Comprehensive Guide To Metal Perforated Making Machine

2025-06-09 12:00Metal perforated making machine is a kind of equipment specially used to process various hole types on metal materials. Whether it is used in construction, automobile industry or home appliance manufacturing, perforated metal machine plays a vital role. This article will answer your questions about metal perforated making machine in detail, helping you to better understand the working principle, components and advantages of this perforated metal machine. If you are interested in metal perforated making machine, please feel free to contact KINGREAL for more information!

Definition of Metal Perforated Making Machine

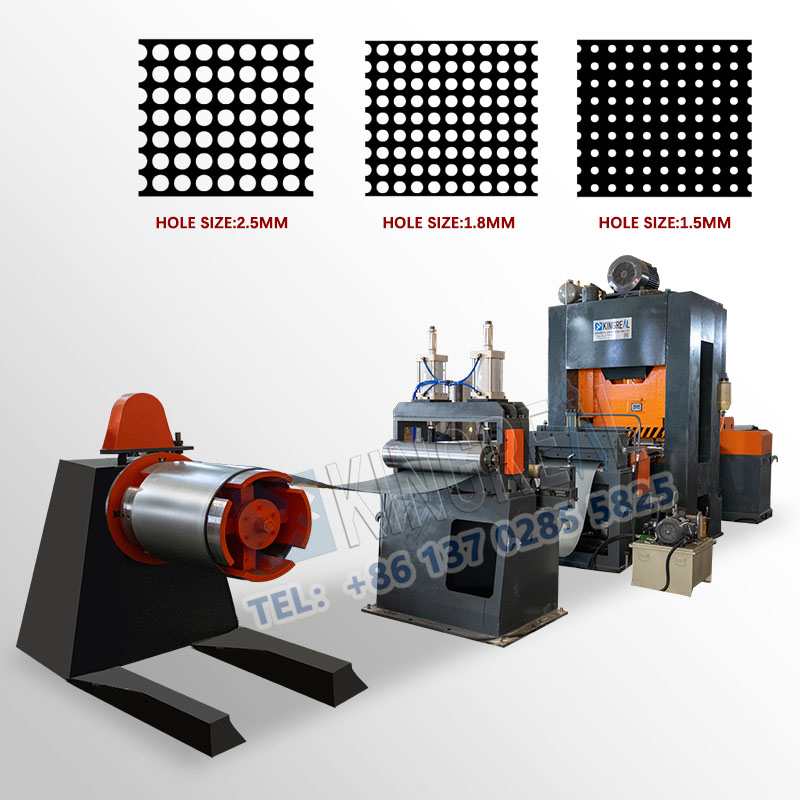

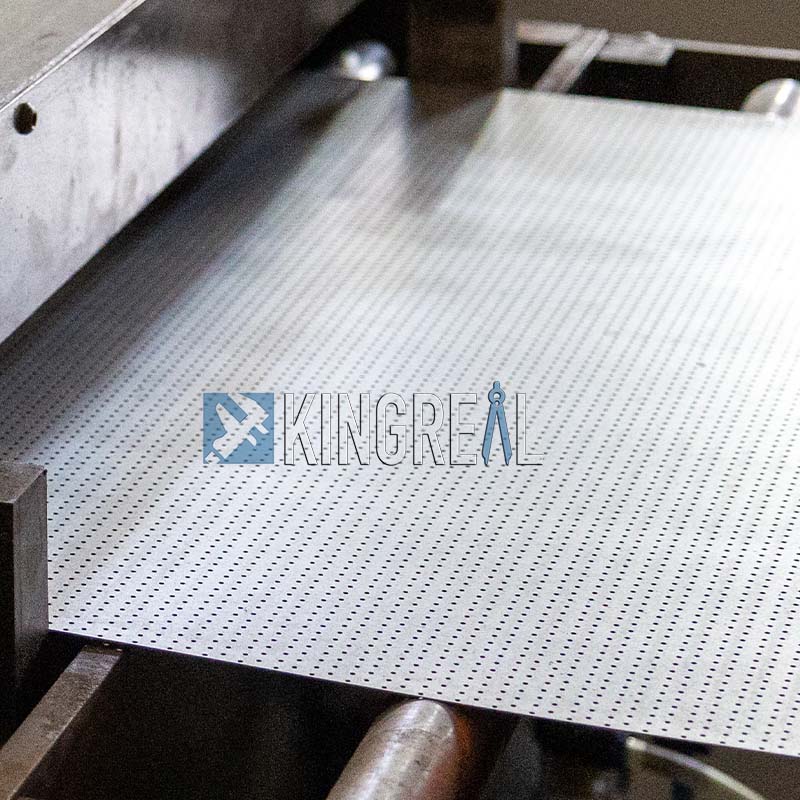

Perforated metal machine is an efficient production equipment that can punch different types of holes on the surface of metal materials such as aluminum, iron, stainless steel, etc. These holes can be used as channels for ventilation and drainage. KINGREAL metal perforated making machine meets the requirements of customers under various production needs with its excellent performance and reliability.

