Mexico Project -- solar strut channel machine

2025-02-27 12:07In recent years, the global demand for renewable energy has risen sharply, and the photovoltaic industry, as an important part of it, is booming. In order to meet the needs of the market, KINGREAL cooperated with Mexican customers to customize a solar mounting strut channel machine.

The equipment is designed to efficiently produce photovoltaic brackets and provide high-quality solar strut channel solutions for the solar industry in Mexico. At present, the machine has been manufactured and is waiting for shipment.

Trial solar strut channel making machine link

Before confirming that it can be shipped, KINGREAL's engineers conducted a strict trial solar strut channel machine link on the solar mounting strut channel machine. This process is crucial to ensure that the equipment can operate stably and efficiently in actual production.

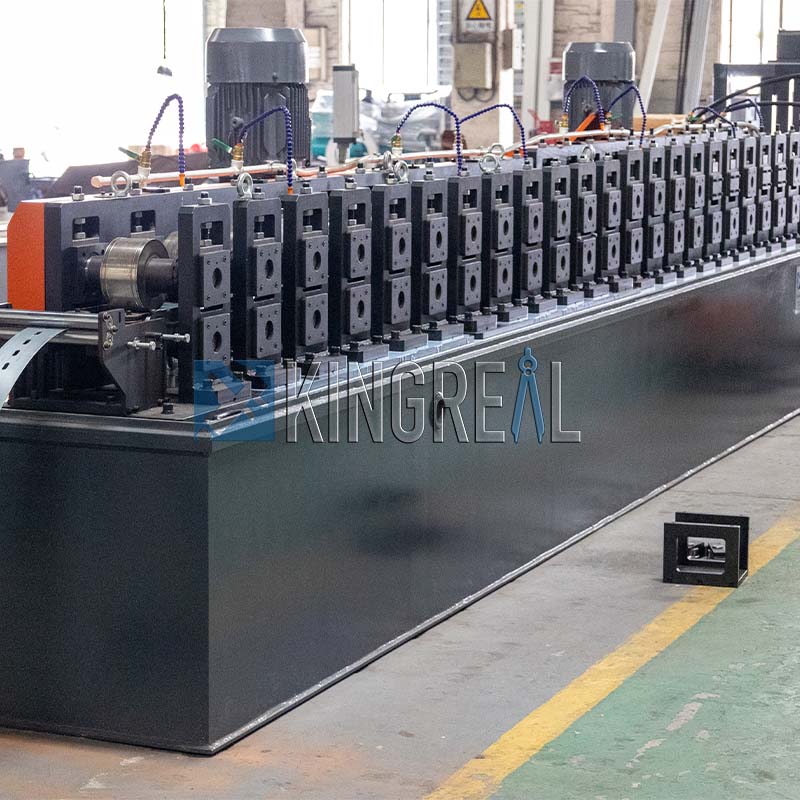

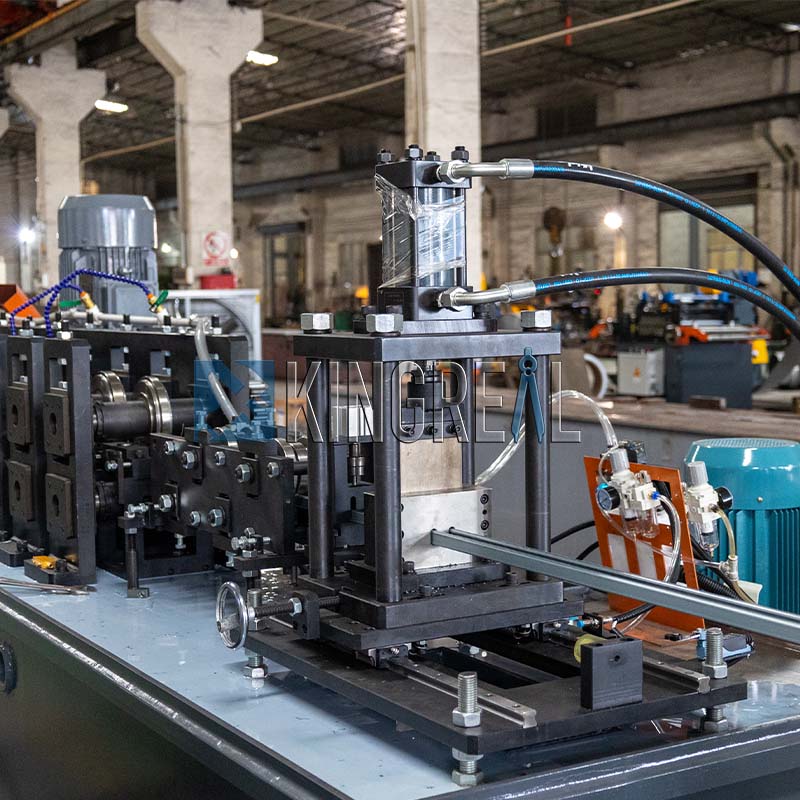

Assembly of the solar strut channel making machine

First, the engineer assembled a complete production line with components such as a 2-in-1 decoiler and leveling machine, a roll forming machine, a punching machine, a shearing system, and a packaging machine. After the assembly was completed, a series of commissioning was carried out to ensure the coordination and overall performance of each component.

