How the pallet upright rack machine works?

2025-09-05 12:00Video About Pallet Upright Rack Machine

1/ Description of Pallet Upright Rack Machine

In modern warehouse management, pallet upright rack machines are crucial equipment, efficiently producing the profiles used to support pallet racking system. These pallet upright rack making machines primarily include Upright Rack Making Machine, Rack Box Beaming Machine, Pallet Rack Step Beam Machine, and Slotted Angle Making Machine, all of which provide the necessary support for racking systems. Using galvanized or cold-rolled steel as raw material, pallet upright rack machines, through a series of precise steps, transform the metal into profiles with specific shapes and dimensions. The efficiency and precision of these pallet upright rack making machines have earned them a prominent position in the industry.

2/ Importance of Pallet Upright Racks

Pallet upright racks are auxiliary systems for material handling and storage, designed to store materials on pallets. While there are many different types of pallet racks, all allow palletized materials to be stored horizontally in multiple rows, significantly improving storage efficiency. As the demands of modern warehouses continue to increase, so too has the market demand for pallet upright rack making machines. Warehouse racking has become an indispensable element in most modern warehouses, manufacturing facilities, retail centers, and other storage and distribution facilities. All types of pallet racking increase storage density, which is crucial for optimizing space utilization and reducing operating costs.

3/ Operating Principle of Pallet Upright Rack Machine

A pallet upright rack making machine primarily uses rollers to roll metal materials into the customer's desired shape. The rollers are made of high-hardness material and undergo a hardening process to ensure precision and long pallet upright rack machine life. Throughout the entire pallet upright rack making machine operation, a frequency converter controls the motor speed, and a PLC system automatically controls the length and quantity, enabling continuous, automated production. This efficient operating principle has earned the pallet upright rack machine a high reputation in the industry.

4/ Pallet Upright Rack Making Machine Solutions

KINGREAL offers a complete pallet racking system solution, including several different types of pallet upright rack making machines, such as the Upright Rack Making Machine, Rack Box Beaming Machine, Pallet Rack Step Beam Machine, and Slotted Angle Making Machine. The profiles produced by these pallet upright rack machines are combined and spliced together to form a stable and sturdy pallet racking system.

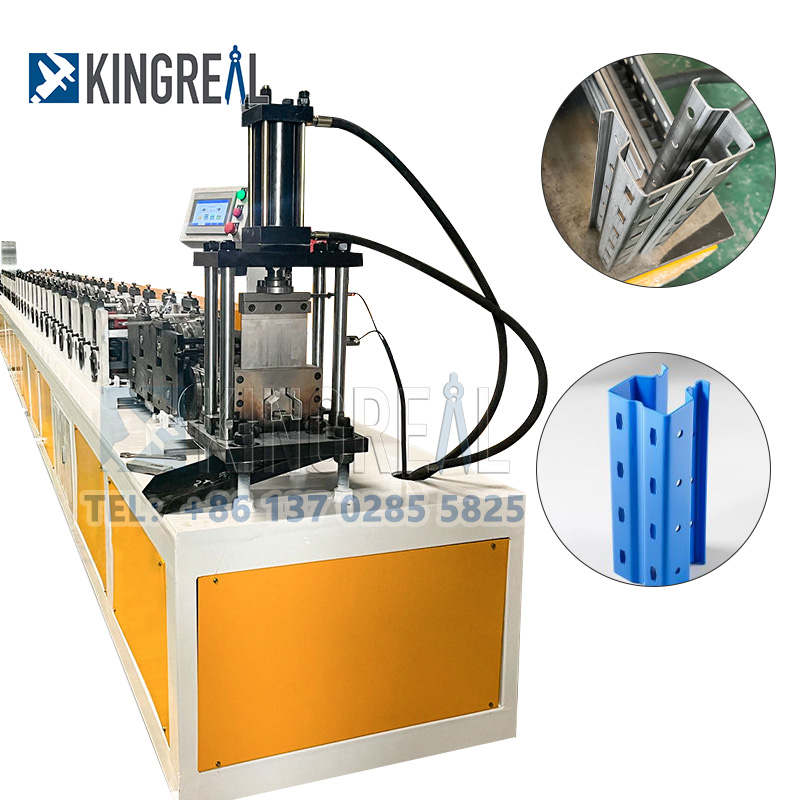

The Upright Rack Making Machine is one of the core components of the pallet upright rack making machine. Driven by a gearbox and motor, this pallet upright rack machine efficiently processes thick, hard materials into standard upright racks. The rollers are mounted on 80mm diameter shafts, ensuring long-term operation at various forming speeds to accommodate diverse production needs. Designed for production flexibility, the pallet upright rack machine can be adjusted to meet specific customer requirements, thereby improving production efficiency. The Upright Rack Making Machine boasts high-precision forming capabilities, ensuring that each upright rack meets exacting standards for size and shape. The implementation of this upright rack machine not only improves production efficiency but also reduces labor costs, giving the company an advantage in a competitive market. |  |

