Warehouse Pallet Rack Machine

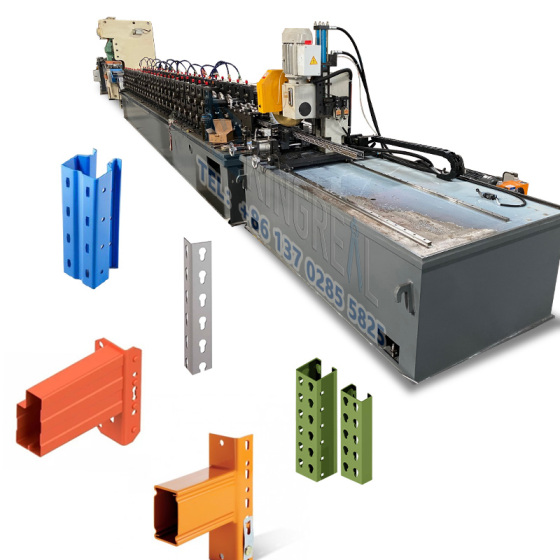

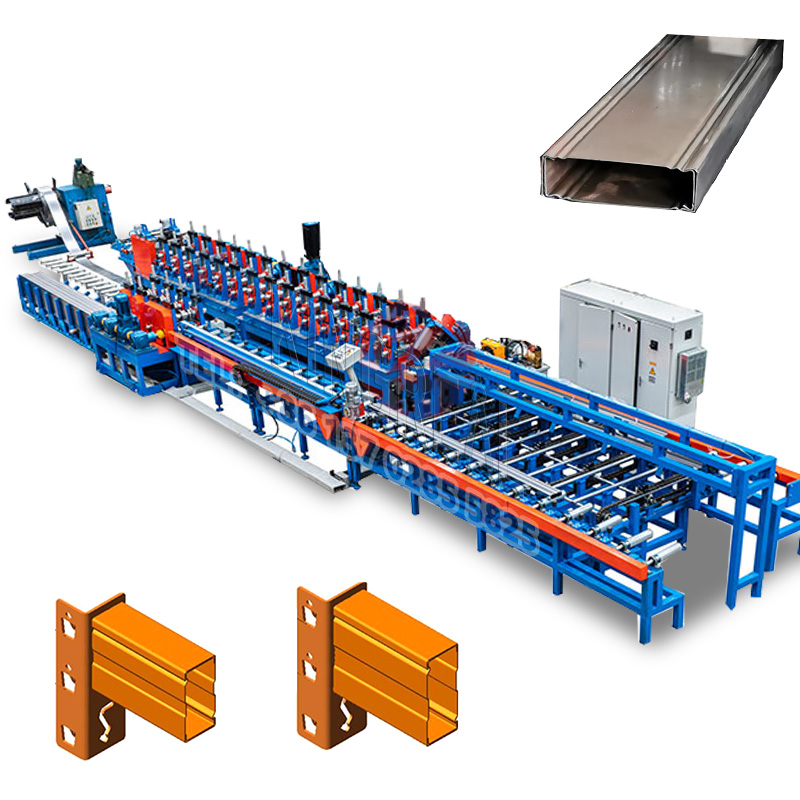

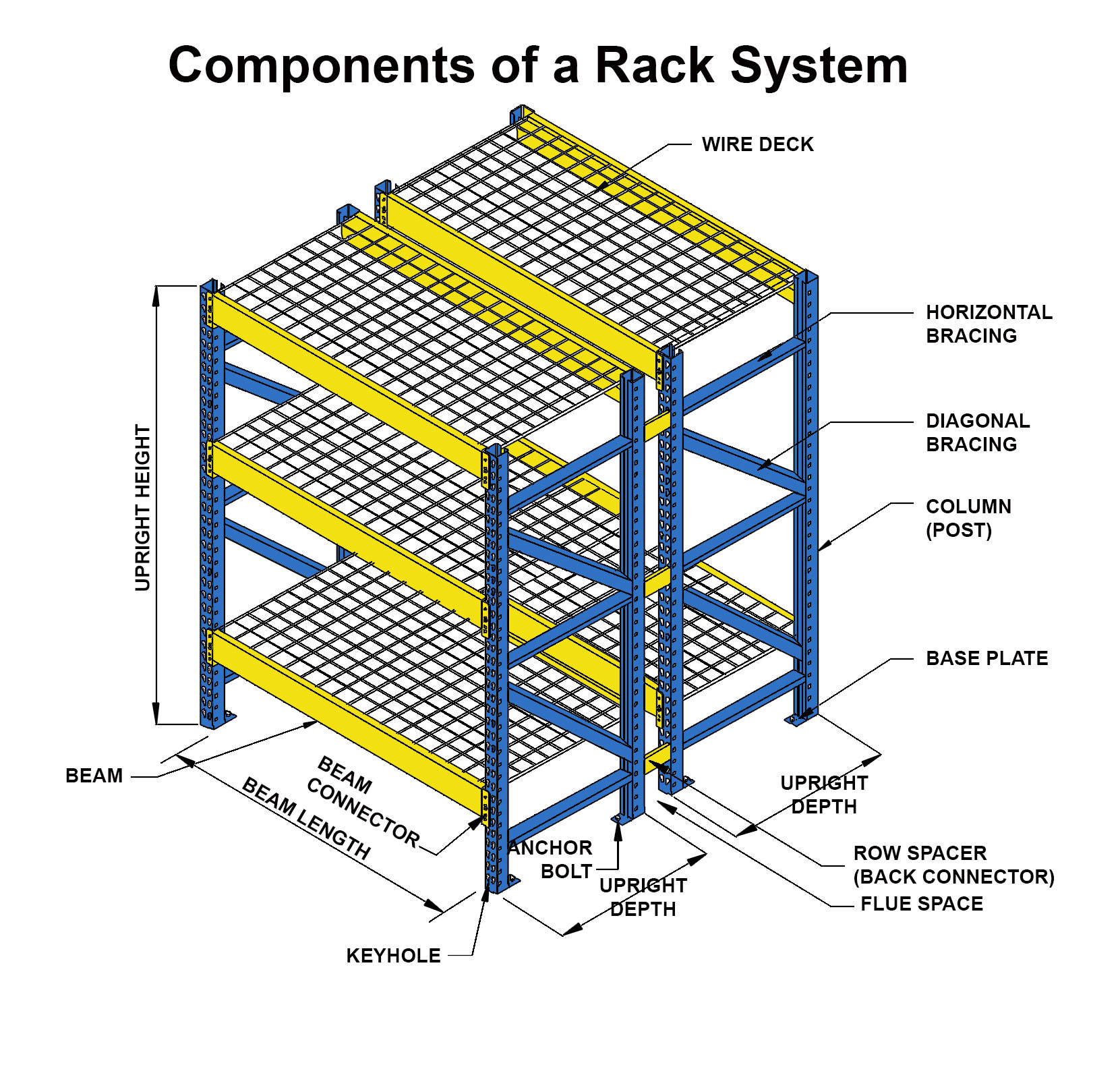

KINGREAL provides customers with various types of warehouse pallet rack machines, including upright rack making machines, box beam making machines, p beam making machines, which are used to manufacture pallet racking system components (box beams, p beams and upright racks).

- KINGREAL

- China

- Information

- Download

Video About Warehouse Pallet Rack Machine

Introduction of Warehouse Pallet Rack Machine

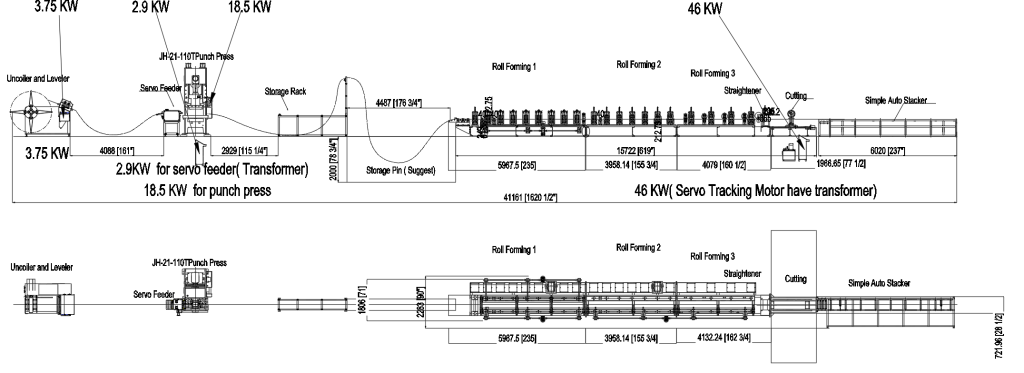

KINGREAL provides customers with various types of warehouse pallet rack machines, including upright rack making machines, box beam making machines, p beam making machines, which are used to manufacture pallet racking system components (box beams, p beams and upright racks). It mainly rolls the metal coils into the shape of the finished product required by the customer, and then cuts them accurately through the shearing station according to the length set by the customer on the PLC control panel.

Pallet upright rack roll forming machine is widely used in pallet rack system. KINGREAL warehouse pallet rack machine can automatically switch the width and height through the motor to produce finished products of various sizes. Just enter the required data into the touch screen and wait for a few seconds to complete. At the same time, this pallet upright rack roll forming machine can process a variety of metal raw materials, including cold rolled steel, galvanized coils, color coated coils, carbon steel, stainless steel and aluminum. The finished products produced by KINGREAL warehouse pallet rack machine meet ISO, CE and FEM standards, and are suitable for warehouses, supermarkets, industries and homes.

