How does a drywall profile machine work?

2025-06-27 12:00Drywall profile machines are one of the essential roll forming machines in the construction industry. These drywall stud and track machines are used to make frames for building walls, providing support and stability to the walls. In this article, KINGREAL will discuss various aspects of drywall profile machines with you, including its production process, advantages, potential applications, and more. |  |

How Does a Drywall Stud and Track Machine Work?

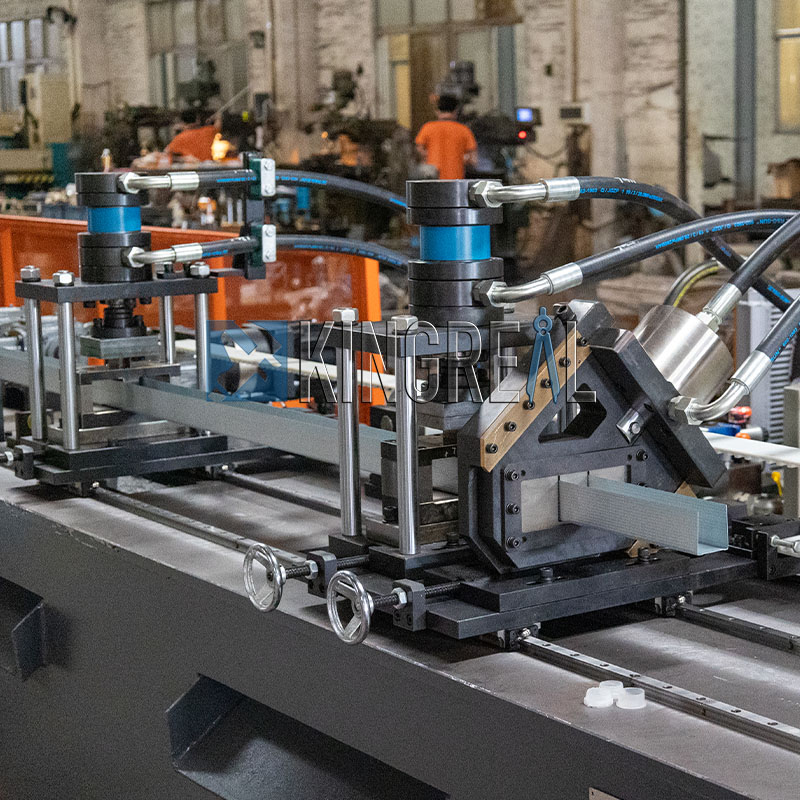

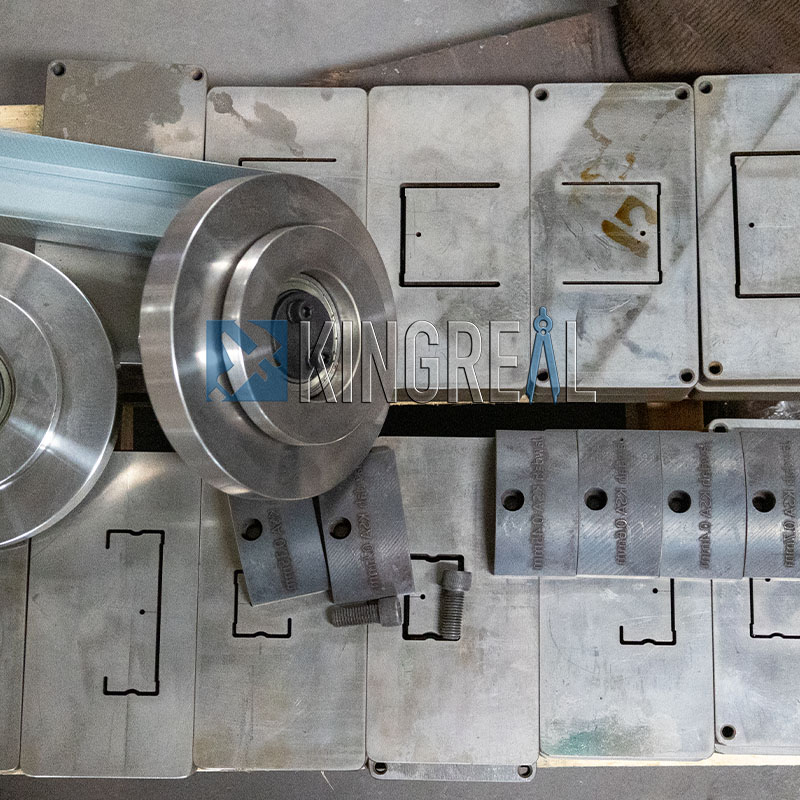

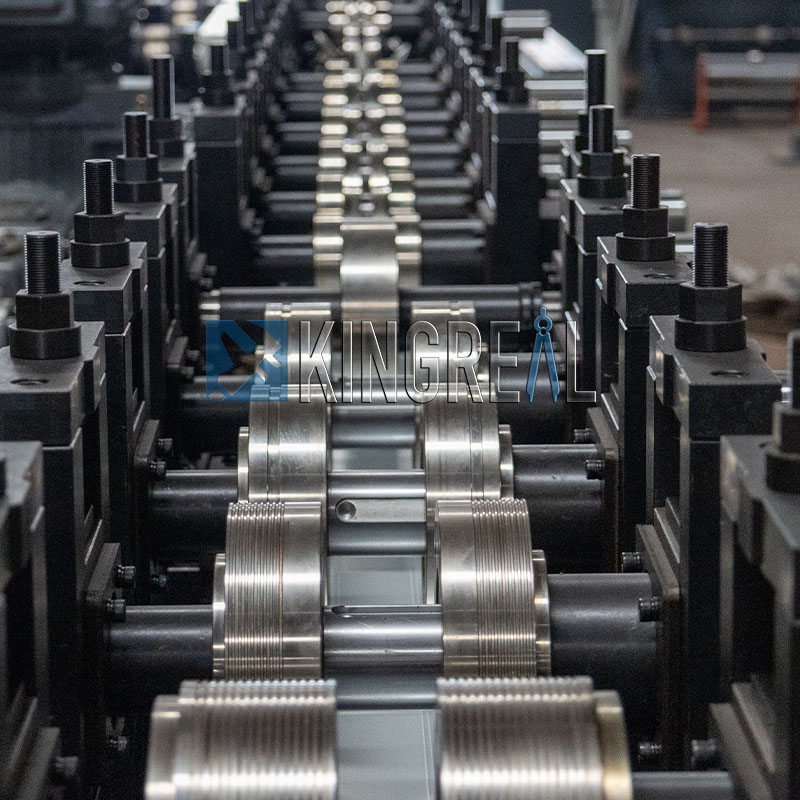

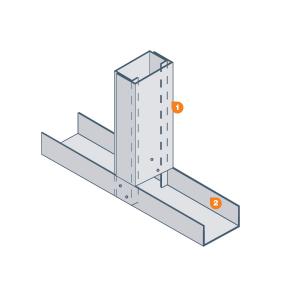

The drywall profile machine uses a series of rollers to form and cut metal coils into the required profile shape. The drywall stud and track machine can manufacture different profiles of different sizes, including u track and c stud. The manufacturing process of these profiles is to feed a continuous metal coil into the machine, which is then formed and cut by rollers. The process is automated, and the drywall profile machine can produce profiles at high speed.

The metal coils used in drywall stud and track machines are usually made of galvanized steel or aluminum. Galvanized steel is favored for its high strength, durability, and corrosion resistance, while aluminum is favored for its light weight and flexibility. Both materials are widely used in the construction industry and are ideal for making drywall profiles.