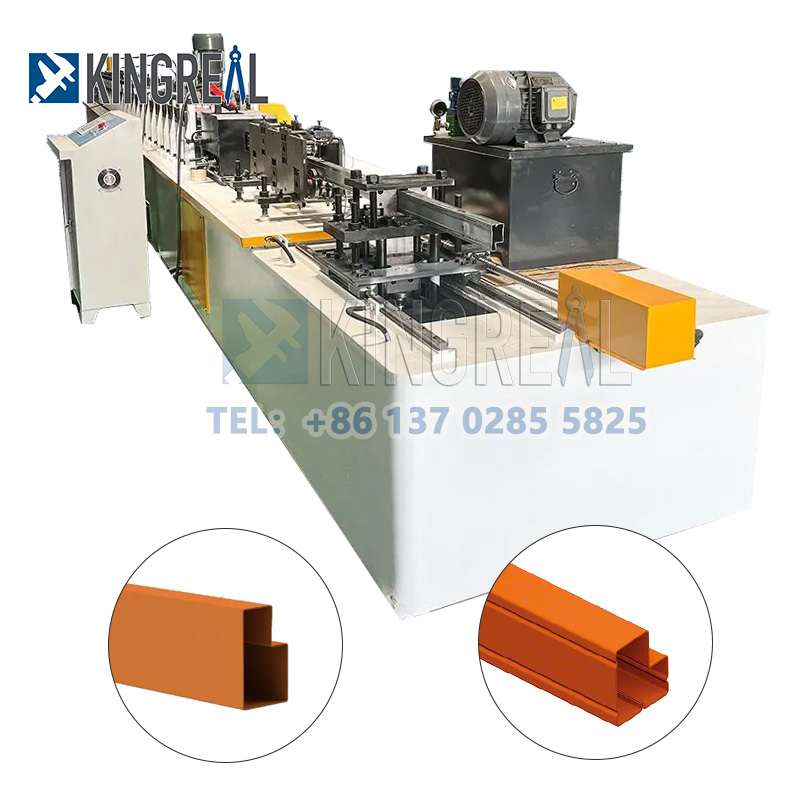

The Rack Box Beaming Machine is specifically designed for forming box beams. Designed to improve production efficiency and streamline the operation process, KINGREAL Rack Box Beaming Machine completes box beam production in a single step. Operators simply place the metal material into the Rack Box Beaming Machine, which forms and cuts the resulting beam, eliminating the need for fastening or welding. This one-piece forming design makes the production process more efficient and is particularly suitable for applications requiring high speed and flexibility. Furthermore, the box beam's structural design provides excellent load-bearing performance, making it suitable for various heavy-duty racking systems. With increasing market demand for box beams, KINGREAL Rack Box Beaming Machine can help customers quickly respond to market changes and increase production capacity. |  |

| Pallet Rack Step Beam Machine The Pallet Rack Step Beam Machine is a key piece of equipment designed by KINGREAL to meet customer customization needs. It primarily consists of a manual decoiler, a roll forming machine, a circular saw cutter, an electrical control system, and an output table. Its flexibility and efficiency make it widely applicable for producing step beams of various sizes and designs. During the production process, operators can adjust machine settings as needed to produce step beams that meet specific requirements. This high degree of customization makes the Pallet Rack Step Beam Machine highly competitive in the market. This Pallet Rack Step Beam Machine not only ensures high production efficiency but also ensures product precision and stability, meeting customers' stringent quality requirements. |  |

The Slotted Angle Making Machine is a fully automatic roll-forming machine for slotted angles, capable of producing slotted angles in a variety of sizes. This Slotted Angle Making Machine’s design takes into account market demand for connectors. Both flanges of the profile feature continuous punching, facilitating connection or bolting. This makes the slotted angle more flexible in pallet racking systems. This Slotted Angle Making Machine offers high forming accuracy and cut-to-length capabilities, significantly increasing customers' production capacity. Using the slotted angle making machine, companies can quickly produce connectors that meet diverse application requirements, improving overall production efficiency. |  |

5/ Advantages of Pallet Upright Rack Machine Solution

KINGREAL pallet upright rack making machine solution is more than just a single piece of equipment; it's a complete production line. By effectively combining multiple roll forming machines, customers can achieve fully automated production from raw materials to finished product. The advantages of this solution include:

-High Efficiency: The entire pallet upright rack machine boasts a high degree of automation, significantly improving production efficiency and reducing manual intervention.

-High Precision: Each pallet upright rack making machine is precisely calibrated to ensure the production of standard racking profiles, enhancing the quality of the final product.

-Flexibility: Customers can quickly adjust production settings based on market demand to meet diverse product requirements.

-Cost-Effectiveness: By optimizing the production process, material waste and labor costs are reduced, giving the company greater room for cost control.

-Long-Term Stability: KINGREAL pallet upright rack machine undergoes rigorous quality testing to ensure its long-term stability and reliability.