Steel Framing Machine

KINGREAL steel framing machine efficiently produces galvanized and galvanized steel in thicknesses ranging from 0.7 to 1.2 mm and coil widths up to 218 mm. With a production speed of up to 700 m/h, the metal framing machine can quickly meet market demand. This highly efficient steel framing machine allows customers to produce high-precision profiles in various sizes and types, including C-shaped profiles and top hat profiles, ensuring they meet diverse building needs.

- KINGREAL

- Information

- Download

Video About Steel Framing Machine

Description of Steel Framing Machine

KINGREAL steel framing machine efficiently produces galvanized and galvanized steel in thicknesses ranging from 0.7 to 1.2 mm and coil widths up to 218 mm. With a production speed of up to 700 m/h, the metal framing machine can quickly meet market demand. This highly efficient steel framing machine allows customers to produce high-precision profiles in various sizes and types, including C-shaped profiles and top hat profiles, ensuring they meet diverse building needs. KINGREAL not only manufactures metal framing machines but also provides comprehensive services from steel framing machine design to installation. KINGREAL excels in providing customized metal framing machine solutions to meet customers' unique needs. Whether you're a developer, contractor, or steel fabricator, KINGREAL steel framing machine manufacturing solutions are designed to maximize value, reduce costs, and accelerate project schedules. |  |

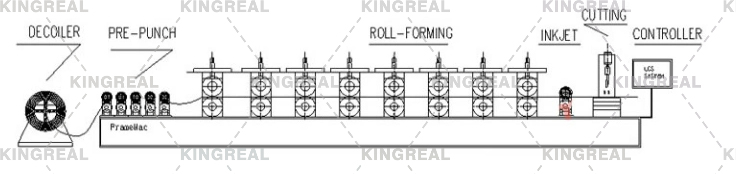

Working Process of Steel Framing Machine

Decoiler -- Roll Forming Machine -- Punching Station -- Cutting Station -- Product Table

Parameter of Steel Framing Machine

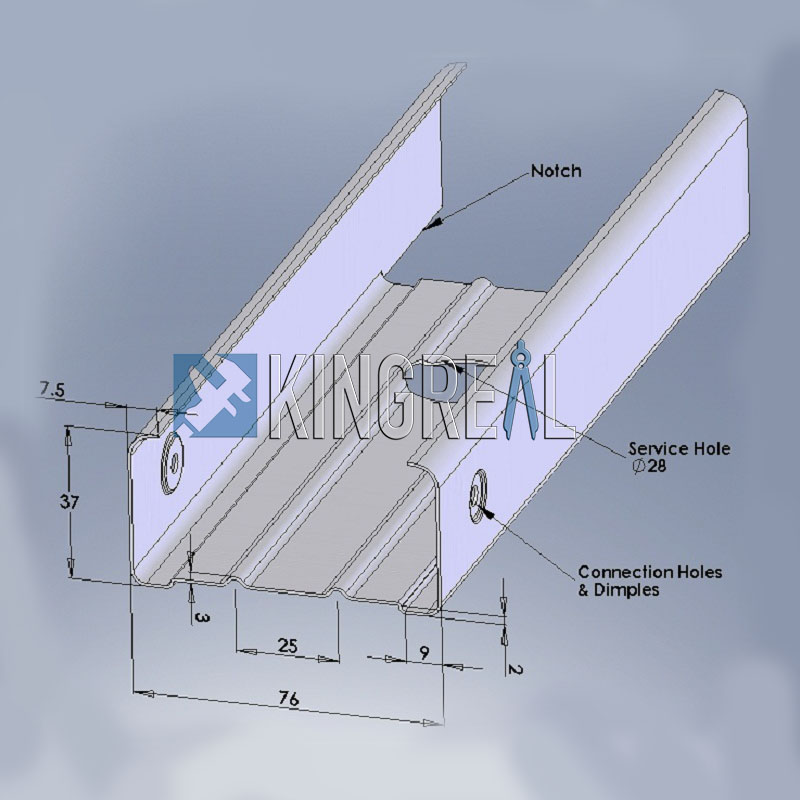

| Section Size | 41*76mm |

| Material Thickness | 0.7-1.2mm(G345-G550GI) |

| Raw Material Width | 218mm |

| Production Speed | 300-700m/h |

| Main Drive Power | 7.5kw |

| Power Supply | 3P415V50Hz |

| Hydraulic Power | 5.5kw |

| Hydraulic Oil Tank Volume | 120L |

| Hydraulic Control | Automatic Control System Monitoring |

| Manual Machine Controller | Wireless |

| Standard Punch Tooling | Screw Hole、Web-Notch A、Web-Notch B、Lip-Cut、Shearing |

| Length Tolerance | ±0.5mm |

| Inkjet | Standard |

Features of Metal Framing Machine

01|Highly flexible speed for metal framing machine

KINGREAL steel framing machine speed design takes into account customer needs, allowing for flexible speed adjustment based on project requirements. This flexibility allows customers to flexibly adjust the metal framing machine's operating speed based on factors such as production scale, material type, and project schedule, ultimately achieving optimal production results.

