Metal Perforated Machine

1. What is the Function of a Metal Perforated Machine?

The main function of a metal perforated machine is to punch holes of different shapes and sizes on the surface of metal materials to meet various manufacturing needs. Unlike traditional punching methods, the metal perforated machine, with its high efficiency and precision, can complete the processing of multiple holes in a very short time, significantly improving production efficiency. Specifically, the steel perforated machine has an extremely fast punching speed and can perform continuous punching, typically reaching 180SPM, suitable for high-volume production.

In addition, the metal perforated machine has the capability of high-precision hole processing, especially suitable for fields with strict requirements for size and accuracy. By equipping advanced punching dies, it can ensure that the size and shape of each hole are consistent and regular. It's worth mentioning that the KINGREAL team has designed a steel perforated machine capable of punching micro-holes of 1.0mm and 1.5mm, and the metal perforated making machine is already running stably in the factories of KINGREAL customers in Greece and Morocco, bringing them substantial profits.

The automation of the metal perforated making machine is reflected in the fact that users only need to set parameters on the PLC control panel, and the metal perforated machine will operate automatically. During steel perforated machine operation, operators only need to organize the perforated materials and monitor the metal perforated making machine in real time to handle any unexpected situations.

2. How to Perforate Sheet Metal?

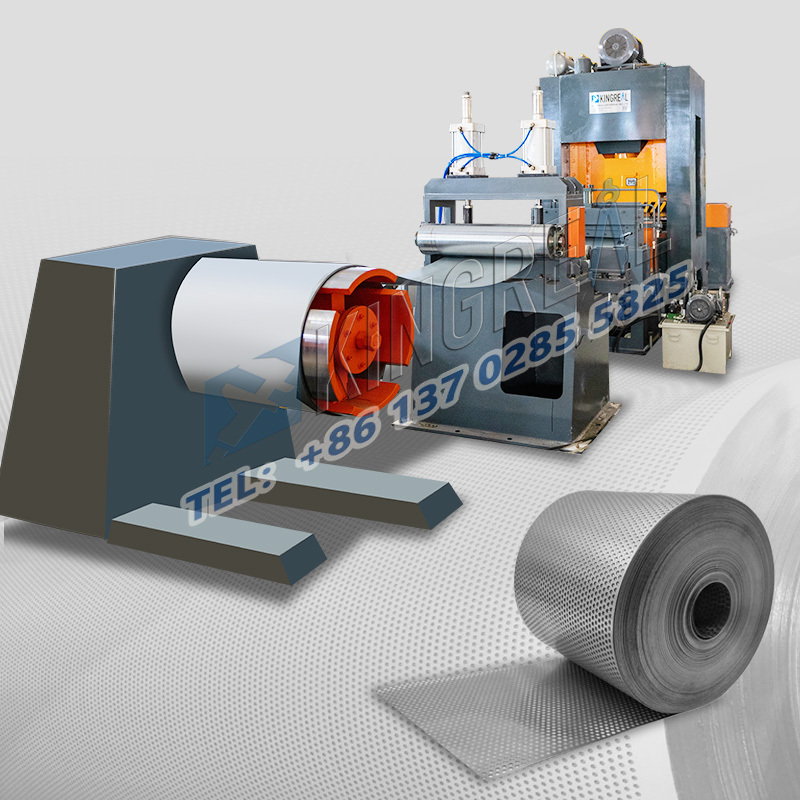

A complete metal perforated machine usually consists of multiple precision components, including a decoiler, a leveling machine, a punching machine, and a recoiler or shearing station. First, the decoiler unwinds the coil material to facilitate subsequent processes. Next, the leveling machine flattens the unwound material, ensuring a smooth surface and improving the accuracy of subsequent punching. The leveled material is then automatically transported to the punching machine. KINGREAL uses durable DC53 dies to ensure high-precision punching even at high speeds. The pneumatic braking system of the punching machine enables fast and efficient punching, ensuring the quality of each hole. Finally, the perforated metal material can be precisely cut by a shearing station to produce perforated sheets that meet the customer's actual needs. Alternatively, the perforated material can be rewound by a recoiler for subsequent processing and storage.

3. Different Patterns for Metal Perforated Machine

KINGREAL steel perforated machines can process a variety of metal materials, such as steel, stainless steel, aluminum, iron, and copper, and support diverse hole patterns, including round holes, long round holes, square holes, triangle holes, diamond holes, hexagonal holes, and crossed holes.

Based on customer-provided drawings, KINGREAL can customize punching dies for each specific hole pattern. By changing different dies, multiple different patterns of perforated metal sheets can be produced on the same metal perforated making machine. It's worth mentioning that KINGREAL newly developed metal perforated making machine can produce micro-holes of 1.0mm and 1.5mm, which places higher demands on manufacturing precision and die durability. This metal perforated machine allows KINGREAL customers to expand their product lines and meet more complex market demands.

4. What is the Price of a Metal Perforated Machine?

KINGREAL steel perforated machines are fully customized, and the price varies depending on several factors. The following are the main factors affecting the price of a metal perforated machine:

4.1 Steel Perforated Machine Configuration and Punching Dies

The configuration of each machine, including the number of punching dies required and their manufacturing difficulty, directly affects the final price. Micro-hole dies are more difficult to manufacture, so their cost is usually higher. Dies for different hole patterns may also change the overall quotation.

4.2 Performance Parameters of Metal Perforated Machine Components

The performance parameters of the components of the metal perforated making machine are also important factors in pricing. For example, the material weight supported by the decoiler, the number of rollers and straightening accuracy of the leveling machine, and the tonnage of the punching machine (e.g., 125 tons, 160 tons, or 200 tons) will all affect the final price of the steel perforated machine. These parameters determine the metal perforated making machine's load capacity and operational stability.

4.3 Additional Components for Steel Perforated Machine

In addition, customers may choose to add some extra accessories without affecting the normal operation of the metal perforated making machine, which will also affect the price. For example, equipping with a feeding trolley and unloading trolley can improve production efficiency and facilitate the automatic handling of raw materials and unloading of finished products. The inclusion of a metal sheet cleaning machine to clean oil stains generated during processing also contributes to improving the automation and efficiency of the entire production process.