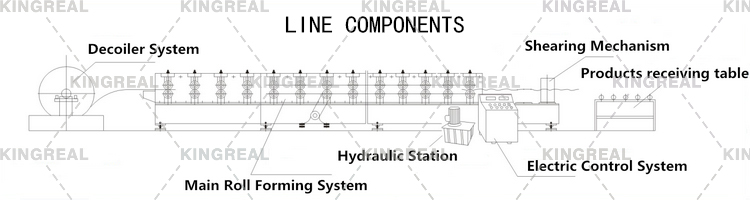

Workflow of Drywall Profile Machine

Decoiler -- Main Roll Forming Machine -- Hydraulic Fly Punching and Shearing Station -- Product Table |

|

Advantages of Drywall Stud and Track Machine

①Highly flexible drywall profile machine KINGREAL drywall stud and track machine can produce two types of finished products, u track and c stud, by adjusting the rollers of the roll forming machine. This dual function not only improves production efficiency, but also allows customers to flexibly adjust the drywall profile machine according to the needs of different construction projects. . For example, in projects that require fast delivery, customers can choose to produce c stud, and when higher strength structures are required, they can switch to u track. This adaptability greatly enhances the competitiveness of customers and helps them gain an invincible position in the market. In addition, the design of the drywall stud and track machine also takes into account the ease of operation. Users only need simple operation training to be proficient in using it, which further reduces the threshold for use. |  |

