How does an aluminum ceiling tile production line operate?

2025-05-16 12:00

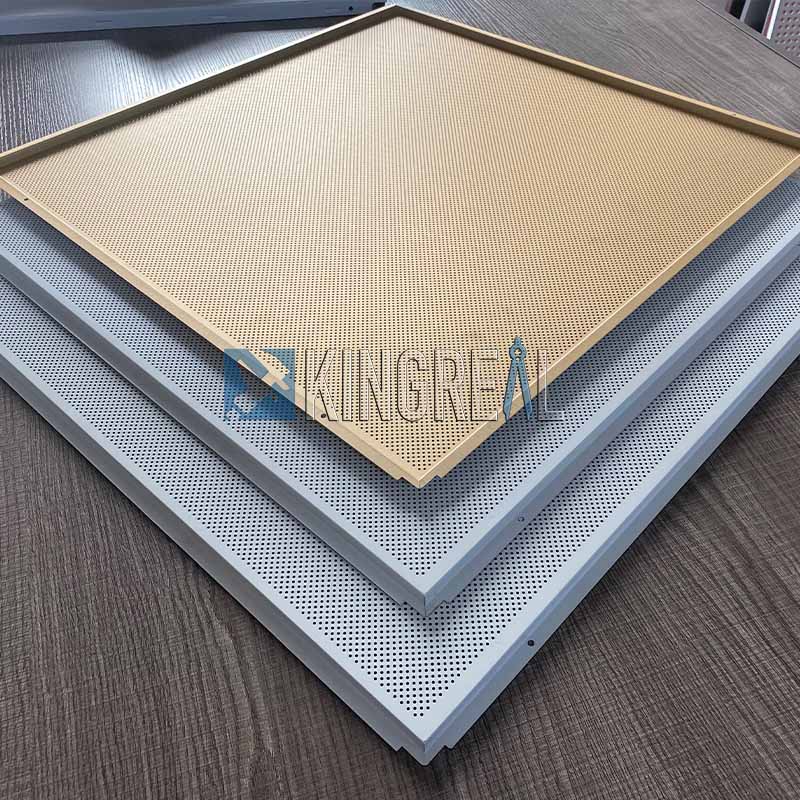

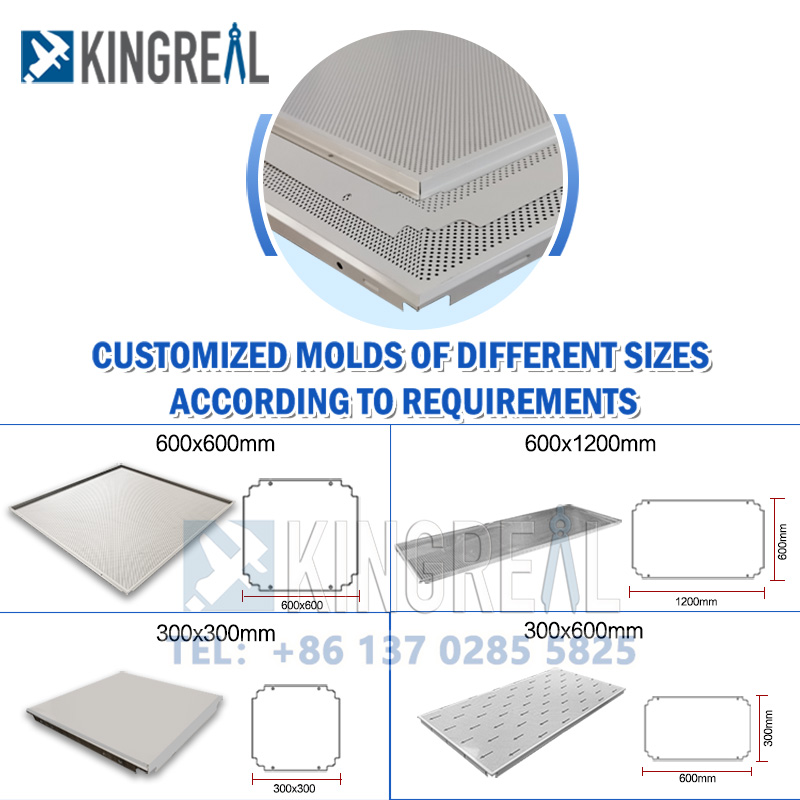

Aluminum ceiling tile production line is a combination of equipment specifically used to process metal aluminum coils into various aluminum ceiling tiles. Through a series of advanced mechanical components such as Hydraulic Decoiler, Precision Straightener, Punching Machine, Servo Feeding Machine,Notching And Shearing Press, 2nd Precision Straightener, Flipping machine, Automatic tiles feeding machine, Auto Bending Forming Machine, this aluminum ceiling tile machine can efficiently produce metal ceiling panels of various sizes such as 600x600mm, 300x300mm, 300x600mm, 300x1200mm, 600x1200mm, etc., covering different types such as Lay In metal ceiling panel, Lay On metal ceiling panel, Clip In metal ceiling panel and Tegular metal ceiling panel. This article will introduce in detail how the aluminum ceiling tile production line works, the advantages of the aluminum ceiling tile machine, and the advantages of aluminum ceiling tiles.

How the Aluminum Ceiling Tile Machine Works?

The operation process of the aluminum ceiling tile production line is a highly automated process designed to improve production efficiency, reduce manual operations, and thus reduce production costs. The following is the specific workflow of this aluminum ceiling tile machine:

