Stud And Track Machine

1/How Does the Stud and Track Machine Work?

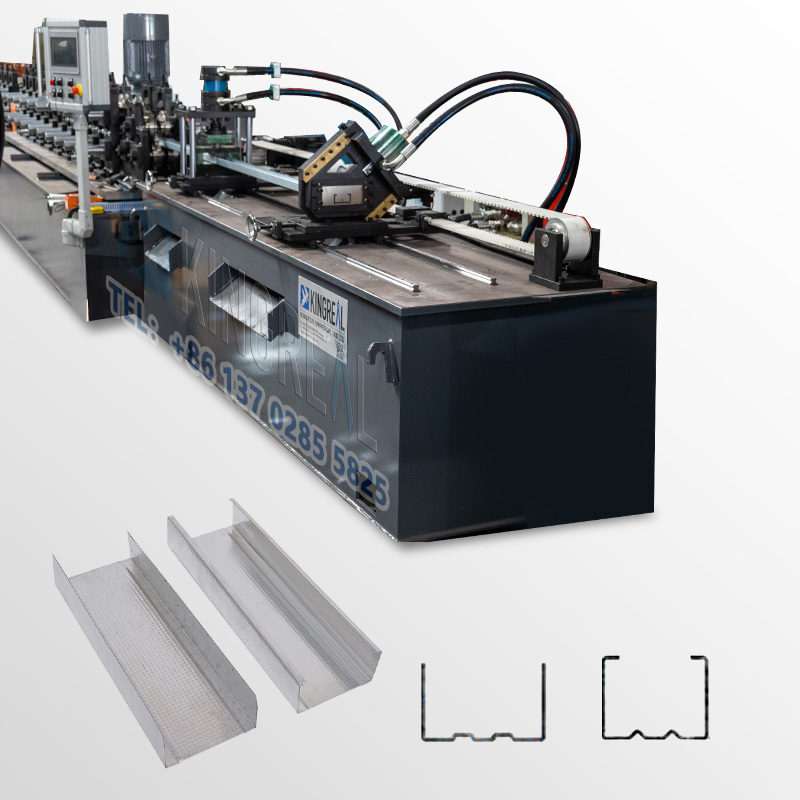

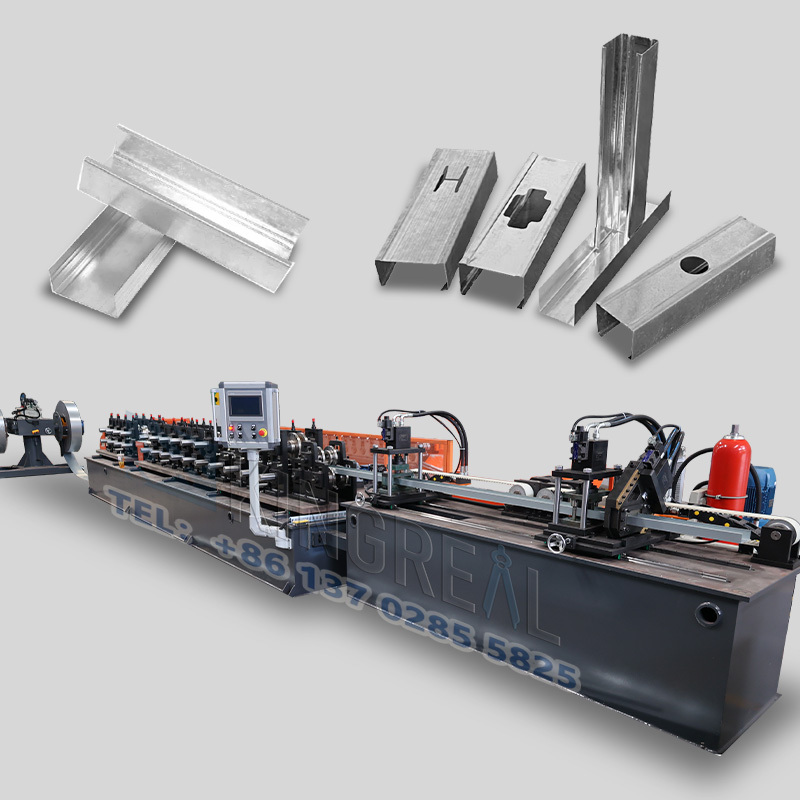

The stud and track machine is specifically designed for producing metal stud and track. This stud and track machine mainly consists of several precision components, including a decoiler, a main roll forming machine, a hydraulic fly punching and cutting system, and a output table surface. First, the decoiler unwinds galvanized coils with a thickness ranging from 0.35-1.0 mm, preparing the material for subsequent processing. The uncoiled material then enters the main roll forming machine, where it is processed into C-shaped or U-shaped drywall profiles by a series of roller sets. During this process, the design and arrangement of the rollers directly affect the precision and surface quality of the finished product. After forming, the stud and track machine uses a hydraulic fly punching and cutting system to quickly punch and shear the drywall profiles. This step ensures high precision and a burr-free surface, reducing the workload of subsequent processing. Finally, the formed and punched products are output from the discharge table for easy packaging and transportation.

The stud and track machine can automatically produce 120m/min. The stud and track machine boasts a high degree of automation; once the parameters are set, the stud and track machine can operate independently with minimal human intervention. Furthermore, the stud and track machine employs high-precision manufacturing processes, producing products with smooth surfaces and accurate dimensions, ensuring that every partition wall joist meets standards.

2/ What is the Difference Between Stud and Track Drywall?

By adjusting the roller assembly, KINGREAL can produce two different types of drywall profiles (stud and track) in a single stud and track machine. They differ significantly in structure and application.

-Shape Difference: C stud joists have a C-shaped cross-section and are primarily used as vertical load-bearing components in partition walls. U tracks have a U-shaped cross-section and primarily serve as horizontal support structures for partition walls.

-Application Difference: C stud joists, as vertical profiles, are typically installed within u tracks to support partition wall finishes (such as gypsum board, calcium silicate board, and fiber cement board). U tracks are used to stably fix the partition wall to the floor and ceiling.

