New Design: Roof Sheet Making Machine with Auto Stacker

2024-12-24 14:22

Video About Roof Sheet Making Machine

Video About Roof Sheet Making Machine

Definition of Roof Sheet Making Machine

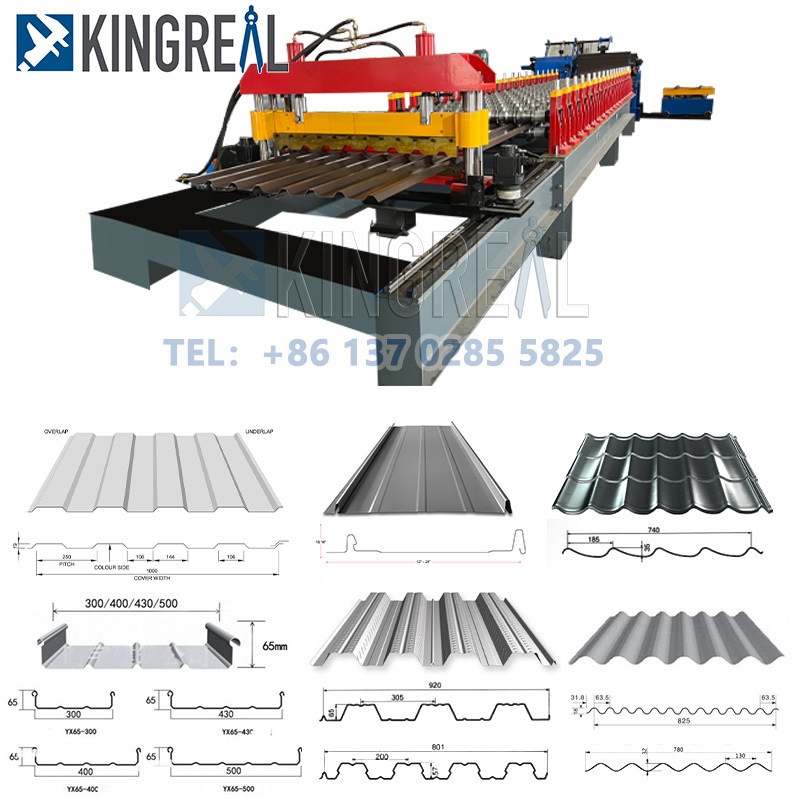

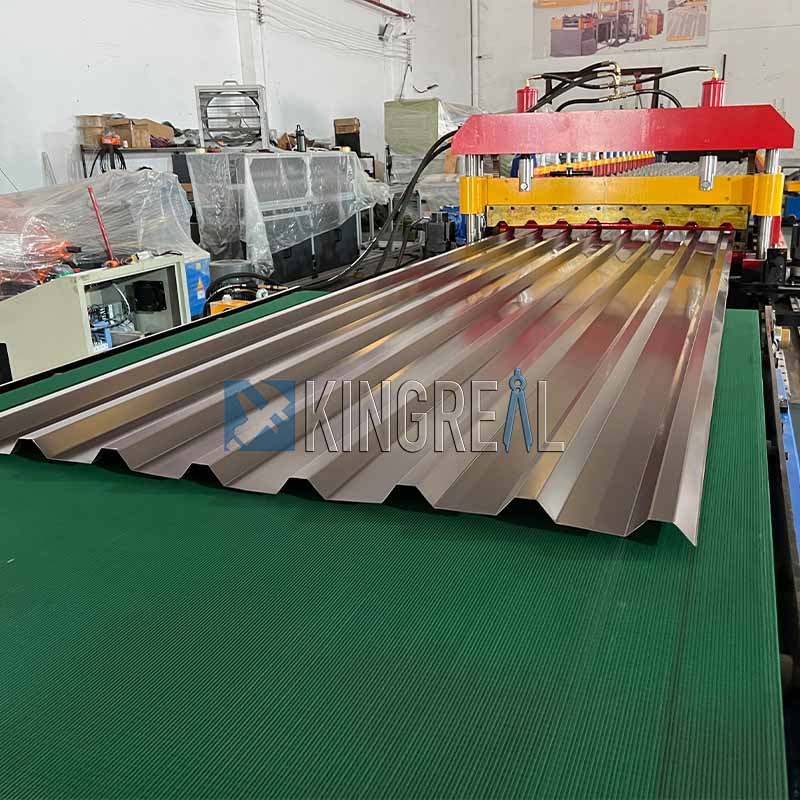

Metal roof panel roll forming machine is composed of decoiler, roll forming machine, and cutting station. The metal roof panels it produces have a smooth and beautiful appearance, uniform paint pattern, high strength, and excellent durability. They are widely used in industrial and civil construction fields, including roof and wall construction of factories, warehouses, gymnasiums, exhibition halls, theaters, etc.

KINGREAL roof sheet making machine is a high-end equipment that can produce various types of metal roof panels, such as glazed tiles, curved tiles, IBR panels, etc. Due to its excellent drainage performance, optimal weight bearing capacity, corrosion resistance and durability, the roof panels produced by KINGREAL metal roof panel roll forming machine have become the preferred material for house construction in Africa. And KINGREAL roof sheet making machine is compatible with a variety of raw materials, including GI,GL,PPGI,PPGL,Aluminum coils, which can meet the diverse needs of different customers. In addition, KINGREAL roofing sheet machines are favored by customers for their high-speed production, fully automated operation and high-precision finished products, which not only improves production efficiency, but also significantly reduces labor costs. |  |

New design - KINGREAL roof sheet making machine equipped with automatic stacker

KINGREAL has been redesigning the machine to better meet customer needs. Through KINGREAL engineers' market research and customer feedback, it was found that after customers produce metal roofs through roof sheet making machines, workers are required to carry, stack and pack the heavy finished products, which is time-consuming and labor-intensive.

KINGREAL engineers believe that such metal roof panel roll forming machines cannot be called automated equipment. Therefore, in order to better improve customer production efficiency and meet the market to the greatest extent, KINGREAL launched a fully automatic metal roof panel roll forming machine equipped with a stacker. |  |