KINGREAL will formulate personalized pallet upright rack roll forming machine manufacturing solutions based on the drawings, tolerances and budgets provided by customers, and provide professional one-to-one services to meet your various needs.

|  |

Various Types of About Us Warehouse Pallet Rack Machine

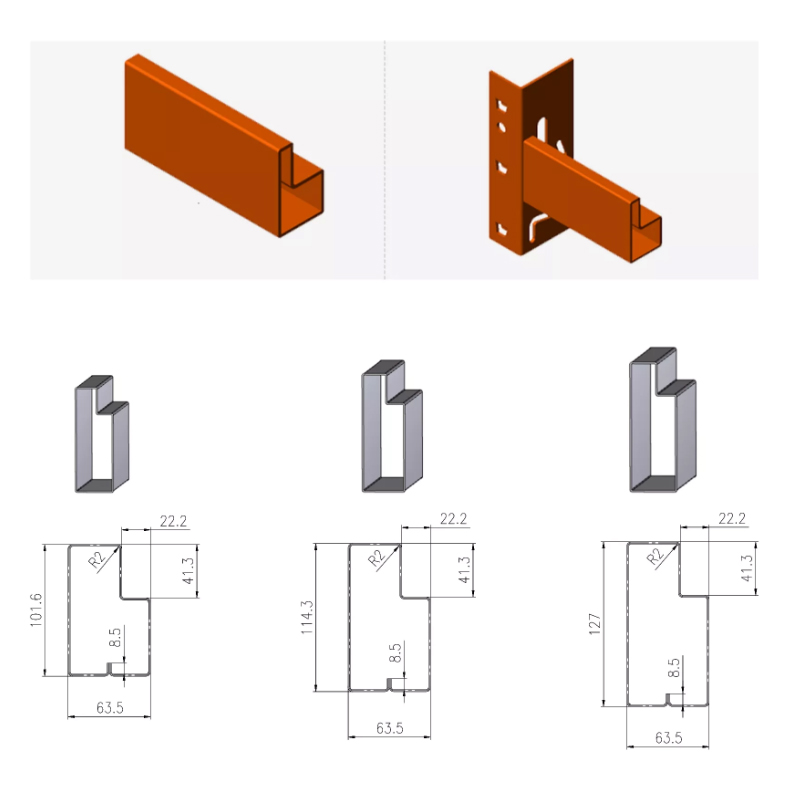

1.Upright Rack Making Machine

1.1 Introduction of the upright rack making machine:

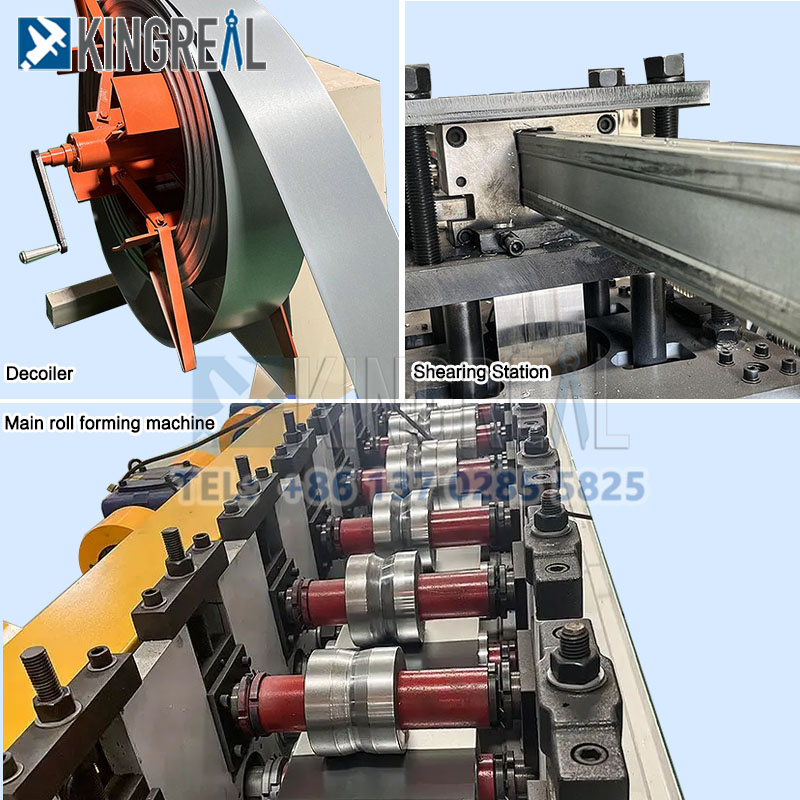

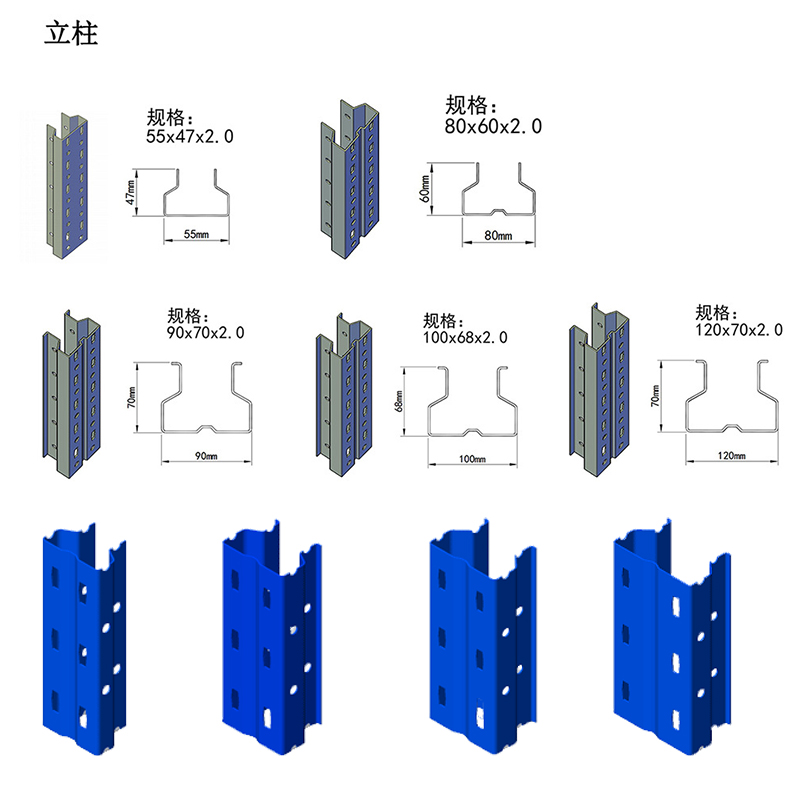

Upright Rack Making Machine, also known as Omega Rack Upright Machine, can process various metal raw materials with a thickness of 1.5-3 mm. The finished products produced play the role of vertical support in the pallet rack system. A KINGREAL upright rack making machine can produce uprights of different sizes to meet the diverse production needs of customers. In addition, KINGREAL engineers can also equip the customer's upright rack making machine with a 2-in-1 decoiler and leveling machine. The integrated design of the decoiler and the straightening machine saves space for customers. |  |

