What are advantages of KINGREAL drywall profile machine?

2025-05-03 12:00

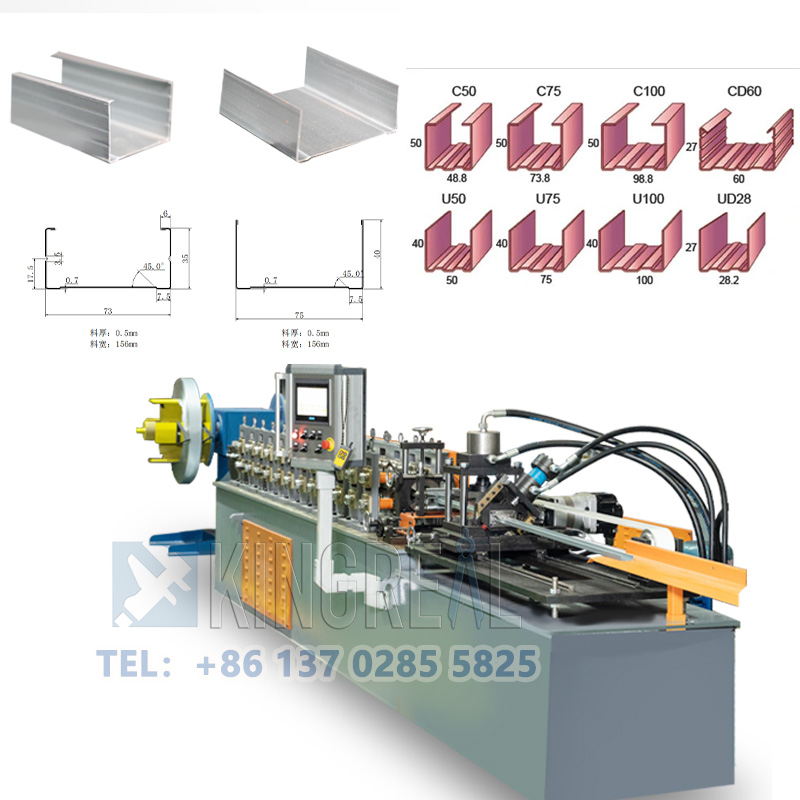

In the modern construction industry, the drywall profile machine is a key equipment that is gradually gaining favor among more and more builders and manufacturers. The drywall stud and track machine is designed for the production of galvanized steel non-load-bearing partition walls and has a wide range of applications, ranging from small residential to large commercial and industrial projects. KINGREAL can provide drywall profile machines with different configurations according to customer needs. If you are interested in KINGREAL drywall stud and track machines, please come and consult!

In this article, KINGREAL will discuss with you in detail the workflow of the drywall profile machine, the advantages of the drywall stud and track machine, and why you should consider investing in this drywall profile machine.

Introduction to Drywall Stud and Track Machine

The drywall profile machine is a special equipment for the production of drywall studs and tracks. It can produce studs and tracks of different sizes according to customer needs to meet various construction and decoration requirements. The design of this drywall stud and track machine makes it have the characteristics of excellent performance, low cost and long service life, suitable for production needs of all sizes.

Application range of Drywall Profile Machine

The drywall profile machine is widely used in residential, commercial and industrial buildings.

By using this drywall stud and track machine, builders can quickly and effectively manufacture standard studs and tracks, ensuring the efficiency and safety of the construction process. In modern buildings, the use of non-load-bearing partitions is becoming more and more common, and the market demand for drywall profile machines is also growing.

Workflow of Drywall Stud and Track Machine

The work flow of drywall profile machine is relatively simple, but it involves multiple links to ensure the quality and precision of the final product. The following is the main work flow of drywall stud and track machine:

