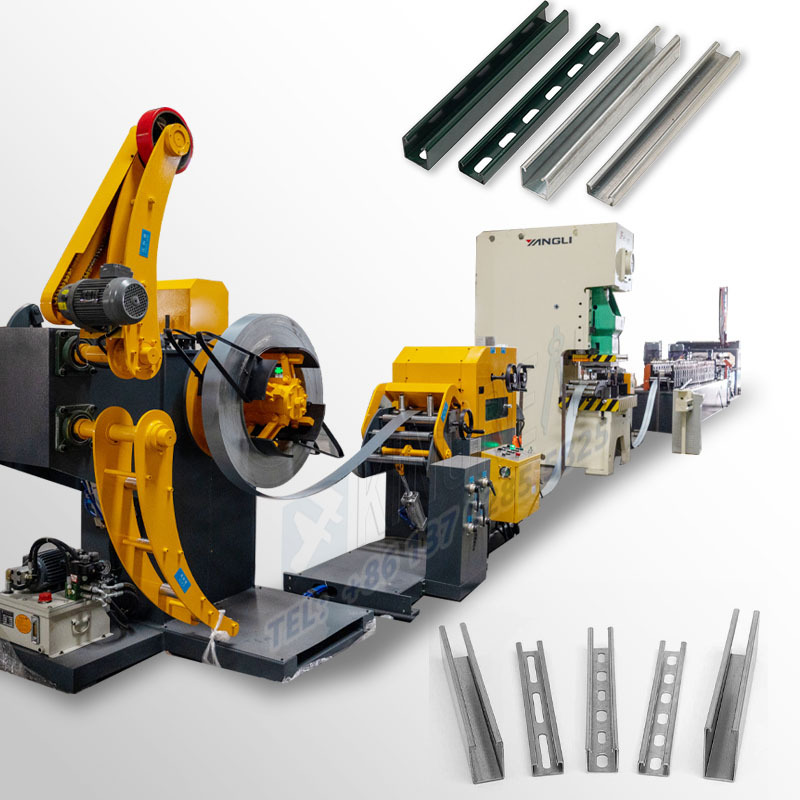

Slotted Channel Framing Making Machine

KINGREAL Slotted Channel Framing Making Machine can produce various types and sizes of slotted channels for structural support system to meet customer different production needs.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Slotted Channel Framing Making Machine

Introduction of Slotted Channel Framing Making Machine

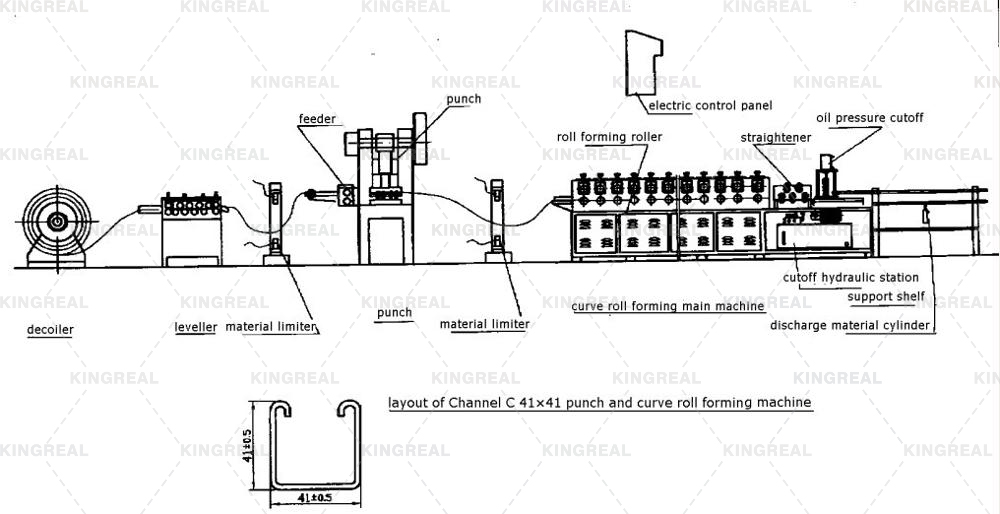

The slotted channel framing making machine is a featured machine used to manufacture slotted channels. The slotted channel roll forming machine is designed to efficiently and accurately form metal or other materials into the required shapes of these solar channels, which are essential for strengthening buildings and structures to withstand earthquakes. The slotted channel framing making machine can use a variety of techniques such as uncoiling, leveling, punching, forming and cutting to produce the components required for support systems. Its precise and reliable operation helps to ensure the safety and seismic resistance of building structures in earthquake-prone areas. In addition, these slotted channels are also used to support mechanical parts such as lines, pipes or air conditioning ventilation systems. Its slotted characteristics make it flexible to install and is also common in the plumbing and electrical industries.

