News

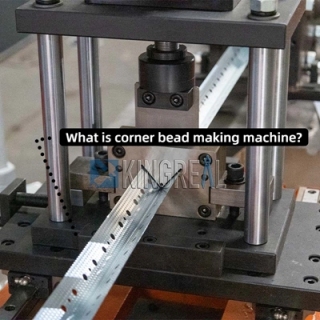

The corner bead making machine is used to produce corner bead of various sizes and types, typically using metal materials with a thickness ranging from 0.2-1.2mm. Punching, logo embossing, and other custom features can be customized to meet specific customer needs. This corner bead machine can be customized to your specific specifications, perfectly matching your project's requirements. Comprehensive safety features ensure peace of mind for operators. Furthermore, the low-noise corner bead making machine offers significant advantages in environments with strict noise requirements. The fully automated design allows for efficient production within the factory.

Step beam making machines are essential equipment in modern warehousing. By rolling flat metal strips into the desired profiles, the step beams produced by these pallet rack step beam machines form a crucial component of the backbone of racking systems, primarily serving as vertical supports. These profiles typically feature a series of punched or slotted holes for adjusting the crossbar position, ensuring racking stability and load-bearing capacity. This article will explore in detail the applications of step beam making machines and their importance across various industries.

The light gauge steel framing machine for light steel villa profiles is an efficient equipment that utilizes advanced CAD-assisted design and CAM-assisted production and manufacturing technology for light steel houses. It can not only design building structures, but also realize 2D and 3D modeling of interior design and landscape design. The light steel villa structure machine can automatically generate material tables and estimation facilities to effectively calculate design costs by meeting the personalized needs of customers through precise engineering construction drawings. The produced profiles can complete the skeleton work of light steel villas through simple and orderly installation, and are widely used in the construction industry.

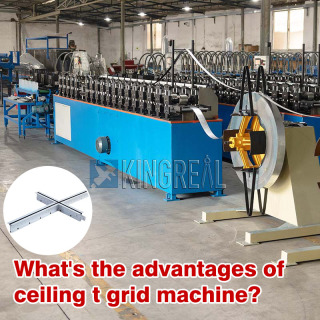

As an important equipment in the production of modern building materials, the ceiling t grid machine is widely used in the manufacture of metal ceilings. It produces the main t (runner t) and the cross T by processing iron plates of different thicknesses and roll-coated iron plates, providing stable and solid ceilings for buildings. This article will discuss in detail the workflow, technical parameters and multiple advantages of the ceiling t bar machine in the industry.

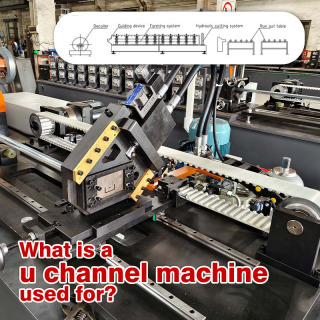

U channel machine, also known as intermediate channel machine, main channel making machine, pop bottom channel machine and ceiling u profile making machine, is an indispensable and important equipment in modern construction and decoration.

As people pay more attention to sustainable development, the demand for solar channels is growing. As an important equipment, solar channel machine plays an indispensable role. With its advanced technology and continuous innovative design, KINGREAL provides customers with efficient and intelligent solar channel making machines to meet the market's diversified needs for solar channels.

C purlin roll forming machine is a kind of equipment used to continuously produce c purlin by passing galvanized or cold-rolled steel strip through a series of processes such as feeding, punching, bending, cutting, etc. The profiles produced by this c purlin machine have a C-shaped cross-section and are mainly used for roof and wall joists in building shell structures. Due to its light weight, easy installation and transportation, c purlins are widely used in the construction industry, especially in large warehouses, industrial plants and commercial buildings. This article will discuss the working process, technical parameters and many advantages of c purlin roll forming machine in detail.

IBR roof sheet making machine is a kind of equipment specially used for producing IBR roof sheets, which has important market value and application prospects. This ibr metal roof sheet making machine is designed to improve production efficiency, reduce costs and meet the diversified needs of modern buildings. With the rapid development of the construction industry in South Africa, ibr roof sheet making machine is more and more widely used in the market and has become an indispensable production equipment for construction companies and developers.

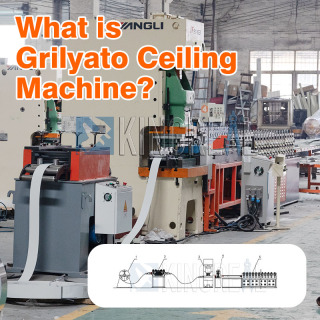

The grilyato ceiling machine usually processes iron plates with a thickness range of 0.25-0.4mm or aluminum plates with a thickness range of 0.3-0.4mm into various types of open cell ceilings required by customers, such as U-shaped grilyato ceilings, C-shaped grilyato ceilings and pyramid grilyato ceilings. The common sizes of grilyato ceilings produced by these open cell ceiling machines are 25X25MM, 30X30MM, 38X38MM, 50X50MM, 65X65MM, which are open and flexible. This open cell ceiling machine is efficient and stable at a speed of 30m/min.

As a step beam making machine manufacturer with more than two decades of experience, KINGREAL has always been committed to the close integration of technological innovation and market demand. KINGREAL is very pleased to introduce our latest technological breakthroughs for p beam making machine in 2025. This step beam making machine can not only efficiently produce step beams of various specifications, but also work with other equipment such as rack box beaming machine, slotted angle making machine, upright rack making machine, etc. to provide customers with a complete storage rack system.