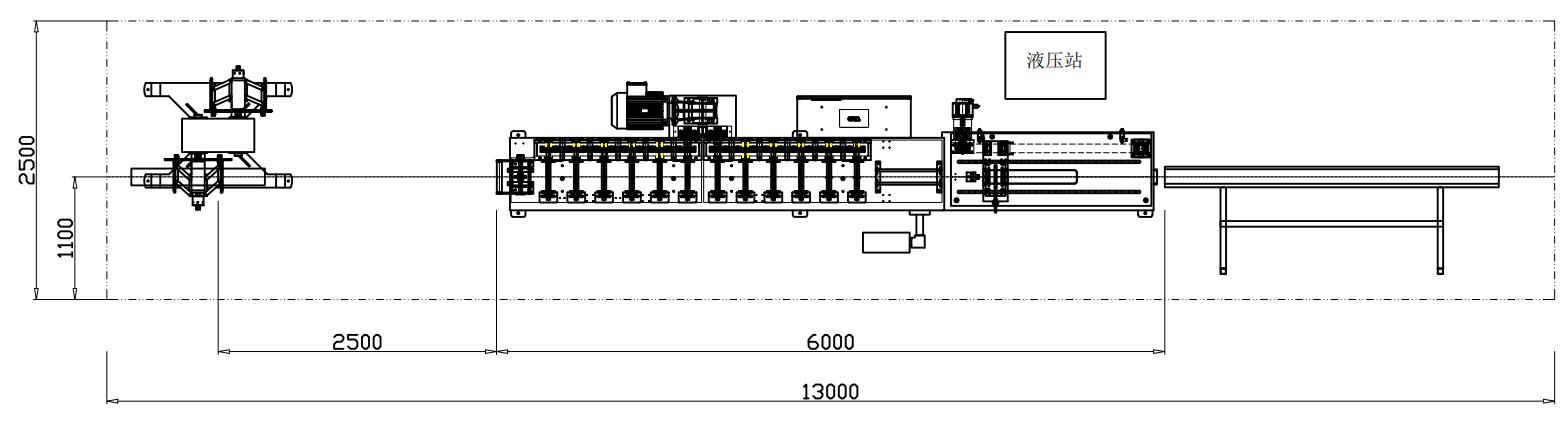

Decoiler for drywall profile machine: Unroll the coil and feed it into the main roll forming machine. This step is the starting link of the entire production process, ensuring the flatness and smoothness of the material.

Main Roll Forming Machine for drywall profile machine: The unfolded metal material is formed by a series of rollers to form it into the required studs and track shape. This process is the core of the entire drywall profile machine and determines the precision and appearance of the product.

Hydraulic Fly Punching and Shearing for drywall profile machine: During the forming process, the drywall stud and track machine will cut and punch the material. The hydraulic cutting system ensures the accuracy of cutting and the smoothness of the workpiece.

Product Table for drywall profile machine: Finally, the finished studs and tracks will be sent to the product table for subsequent packaging and transportation.

Advantages of Drywall Profile Machine

1. Automation system

KINGREAL drywall stud and track machine is equipped with an advanced automation system, the electrical panel is easy to operate, and provides manual and automatic working modes. Through the man-machine interface (MMI), the operator can easily select different working modes to achieve an efficient production process. This automation design not only improves production efficiency, but also makes it more convenient for operators to operate.

2. High-quality roller set

The roller set of the drywall profile machine is made of CR12Mov mold steel, with hard chrome plating on the surface, which has excellent durability and wear resistance. This design ensures the stability of the roller in long-term use and enables the product to achieve the best shape and size. High-quality roller sets are the key factors to ensure forming accuracy.

3. Accurate cutting system

The machine adopts an automatic cutting system, and the cutter precisely fits the shape of the workpiece to ensure the surface finish and precision of the workpiece after cutting. This high-precision cutting system not only improves production efficiency, but also reduces material waste, saving costs for the enterprise.

4. Double-head decoiler

The drywall stud and track machine is equipped with a double-head decoiler, which can unwind on the left and roll on the right, so as to achieve uninterrupted processing and production. This design avoids downtime and waiting due to exhaustion of coils, and improves the continuity and efficiency of the drywall profile machine.

5. Low energy consumption and high efficiency

The drywall stud and track machine is designed with full consideration of energy consumption. It adopts advanced motors and transmission systems, so that the drywall profile machine can operate efficiently while maintaining energy consumption at a low level. This low energy consumption feature not only conforms to modern environmental protection concepts, but also reduces operating costs for enterprises.

6. Long service life

Because the drywall stud and track machine adopts high-quality materials and advanced technology, its service life is relatively long. During the long production process, the drywall profile machine can maintain an efficient working state, reduce failures and downtime, thereby improving production efficiency.

7. Strong adaptability

The design of the drywall profile machine enables it to be flexibly adjusted according to market demand and adapt to the production of keels and rails of different specifications. This adaptability enables manufacturers to respond quickly to customer needs and meet diverse market requirements.

8. Convenient maintenance

The design of the drywall stud and track machine also takes into account the convenience of maintenance, and operators can easily perform daily inspections and maintenance. Regular maintenance can effectively extend the service life of the drywall stud and track machine and ensure the normal operation of the drywall profile machine.