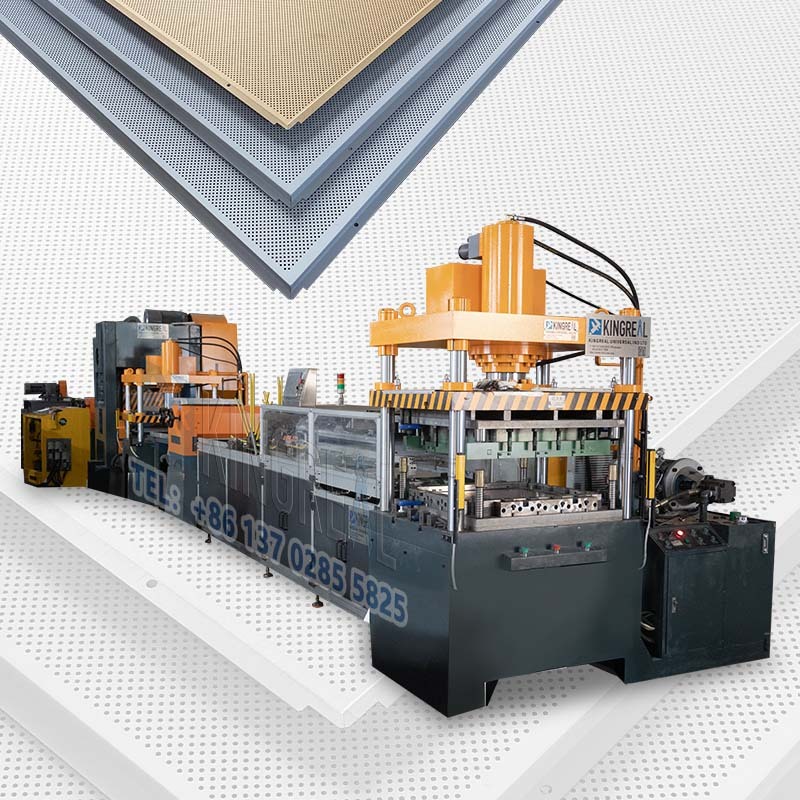

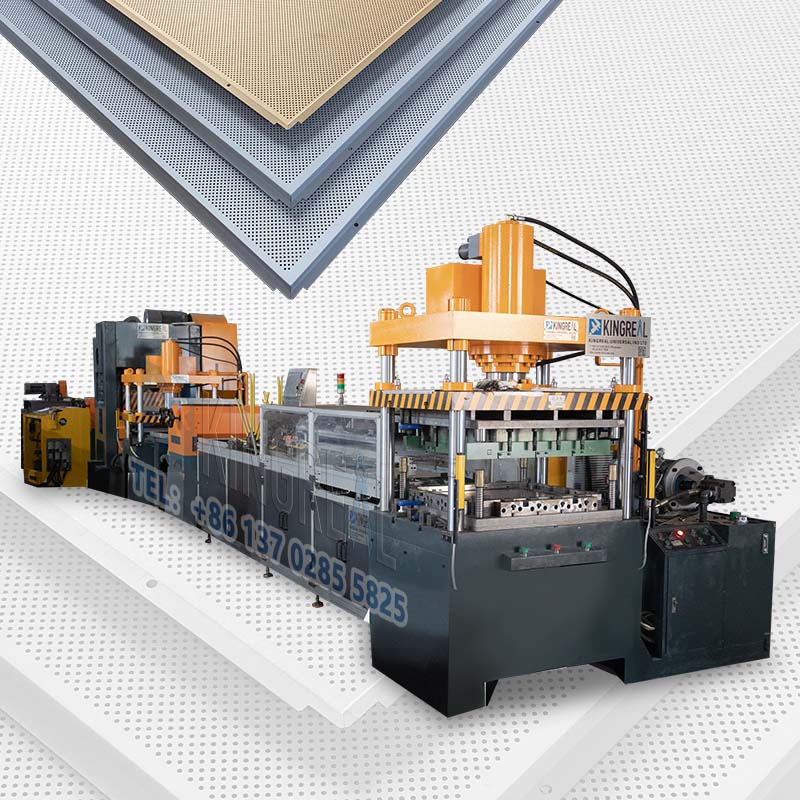

Suspended Ceiling Tile Making Machine

KINGREAL suspended ceiling tile making machines can produce suspended ceiling tiles of varying thicknesses, widths, capacities, and materials. KINGREAL also offers mold design services to customize your suspended ceiling tile production line.