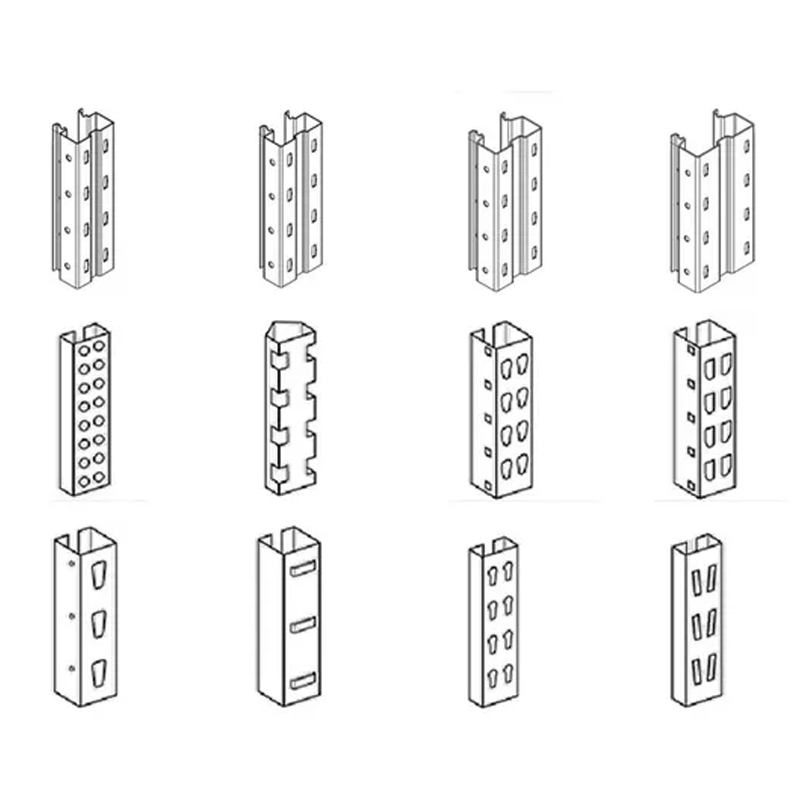

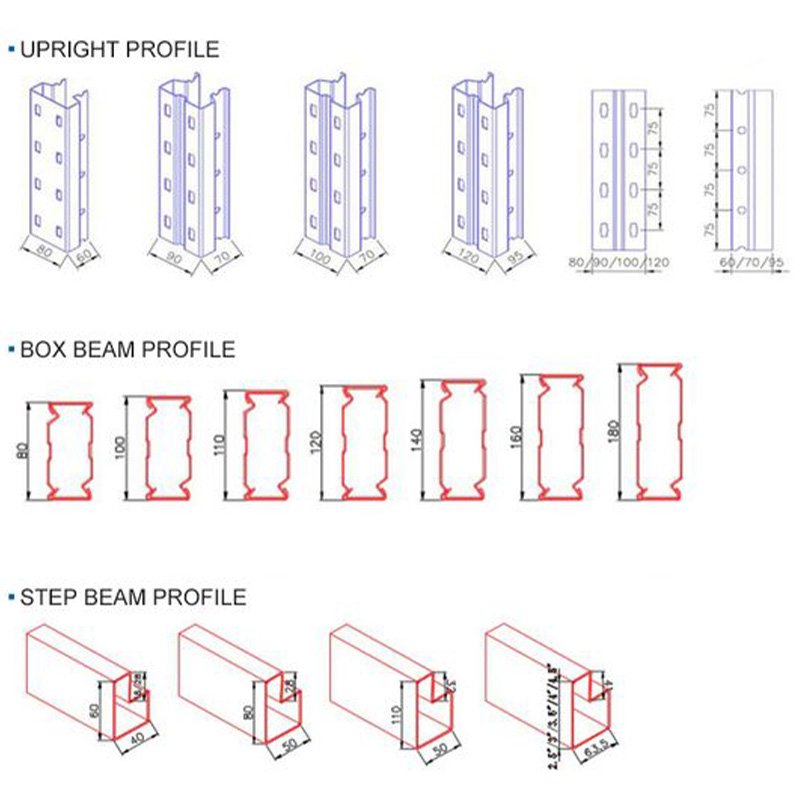

1.2 Drawings about upright rack:

|  |

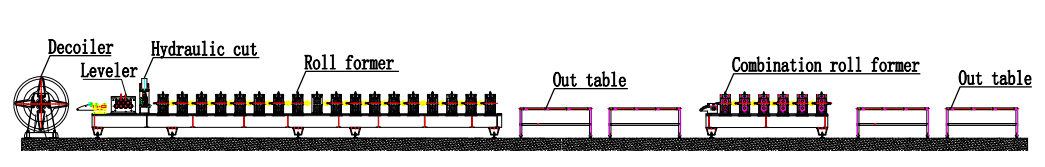

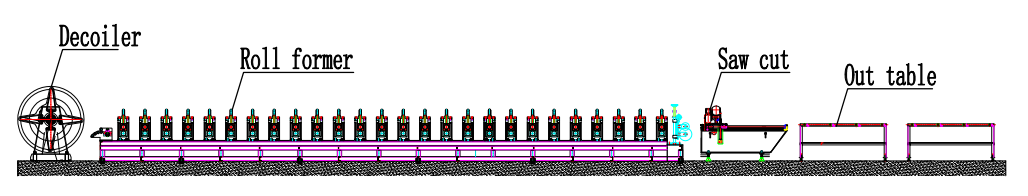

1.3 Workflow of upright rack making machine:

Decoiler -- Leveling Machine -- Press Machine -- Roll Forming Machine -- Cutting Station -- Output Table |  |

1.4 Parameter of upright rack making machine

| Upright Rack Making Machine | ||

| Item | Specification | Configuration optional |

Material : | A) Galvanized Coil | Thickness(MM):1.5/1.8/2.0/2.5/2.75/3.0 |

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Stainless Steel | ||

| E) Aluminum | ||

| F) Carbon steel Coil | ||

| Yield strength : | 250 - 350 Mpa | |

| Tensile stress : | 350 Mpa-500 Mpa | |

| Nominal forming speed(M/MIN) | 10-20 | * Or according to your requirement |

| Forming station : | 18-26 | * According to your profile drawings |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system | Hydraulic punching station | * Punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Forged Iron station | * Cantilever type (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 60Hz | * Or according to your requirement |

