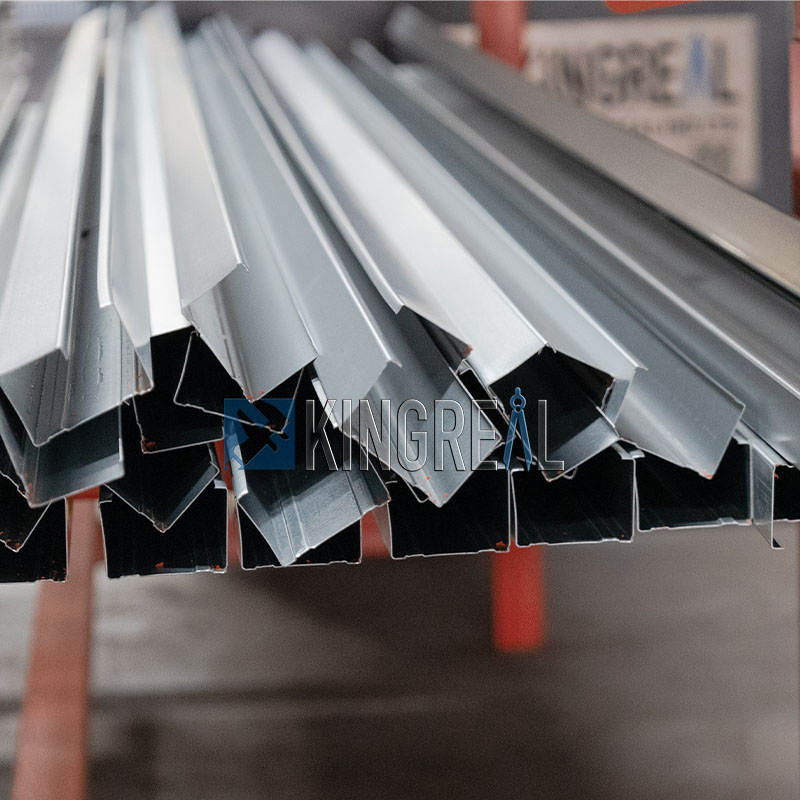

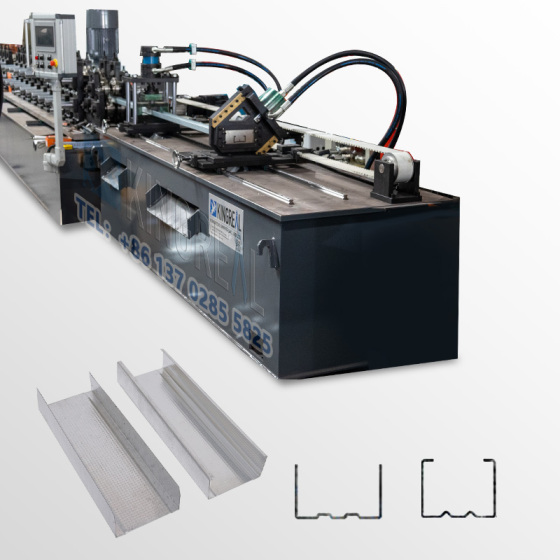

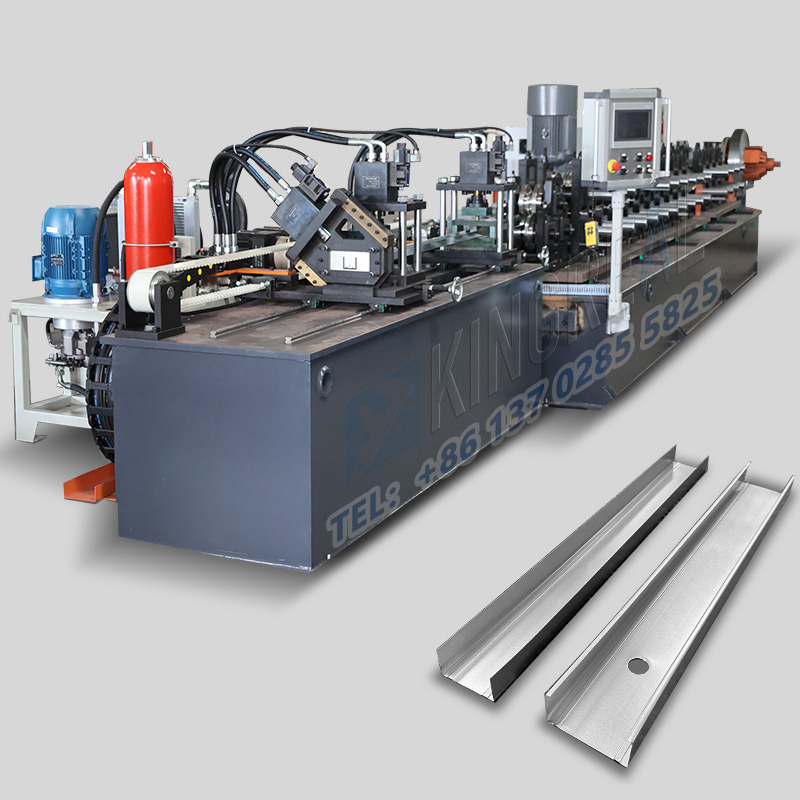

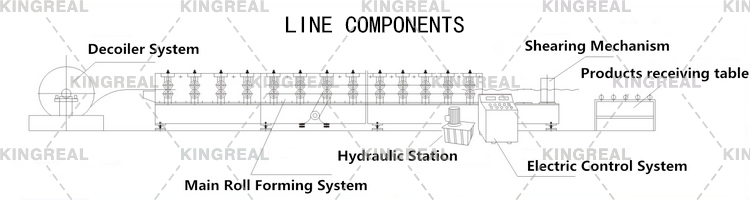

KINGREAL drywall profile making machine can produce metal stud and track, a frame structure material used in building partition wall systems to support and fix wall materials. This metal stud and track machine usually uses 0.35-1.0MM thick galvanized coils or 0.35-1.0MM thick roll-coated coils as raw materials, and can produce drywall profiles with widths ranging from 40mm to 150mm. This drywall profile machine consists of multiple precision components such as Decoiler, Main Roll Forming Machine, Hydraulic Fly Punching and Shearing system, Product Table, etc., with the characteristics of fast running speed, precise forming and cutting. And with the automatic packaging machine, this metal stud and track machine can help customers save at least $100,000 in labor costs each year. |  |

Workflow of Drywall Profile Machine

Decoiler --Main Roll Forming Machine-- Hydraulic Fly Punching and Shearing System-- Product Table

Parameters of Metal Stud and Track Machine

| Material | GI Strip |

| Material Thickness | 0.35mm-1.05mm |

Production Speed | 60-80m/min with punching on the bottom, 80-100m/min without punching |