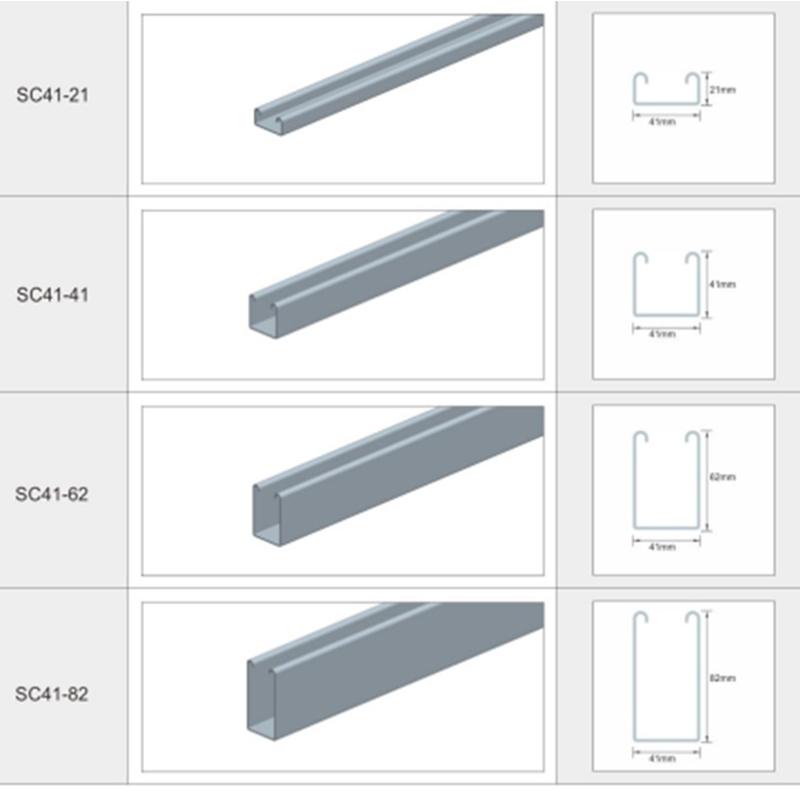

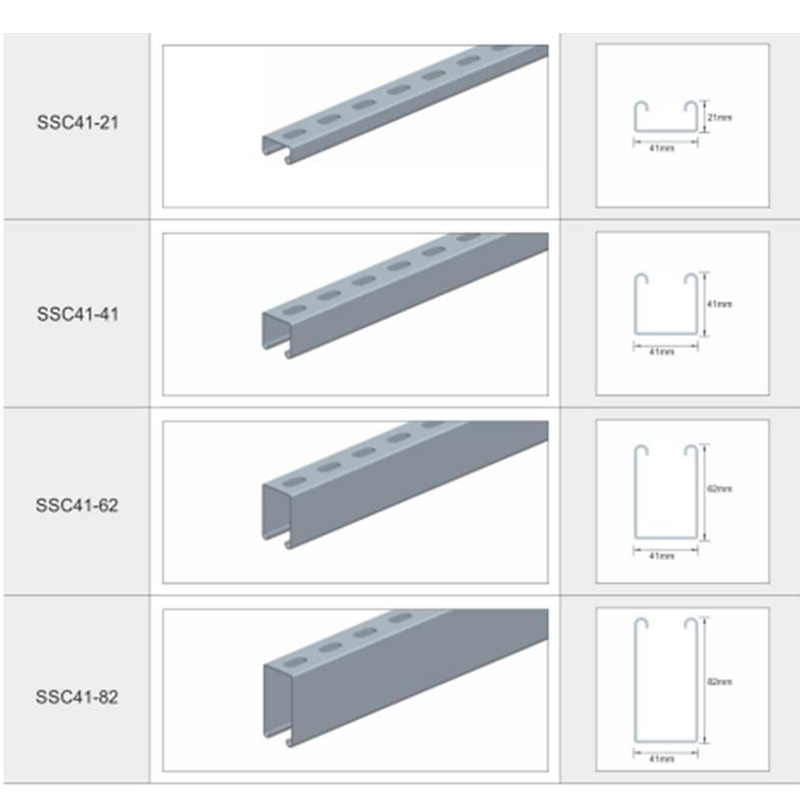

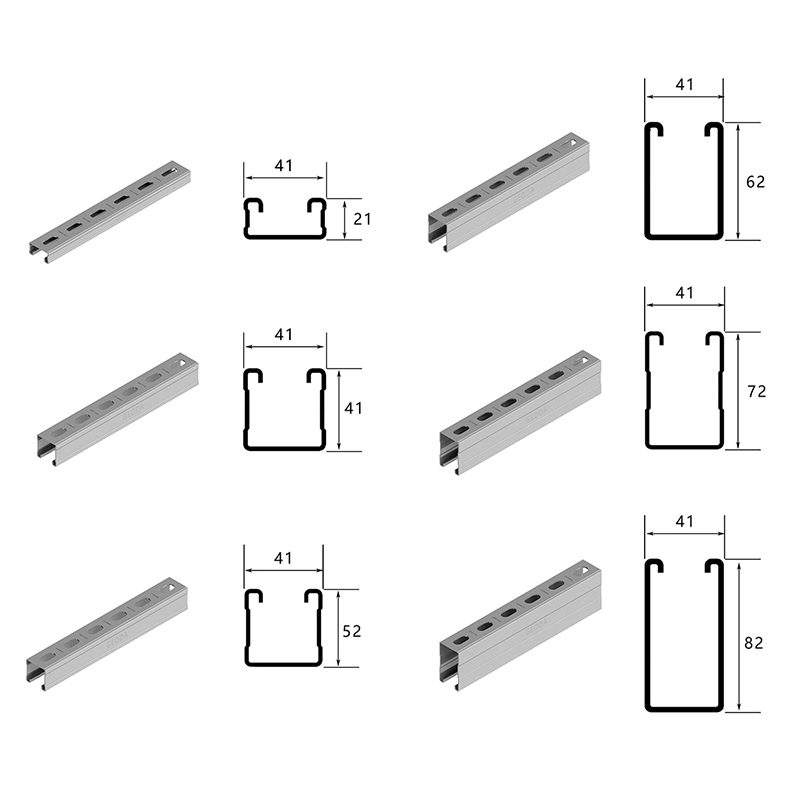

KINGREAL slotted channel framing making machines have been running in customer factories in many countries around the world. The slotted channel roll forming machine is capable of roll-forming 41*41mm and 41*21mm solar channels. For more information or technical assistance, please contact KINGREAL. |  |

Workflow of Slotted Channel Roll Forming Machine

Decoiler ↓ Straightener ↓ Punching Machine ↓ Roll Forming Machine ↓ Cutting Station |  |

Parameters of Slotted Channel Framing Making Machine

| Item | Value |

| Applicable Industries | Hotels, Shops, Houses, Company...... |

| Production Capacity | 10-15m/min |

| Voltage | 380V 50Hz 3phases or as your requirement |

| Dimension(L*W*H) | 8*1.2*1.3 |

| Weight | 5000kg |

| Key Selling Points | Easy to Operate |

| Rolling thickness | 0.3-0.8mm |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Pressure vessel, Motor, Other, Bearing, Gear, Pump, Gearbox, Engine, PLC |