Formal trial solar mounting strut channel machine

During the trial solar strut channel machine process, the engineer put the metal coil into the machine for formal trial machine, mainly testing the following aspects:

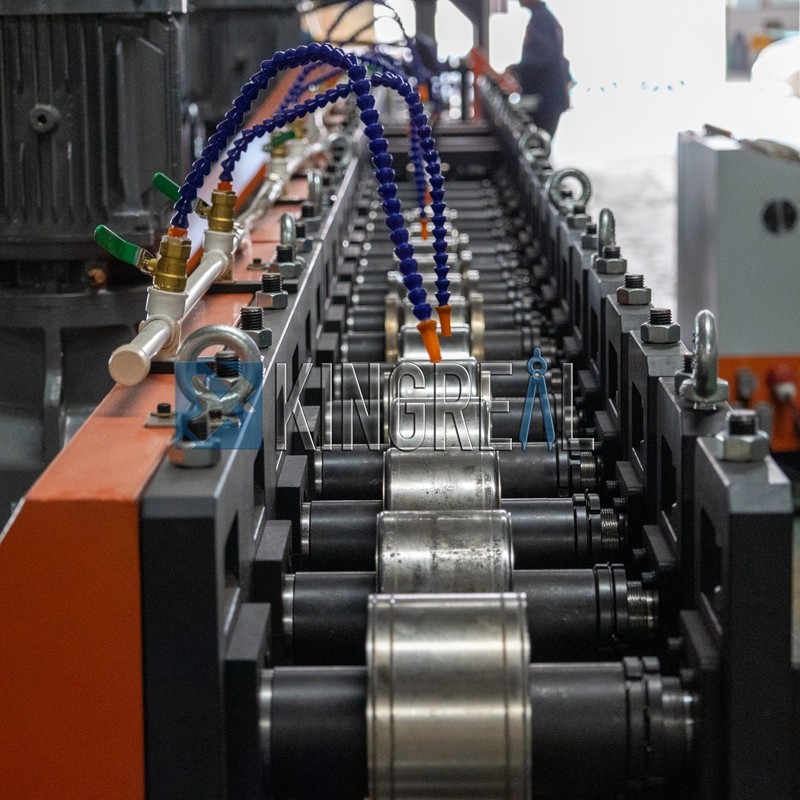

✦ Smooth operation: whether the solar strut channel making machine can run smoothly and unimpeded during operation to ensure the continuity and efficiency of production.

✦ Running speed: Whether the production speed of the solar strut channel making machine can reach the design requirement of 15 m/min. Through debugging, engineers verified the running stability of the solar strut channel machine under different load conditions.

✦ Packaging machine test: The performance of the fully automatic packaging machine is also one of the focuses of the test. Engineers observe whether the packaging machine can automatically complete the packing process and ensure the neatness and standardization of the solar strut channels.

✦ Solar strut channel measurement: During the production process, the solar mounting strut channel machine needs to be able to accurately produce finished products of various sizes, including 41 x 21mm, 41 x 41mm, 41 x 62mm and 41 x 82mm. Engineers measured the solar strut channels of each size to ensure that they meet the customer's production requirements.

Through this series of tests, engineers confirmed the stability and production efficiency of the equipment and ensured the reliable quality of the solar strut channel making machine before shipment.

KINGREAL's new design: solar strut channel machine with auto package unit

KINGREAL introduced a fully automatic packaging machine in this solar strut channel machine, which is an important innovation of this cooperation. The packaging machine is designed to maximize the customer's production efficiency and provide customers with a more convenient operation experience.

Improve production efficiency

The introduction of fully automatic balers makes the production process smoother and reduces the time for manual handling and manual packaging. Traditional production methods often require workers to carry solar strut channels and manually pack them, which not only increases labor costs but also easily causes safety hazards. The fully automatic packaging machine can pack the finished products immediately after they are produced, ensuring seamless connection of production links.

Reduce labor costs

Through the automated packaging process, KINGREAL helps customers significantly reduce labor costs. Customers can shift human resources to other more productive links, thereby improving overall production efficiency. At the same time, reducing manual operations also reduces the risk of errors and accidents caused by human factors.

Improve safety

The use of fully automatic packaging machines has also greatly improved the safety of the production site. It reduces the physical burden of workers during heavy handling and packaging, reduces the incidence of work-related injuries, and ensures the safety and health of employees.