- KINGREAL

- China

- Information

- Download

Video About Suspended Ceiling Tile Making Machine

Definition of Suspended Ceiling Tile Making Machine

KINGREAL suspended ceiling tile making machines can produce suspended ceiling tiles of varying thicknesses, widths, capacities, and materials. PLC-controlled suspended ceiling tile production lines ensure stable operation and guaranteed production quality. Simply changing the mold on the same machine allows for both clip in ceiling tiles and lay in ceiling tiles. The production speed, from unwinding to discharging (including perforation), is approximately 5-6 suspended ceiling tiles per minute. KINGREAL also manufactures suspended ceiling tile production lines of custom widths to meet customer requirements. These suspended ceiling tile making machines are suitable for producing a variety of metal ceiling tile materials.

Common materials processed by these suspended ceiling tile machines include stainless steel, aluminum, galvanized steel, cold-rolled steel, hot-rolled steel, copper, brass, and more. KINGREAL also offers mold design services. Customization of various suspended ceiling tile making machines is possible, and we welcome samples or drawings.

KINGREAL featured suspended ceiling tile production lines are as follows:

-300x300mm suspended ceiling tile making machine

-600x600mm suspended ceiling tile making machine

-600x1200mm suspended ceiling tile making machine

-Fully automatic suspended ceiling tile making machine

-Semi-automatic suspended ceiling tile making machine

-Clip in suspended ceiling tile making machine

-Lay in suspended ceiling tile making machine

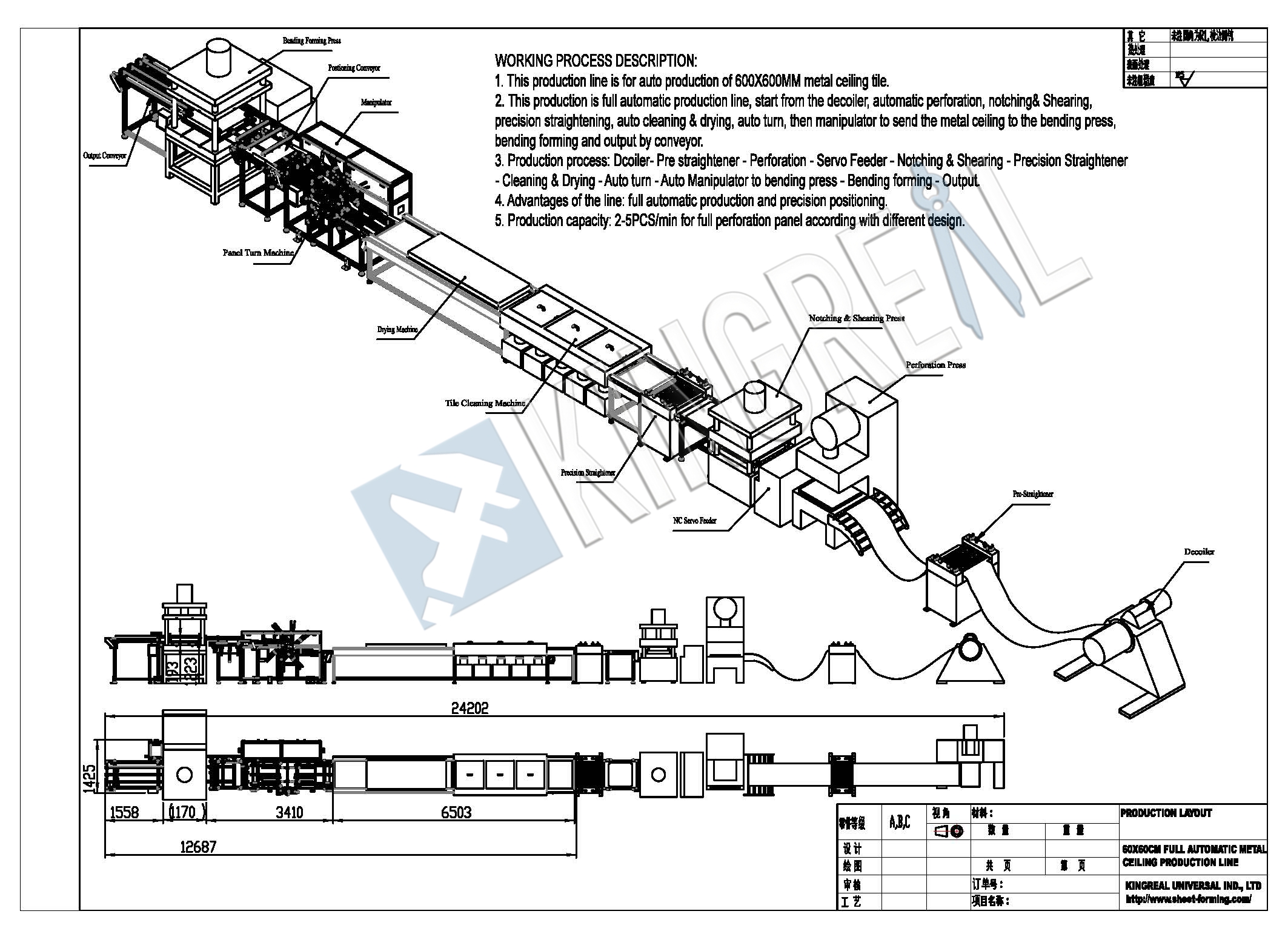

Working Process of Suspended Ceiling Tile Production Line

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching and Shearing Press -- 2nd Precision Straightener -- Flipping Machine -- Automatic Tile Feeding Machine -- Auto Bending Forming Machine

Parameters of Suspended Ceiling Tile Making Machine

| Hydraulic Decoiler | Width of Material | <700mm |

| Maximum Load | 5tons | |

Precision Straightener | Width of Material | <700mm |

| Thickness of Material | 0.3-2.2mm | |

| Feeding Speed | 25m/min | |

High Speed Punching Machine | Output Pressure Force | 125tons |

| Punching Rows | 4 Rows for GI Steel Material 8 Rows for Aluminum Material | |

| Punching Stroke | 20mm | |

| Adjustable Thickness | 10mm | |

| Punching Pierce | 150-180Times/min | |

| Hydraulic Notching & Shearing Press | Cylinder Pressure Force | 60tons |

| Cylinder Stroke | 200mm | |

120Ton Hydraulic Bending Press(Automatic) | Main Cylinder Pressure Force | 100tons |