| Machine color : | According to your requirement | |

1.5 Main components of upright rack making machine

| Decoiler for upright rack making machine: KINGREAL equips the upright rack making machine with a hydraulic decoiler. Due to the large thickness of the metal coil, KINGREAL engineers equipped the decoiler with a pressure arm to prevent the coil from unwinding suddenly. The entire decoiling process is driven by a hydraulic station to ensure that the steel coil is firmly fixed in place to prevent any accidents. This decoiler can automatically expand and contract and actively feed. Effectively improve production efficiency for customers Leveling Machine for upright rack making machine: The straightening machine equipped by KINGREAL for the upright rack making machine can effectively remove the uneven parts of the steel coil, improve the flatness and parallelism of the steel coil, and thus improve the quality of the steel coil. Usually, the thickness of the metal raw materials processed by the upright rack making machine reaches up to 3 mm, so the straightening machine is an important component in this upright rack making machine. KINGREAL engineers will customize the rollers of the leveling machine according to the actual thickness of the coil processed by the customer. Press Machine for upright rack making machine: KINGREAL equips the upright rack making machine with a 125-ton press machine. The advantages of this punch are its fast punching speed, high precision, and excellent safety. If someone suddenly appears during the punching process, the operator can click Pause with one button, and the punching action will stop immediately. In contrast, other mechanical punching machines usually need to complete a punching action before stopping, which is relatively less safe. Roll Forming Machine for upright rack making machine: The roll forming machine equipped by KINGREAL for the upright rack making machine adopts an integrated cast iron structure and a gearbox drive system. It can ensure the stability and efficient operation of the machine. And to ensure the best performance of the upright rack making machine, KINGREAL can provide customers with customized motor services for the entire production line. Cutting Station for upright rack making machine: Flying shear means that the machine will not stop running during the cutting process. Through the PLC control cabinet, customers only need to enter the required cutting length on the PLC screen, and the cutting machine can cut accurately. |

