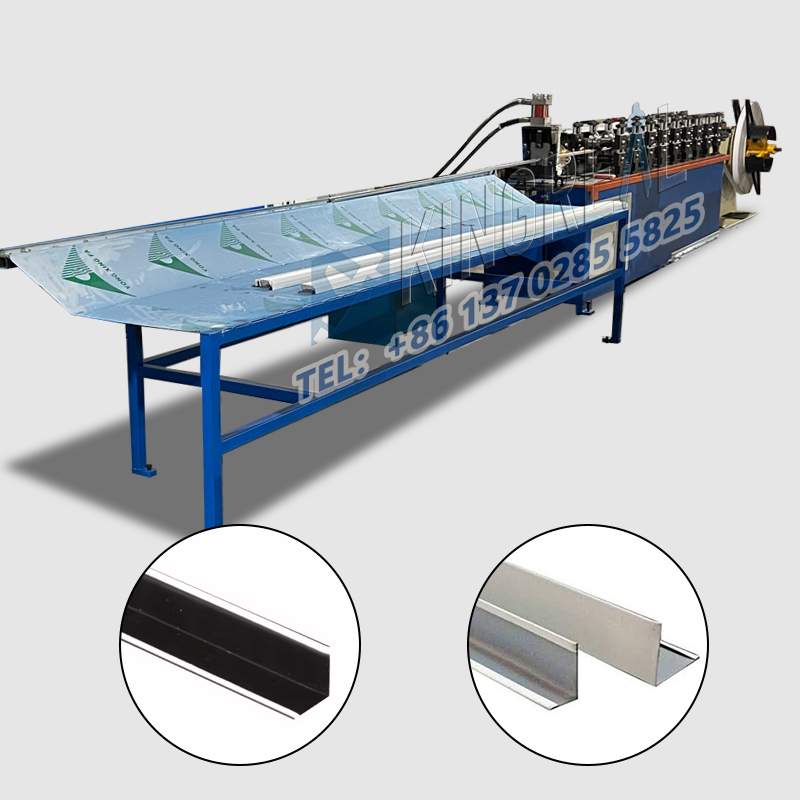

T Bar Ceiling Roll Forming Machine

KINGREAL offers a complete ceiling t bar system for both gypsum board and metal ceiling applications. These machines include t bar ceiling roll forming machine and ceiling grid wall angle machine, which enables efficient and precise production to meet market demands for a wide range of profile types and sizes.