| Main frame: | 400 H steel |

| Control system: | PLC with touch screen |

| Roller material: | Gcr15 |

| Material of cutting | Cr12mov with quench HRC58-62° |

Advantages of Slotted Channel Roll Forming Machine

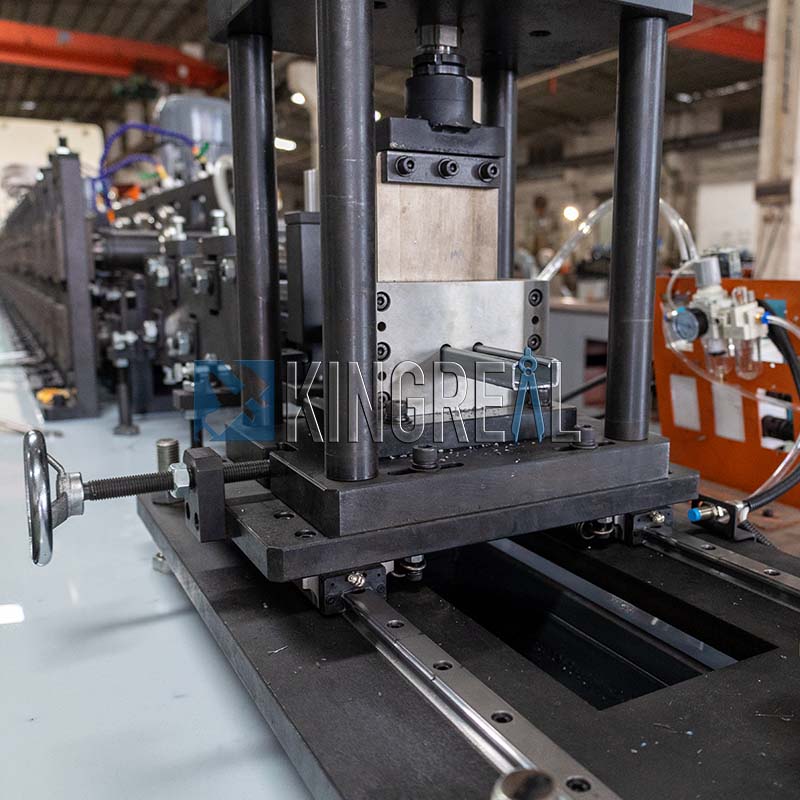

1. Equipped with a punching machine for slotted channel framing making machine A highlight of the slotted channel roll forming machine is its punching machine. With this machine, customers can easily meet their needs for brackets with holes. KINGREAL customizes the punching die according to the drawings provided by the customer to ensure the consistency and high precision of the hole diameter of each finished product. The design of this slotted channel framing making machine equipped with a punching machine not only improves production efficiency for customers, but also ensures the quality and reliability of the product, fully meeting the specific requirements of customers. Whether it is used for the support of building structures or other application scenarios, the precise hole position design can effectively improve the seismic performance. |  |

2. Multi-specification slotted channel roll forming machine Another significant advantage of this slotted channel roll forming machine is its multi-specification production capacity. The slotted channel framing making machine is able to produce finished products of different sizes to meet the needs of different projects. KINGREAL provides two flexible ways to complete the production of brackets of different specifications: one is manual adjustment, and the other is to replace several sets of rollers. Customers can choose the most suitable production method according to actual needs to ensure that production efficiency is improved while meeting design standards. This flexibility enables the slotted channel roll forming machine to adapt to various construction projects and reduce production costs. |  |

3. Hydraulic follow-up shear system for slotted channel framing making machine Another significant invention is the hydraulic follow shear system that KINGREAL fitted for this slotted channel roll forming machine. The system guarantees that every solar channel satisfies the design specifications by accurately cutting to match the length specified by the customer. Quick cutting speed and the slotted channel framing making machine will not stop during the cutting procedure of the hydraulic followup shear significantly increase manufacturing efficiency. Thus, producers may not only rapidly meet market demand but also guarantee the continuity of manufacturing and minimize the time lost due to downtime. |  |

4. Full automatic slotted channel roll forming machine Modern production would find the slotted channel framing making machine ideal since its completely automated construction. Including process streams such unfolding, leveling, punching, forming, and cutting, the slotted channel roll forming machine comprises several precision components. Customers just have to enter the settings on the control panel; the device will start running by itself; the whole operation process doesn't demand too much human involvement. Employees only need to observe the machine and make sure it is running as usual. Besides enhancing production efficiency, this degree of automation lowers the likelihood of human errors, hence increasing the safety and dependability of the manufacturing line. |  |

5. Actual time monitoring device for slotted channel framing making machine The slotted channel roll forming machine also has a real-time monitoring system to help to increase the safety and dependability of the slotted channel framing making machine. Should the machine fail or be unusual, the system will immediately alert the error and identify the exact part of the problem. Through prompt error feedback, consumers can efficiently lower possible production losses and guarantee the smooth course of the manufacturing process; this function not only enables operators to rapidly find the problem and minimize downtime, but also promotes slotted channel roll forming machine maintenance and maintenance. |  |

Application of Slotted Channel Framing Making Machine

Slotted Channel Framing Making Machine plays an important role in modern construction and industrial manufacturing. The slotted channel produced by this slotted channel roll forming machine is widely used in a variety of support structures due to its excellent performance and flexible design, and has become an indispensable part of the construction industry.

In terms of seismic support, the advantages of slotted channel are also significant. The vibration and impact caused by earthquakes pose a huge threat to buildings. Using high-quality slotted channel as seismic support can significantly improve the seismic resistance of buildings. The support channel produced by slotted channel roll forming machine is precisely designed to provide better toughness and stability when an earthquake occurs, reduce the risk of structural damage, and thus protect the safety of people inside the building.

Slotted channel also plays an important role in supporting pipes and ducts. Pipe systems in buildings and industrial facilities require reliable support to ensure their normal operation. The corrosion resistance and load-bearing capacity of slotted channel make it an ideal choice, which can effectively reduce the vibration of pipelines and extend their service life. Manufacturers can use slotted channel roll forming machine to produce channel steel of different specifications to meet the needs of various pipeline systems and ensure the safe and stable operation of pipelines.

The support of air ducts and cable trays is also an important area of application for slotted channel. The air duct needs to withstand the pressure caused by the air flow, while the cable tray needs to support the weight of a large number of cables. With its strength and stability, slotted channel can provide reliable support for these systems. By using slotted channel, buildings and industrial facilities can be more flexible in layout design to ensure the safe arrangement of air ducts and cables.

In addition, slotted channel can also be used to manufacture other general frames. Whether it is in the support of mechanical equipment or in other industrial structures, channel steel can provide stable frame support. This flexibility makes the slotted channel roll forming machine have broad application prospects in different fields and can meet the needs of various industries.