| Master Cylinder Stroke | 350mm | |

| Lower Cylinder Pressure Force | 20tons | |

| Lower Cylinder Pressure Stroke | 150mm |

Technical Explanation About Suspended Ceiling Tile Production Line

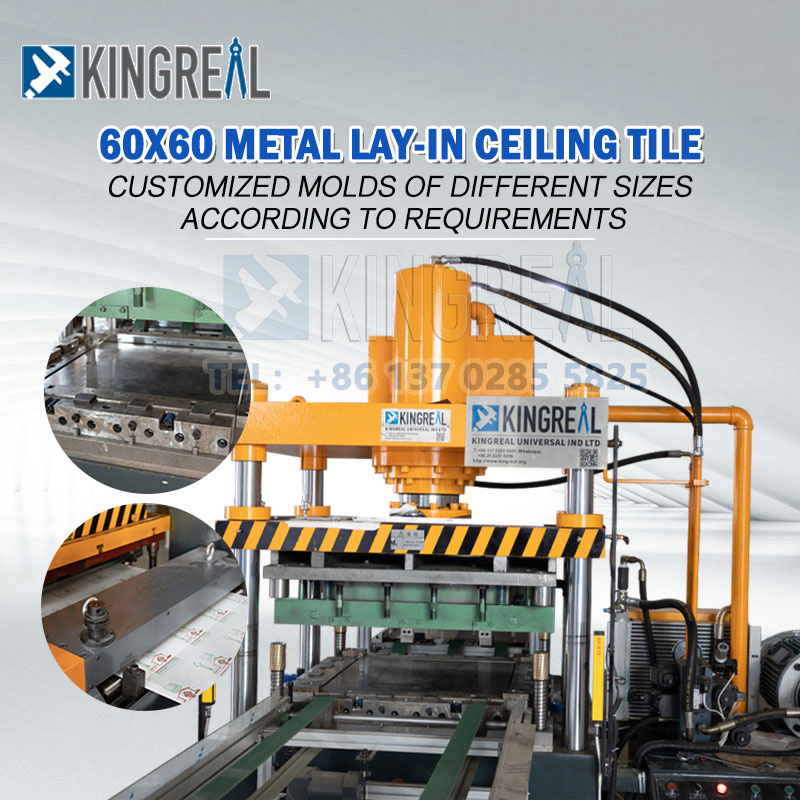

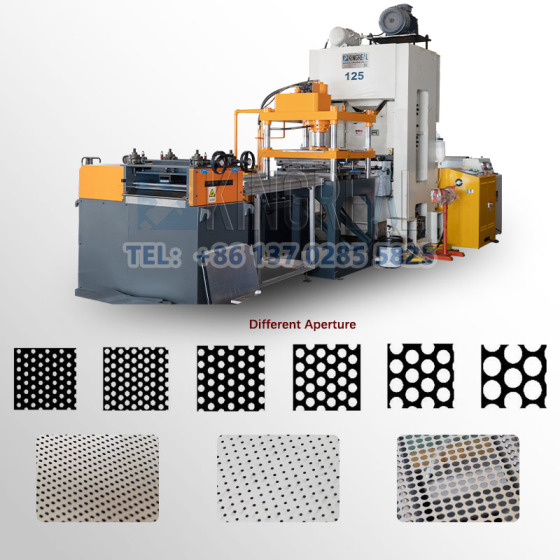

1)Molds for suspended ceiling tile machine

Molds are the most critical component of the suspended ceiling tile machine, primarily used for processing steps such as cutting, forming, bending, and punching. Common punching hole diameters are 1.8mm and 2.5mm. KINGREAL can also design dies for different hole diameters, such as 0.8mm, 2.0mm, 2.3mm, and 3.0mm, upon request.

The dies KINGREAL provides for suspended ceiling tile machines are made of CR12 or CR12MOV material, heat-treated to HRC 58-60 degrees. By changing the die, metal ceilings of varying sizes, types, and hole patterns can be produced.

2) Precision leveling machine for suspended ceiling tile production line

KINGREAL equips its suspended ceiling tile production line with two 21-roller precision leveling machines, each consisting of 10 upper rollers and 11 lower rollers. Compared to the commonly used 7-roller rough leveling machines, KINGREAL configuration is more advanced.

The first leveling machine, located after the decoiler, flattens the metal strip; the second leveling machine, after the hydraulic shearing press, ensures the flatness of the material after punching.

3)Punch press for suspended ceiling tile making machine

Punch presses are used to punch holes in metal surfaces. KINGREAL offers presses with varying specifications to suit various production needs. High-end presses have speeds of 160-240 SPM (processing 6 aluminum sheets or 3 steel sheets per minute), while mid-range presses have speeds of 150-180 SPM (processing 5-6 aluminum sheets or 4-5 steel sheets per minute).

Many suspended ceiling tile production lines on the market only offer low-end presses with speeds of 100-120 SPM (processing 3 aluminum sheets or 1.5-2 steel sheets per minute).