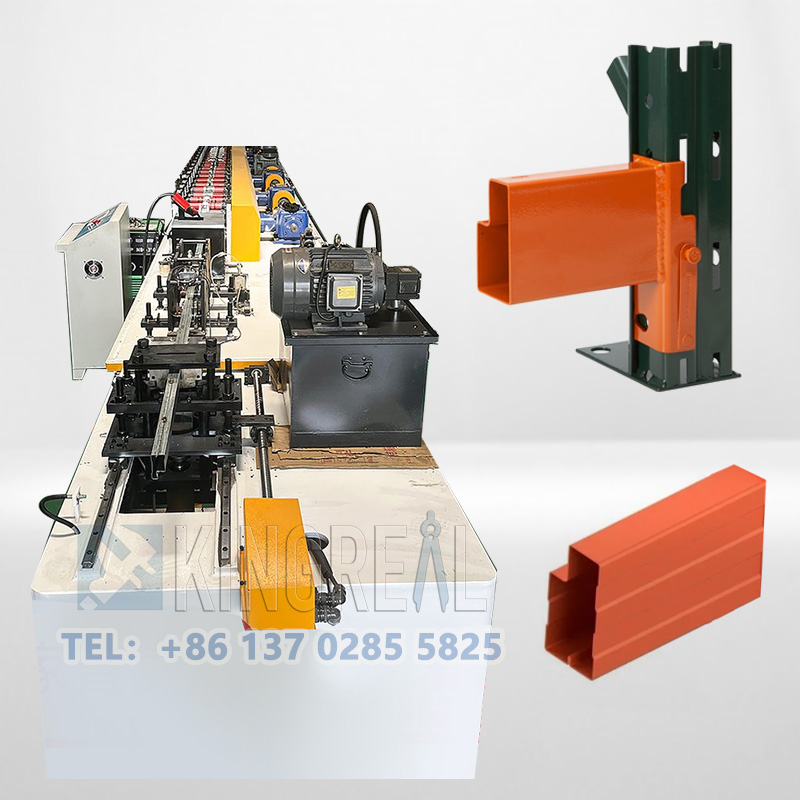

2. Box Beam Making Machine

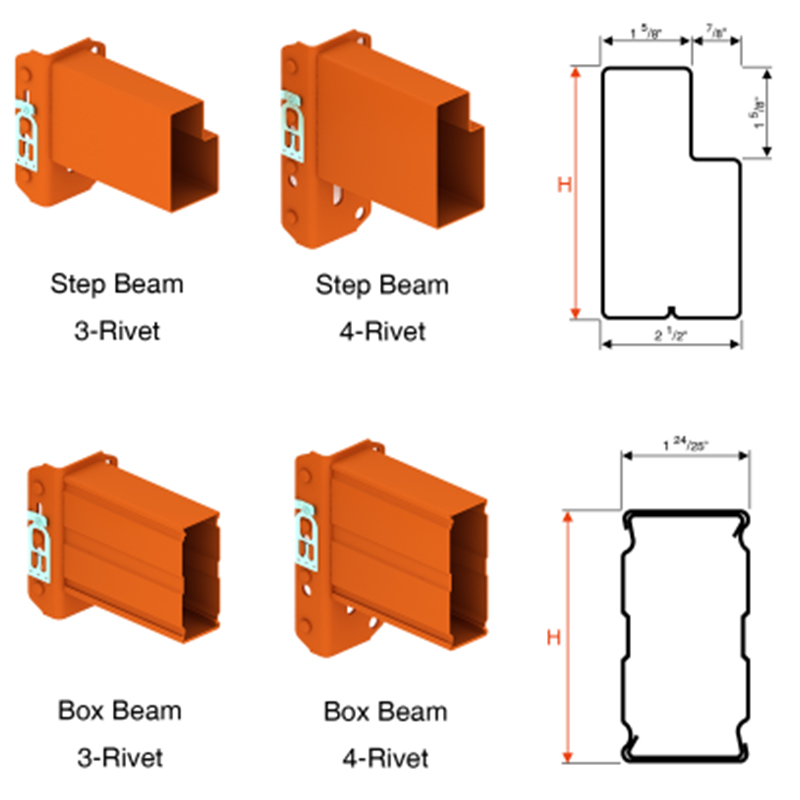

2.1 Introduction of box beam making machine

The box beam produced by the Box Beam Making Machine is an indispensable component in the shelf system. It is usually made of hot-rolled steel or cold-rolled steel with a thickness between 1.5 mm and 2 mm. The Box Beam Making Machine can produce Box Beams of different sizes. It is made of two high-strength galvanized steel "C" sections and mechanically locked together to form the final product. Since the basic shape of the box beam is rectangular, it can withstand greater loads. It has the characteristics of being suitable for various load capacities, compatible with various pallet sizes, and easy to clean and maintain. |  |

2.2 Drawings about box beam making machine

|  |

2.3 Workflow of box beam making machine

Decoiler -- Feeding-- Roll Forming Machine -- Curving and Interlocking -- Hydraulic cutting Station -- Output Table |  |

2.4 Parameters of box beam making machine

| No. | ITEM | PARAMETER | REMARK | |

| 1 | MATERIAL | Type | Cold-rolled strip steel, galvanized sheet | |

| T.(mm) | 1.0mm | |||

| Material strength | G300 MPA | |||

| 2 | Forming speed (m/min) | 5-8m | Including hole | |

| 3 | Forming main power (KW) | 11KW | For Your Reference | |

| 4 | Hydraulic power (KW) | 11KW | For Your Reference | |

| 5 | Total Power | 22 KW | For Your Reference | |

| 6 | Voltage | AC380V,50Hz,3Phase | Customized | |

2.5 Main components of box beam making machine

| Decoiler for box beam making machine: Used to clamp and unwind the rolled steel coil. The decoiler equipped by KINGREAL for the box beam making machine provides stable hydraulic pressure to unwind the steel coil, ensuring that the steel coil maintains flatness and straightness. Feeding for box beam making machine: This device is responsible for accurately and constantly feeding the steel coil into the roll forming machine. Usually, the feeding method is roller or chain. Chain feeding is more stable in high-speed production because the chain transmission power is greater. Roll Forming Machine for box beam making machine: It mainly consists of a series of roller press stations. The roller group is designed by KINGREAL engineers based on the box beam drawings and dimensions provided by the customer, so it can be accurately formed. During the roll forming process, the steel strip is gradually formed into the required box beam shape. Curving and Interlocking for box beam making machine: After the profile is roll-formed, the profile will be conveyed to the turning platform, and one of the profiles will automatically turn over to align the two profiles up and down. The guide roller ensures precise alignment, and then the two profiles are fed into the seaming machine, which is seamless and automated without human intervention. The seaming machine equipped by KINGREAL for the machine efficiently and firmly connects the two profiles together. No manual welding or additional welders are required. Hydraulic cutting Station for box beam making machine: The cutting machine cuts the box beam profile into the required length according to the machine control program. KINGREAL can provide different types of cutting machines to provide customers with a variety of machine manufacturing solutions, including circular saw cutting, die cutting, laser cutting, etc. |