②High-speed drywall profile machine KINGREAL drywall stud and track machine can achieve a maximum production speed of 120 m/min, which is far higher than the efficiency of traditional manual profile making. Through the automated production process, customers can not only significantly reduce production time, but also minimize labor costs. The profile production that used to require multiple workers to complete can now be completed independently by only one drywall profile machine. More importantly, automated production brings not only speed improvement, but also consistency of product quality. Traditional manual production often leads to inconsistency of profiles due to human factors, increasing the risk of rework and material waste. KINGREAL drywall stud and track machine can maintain stable production quality at high speed to ensure that each profile meets the standard requirements. This consistency allows customers to be more assured in subsequent construction and reduces construction delays caused by material problems. |  |

③ Multi-specification drywall profile machine In order to meet the needs of different projects, KINGREAL drywall stud and track machine has the ability to produce in multiple specifications. By simply adjusting the width of the required finished product on the control panel, the roller of the roll forming machine will automatically expand to the corresponding width for production. This design not only improves the flexibility of production, but also allows customers to respond quickly when faced with different specifications. For example, in some projects, customers may need wider drywall profiles to carry greater loads, while in other cases narrower drywall profiles are required to save materials and costs. This multi-specification adaptability allows customers to flexibly choose in different projects, optimize resource allocation, and improve overall economic benefits. In addition, the automatic adjustment function of the drywall profile machine also greatly reduces the debugging time, making the production process smoother. |  |

④ Highly automated drywall profile machine KINGREAL drywall stud and track machine can be equipped with an automatic packaging unit to complete the full process automation from production to packaging. After the dyrwall profile is produced, the finished product will be automatically transported to the packaging machine for bundling and stacking. This automated design not only improves production efficiency, but also ensures the safety of the finished product during transportation. The introduction of the automatic packaging unit eliminates the heavy manual packaging work, and the staff can devote more energy to other more important tasks. At the same time, the automation system can ensure that each batch of products is packaged according to uniform standards, reducing the risk of errors that may be caused by manual operation. |  |

