- Home

- >

- Products

- >

- Box Beam Machine

- >

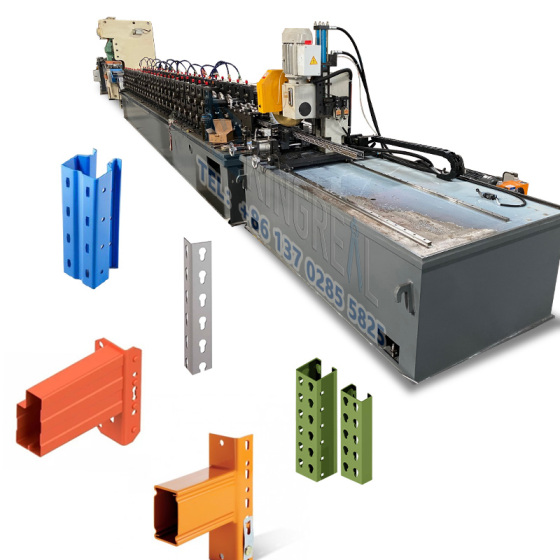

Box Beam Machine

KINGREAL box beam making machine is specially developed for the production of C-shaped beams fixed between columns. This box beam making machine is efficient, precise and automated, and can meet the needs of modern warehousing and logistics industries for box beams. KINGREAL box beam machine can produce box beams of different sizes according to customer requirements.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Box Beam Making Machine

Definition of Box Beam Making Machine

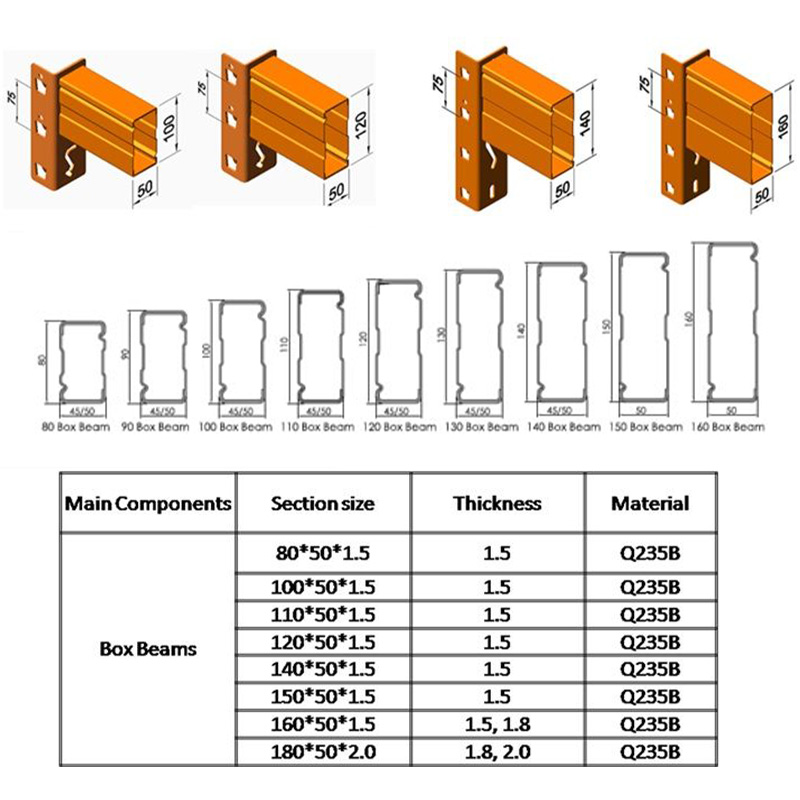

KINGREAL box beam machine can form materials with a thickness of 1.0-2.0mm, including pre-galvanized steel, hot-rolled steel and cold-rolled steel. The standard sizes of box beams are 50mm, 95mm, 110mm, 120mm, 130mm, 140mm, 150mm and 160mm. If there are special size requirements, please provide drawings to KINGREAL so that we can tailor the most suitable solution for you.