| Shearing Accuracy | ±1.0mm/3m |

| Shearing Accuracy | Bending is less than 1‰/m |

What Kind of Drywall profiles can KINGREAL Drywall Profile Machine Produce?

| Item | Drawing | Specification(mm) | |||

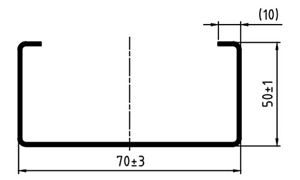

Stud |  | A | B | C | D |

| 45 | 34 | 5 | 0.4-1.2 | ||

| 51 | 35 | 5 | 0.4-1.2 | ||

| 63 | 35 | 5 | 0.4-1.2 | ||

| 70 | 35 | 5 | 0.4-1.2 | ||

| 75 | 35 | 5 | 0.4-1.2 | ||

| 92 | 35 | 5 | 0.4-1.2 | ||

| 100 | 35/50 | 5 | 0.4-1.2 | ||

| 150 | 35/50 | 5 | 0.4-1.2 | ||

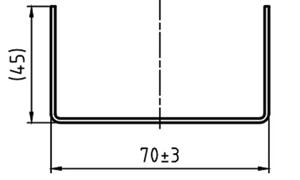

Track |  | A | B | D | |

| 46 | 28 | 0.4-1.2 | |||

| 52 | 24 | 0.4-1.2 | |||

| 65 | 24 | 0.4-1.2 | |||

| 72 | 25/30 | 0.4-1.2 | |||

| 77 | 30 | 0.4-1.2 | |||

| 94 | 30/35 | 0.4-1.2 | |||

| 102 | 35 | 0.4-1.2 | |||

| 152 | 35 | 0.4-1.2 | |||

Features of Metal Stud and Track Machine

1. Automatic width adjustment for drywall profile making machine

This metal stud and track machine has a flexible width adjustment function and can produce finished products of different widths. Users only need to enter the required width parameters on the PLC control panel, and the rollers of the roll forming machine will automatically adjust to the corresponding width.

