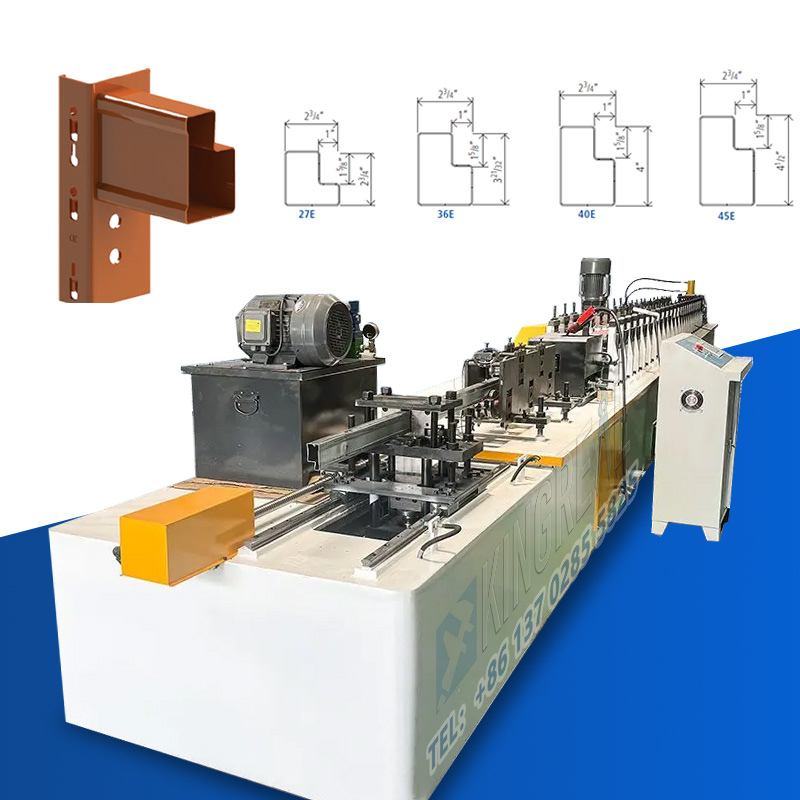

Technological breakthrough: step beam making machine

2025-07-11 12:00"As a step beam making machine manufacturer with more than two decades of experience, KINGREAL has always been committed to the close integration of technological innovation and market demand. KINGREAL is very pleased to introduce our latest technological breakthroughs for p beam making machine in 2025. This step beam making machine can not only efficiently produce step beams of various specifications, but also work with other equipment such as rack box beaming machine, slotted angle making machine, upright rack making machine, etc. to provide customers with a complete storage rack system."

Necessity of Technological Innovation

With the changes in market demand, the manufacturing industry is facing higher efficiency and lower cost pressure. KINGREAL has discovered some technical bottlenecks in step beam production through visits to past customers and in-depth research on the 2025 market. In order to meet these challenges, KINGREAL has carried out a comprehensive technical upgrade for the p beam making machine to ensure that it has reached the industry-leading level in terms of safety, efficiency and product quality.

Core Technical Highlights of Step Beam Making Machine

PLC control panel

In this step beam making machine, KINGREAL uses a PLC control panel. This system not only improves the level of automation, but also greatly improves the safety and efficiency of the production process. Through intelligent program control, the probability of human error during operation is greatly reduced, thus ensuring the stability of production.

High-strength channel steel welding frame

The forming frame is welded with high-strength channel steel, which has extremely high strength and durability. This design concept ensures that the p beam making machine remains stable under long-term high-intensity work, extends the service life of the step beam making machine, and provides customers with a higher return on investment.

High-strength material for the roll shaft

KINGREAL uses 40Cr in the material selection of the roll shaft, and after quenching and tempering, its hardness reaches HB280. This ensures that during the long production process, the roll shaft can withstand high-intensity workloads while maintaining good wear resistance.

High-quality materials for the forming mold

The forming mold is made of GCr15 material and is quenched to a hardness of HRC56-62. This high-hardness mold design significantly improves the accuracy and strength of the produced step beams.

Advanced transmission structure

In terms of transmission structure, KINGREAL provides two options: gearbox transmission and chain transmission. Customers can choose according to actual needs. No matter which transmission method is used, the stability and efficiency of the machine can be ensured during the working process.