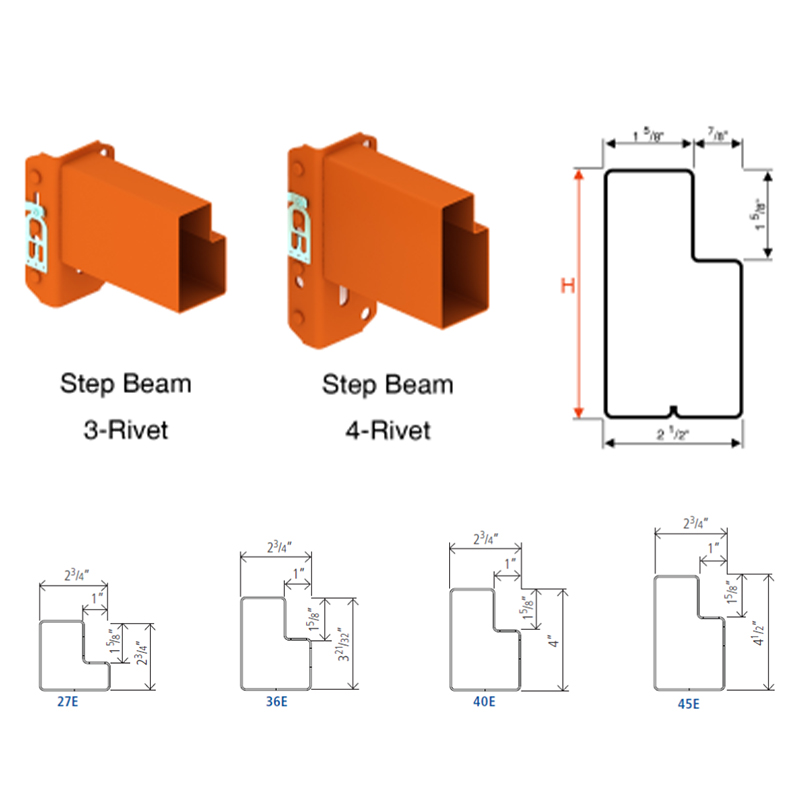

3. P Beam Making Machine

3.1 Introduction of p beam making machine

Step beam making machine, also known as P Beam Making Machine, is specially developed for the production of beams fixed between vertical shelves. It is usually processed with various metal raw materials with a thickness of 1.5-3mm. It is one of the light shelf components used for goods display, placement, and product display in warehouses, supermarkets, large, medium and small shopping malls, etc. KINGREAL can provide a variety of p beam making machine manufacturing solutions according to the different production needs of customers, including manual p beam making machine, semi-automatic p beam making machine and fully automatic p beam making machine. The maximum production speed can reach 20m/min. |  |

3.2 Drawings about p beam making machine

|  |

3.3 Workflow of p beam making machine

Decoiler -- Guiding -- Leveler -- Pre-punching -- Roll Forming Machine -- Welder --Hydraulic Cutting Station -- Output Table |  |

3.4 Parameter of p beam making machine

| Step Beam Roll Forming Machine | ||

Machinable Material | A) Galvanized Coil | Thickness(MM): 1.5-3.0 as per customer |

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Carbon Steel | ||

| Yield Strength | 250 – 350 Mpa | |

| Tensile Stress | 350 Mpa-500 Mpa | |

| Nominal Forming Speed(M/Min) | 10-20 | * Or According To Your Requirement |

| Forming Station | 26 | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Cast Iron Stands (Optional) |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Welding System | Spot Welding | * Laser Welding (Optional) |

Cutting System | Saw Cut | * Flying Cut (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

Machine Color | According To Your Requirement | |

3.5 Main components of p beam making machine

| Decoiler for p beam making machine: KINGREAL has equipped this decoiler with protective iron leaves to prevent the coil from slipping during the unwinding process. This design not only ensures the safety of the workers, but also ensures the integrity of the coil and the machine. Guiding & Leveler for p beam making machine: To keep the coil aligned with the center line of the roll forming machine and prevent bending, KINGREAL has equipped this p beam making machine with four guide rollers. After that, the coil enters the straightening machine, which eliminates the unevenness of the coil and improves its flatness and parallelism. Pre-punching for p beam making machine : Before forming, a notch is punched on both sides of the coil. These notches gradually converge during the roll forming process and finally merge into a rectangular hole. Roll Forming Machine for p beam making machine : This p beam making machine can produce step beams of various sizes, ranging from 70 mm to 140 mm in height. Since the left and right roll forming stations are precisely controlled by PLC and encoders, the step beams produced have excellent straightness and centering. Welder for p beam making machine: The reason why KINGREAL equips the machine with Welder is to ensure the safe load-bearing capacity of the racking system. The closed interface of the step beam should be kept for a long time and must not be opened. This equipment saves the labor cost of welders for customers. In addition, KINGREAL can also provide customers with a full set of welding configurations to improve welding quality. Hydraulic Cutting Station for p beam making machine: Through KINGREAL PLC control system, the step beam can be cut into any length and quantity. The p beam making machine is equipped with an encoder, and the length cutting is extremely accurate, with an error within 0.5 mm. |

Application of Warehouse Pallet Rack Machine

The profiles produced by KINGREAL pallet upright rack roll forming machine are often used in shelf systems in warehouses, supermarkets and other public places. The purpose is to quickly build, flexibly adjust and reuse an easy-to-manage storage system. |  |