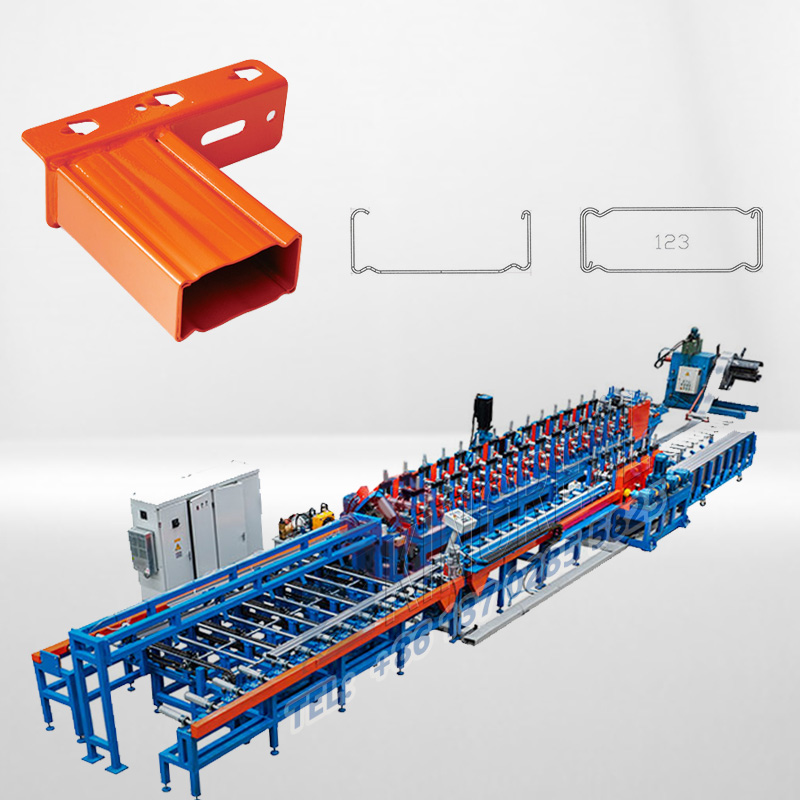

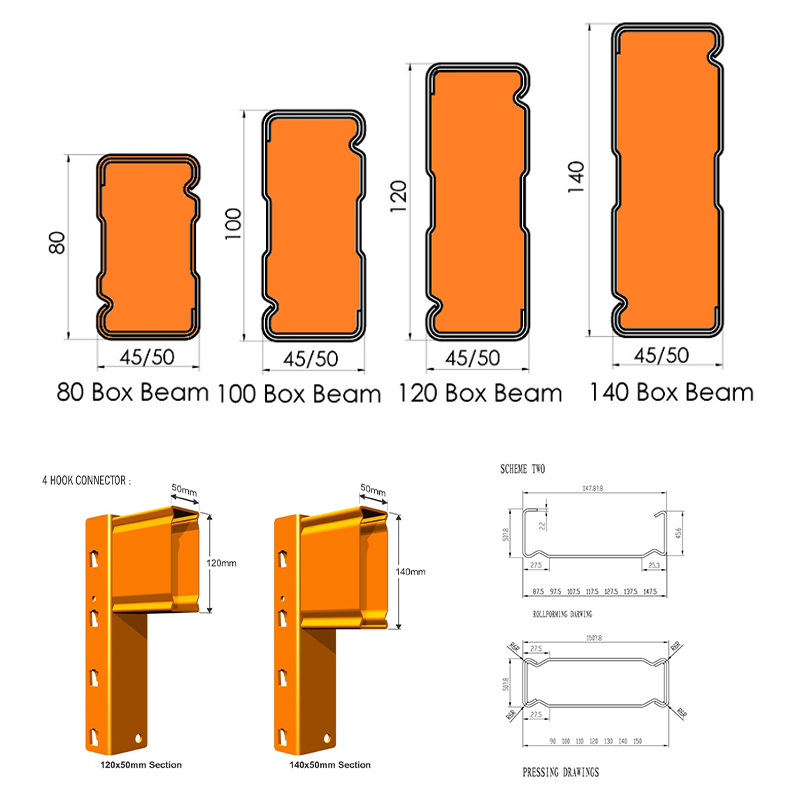

Box beam is a roll-formed beam made of two C-shaped high-strength galvanized steels and mechanically locked together. Its unique structural design makes the box beam perform well in load-bearing capacity and stability, becoming an indispensable part of modern racking systems.