1. Decoiler for aluminum ceiling tile machine

The production process starts with a hydraulic decoiler, which is responsible for unrolling the metal aluminum coil to ensure smooth material supply. The design of the decoiler can automatically adjust to adapt to aluminum coils of different diameters to ensure the continuity of the aluminum ceiling tile production line.

2. Precision leveling machine for aluminum ceiling tile production line

The unrolled aluminum coil enters the precision leveling machine, which corrects the corrugations and bends in the coil to make it flat. Flat aluminum plates are an important basis for subsequent processing. Only by ensuring the flatness of the material can high-quality metal ceiling boards be produced.

3. Punching machine for aluminum ceiling tile machine

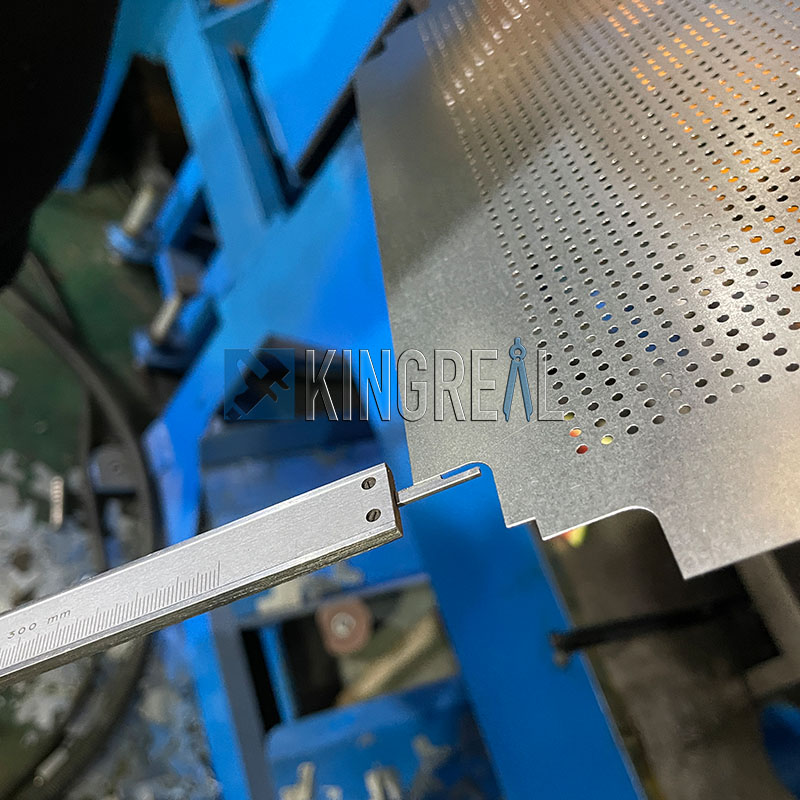

The flattened aluminum plate is then sent to the punching machine. The punching machine for aluminum ceiling tile machine punches the aluminum plate according to the design requirements to facilitate subsequent processing steps. The diameter and shape of the punching can be adjusted according to customer needs to ensure that different design requirements are met.

