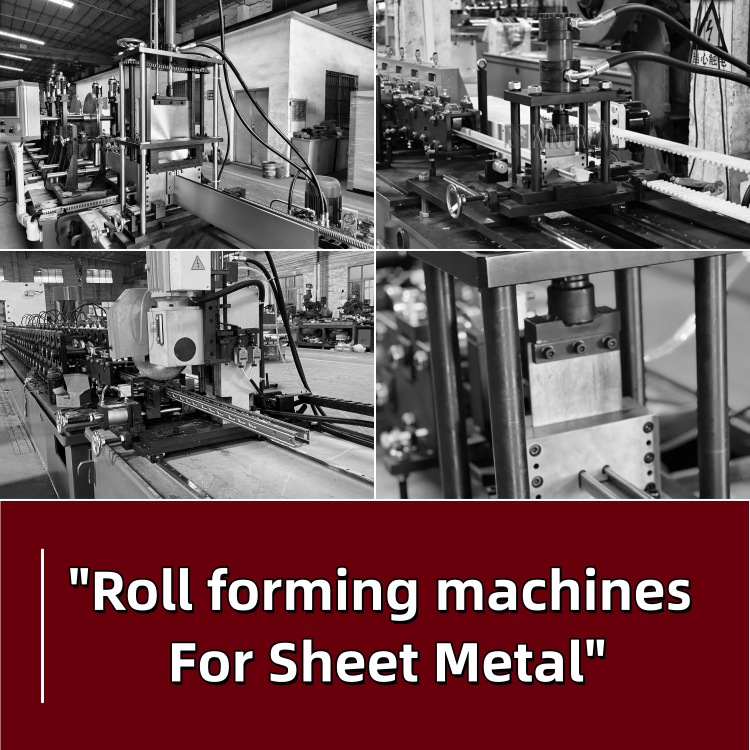

Roll Forming Machines For Sheet Metal

2025-10-29 17:38With the accelerated development of industrialization, the sheet metal processing industry plays an increasingly important role in modern manufacturing. Sheet metal processing is not only the foundation of manufacturing but also a core link in many high-tech industries. Sheet metal processing technology is always developing as demand for materials increases in industries including construction, automotive, aviation, and electronics. creative to satisfy ever more sophisticated market requirements. Particularly against the backdrop of growing intense worldwide rivalry, companies must quickly raise product quality and production efficiency to keep their competitive edge.

As a professional manufacturer of roll forming machines, KINGREAL is committed to providing high-precision, high-efficiency forming solutions to meet the diverse needs of customers. KINGREAL roll forming machines can process not only thin, medium-thick, and precision materials but also handle the production challenges of complex profiles, ensuring high quality and consistency of finished products. Whether used in the construction industry for ceiling and wall support structures or in various metal processing fields, KINGREAL roll forming machines play an indispensable role.

KINGREAL roll forming machines are widely used in multiple fields. These include:

1. Suspended Ceiling Making Machine

These roll forming machines are designed specifically for producing various types of suspended ceilings, meeting the diverse market demands for ceiling materials.

2. Ceiling Gypsum Board Frame Machine

These roll forming machines are used to produce ceiling t bar, a crucial component of suspended ceiling systems, ensuring their stability and aesthetics.

KINGREAL drywall profile forming machines are specifically designed to produce stud and track that support walls, helping customers achieve efficient construction in their building projects.

4. Pallet Upright Rack Roll Forming Machine

The combination of shelf panel making machines and warehouse pallet rack machines is designed to achieve the optimal balance of productivity and flexibility, suitable for a variety of warehousing and commercial environments.

5. Solar Channel Making Machine

Designed specifically for the production of photovoltaic brackets, these roll forming machines produce profiles for securing solar panels, supporting the development of renewable energy.

In these applications, KINGREAL roll forming machines help customers maximize productivity and optimize resource utilization with their superior performance and flexible configuration.

How a Roll Forming Machine Works?

The operating principle of a roll forming machine is relatively simple yet highly efficient. Its primary function is to unwind and flatten large coils of metal, gradually processing them into finished parts or profiles. The detailed process is as follows:

-Unwinding and Flattening: The raw material is fed into the roll forming machine in coil form, where it is first unwound by an unwinding device and then flattened by a flattening device.

-Roll Forming: The material is then fed onto a powered tandem roller conveyor, which gradually forms the material into the desired profile shape. The roll forming process is continuous, with the material passing through multiple rollers, ensuring the precision and consistency of the finished product.

-Cutting and Forming: After processing, the roll forming machine can cut the finished product to the desired length using an in-line cutting device, ensuring that each product meets the customer's exact production requirements.

Complete Roll Forming Machine Solutions

KINGREAL roll forming machines are designed to enable the complete production process of finished products. Each roll forming machine incorporates multiple processes, such as feeding, roll forming, punching, and bending, enabling customers to complete multiple operations on a single piece of roll forming machine. State-of-the-art roll forming machines are also equipped with automated packaging systems to enhance production efficiency.

1. Completely In-House Roll Forming Machines

All KINGREAL roll forming machines utilize high-quality components manufactured entirely in-house. Inspection and verification are conducted at all times during the production process to ensure that each roll forming machine meets KINGREAL quality standards. Equipped with state-of-the-art machinery and technologies, the KINGREAL workshop guarantees the production of every part to the utmost accuracy.

2. Traceability of the Production Process

The KINGREAL team rigorously monitors every stage of production, ensuring project progress adheres to schedule and providing full roll forming machine traceability. This strict administration guarantees product consistency and dependability in addition to increasing production efficiency.

Metal Forming Experts

With over 20 years of experience in sheet metal roll forming, KINGREAL provides professional forming solutions to customers worldwide. KINGREAL roll forming machines encompass a variety of technologies to meet the processing needs of diverse materials or profiles. For example, KINGREAL roll forming machines can process a variety of materials, including stainless steel, steel, aluminum, PPGI, galvanized steel, and iron, with thicknesses ranging from 0.35mm to 5mm and even thicker.

1. High-Performance Roll Forming Machine Design

To maximize production and efficiency, KINGREAL roll forming machines use a great deal of cutting-edge technology and automation. This optimizes raw material use and labor costs in addition to enhancing energy efficiency. Meeting the different demands of KINGREAL customers, KINGREAL roll forming machine offers outstanding performance across a broad spectrum of uses.

2. Flexible Production Systems

KINGREAL roll forming machines offer flexible designs, suitable for a wide range of production scenarios, from small batches to large-scale production. KINGREAL product offering includes a variety of technologies, including in-line cutting, punching, and packaging systems, ensuring optimal operation and efficiency throughout the production process.

Roll forming machines are playing an increasingly important role in modern manufacturing. As an industry-leading roll forming machine manufacturer, KINGREAL is committed to providing customers with high-quality, efficient forming solutions. KINGREAL roll forming machines are suitable for processing a wide range of metal materials and meet the diverse needs of diverse markets.

Welcome to contact KINGREAL at any time to learn more about roll forming machines.