Both c studs and u tracks play a crucial role in partition wall systems, forming the foundation of the light steel structure. The synergistic effect of these two components not only ensures the strength and durability of the building but also adapts to the needs of different spatial dimensions. Common u tracks are 100 mm long and suitable for various partition wall specifications. C studs are available in 150 mm, 75 mm, and 50 mm specifications, allowing for appropriate selection based on the partition wall's height and load-bearing requirements to ensure stability and durability.

3/How Much Does a Stud and Track Machine Cost?

The price of a stud and track machine varies depending on customer needs. Factors affecting stud and track machine cost mainly include component parameters, performance, and whether additional functional modules are included.

-Heavy-duty stud and track machine: This type of stud and track machine is suitable for processing materials with a thickness of 0.8-1.2 mm and is typically used in projects with high load-bearing requirements; therefore, the price is relatively high.

-Light-duty stud and track machine: Suitable for processing materials with a thickness of 0.35-0.9 mm, the price is usually more affordable, suitable for small to medium-sized decoration projects.

Additional functional modules for stud and track machine: To improve overall production efficiency, KINGREAL can equip the stud and track machine with a packaging machine for automatic packing, stacking, and labeling, significantly reducing labor costs. Furthermore, for specific customer needs, KINGREAL can add lettering rollers or inkjet devices to print specific logos or other information onto the finished product during the forming process. For users seeking enhanced production safety, KINGREAL also offers protective shield options for the stud and track machine.

KINGREAL excels at customizing stud and track machines to meet specific project requirements, ensuring the stud and track machine meets actual production needs.

4/ Successful Projects

As a signature product of KINGREAL, the stud and track machine has been widely used in many countries, including Saudi Arabia, Mexico, Kazakhstan, Aruba, and Greece. KINGREAL high-quality products and services have earned high praise from customers. In each stud and track machine project, KINGREAL dispatches professional engineers to the customer's factory for equipment installation, operation training, and after-sales upgrade services. These real-world examples fully demonstrate the adaptability and efficiency of the KNGREAL stud and track machine in different markets and environments. It not only creates economic benefits for customers but also contributes KINGREAL strength to the development of the construction industry.