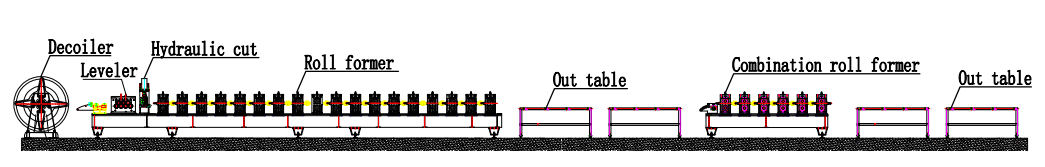

Workflow of Box Beam Making Machine

Decoiler →(cutter and welding for optional)→ Feeding And Guiding →Leveling →Roll Forming → Cutting →Turnover Platform→Boxing →Ran out

Parameters of Box Beam Making Machine

| No. | Item | Unit | Parameters | |

| 1 | Suitable material | Type | SS400/490 etc | |

| Strength | MPa | 235Mpa | ||

| Thickness | mm | 1.2/1.5/1.7/2.0mm | ||

| Coil internal diameter | mm | 508mm | ||

| Coil weight | T | 5T | ||

| 2 | Specification | mm | 550mm | |

| 3 | Line speed | m/min | 20m/min | |

| 4 | Roller material | D2 quenching treatment | ||

| 5 | Roller driven type | External chain transmission | ||

| 6 | Operating system | Windows2000 | ||

| 7 | Total motor power | KW | About 35KW | |

| 8 | Electric control system | PLC automatic control system | ||

Advantages of Box Beam Making Machine

Width Adjustment For Box Beam Machine

KINGREAL box beam machine is extremely convenient when producing plates of different widths. Users can quickly adjust the production width by simply replacing some rollers and gaskets. This design not only reduces the time for production switching, but also reduces the downtime of the box beam machine, making the production process smoother.

In order to further enhance the flexibility of production, KINGREAL box beam machine can also design an automatic width adjustment system according to customer needs. The system can automatically identify the specifications of the required products according to production needs, and continuously and automatically adjust the product size to adapt to box beams of different specifications and shapes. This innovation ensures that in the production process, whether it is mass production or small batch customization, market demand can be quickly responded to.

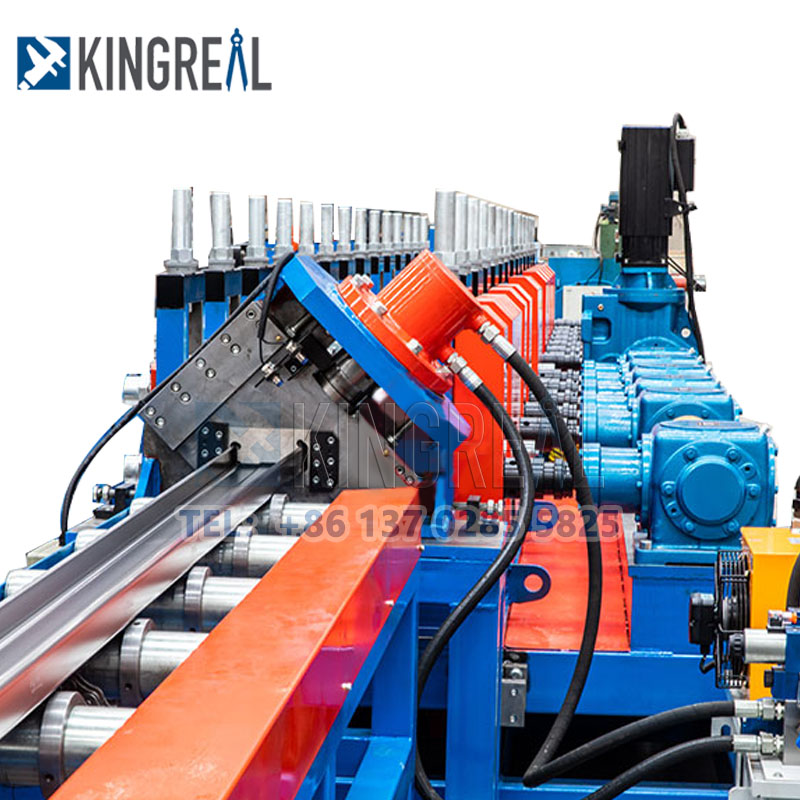

High Precision For Box Beam Making Machine

In the process of producing box beams, precision is crucial. The box beams produced using KINGREAL box beam machine have extremely high precision, beautiful appearance, and can be processed strictly according to the shape design and size of the beam. This high precision not only improves the quality of the finished product, but also ensures its reliability in practical applications.

KINGREAL rollers are made of high-quality gearbox steel, which is quenched and chrome-plated. This process ensures the stability and accuracy of the entire forming process. The rollers are made of high-quality carbon steel, which is tempered and hardened to further enhance its durability and deformation resistance. The selection and processing of these materials ensure the superior performance of the box beam in terms of bearing capacity and service life.