Workflow of Metal Perforated Making Machine

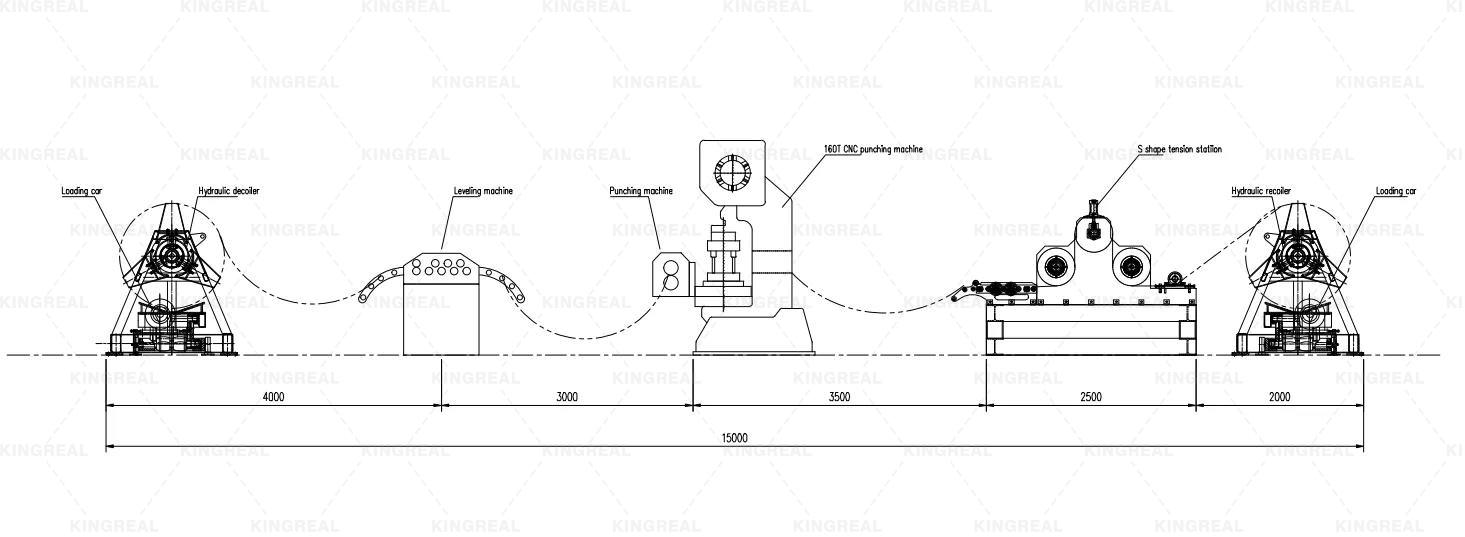

The workflow of metal perforated making machine usually includes the following steps: Decoiler ↓ Leveler ↓ Punching machine ↓ Shearing station or recoiler |  |

Main Components of Perforated Metal Machine

1. Decoiler for perforated metal machine The main function of the decoiler is to unfold the metal coil to prepare for the subsequent leveling and punching. It is designed to ensure smooth feeding of the material and reduce the punching error caused by uneven coils. |  |

| 2. Leveler for perforated metal machine The leveler flattens the metal material through multiple rollers to make its surface smooth. This process is crucial for subsequent punching, because flat materials can effectively improve the accuracy of punching. KINGREAL uses a high-precision leveler to ensure that each coil of material is perfectly flat before entering the puncher. |