This drywall profile machine not only improves production efficiency, but also meets the diverse production needs of customers, adapts to changes in different markets, and provides customers with greater flexibility and convenience.

2. Fly punching and cutting system for drywall profile making machine

The metal stud and track machine equipped with the flying punching and shearing system can achieve high-speed punching and shearing, and there is no need to stop during the punching and shearing process. At the same time, KINGREAL can customize the punching die according to the drawings provided by the customer, so that the finished products produced can meet specific design requirements.

When it is necessary to produce finished products with different hole types, only the punching die needs to be replaced, which greatly improves the flexibility and adaptability of production.

3. Good quality drywall profile making machine

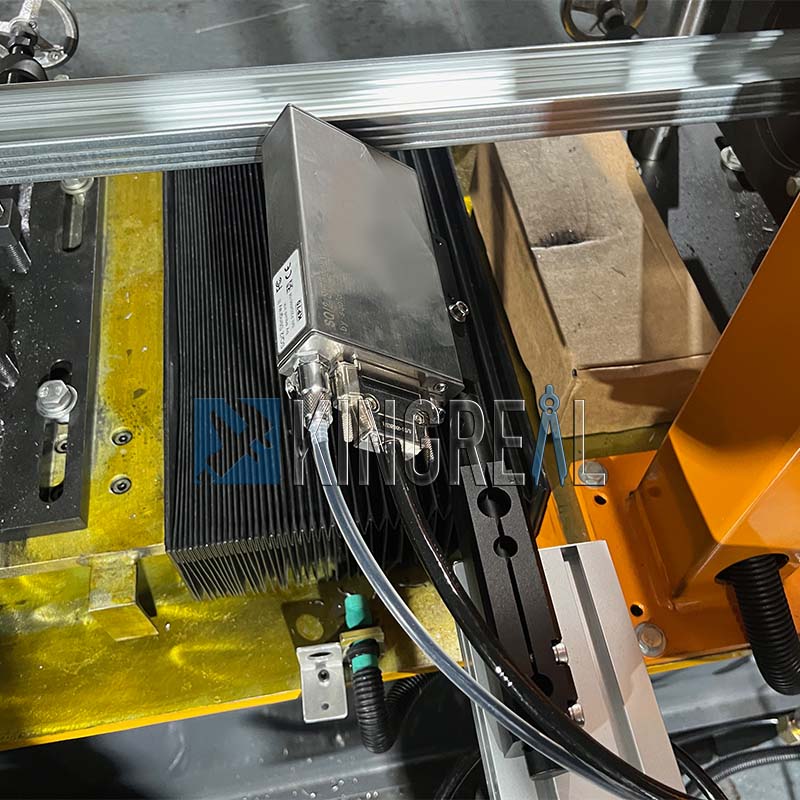

The rollers of the roll forming machine are made of high-durability material CR121Mov, which has high hardness and wear resistance, ensuring the consistency and stability of the forming effect. In addition, the electrical components used in the metal stud and track machine are all well-known domestic and foreign brands, ensuring the safety and stability of the overall operation.

