How Do Drywall Partition Machines for Stud and Track Work?

2025-12-19 15:08Drywall Partition Machines for Drywall

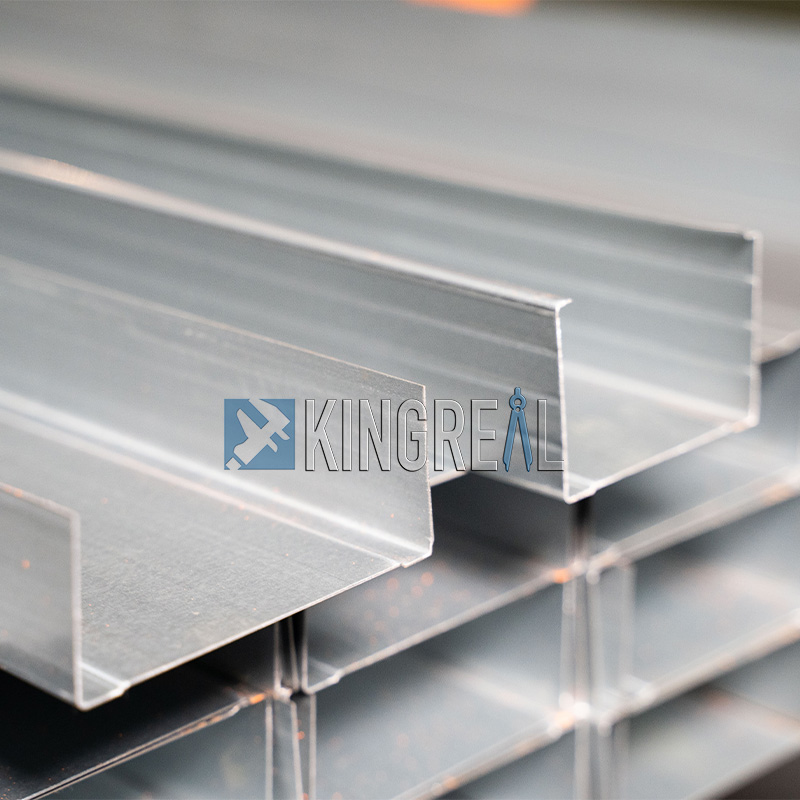

Drywall partition machine, also known as stud and track machine, are essential equipment in the modern construction industry. These drywall partition making machines are specifically designed to manufacture the metal studs and tracks required for drywall partition systems. By automating the production of frame components, these drywall partition machines improve the efficiency and precision of interior wall construction.

How Do Drywall Partition Machines Manufacture Stud and Track?

1. Material Feeding: The drywall partition making machine is equipped with an advanced feeding system that continuously supplies galvanized steel coils or other suitable metal materials. The feeding process is automated, greatly improving efficiency and ensuring continuous production. Through the material feeding system, the metal coils are quickly and accurately fed into the roll forming machine. Because the material supply is continuous, the drywall partition machine can operate continuously under high load conditions, producing a large amount of partition materials to meet the needs of rapid construction.