4. Notching and shearing press for aluminum ceiling tile machine

The aluminum plate then enters the notching and shearing press according to the preset size. This step ensures that the size of each aluminum ceiling board is accurate and meets the design standards.

5. 2nd Precision Straightener for aluminum ceiling tile production line

After cutting, the aluminum ceiling tile machine will perform secondary leveling on the aluminum plate to ensure the straightness of the aluminum plate.

6. Flipping machine & Automatic tiles feeding machine for aluminum ceiling tile machine

The formed aluminum ceiling tile is processed by the flipping machine for subsequent automatic feeding. The flipping machine can automatically flip the metal ceiling board to ensure smoothness on the aluminum ceiling tile production line.

7. Auto bending forming machine for aluminum ceiling tile machine

The aluminum plate will be fed into the automatic bending forming machine. In the forming press, the aluminum plate is finally formed after a high-precision one-time pressing to ensure the quality of the finished product.

Advantages of Aluminum Ceiling Tile Production Line

The design and construction of thealuminum ceiling tile machine give it obvious advantages in function and efficiency. The following are several main advantages of this aluminum ceiling tile production line, elaborating on its technical characteristics and market value.

1. Flexible mold replacement On the same aluminum ceiling tile machine, Clip In metal ceiling tiles and Lay In metal ceiling tiles can be easily produced by changing the mold. This flexibility enables the aluminum ceiling tile production line to adapt to diverse market demands and meet the requirements of different customers. Customers can quickly switch to produce different types of metal ceiling panels according to market trends and order requirements, which enhances the efficiency and flexibility of the aluminum ceiling tile machine. |  |

2. Fast production speed The production speed of the aluminum ceiling tile production line is very fast, from unwinding to discharging (including perforation), the production speed is about 5-6 pieces per minute. This efficient production capacity enables enterprises to meet the needs of a large number of orders in a short time, especially suitable for a rapidly changing market environment. The fast production process not only increases output, but also effectively reduces unit production costs and improves the profitability of enterprises. |  |

3. Multi-size production capacity The aluminum ceiling tile machine is able to produce aluminum ceiling boards of different sizes by changing molds to adapt to the diverse product needs in the market. This flexibility allows customers to quickly adjust production plans according to market changes, thereby meeting customer needs for metal ceiling panels of different specifications. Whether it is small batch customization or large-scale production, the aluminum ceiling tile production line can respond quickly and provide efficient solutions. |  |

4. High-precision processing Each equipment of the aluminum ceiling tile production line adopts advanced technology and high-precision mechanical components to ensure high accuracy of each production step. The use of precision leveling machines and servo feeders ensures the stability and consistency of aluminum plates during processing. This high-precision processing capability not only improves product quality, but also reduces material waste, thereby reducing production costs. |  |

5. High degree of automation The automated design of the aluminum ceiling tile machine greatly reduces manual operation and improves production efficiency. The automated equipment in each link can achieve seamless docking, reduce manual intervention, and reduce the risk of operational errors. Automated production also enables companies to save money on personnel costs and improve overall operational efficiency. |  |

Advantages of Aluminum Ceiling Panels

Aluminum ceiling boards not only have excellent physical properties, but also have excellent aesthetics and practicality. Here are some of the main advantages of aluminum ceiling tiles:

Lightweight and durable: Aluminum makes the metal ceiling board light and durable, suitable for long-term use without deformation.

Fireproof performance: Aluminum ceiling tiles have good fireproof performance and can effectively improve the safety of buildings.

Easy to clean: The aluminum ceiling board has a smooth surface, is easy to clean and maintain, and is suitable for use in various places.

Beautiful and diverse: Aluminum ceiling panels can be designed in a variety of ways according to customer needs, suitable for decoration in different styles.