Metal Stamping Production Equipment Solution

KINGREAL can provide complete metal stamping production equipment solutions, including false ceiling channel machine, drywall profile machine and warehouse pallet rack machine, to meet various customer needs.

- KINGREAL

- China

- Information

What is a Metal Stamping Production Equipment Solution?

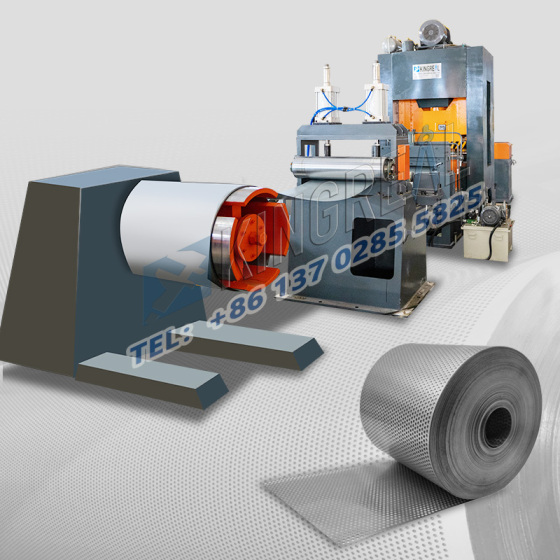

A metal stamping production equipment solution is a comprehensive manufacturing process. This process involves feeding metal material into a stamping press, where it is shaped by dies to achieve the desired form. From punching, blanking, embossing, bending, flanging to embossing, metal stamping production equipment covers a variety of sheet metal forming processes. In this process, metal stamping production equipment are typically equipped with progressive dies, using coiled steel as raw material.

The coiled steel is unwound from a drum, leveled by a straightener, and then fed into the press and die by a feeder at a predetermined length. The number of stations in the die can be determined based on the complexity of the part. This flexibility allows metal stamping production equipment solutions to meet diverse customer needs.

Working Process of Metal Stamping Production Equipment

Decorator -- Straightener -- Metal Punching Machine

KINGREAL Advanced Metal Stamping Production Equipment Solution

KINGREAL provides complete metal stamping production equipment solutions. KINGREAL not only offers metal stamping production equipment producing metal parts of various specifications and shapes, but also provides a variety of machines, such as false ceiling channel machine, drywall profile machine, and warehouse pallet rack machine. These machines produce the profiles essential for steel structures and shelving systems. Assembling these profiles together to form a complete system significantly improves production efficiency and product quality.

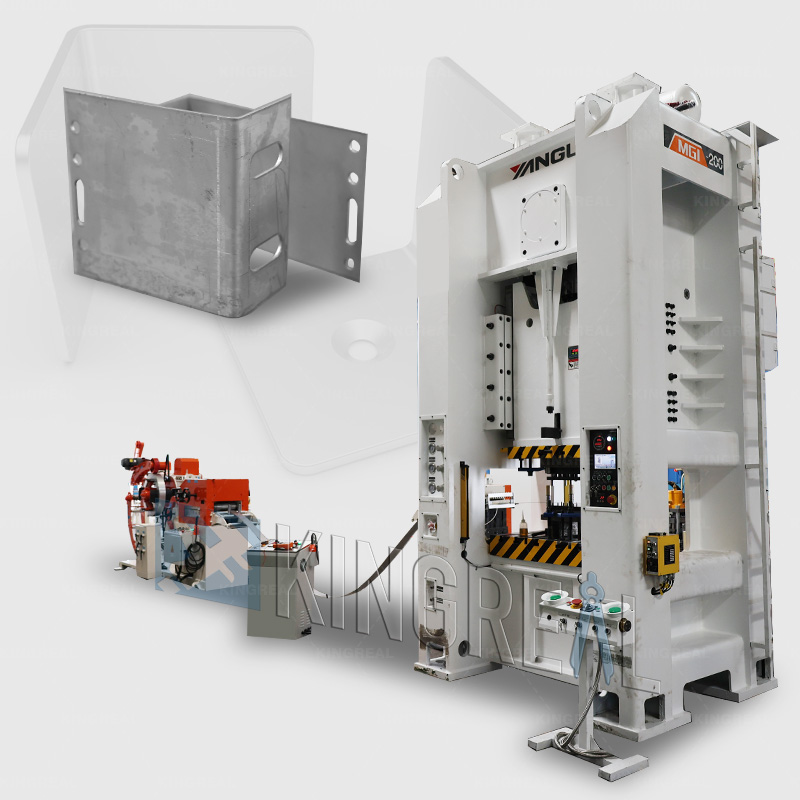

KINGREAL offers a range of high-quality metal stamping presses with stamping pressures ranging from 125 to 200 tons. KINGREAL provides various types of metal stamping production equipment to help customers manufacture metal stampings efficiently and accurately. These metal stamping production equipment are designed not only for performance but also for ease of use, ensuring operators can quickly learn and operate them with reduced complexity.