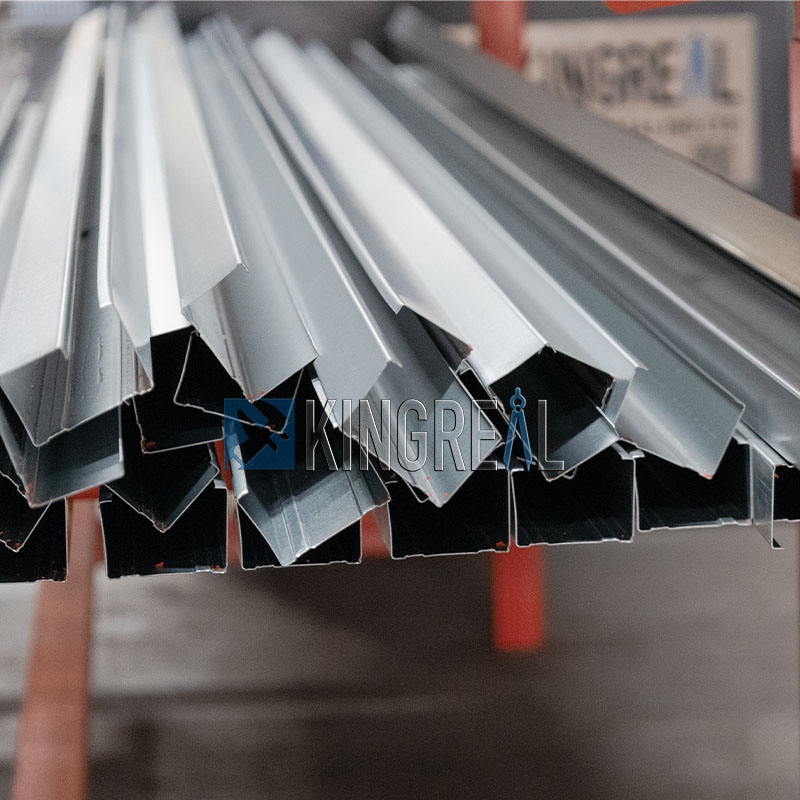

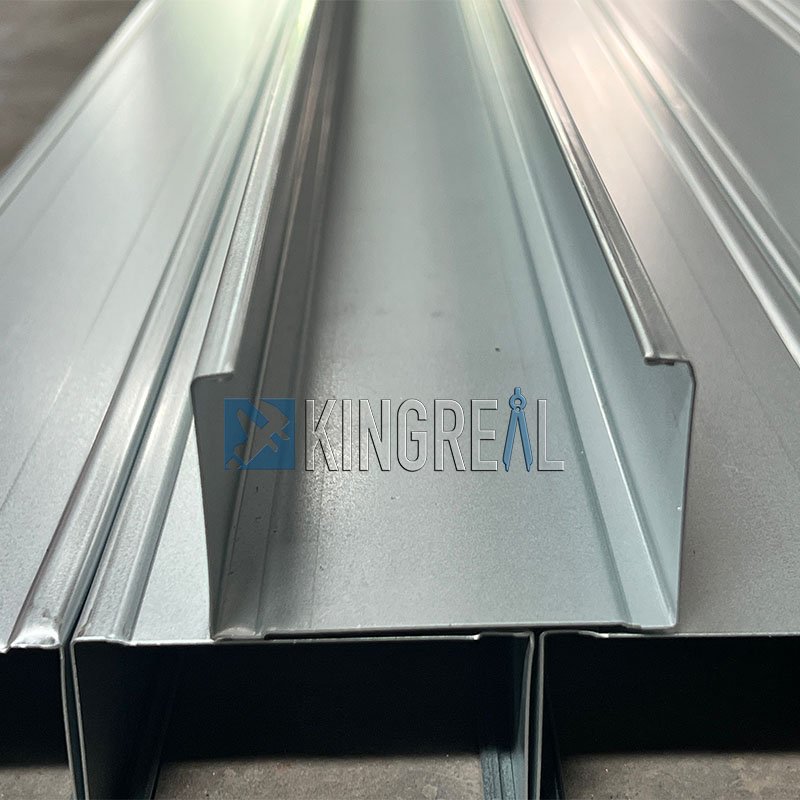

2. Roll Forming: As the metal material passes through the roll forming machine, it goes through a series of precisely designed rollers. The roll forming process is the core of the drywall partition making machine, gradually shaping the material into the desired cross-sectional shape using the rollers. For the production of studs and tracks, the design of the rollers is crucial; they are precisely calculated to create metal components of specific sizes and shapes. During the forming process, the rollers not only provide the basic shape for the studs and tracks but also process the flanges, edges, and embossing to enhance their strength and rigidity. This design ensures that the manufactured metal components remain stable under load and vibration conditions, greatly improving the durability of the partition system.

3. Punching and Cutting: After the stud or track reaches the preset length, the flying shear system of the drywall partition machine operates on the material. A fly shearing is typically used to quickly and accurately cut the formed metal components to the required length. The punching station then punches holes in the studs and tracks, facilitating the passage of electrical wires, pipes, and other utilities. In this way, the drywall partition machine not only improves production efficiency but also provides great convenience for subsequent construction stages. Through the smooth completion of these processes, the drywall partition making machine can provide high-quality, compliant metal components to the construction site, ensuring that the construction team can efficiently complete wall installation.

4. Stacking and Packaging: The workflow of the drywall partition machine doesn't stop after cutting and punching. After the metal components are formed, cut, and punched, the drywall partition making machine can automatically stack and package the finished products. This process ensures the safety and stability of the products during transportation. Drywall partition machines equipped with a packaging machine can achieve automated stacking and bundling, significantly reducing the difficulty and cost of subsequent manual transportation. This automated design improves production efficiency while also guaranteeing product quality, ensuring that each batch of metal components arrives at the construction site in optimal condition.

What are the Advantages of Using KINGREAL Drywall Partition Machines?

1. Increased Efficiency: Using KINGREAL drywall partition machine, the manufacturing process is highly automated, equipped with an intelligent servo drive system, achieving a production speed of up to 120m/min and a daily capacity of 60 tons. This technology significantly improves production efficiency, quickly meeting the bulk demand for partition wall studs in large construction projects. Compared to traditional equipment, the drywall partition making machine can produce a large quantity of high-quality metal studs and tracks in a short time, significantly shortening the construction cycle and reducing labor input, thereby improving overall work efficiency.

2. Improved Accuracy and Precision: The drywall partition machine is equipped with a high-precision detection system to ensure the accuracy of metal components during forming, cutting, and punching. Each component's dimensions and hole positions are strictly controlled, guaranteeing product consistency. This precision is especially important on the construction site, ensuring easy installation and the stability of the final wall structure.

3. Increased Flexibility: The modular design of the drywall partition making machine allows it to flexibly adapt to different needs. By adjusting the rollers and molds, users can produce metal studs and tracks of different sizes and shapes according to project requirements. This flexibility not only improves production efficiency but also expands the market adaptability of the drywall partition machine, especially in high-end customized projects. The advanced cutting system can achieve millimeter-level precision cutting according to set length parameters, strictly controlling errors within a very small range. At the same time, high-precision roll forming technology ensures that the studs have a flat and smooth surface and consistent dimensions, with a cumulative error of no more than ±1 mm for 16-meter-long studs, meeting the stringent standards of the construction industry.

4. Convenient Switching: The drywall partition making machine adopts a modular quick-change design, allowing mold changes to be completed within 30 minutes, compatible with the production of stud, track, and other specifications of profiles. The advanced operating interface allows users to preset programs, instantly switching between the production of different specifications of studs, reducing the stud specification switching time from the original average of 2 hours to less than 10 minutes.

5. Improved Cost-Effectiveness: Using the drywall partition machine for in-house production of metal studs and tracks can significantly reduce the cost of purchasing finished products and minimize material waste. At the same time, in-house production capabilities help to better control the supply chain, allowing projects to quickly respond to changes and adjust production plans in a timely manner, further improving overall economic efficiency.

Are you looking for a high-quality drywall partition making machine for your business? Browse KINGREAL product range or contact KINGREAL friendly customer service team today to discuss your needs.