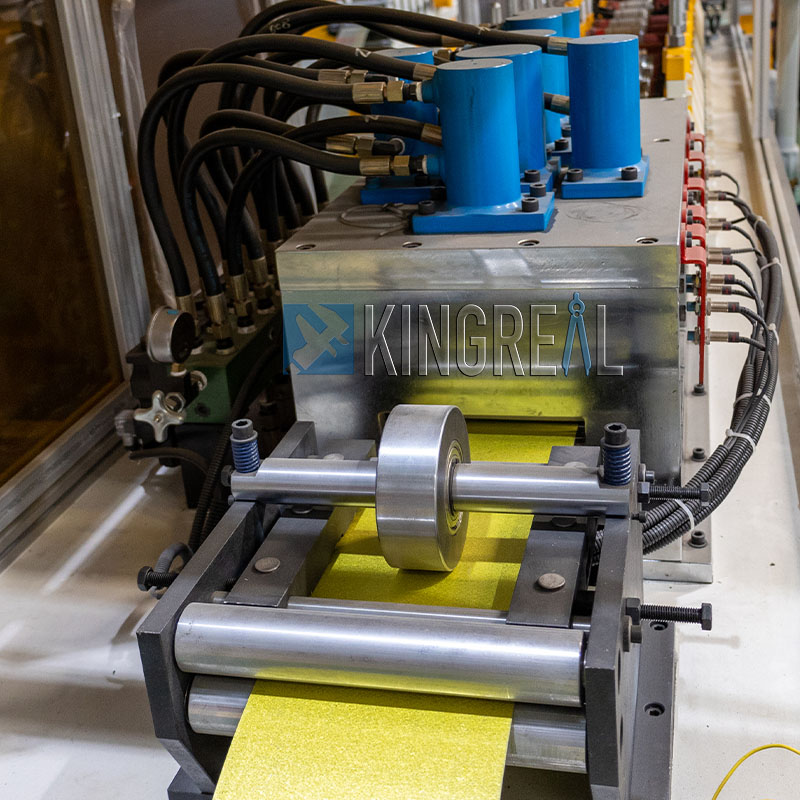

02|Automatic measuring system for steel framing machine

KINGREAL metal framing machine is equipped with an advanced automatic measuring system that automatically detects and adjusts material thickness in real time to accommodate a wide range of metal materials, ranging from 0.7 to 1.2 mm. This automatic correction not only enhances production accuracy but also lowers the need for hand intervention, therefore guaranteeing that every product satisfies demanding quality levels.

03|Efficient frame production capabilities for steel framing machine

KINGREAL metal framing machine can quickly and economically produce a variety of building frames, including wall panels, floor trusses, and roof trusses. These frames are the foundation of modern buildings, ensuring structural stability and safety.

04|Precision production quality assurance for steel framing machine

KINGREAL metal framing machine ensures finished products are accurate to within ±0.5mm. This high-precision production capability ensures smoother assembly and installation during subsequent construction, reducing rework and losses caused by substandard materials.

KINGREAL steel framing machine is meticulously designed and manufactured using advanced technology platforms, ensuring stringent quality control at every stage of production. Whether it's finished product size, hole placement, or overall structural integrity, KINGREAL consistently maintains high production standards to meet the needs of customers across various industries.

05|Diverse design options for metal framing machine

KINGREAL steel framing machine supports the production of a variety of finished products, meeting various customer design requirements. For special hole placements and profile dimensions, detailed drawings are required to ensure the final product perfectly matches the customer's design intent.

Advantages of Metal Framing Machine

01|Proprietary CNC system for metal framing machine

KINGREAL steel framing machine is equipped with an advanced, proprietary CNC system. Centralized management of the whole production line is made possible by this approach, which also integrates smoothly with several design programs to guarantee accurate and effective manufacture. Operators may rapidly define, change, and keep track of production in real time.

