Solar Channel Machine for Solar Frames

2026-01-12 19:00With the ever-increasing global demand for clean energy, the photovoltaic (PV) industry is undergoing a rapid and profound transformation. As a crucial component of PV systems, PV mounting systems bear the weight of solar modules and ensure their stability and safety under various environmental conditions. To meet the growing demands of the PV market, solar channel machine plays a vital role throughout the entire production chain. A PV system consists of multiple components, and the solar channel is one of these core components. It directly supports and bears the weight of the solar modules, effectively distributing the load to ensure the entire system performs well in various climatic environments. Commonly used cu solar channels possess high strength and corrosion resistance, enabling them to withstand the challenges of wind and harsh weather, thus guaranteeing the stability and long-term reliability of the PV system.

▍The Role of Solar Channel Machine for Solar Frames

CU solar channels are not only the basic structure of a PV system, but they also directly affect the overall performance and power generation efficiency of the system. Therefore, the role of cu solar channel machine in this process becomes particularly important. This solar channel machine can efficiently produce various types of cu solar channel modules, thereby improving the reliability of PV system installation and use.

1. Materials and processing technology of KINGREAL solar channel machines

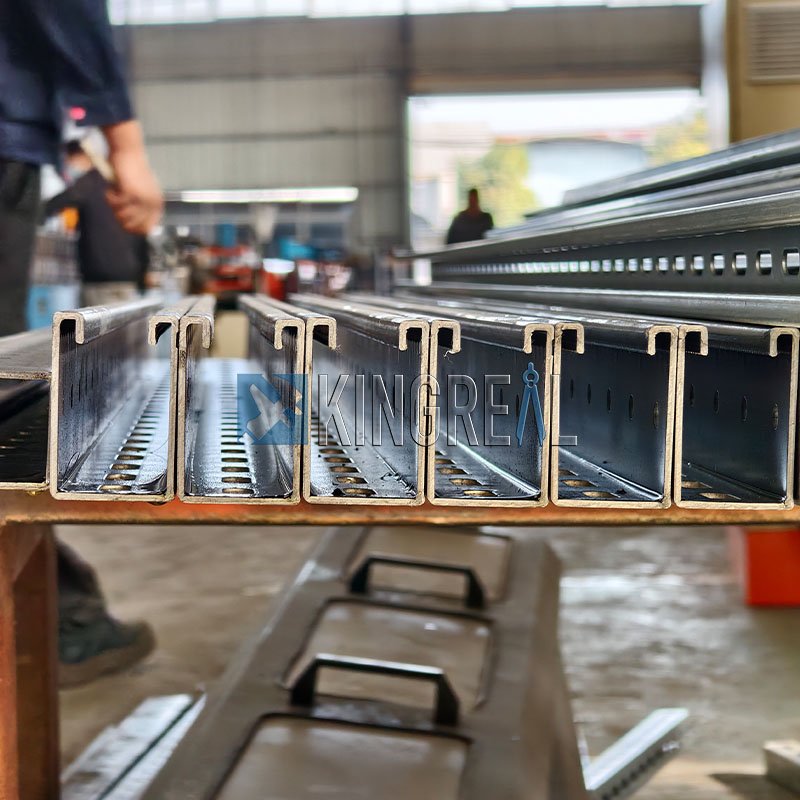

KINGREAL cu solar channel machines are capable of processing a variety of materials, including hot-rolled steel, cold-rolled steel, and aluminum. This flexibility allows for the production of various types of cu solar channels, such as solid, slotted, and perforated designs. These cu solar channels are renowned for their high strength and durability, adaptable to multiple installation environments.

By manually changing the gaskets, this cu solar channel machine can efficiently produce channel sizes such as 40 x 21, 41 x 41, and 41 x 62. This flexible production capability not only shortens changeover time and improves production efficiency but also enables faster delivery of photovoltaic projects. In an increasingly competitive market, a solar channel machine that can quickly respond to customer needs is key to success.

2. CU solar channel and module integration

KINGREAL solar channel machines produce cu solar channels with high compatibility, seamlessly integrating with photovoltaic modules, bases, plastic wing nuts, and other auxiliary components to form a complete photovoltaic system. This interchangeability significantly improves the power generation efficiency and operational stability of the photovoltaic system. During installation, high-quality cu solar channels can withstand the weight of the solar modules and effectively resist wind and other external interference, ensuring the long-term reliable operation of the photovoltaic power generation system. It is worth noting that with technological advancements, the design of solar channels has been continuously optimized, making installation and subsequent maintenance more convenient and reducing the workload of construction personnel.

▍Multiple Applications of CU Solar Channel Machines

KINGREAL solar channel machine can produce various types of cu solar channels to meet the needs of different solar frames, such as solar carports and ground-mounted solar farms. These photovoltaic mounting systems are not only highly efficient in energy production but also provide shading solutions for carports. By combining photovoltaic mounting systems with carports, limited space can be utilized, and equipment efficiency can be improved. Furthermore, in rooftop solar systems, mounting systems produced by KINGREAL solar channel machines ensure the fixation of solar panels on the roof without affecting the structural integrity of the roof. This flexibility in system design means that photovoltaic power generation is not limited to large factories; residential users can easily install and enjoy the benefits of clean energy. By optimizing the mounting design, natural light can be better utilized, improving the efficiency of photovoltaic power generation.

▍Different Types of Solar Channel Machines for Solar Frames

KINGREAL cu solar channel machines can be highly customized to meet production speed and operational requirements. For most market projects, both the high-speed cu solar channel machine and the standard model are sufficient. The high-speed solar channel machine is equipped with a servo feeder for precise material handling, uses a hydraulic punch for rapid punching, and a flying saw cutting system for seamless, uninterrupted continuous production.

In comparison, the standard cu solar channel machine, while simpler to operate, also features hydraulic punching capabilities and a stop-and-cut system, allowing for automatic pausing before cutting. These technological advancements not only improve production efficiency but also enhance the precision and quality of cu solar channel production.

With continuous technological advancements and the expansion of the photovoltaic industry, solar channel machines will play an increasingly important role. In the future, intelligentization and automation will be the main trends in cu solar channel machine development. Research into the intelligentization of solar channel machines will likely enable more efficient production lines, reduce manual intervention, and improve production safety and stability.

KINGREAL has accumulated extensive experience in cu solar channel machine design and manufacturing, committed to meeting customers' individual needs and providing customized solar channel machine solutions. To improve work efficiency and product quality, KINGREAL equips cu solar channel machines with high-efficiency packaging machines, achieving automated strapping and stacking, significantly reducing labor costs. This not only improves work efficiency but also ensures the consistency and safety of finished products.

Furthermore, KINGREAL can add two sets of wheels to the roll forming machine to produce reinforced finished products, a design intended to enhance product robustness. Simultaneously, the solar channel machine can perform serration and punching processes during production, utilizing a specific design on the punching die for precise machining. This design not only enhances the product's friction, making it more stable during use, but also improves overall functionality.

If you would like to learn more about solar channel machines or specific product details, please feel free to contact KINGREAL. We are dedicated to providing you with professional consultation and service.