Complete Metal Stamping Production Equipment Solution

In a metal stamping production equipment solution, the machines do not exist in isolation; the profiles produced by many machines need to work together to complete a complete system. KINGREAL metal stamping equipment solutions include not only metal stamping production equipment but also primarily provide false ceiling channel machine, drywall profile machine, and warehouse pallet rack machine.

Solution 1: Metal Stamping Production Equipment for False Ceiling Channel Machine

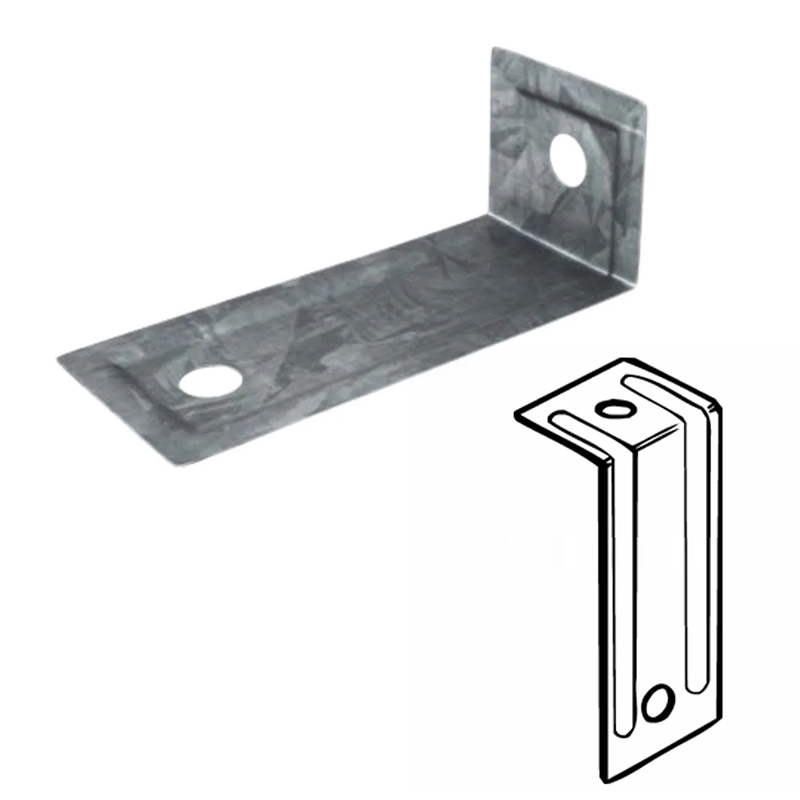

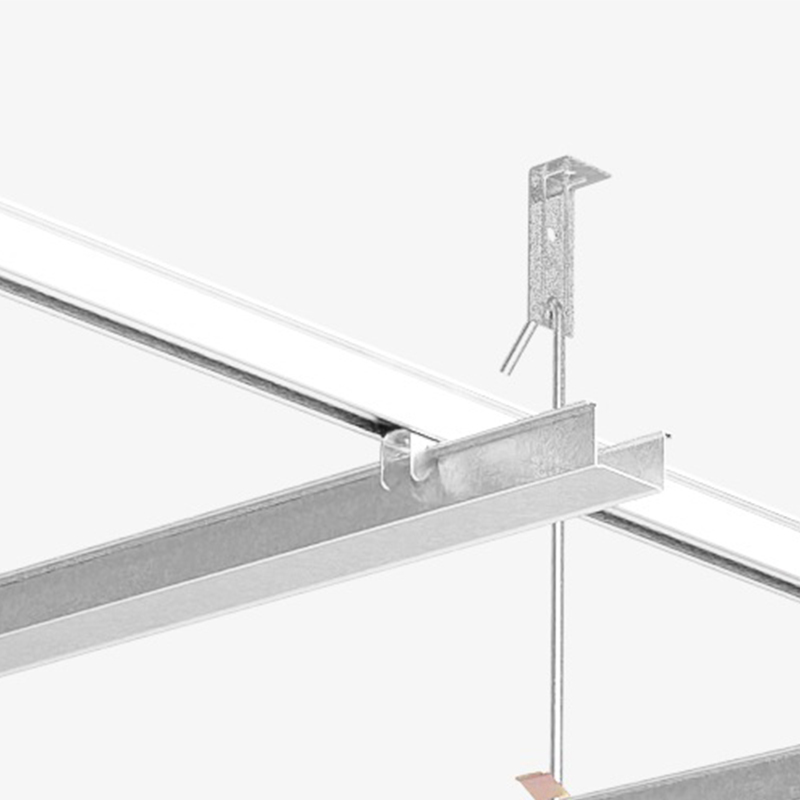

Used in conjunction with false ceiling channel machine (specifically including hat channel machine, u channel making machine, angle bead roll forming machine), metal stamping production equipment produces high-quality spring clips and ceiling joists. These products are designed for commercial and residential spaces, providing a robust frame and easy installation, ensuring durable ceiling support.

In ceiling support solutions, KINGREAL metal stamping production equipment produce spring clips of various sizes and hole patterns. These clips are used to connect the main channel and furring channel produced by the false ceiling channel machine, ensuring the stability of the entire suspension system. If wiring needs to be installed in the ceiling system, the spring clips can work in conjunction with wire clips to ensure neat arrangement and secure positioning of wires within the ceiling.

Solution 2: Metal Stamping Production Equipment for Drywall Profile Machine

Nogging brackets, sill connectors, and wall brace are produced by metal stamping production equipment, are used in partition wall systems in conjunction with studs and tracks produced by drywall profile machines. Nogging brackets are high-strength supports, typically fixed to the flanges of the studs. This design effectively increases the overall stability of the partition wall, especially under external pressure or impact, ensuring the wall is less prone to deformation.

Sill connectors tightly connect the vertical studs to the horizontal tracks, providing essential structural support for the overall wall structure. Wall braces are specifically designed for stand-alone stud walls in commercial applications, providing additional reinforcement. For walls with high loads, wall bracelets significantly improve the overall load-bearing capacity, ensuring the safety of the partition wall during use.

Solution 3: Metal Stamping Production Equipment for Warehouse Pallet Rack Machine