3. Punching machine for perforated metal machine The punching machine is the core component of the metal perforated making machine, responsible for punching holes of various shapes from the metal material. KINGREAL punching machine is equipped with an efficient pneumatic brake system to ensure accurate punching at high speeds. With the durable DC53 die, the perforated metal machine can maintain high accuracy over long periods of operation, ensuring that each hole is of the same size and burr-free. |  |

| 4. Shearing station or recoiler for perforated metal machine Depending on the customer's production needs, the last step of the metal perforated making machine can be shearing or winding. The shearing station cuts the punched metal material into the required size, while the recoiler rolls it up for subsequent storage and transportation. |

Advantages of KINGREAL Perforated Metal Machine

1. Precision punching

KINGREAL metal perforated making machine is known for its excellent precision punching technology, especially through the advanced pneumatic brake system, which achieves a perfect combination of high speed and precision. In traditional perforated metal machines, the punching accuracy is often affected by mechanical wear and improper operation, while KINGREAL perforated metal machine significantly improves durability and precision by adopting high-quality DC53 dies. The DC53 die has extremely high hardness and toughness, and can withstand long-term punching operations without deformation, thus ensuring that the size and shape of each hole remain consistent in continuous production.

2. Perforated metal machine with feeding trolley

In order to further improve the efficiency of punching, KINGREAL is equipped with an advanced feeding trolley in the metal perforated making machine. This design is to replace the traditional manual handling method and maximize production efficiency. The feeding trolley can automatically and accurately feed the metal coil into the decoiler, reducing the complexity and risk of manual operation.

During the production process, the introduction of the feeding trolley also reduces the labor intensity of workers, allowing them to focus more on other key operations. In addition, automatic feeding can also ensure that the material is not damaged during the transmission process, ensuring the integrity of the material and the quality of subsequent punching.

3. High flatness for perforated metal machine

Leveling is a key link in the punching process, affecting the quality and accuracy of punching. KINGREAL flattening machine uses a nine-roller flattening device, consisting of 4 upper rollers and 5 lower rollers, which can effectively flatten the coil and improve the accuracy and quality of punching. The flattening machine is designed to ensure that each roll of metal material is in the best condition before entering the metal perforated making machine.

Before punching, the flattening machine applies uniform pressure to the metal material to make its surface smooth and free of ripples. This process not only eliminates the unevenness of the material surface, but also effectively avoids the punching error caused by the unevenness of the material. The improvement of flatness is directly related to the accuracy of punching. Only materials that have been finely flattened can achieve the ideal effect during the punching process.

Quality Assurance

● KINGREAL follows a strict quality control process in the manufacturing process of the perforated metal machine. After each metal perforated making machine is manufactured, it will undergo a comprehensive trial run and quality inspection to ensure that the perforated metal sheet produced meets the actual production needs of the customer. Only after all standards are met will the equipment be judged as qualified and sent to the customer's factory.

Success Cases about KINGREAL Perforated Metal Machine

KINGREAL has established close cooperative relations with customers in many countries, including Indonesia, India, Bangladesh, Brazil, Egypt and the Philippines. The following is a success case:

In 2024, KINGREAL reached a friendly cooperation with a Brazilian customer. KINGREAL engineers personally went to Brazil to install the metal perforated making machine for customers. The whole process includes machine component inspection, installation, test perforated metal machine and operation guidance. KINGREAL engineers taught Brazilian workers in detail how to start the metal perforated making machine, how to change the punching die and other operations to ensure that Brazilian customers can use the equipment smoothly and improve production efficiency.

Perforated metal machines play an indispensable role in modern manufacturing. Whether you have many years of industry experience or are new to this field, it is crucial to understand the working principle, components and advantages of metal perforated making machines. KINGREAL is committed to providing customers with efficient and accurate punching solutions. If you have any questions or needs about perforated metal machines, please feel free to contact KINGREAL, we will serve you wholeheartedly!