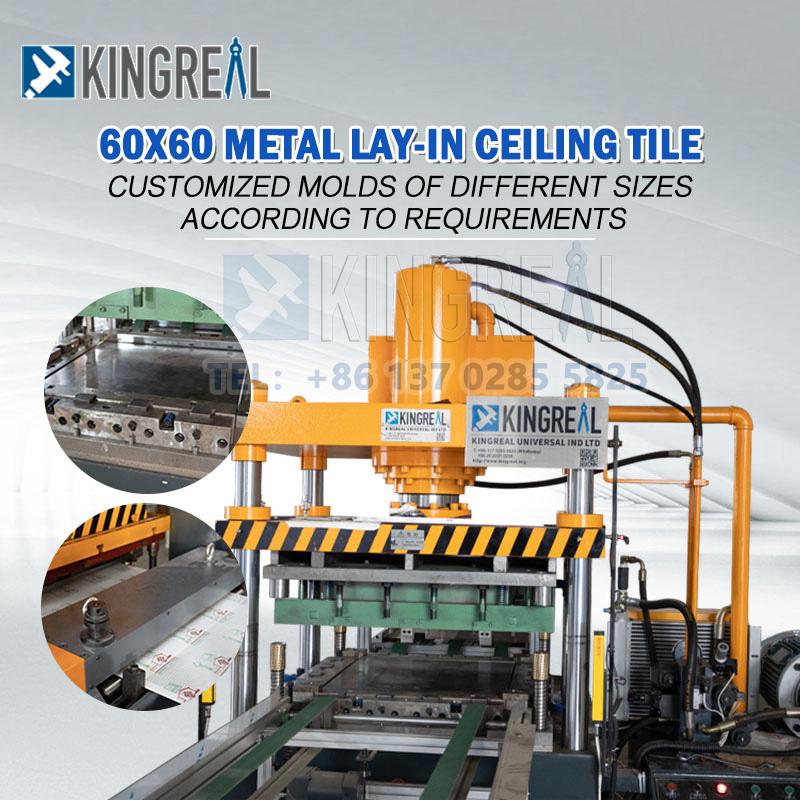

4)Auto bending forming machine for suspended ceiling tile machine

KINGREAL Auto bending forming machines are used to press and form the four corners of metal sheets. By changing the mold, they can produce different types of products, such as clip in ceiling tile, lay in ceiling tile (T24, T15). Most suspended ceiling tile machines on the market are equipped with 120-ton bending forming machines. KINGREAL offers bending forming machines of varying sizes to meet customer needs.

For example, customers requiring 600x600mm ceiling tile can receive a 140-ton bending forming machine, while those requiring 600x1200mm ceiling tile can receive a 230-ton bending forming machine equipped with a cooling fan.

5)Acoustic fleece sticking machine for suspended ceiling tile production line

KINGREAL offers various material roll sizes to meet customer needs. The acoustic fleece sticking machine automatically connects to the suspended ceiling tile machine, eliminating the need for subsequent manual processing.

The suspended ceiling tile production line consists of a fleece sticking section, a drying section and an air-fan cooling section, primarily for applying acoustically non-woven fabric to ceiling tiles to enhance sound insulation.

6)Metal sheet cleaning machine for suspended ceiling tile making machine

The metal sheet cleaning machine, located after the suspended ceiling tile machine, consists of a washing section (including brushes, a water tank, and a drain pipe), a drying section (including a drying oven), and an optional oiling section (including an oil tank).

It can be customized to suit the width, thickness, and speed of the ceiling tiles being washed. Typically, the metal sheet cleaning machine's speed ranges from 0 to 7 m/min, and the number of water tanks and drying ovens is determined based on actual needs. Heated water and detergent can be used for cleaning. The drying section achieves rapid double-sided drying, while the oiling section allows for rapid double-sided oiling. The oil can be recycled, effectively removing oil stains and dust from the production process.

Successful Project about Suspended Ceiling Tile Production Line

1)KINGREAL suspended ceiling tile making machine in Italy

This Italian customer needed new, efficient suspended ceiling tile production line due to production expansion. KINGREAL equipped their suspended ceiling tile machine with a tiles flipping machine and an automatic tiles feeding machine. The tiles flipping machine can flip the sheet 180 degrees, preventing workplace injuries.

2)KINGREAL suspended ceiling tile production line in India

This Indian customer purchased a semi-automatic suspended ceiling tile machine and recently requested additional equipment due to expansion. KINGREAL, based on their needs, equipped it with a tiles flipping machine, an automatic tiles feeding machine, and an auto bending forming press with customized parameters, achieving fully automated production.

3)Fully automatic suspended ceiling tile production line in Ukraine

The Ukrainian customer had production requirements for various specifications and provided drawings in advance. KINGREAL took customers on a tour of the factory and demonstrated how to produce 600x600mm and 600x1200mm ceiling tiles, as well as clip in ceiling tile and lay in ceiling tile(T24, T15) on the suspended ceiling tile production line by changing the mold.

KINGREAL Exhibition