Through these sophisticated processes and materials, KINGREAL box beam making machine is not only a production equipment, but also an important guarantee for customers to achieve high quality standards in the production process.

High Degree Of Box Beam Machine Automation

In modern production, the degree of automation is directly related to production efficiency and safety. KINGREAL box beam machine is equipped with a variety of safety protection systems during operation to ensure the safety of workers and reduce the risk of accidents.

KINGREAL box beam making machine is equipped with multiple safety protection measures, including emergency stop buttons, overload protection and automatic alarm systems. These systems can issue alarms and automatically shut down when the box beam making machine is abnormal, greatly reducing the risk of personal injury and box beam machine damage. KINGREAL is well aware that safety is always the first priority in the production environment, so we put safety first in the design.

Drawing About Box Beam

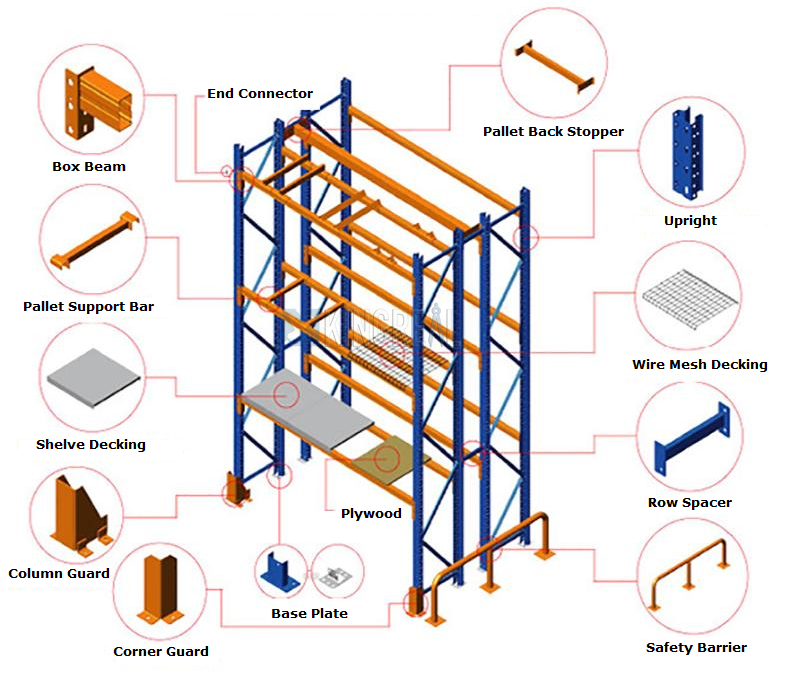

A Complete Warehousing System

In addition to the box beam making machine, KINGREAL can also provide a variety of equipment such as step beam machine, ◥upright post machine, stotted angle making machine, shelf panel machine, ◥etc. to form a complete warehousing system. By organically combining various types of equipment, customers can achieve integrated production and ensure that all components of the rack fit perfectly.

How To Achieve It?

In this complete warehousing system, the box beam machine is responsible for producing the load-bearing box beams, the step beam machine is used to manufacture the beams, the upright post machine manufactures the columns, and the thick angle profile machine and shelf panel machine provide the support and panels. These finished products are used together to form an efficient and stable racking structure that can meet the flexibility of different storage needs.

Application Areas of Box Beam Machine

The box beams produced by KINGREAL box beam making machine are mainly used to be installed on the side of the rack to share the weight of the box beams. These structures can meet different load-bearing requirements and improve the stability and support capacity of the entire rack. 1. Warehousing and logistics Box beams are widely used in various warehouse and logistics racking systems, including but not limited to pallet racks, cantilever racks, modular racks and mobile racks. These systems help companies effectively manage and store various goods, improving the space utilization and operating efficiency of warehouses.

2. Factory applications In industrial manufacturing, the application of box beams is equally important. They are widely used as supporting structures for production lines, carrying heavy equipment and materials, and ensuring the smooth progress of production processes.

3. Supermarkets and retail In the retail industry, box beams are used to build shelves and can withstand the weight of a large number of goods. Its design not only ensures the stability of the shelves, but also improves the beauty of the store and promotes the consumer's purchasing experience.

4. Other industries In addition to the above fields, box beams can also be used in many industries such as construction and transportation. Its flexible design and strong load-bearing capacity make box beams suitable for various fields. |  |