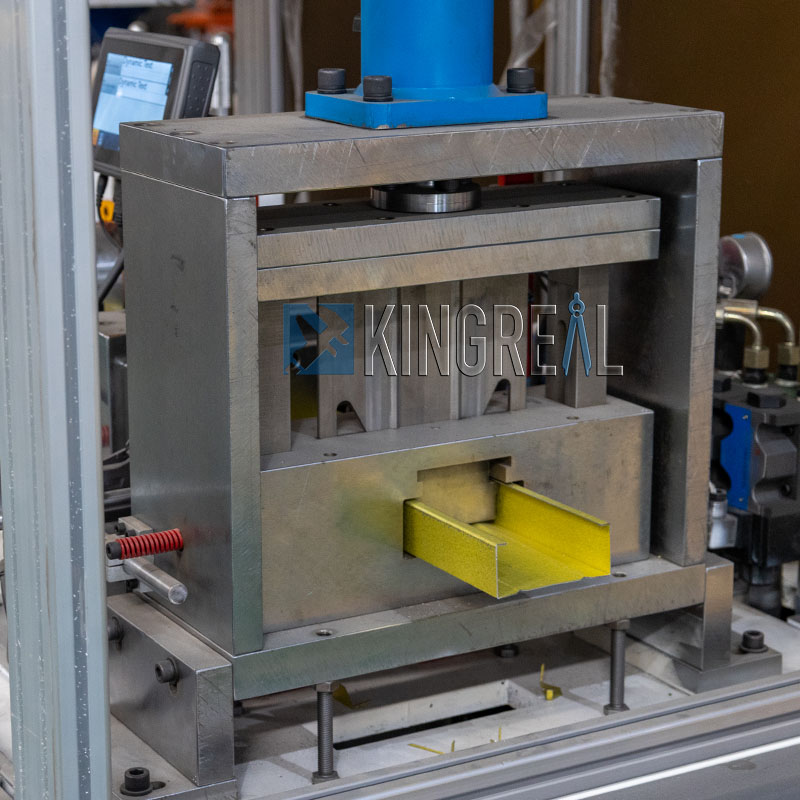

02|Customized punching dies for steel framing machine

To meet diverse customer needs, KINGREAL offers custom-designed punching dies. Whether it's dimple holes, chamfer cuts, web notches, lip cuts, or service holes, swage holes, shear holes, bolt holes, or other different hole types, KINGREAL engineers can customize the design based on specific customer drawings. This flexibility enables customers to produce high-quality profiles with a variety of hole shapes and diameters tailored to their specific needs.

In addition, the punching station on KINGREAL metal framing machine supports unlimited stacking of punching dies, allowing customers to add or replace dies as needed to meet the needs of multiple hole shapes and diameters on the same finished product.

03|Mobile steel framing machine

KINGREAL has developed a "mobile factory" concept to improve the efficiency of construction projects. KINGREAL metal framing machine can be mounted on a small truck, making it mobile. Customers can bring the steel framing machine directly to the construction site for production, saving the time and labor costs of transporting profiles to the site while also improving work efficiency. This innovative approach allows customers to quickly produce the required steel structural profiles on-site, ensuring smooth project progress.

04|Maintenance-free inkjet printer for steel framing machine

To enhance production efficiency, the KINGREAL metal framing machine is equipped with a built-in inkjet printer. By printing codes on the keel, customers can quickly identify and sort profiles, avoiding mix-ups during construction. This design not only improves work efficiency but also reduces manual sorting errors, ensuring smooth construction progress.

Metal Framing Machine in KINGREAL Factory

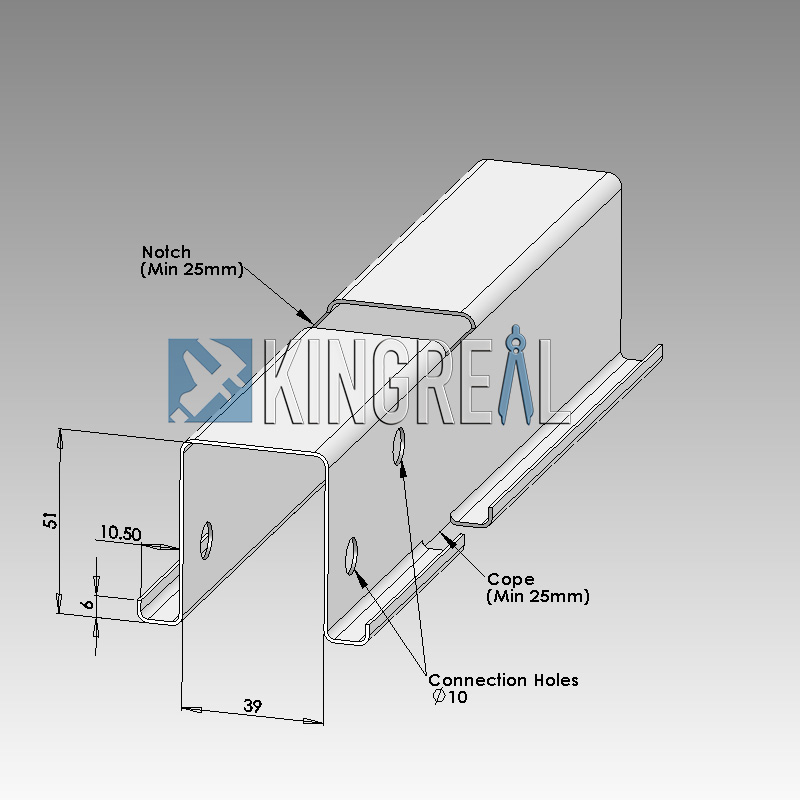

Drawing About Light Steel Frame

Applications of Steel Framing Machine

With the continued rise in global housing demand, especially in developed countries like the United States, developers and manufacturers are facing increasing pressure. Adoption of creative construction materials and technologies is essential to expedite construction schedules without sacrificing construction quality. The steel structural profiles produced by the KINGREAL metal framing machine are the perfect solution. KINGREAL steel framing machines produce profiles that are lightweight, standardized, complete, and durable. These characteristics effectively reduce labor costs, speed up assembly, and improve overall construction site efficiency. By using KINGREAL metal framing machines, customers can not only shorten construction schedules but also stay ahead in a highly competitive market. Whether it's a residential, commercial, or industrial building, KINGREAL steel framing machines provide high-quality steel structural profiles, ensuring the safety and stability of the building. |  |