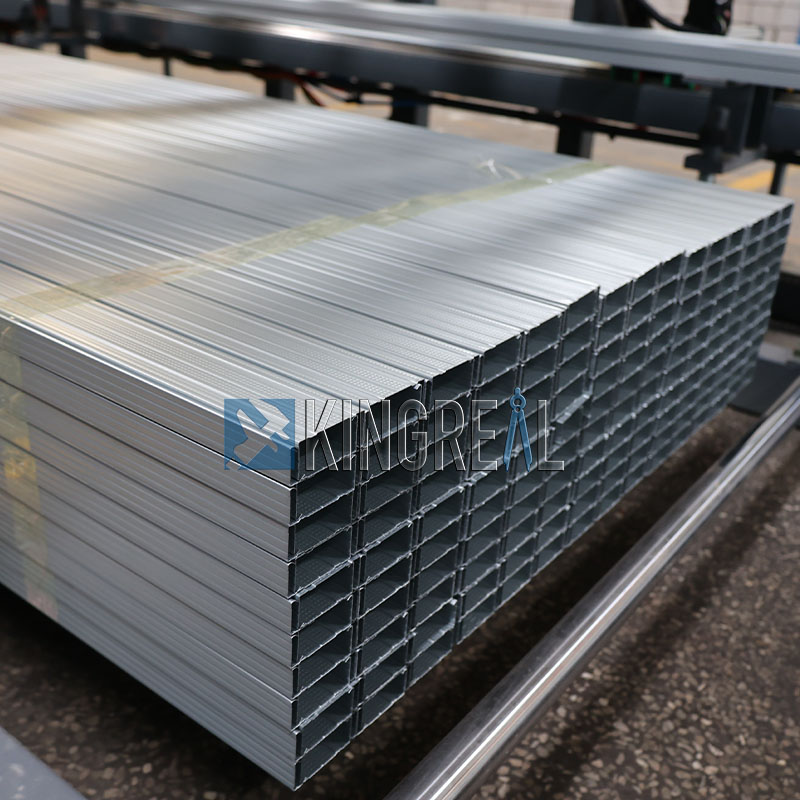

To further enhance the added value of the product, the drywall profile machine can also be equipped with a metal knurling roller for knurling on the surface of the metal sheet. This not only increases friction, but also improves the aesthetics of the product, making the finished product more competitive in the market.

Different Drywall Profile Making Machine Manufacturing Solutions

KINGREAL provides exclusive metal stud and track machine manufacturing solutions based on the actual production needs of customers, combined with drawings and factors such as performance, safety requirements and climate environment in the customer's country. This makes each drywall profile machine sold unique in performance and configuration, including the following metal stud and track machine feature solutions:

1. For the hot Middle East

In order to ensure the normal operation of the drywall profile machine in a high temperature environment, KINGREAL has equipped the metal stud and track machine with an oil cooling device.

In addition to the drywall profile machine's own fan, this device mainly protects the motor to avoid shutdown due to overheating. Such a machine design ensures the reliability of the metal stud and track machine under extreme climatic conditions and reduces the failure rate.

2. Light duty & heavy duty drywall profile Making machine

In order to meet customers' processing needs for coils of different thicknesses, KINGREAL provides two options: light duty metal stud and track machine and heavy duty drywall profile machines.

The light duty drywall profile machine is suitable for processing metal coils with a thickness of 0.35-0.9mm and a running speed of 50-60m/min;

The heavy duty metal stud and track machine is suitable for processing metal coils with a thickness of 0.8-1.2mm and a running speed of 60-80m/min.

The advantage of launching two drywall profile machines is that customers can freely choose according to their own production needs to ensure the best performance and economy of the metal stud and track machine.

3. Auto packaging unit for drywall profile Making machine

In order to improve the efficiency of the entire production process, KINGREAL can equip the metal stud and track machine with a packaging unit.

After the drywall profile is discharged, it will be automatically transported to the packaging machine for bundling and stacking, reducing the need for manual handling.

This drywall profile machine not only improves production efficiency, but also ensures the stability and quality of the stud and track.

4. Inkjet device for metal stud and track machine

The roll forming machine is equipped with an inkjet device, which can print the customer's required logo on the surface of the finished product while the profile is being formed.

This function not only improves the market competitiveness of the finished product, but also makes it easier for customers to identify the model and brand.

In addition, if you need to change a different logo, you only need to make a simple modification on the PLC control panel, which is convenient and quick to operate.

5. Protective shield for drywall profile Making machine

Since some countries have high requirements for the safety performance of metal stud and track machines, KINGREAL provides an optional protective shield for the drywall profile making machine.

The protective shield can effectively reduce safety hazards when the metal stud and track machine is running and ensure the safety of the operator. When the drywall profile machine is suspended, the protective shield can be easily opened for cleaning and daily maintenance.

This design greatly improves the safety of the metal stud and track machine and meets the market's demand for high-standard safety performance.

Drywall Profile Making Machine Product Display