- KINGREAL

- Information

- Download

Video About T Bar Ceiling Roll Forming Machine

Definition of T Bar Ceiling Roll Forming Machine

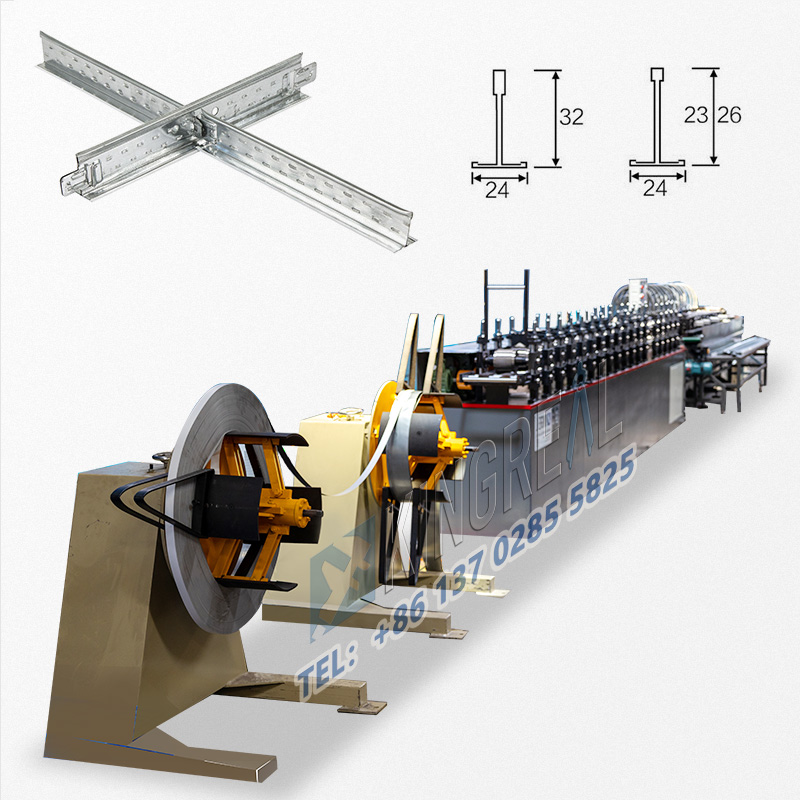

KINGREAL ceiling t bar system offers a comprehensive range of production equipment and roll-forming machines, including t bar ceiling roll forming machine and ceiling grid wall angle machine. These t bar ceiling roll forming machines efficiently produce ceiling t bar systems (including main t and cross t) used to support ceiling panels, as well as shadowline wall angle used to connect wall edges to the ceiling t bar system. This ceiling t grid roll forming machine enables efficient and precise production to meet market demand for profiles of varying types and sizes. KINGREAL t bar ceiling roll forming machines are specifically designed to process galvanized and roll-coated coils with thicknesses ranging from 0.3 to 1.2 mm, capable of producing a wide variety of metal profiles.

KINGREAL ceiling t grid roll forming machines are available in multiple versions, allowing customers to choose based on desired profile type, production output, and degree of automation. Common production widths are 24 mm and 15 mm, with lengths ranging from 3,000 to 6,000 mm. If you have specific production requirements, please provide your drawings to KINGREAL and we will offer a customize ceiling t grid roll forming machine for you. The ceiling t grids produced by KINGREAL ceiling t grid roll forming machine and ceiling grid wall angle machine provide a sturdy metal framework for ceiling structures. These frames not only support the ceiling tiles but also create concealed spaces to accommodate electrical wiring, pipes, and plumbing. They also facilitate future maintenance, ensuring the smooth operation of utilities and systems.

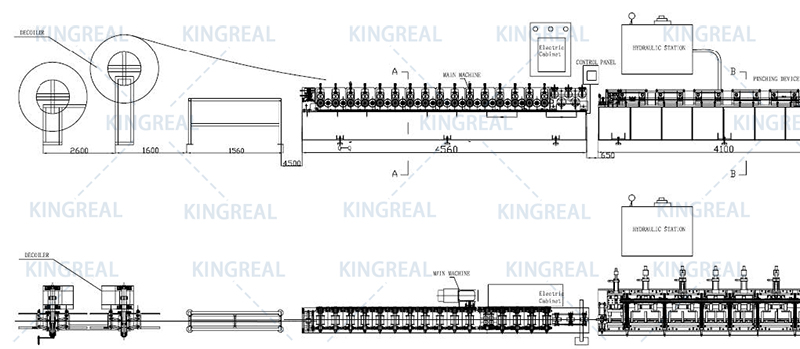

Workflow of T Bar Ceiling Roll Forming Machine

Hydraulic Decoiler --Main Roll Forming Machine--Punching and Shearing Station--Product Table

Parameters of Ceiling T Grid Roll Forming Machine

| Name | Specification |

| Decoiler | 2set, manual decoiler, loading 1.5Ton |

| Roller | 18 Rows Material:Cr12 shaft diameter:Φ40mm |

| Transmission | 5.5kw main motor with K reducer. Gear transmission |

| Side Plate | Thickness 25mm, grinding six-sided, high-precision boring from processing |

| Feeding Positioning | Manual positioning, flexible adjustment at both ends |

| PLC | PLC programming controller |

| Stamp Die | Material:10 Sets,SKD11 |

| Hydraulic motor power | 15KW,EDC24V solenoid valve |

| Output table | 1 set |

| Ball screw | 2, Precision guidance |

| Servo motor | 15KW Servo Motor |

| Total Power | Ceiling t bar roll forming machine is 20.5KW |

| Speed | 30m/min |

Parameters of Ceiling T Bar System

| Item | AxB(mm) | Thickness(mm) | Length(mm) |

| Main t | 38x24 32x24 | 0.3/0.35 | 3660/3600 3050/3000 |

| Cross t | 26x24 24x24 | 0.3/0.35 | 1220/1200 610/600 |

| L Type Wall Angle | 24x24 20x20 20x14.5 | 0.3/0.35/0.4 | 3000 |

| Shadowline wall Angle | 10x10x10x15 15x10x10x20 24x22x22x13 |

Main Component of T Bar Ceiling Roll Forming Machine

1) Decoiler for ceiling t grid roll forming machine

KINGREAL t bar ceiling roll forming machine is equipped with two efficient decoilers, which supply galvanized and galvanized color-coated steel coils. The decoilers are driven by rollers, ensuring precise alignment with the main roll forming machine. KINGREAL can customize the inner and outer diameters and load capacity of the decoilers based on customer needs.