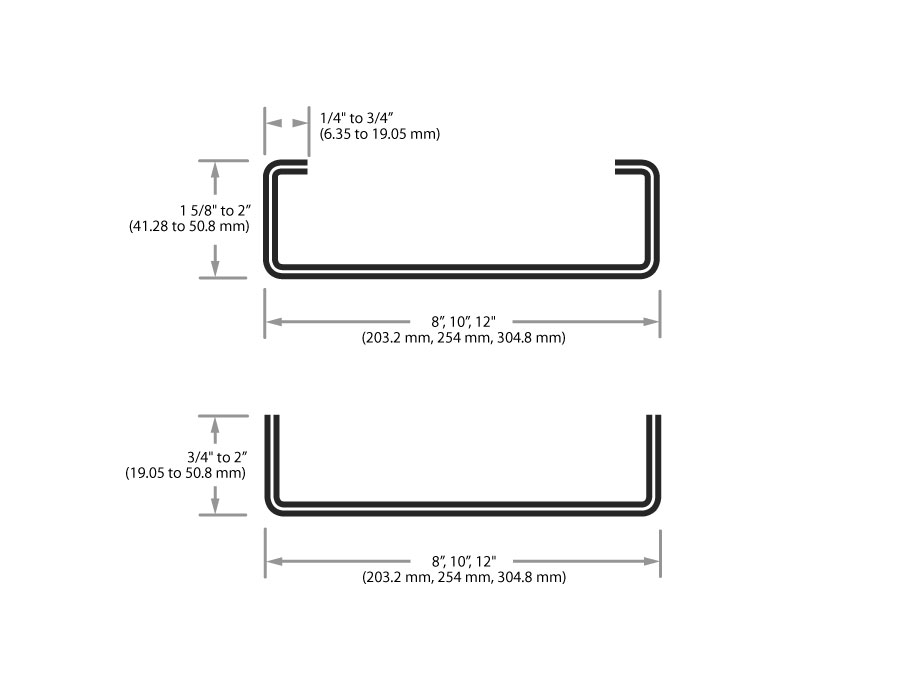

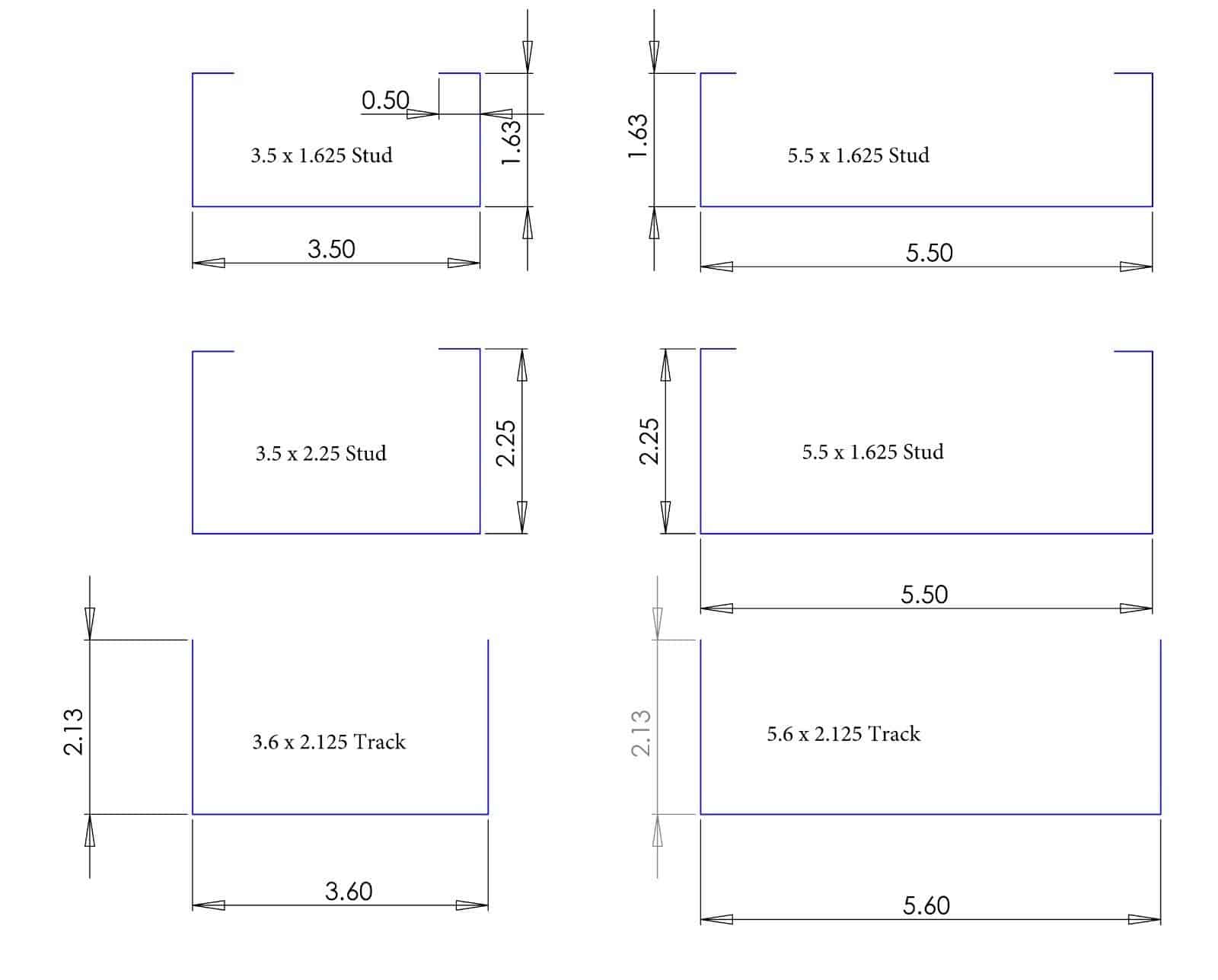

Drawing about Drywall Profile

Drywall stud and track machines usually process galvanized sheets in the thickness range of 0.35-1.0MM or roll-coated sheets in the thickness range of 0.35-1.0MM as raw materials.

|  |  |

Potential Applications of Drywall Profile Machine

Drywall stud and track machines have a variety of potential applications in the construction industry. Some of these applications include: Residential construction: Drywall profile machines are widely used in residential construction to build the frame of the wall. Commercial construction: Drywall stud and track machines are also used in commercial construction to build partition structures. Renovation: Drywall profile machines can be used in renovation projects to replace damaged or outdated profiles. Industrial construction: Drywall stud and track machines can be used in industrial construction projects to build metal structures for warehouses, factories and other industrial buildings. |  |