KINGREAL roof sheet making machine equipped with automatic stacker can do:

⭐Intelligent production process: After the roof sheet making machine completes the production of roof panels, the finished products are accurately transported to the stacker through the automatic conveying system.

⭐Efficient packaging and neat stacking: The stacker can quickly complete the packaging and stacking of finished products, ensuring that the finished products are neatly arranged and firmly packaged.

⭐No manual intervention throughout the process: The entire process does not require manual handling and operation, which completely liberates human resources and greatly reduces labor costs and time costs.

⭐Reduce safety hazards: The design of the automatic stacker minimizes the number of manual interventions and significantly reduces safety risks.

Other advantages of KINGREAL roof sheet making machines

In addition to being equipped with automatic stackers, KINGREAL metal roof tile machines have the following advantages:

High precision In the process of manufacturing KINGREAL metal roof panel roll forming machines, technicians grind the rollers of the roll forming machine at least twice, which ensures that the roller surface is hard and wear-resistant and extends the service life of the equipment. In addition, the number of rollers is sufficient, usually reaching 18-20 rollers, which effectively ensures the consistency of the finished product size and appearance. |  |

Can bear a maximum of 10 metric tons of metal raw materials Generally, tile machines on the market can carry or process up to 5,000 metric tons of metal coils. In order to better meet the production and processing needs of customers, KINGREAL engineers have designed a tile machine that can carry a maximum coil weight of 10 metric tons. |  |

Fast production speed

KINGREAL metal roof panel roll forming machine has a fast production speed, up to 45m/min. It improves production efficiency for customers and meets the needs of mass production. |  |

Various types of finished products can be produced KINGREAL metal roof panel roll forming machine can produce different types of tiles, such as glazed tiles, ibr, corrugated tiles, etc., to meet the different needs of each customer. |  |