2) Roll forming machine for ceiling t grid roll forming machine

KINGREAL rollers for the t bar ceiling roll forming machine are made of Cr12 material, achieving a hardness of HRC 55-56, ensuring forming accuracy within 0.05 mm. The main shaft is constructed of 45# steel, heat-treated, and milled to ensure stability and durability. For customers with higher safety requirements, KINGREAL can also design protective shield to ensure safe operation. The ceiling t grid roll forming machine boasts a production speed of up to 30 m/min, significantly improving production efficiency.

3) Punching and shearing station for t bar ceiling roll forming machine

KINGREAL ceiling t grid roll forming machines can be equipped with multiple punching dies, typically made of SKD11 material with a hardness of 58-60 HRC, and precision milled to ensure efficient and stable production. The cutting system utilizes flying shear technology, enabling continuous cutting without stopping the ceiling t grid roll forming machine. Cutting accuracy can reach within 0.1 mm, meeting stringent production requirements.

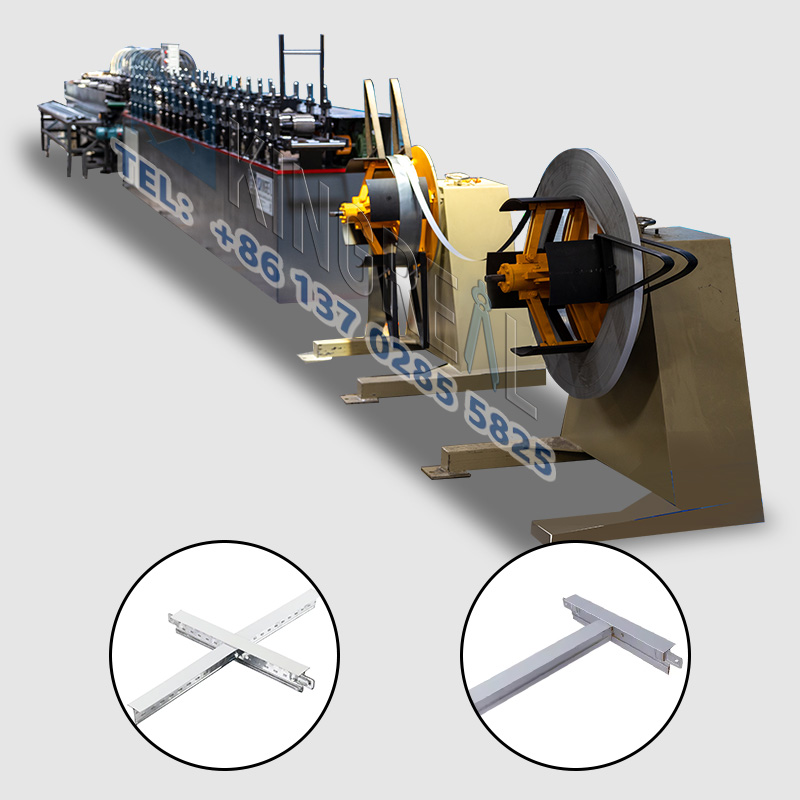

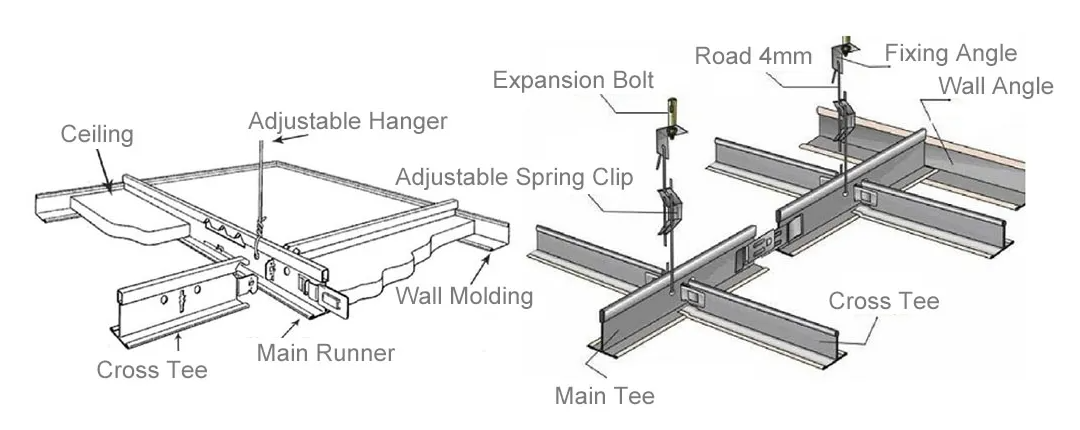

Introduction to Ceiling T Bar System

KINGREAL ceiling t bar system includes a variety of equipment, including t bar ceiling roll forming machine and ceiling grid wall angle machine. All produced profiles are used together in suspended ceiling installations.

Ceiling t grid roll forming machine KINGREAL can customize ceiling t grid roll forming machines for both main t and cross t based on customer drawings and actual production requirements. These ceiling t grid roll forming machines support a variety of profile shapes, including flat ceiling t grid, center black line t bar, FUT ceiling T grid, and silhouette groove ceiling t grid. Customers can select the appropriate t bar ceiling roll forming machine based on their specific application requirements to meet diverse market demands. |  |

Ceiling grid wall angle machine To meet varying production volume and efficiency requirements, KINGREAL has designed three models of ceiling grid wall angle machines with varying speeds: a standard ceiling grid wall angle machine (30 m/min), a medium-speed ceiling grid wall angle machine (40-50 m/min), and a high-speed ceiling grid wall angle machine (over 70 m/min). These ceiling grid wall angle machines can produce both perforated and plain ceiling grid