Metal stamping production equipment produces base plates, upright protectors, and shims, which can be combined with warehouse pallet rack machines to form a complete and efficient racking system. The base plate not only provides a stable foundation but also withstands the weight of goods above. The metal stamping production equipment can precisely manufacture base plates of different sizes and shapes to meet the needs of various warehouses and stores. Furthermore, the upright protectors manufactured using this equipment effectively absorb impact forces, extending the lifespan of the racking. In addition, the metal stamping production equipment ensures the precise dimensions and thickness of the produced shims for optimal assembly. When racking components are under load, the precise shims prevent loosening and displacement of connection points, ensuring the overall stability of the racking.

Successful Metal Stamping Production Equipment Solution Projects

KINGREAL has established strong partnerships with clients in Turkmenistan and Russia, providing effective metal stamping production equipment solutions for their specific project needs. At the initial stage of a project, the KINGREAL team carefully confirms the client's requirements, including the dimensions, shape, and materials of the finished products to be produced. Based on this information, KINGREAL further refines the metal stamping production equipment manufacturing plan and provides the final machine solution.

Once the metal stamping production equipment is completed, KINGREAL invites the client to the factory for inspection. If the client is unable to attend, KINGREAL experienced engineers will conduct the inspection on their behalf and provide feedback to the client through pictures, videos, and reports. Only with the client's permission are the metal stamping production equipment considered qualified and ready for shipment. Through rigorous production and inspection processes, a high-quality metal stamping production equipment solution is ultimately achieved.

FAQ About Metal Stamping Production Equipment Solution

●What metals are used in metal stamping production equipment?

Common alloys used in metal stamping production equipment include steel, stainless steel, copper, brass, nickel, and aluminum. Choosing the appropriate press based on the type of metal you are using can help improve production efficiency and stamping accuracy.

●Is metal stamping hard?

Using a KINGREAL metal stamping production equipment is a convenient method for metal stamping. By choosing a metal stamping production equipment with the appropriate pressure capacity, you can easily obtain high-quality finished products.

●What does a metal stamping production equipment do?

Metal stamping production equipment use processes such as bending, punching, embossing, or coining to transform metal sheets into parts or products of specific shapes. By applying high pressure through dies, they can produce a wide range of products, from simple components to complex precision parts.

●What functions can metal stamping production equipment automate?

Based on your specific part requirements, KINGREAL metal stamping production equipment can integrate multiple process steps such as punching, coining, blanking, bending, and flanging to produce high-precision plastic products.