Specific Upgrade Points of Each Component

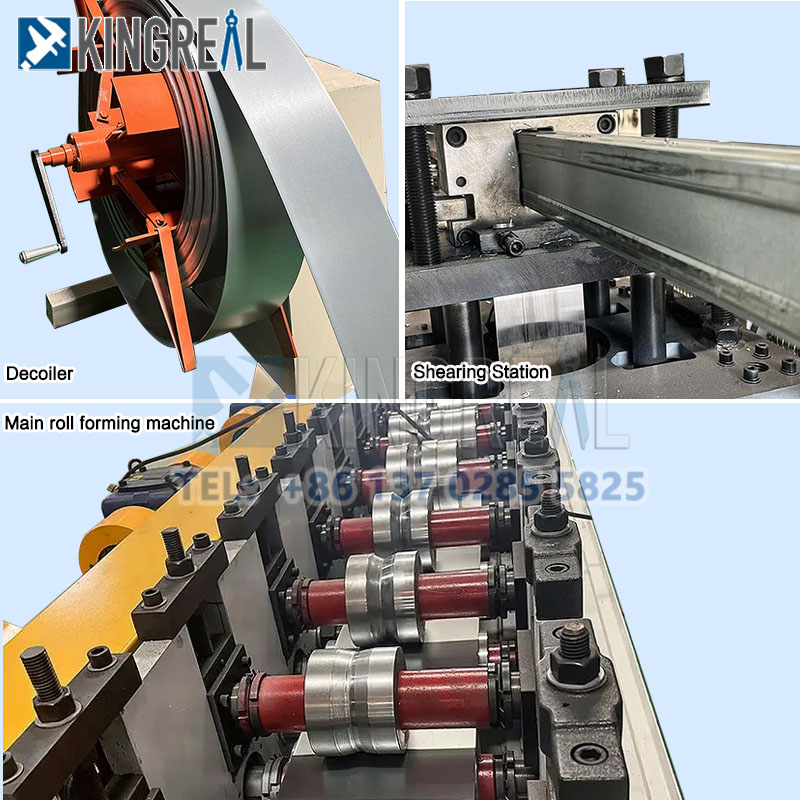

Safety design of the decoiler

On the decoiler, KINGREAL installed a pressure arm to press the steel coil when changing the steel coil to prevent it from accidentally unwinding, thereby ensuring the safety of the workers. In addition, the design of the protective iron sheet also effectively prevents the steel coil from slipping during the unwinding process, further protecting the p beam making machine and workers.

Precise control of the guide and straightening machine

Before entering the subsequent processing link, the steel coil is guided by four guide rollers to ensure that it is consistent with the center line of the step beam making machine to prevent the profile from bending during the forming process. This design significantly improves the overall quality of the steel coil and the step beam, ensuring the accuracy of the final product.

Innovation of pre-punching and hydraulic cutting

In terms of cutting technology, KINGREAL can not only provide traditional hydraulic cutting, but also introduce sawing technology to improve the cutting effect. Although the sawing speed is slower, due to its better cutting quality, KINGREAL innovative slotting technology has also greatly improved the efficiency of hydraulic cutting, making the entire production process more flexible.

Multi-specification p beam making machine

In order to meet the diverse production needs of customers, KINGREAL has designed a step beam making machine that can produce step beams of various sizes. The height range ranges from 70 mm to 140 mm. Through the intelligent PLC control panel and encoder, the synchronous movement of both sides is ensured, so that each step beam can achieve excellent straightness and centering.

Equipment and optimization of welding machine

In order to further improve production efficiency, KINGREAL has equipped the p beam making machine with a welding machine. This not only saves labor costs for customers, but also improves the quality of welding. If customers need it, KINGREAL can also provide a full set of welding configurations to ensure the stability and efficiency of the welding process.

Through a number of technological breakthroughs in the step beam making machine, KINGREAL has ensured its competitiveness in the market. KINGREAL goal is to provide customers with an efficient, safe and stable production solution to help them achieve greater success in the industry. Whether it is used for storage shelves, supermarket shelves or heavy-duty shelves, KINGREAL p beam making machine can meet customer needs and form a strong synergy with other machines.