wall angles, fully customized to meet customer needs to ensure both high efficiency and quality. In addition to L-shaped wall angles, the KINGREAL ceiling t grid roll forming machine can also produce W-shaped wall angle, also known as shadowline wall angle. Simply set parameters such as speed, output, and finished product size on the control panel, and the ceiling grid wall angle machine automatically operates, significantly reducing labor costs and improving production efficiency and quality. The resulting shadowline wall angle is a crucial component of the ceiling t bar system, securing the edge of the brick wall or drywall to the receiving end of the top main t, creating a grooved effect at the ceiling edge. |  |

Drawing About Ceiling T Bar System

2025 T Bar Ceiling Roll Forming Machine Project

In September 2025, KINGREAL successfully manufactured and delivered a fully automatic t bar ceiling roll forming machine to a customer's factory in the Canada. This ceiling t grid roll forming machine allows the production of ceiling t bar sizes using a single t bar ceiling roll forming machine by replacing the roller assembly and cutting die. To meet the needs of Canadian customers, KINGREAL also specially designed this ceiling t grid roll forming machine with a hydraulic oil cooler to ensure long-term stability. This t bar ceiling roll forming machine is particularly suitable for clients with large production runs and high output requirements.

This t bar ceiling roll forming machine has a wide range of applications in the installation of gypsum or metal ceiling systems. After shipment, KINGREAL staff will continuously monitor logistics to ensure the safe delivery of the ceiling t grid roll forming machine to the customer's factory. Upon arrival, KINGREAL engineers will visit the site for on-site installation and commissioning, ensuring the customer can quickly begin production.

What Services Does KINGREAL Provide?

KINGREAL is committed to providing customers with comprehensive and professional services, including factory visits, customized t bar ceiling roll forming machine solutions, ceiling t grid roll forming machine trials, after-sales installation, t bar ceiling roll forming machine repairs, and parts replacement. This ensures that every customer feels safe and satisfied when purchasing and using a KINGREAL ceiling t grid roll forming machine. The following are the main services KINGREAL provides:

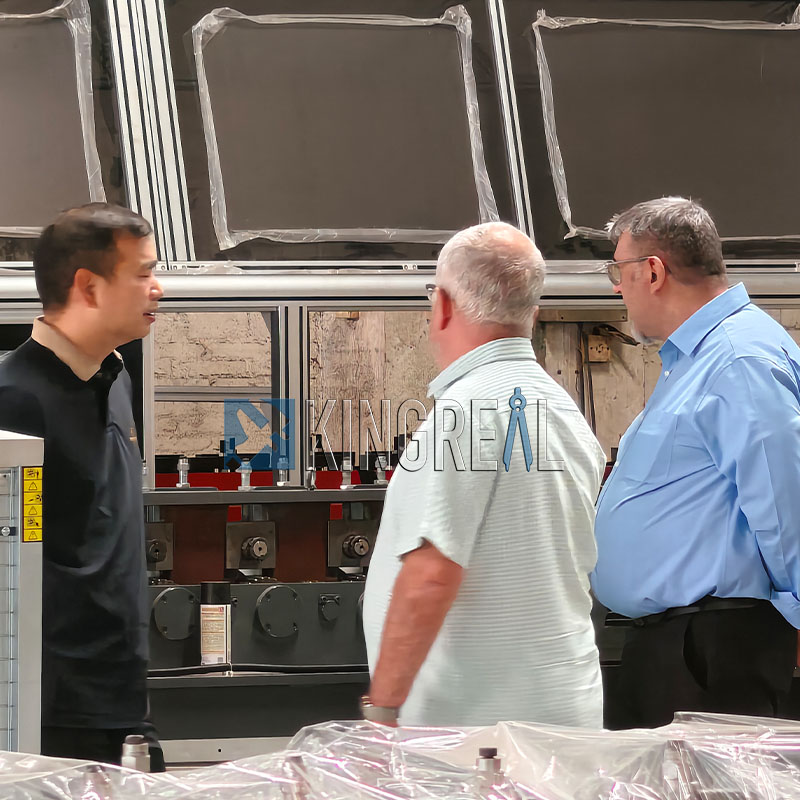

Factory visit service

KINGREAL offers an accompanying factory visit service, welcoming customers from all over the world to visit and inspect the KINGREAL factory in person. During this in-person visit, customers can witness the KINGREAL t bar ceiling roll forming machine production process, ceiling t grid roll forming machine operation, and quality control standards firsthand. This first-hand experience is often more effective than lengthy online discussions.

At the KINGREAL factory, customers can see the various stages of the t bar ceiling roll forming machine process, including the raw material workshop, manufacturing workshop, assembly workshop, and testing workshop. KINGREAL engineers will accompany customers throughout the visit, answer any questions about the ceiling t grid roll forming machine, and ensure they have a comprehensive understanding of KINGREAL t bar ceiling roll forming machines and services.

Personalized ceiling t grid roll forming machine manufacturing solutions

KINGREAL understands that every customer's needs are unique, and therefore offers personalized t bar ceiling roll forming machine manufacturing solutions. KINGREAL engineers will develop a detailed ceiling t grid roll forming machine manufacturing solution based on the customer's specific production requirements, combined with provided drawings and factors such as the local climate.

During the design process, KINGREAL carefully considers the t bar ceiling roll forming machine's performance and parameters to ensure it meets the customer's needs. KINGREAL uses renowned domestic and international appliance brands, offering customers the freedom to choose. Furthermore, to ensure optimal performance, KINGREAL engineers will add necessary components as needed. Therefore, every ceiling t grid roll forming machine sold by KINGREAL is unique and tailored to the customer's specific requirements.

T bar ceiling roll forming machine trial service

After the ceiling t grid roll forming machine is manufactured, KINGREAL will invite the customer to come to the factory for a test run. If the customer is unable to attend, a KINGREAL engineer will conduct the test run on their behalf and promptly send the customer the test results via text, images, and video. The trial run is a crucial step in ensuring t bar ceiling roll forming machine quality. Customers can conduct a comprehensive on-site evaluation of the ceiling t grid roll forming machine's external condition and confirm that the dimensions of each component are consistent with the manufacturing plan.

During the trial run, KINGREAL staff will insert a metal coil and conduct a t bar ceiling roll forming machine test run with the customer. The test focuses on ensuring that the ceiling t grid roll forming machine's production speed, operating stability, and finished product precision meet customer requirements. If the customer is not satisfied with the test results, KINGREAL engineers will perform necessary adjustments to ensure optimal t bar ceiling roll forming machine performance.