What are the Different Types of Steel Slitting Machines?

2025-11-28 15:49"A steel slitting machine is a widely used coil processing device in the metalworking industry, primarily used to cut wide coils into narrow strips. These strips can then be wound up for subsequent processes. Due to their high production speed and precise cutting capabilities, steel slitting lines are essential equipment in metalworking, transformer, motor industries, and other applications requiring precise shearing of metal strips. Depending on the application and the material being processed, steel slitting machines can be categorized into several types. This article will detail these different types of steel slitting lines to better meet customer needs."

▎Different Types of Steel Slitting Machine

1. Based on Different Material Thicknesses

Based on the different material thickness requirements of projects, KINGREAL SLITTING has designed three types of steel slitting machines: light gauge slitting machine, medium gauge slitting machine, and heavy gauge slitting line.

1.1 Light gauge slitting machine

Light gauge slitting machines are specifically designed for longitudinal cutting of metal coils with a thickness of 0.2-3mm. This type of steel slitting machine is widely used in the electronics, medical device, and precision instrument industries. Narrow strips of metal cut by light gauge slitting machines are typically further processed to manufacture precision connectors for mobile phones, micro motor springs, high-end medical device springs, and precision sensor components.

1.2 Medium gauge slitting machine

Medium gauge slitting machines are primarily used for processing metal coils with a thickness of 3-6mm. This type of steel slitting line is suitable for a variety of commonly used metal processing materials and is widely used in the metal processing industry.

Heavy gauge slitting lines are used to process coils with a thickness of 6-16mm. They are designed to cut thick coils into narrow strips of the width required by the customer. Heavy gauge slitting lines are mainly used in heavy industry, shipbuilding, and other industries. This type of steel slitting line can handle thicker metal materials, adapt to more stringent processing requirements, and provide reliable solutions for high-strength applications.

2. Based on Different Materials

With the increasing market demand for material diversity, KINGREAL SLITTING, in addition to providing traditional steel slitting machines, has launched various models of steel slitting lines to meet customers' processing needs for different materials. For example, stainless steel slitting machines are specifically designed for processing stainless steel coils, meeting the unique technical requirements of stainless steel cutting. These stainless steel slitting machines generally feature harder and more wear-resistant blades to ensure cutting precision and material integrity. Aluminum steel coil slitting machines are suitable for processing aluminum alloys, producing lightweight, high-toughness aluminum products.

Due to aluminum's excellent corrosion resistance and machinability, the functionality of aluminum steel coil slitting machines continues to expand, adapting to the production needs of various products. For carbon steel, KINGREAL SLITTING also offers carbon steel slitting machines. These carbon steel slitting machines maintain extremely high processing stability and efficiency under high-intensity cutting conditions, suitable for large-scale, long-cycle production. Furthermore, some of these steel slitting lines are compatible with processing multiple materials, while others are specifically designed for particular materials. KINGREAL SLITTING engineers will professionally design machines based on customer needs to ensure users receive the most suitable steel slitting machine.

3. Customized Needs for Steel Slitting Machine

Each customer has different requirements regarding the precision of narrow strips, production volume, and the smoothness of the finished product surface. KINGREAL SLITTING pays particular attention to the personalized needs of customers, providing customized steel slitting machine solutions.

3.1 Efficiency requirements for steel slitting line

In demanding production environments, high speed steel slitting lines can operate at speeds up to 230m/min. This high-speed cutting capability significantly improves production efficiency, enabling rapid fulfillment of large orders and reducing omissions and delays.

3.2 Output requirements for steel slitting line

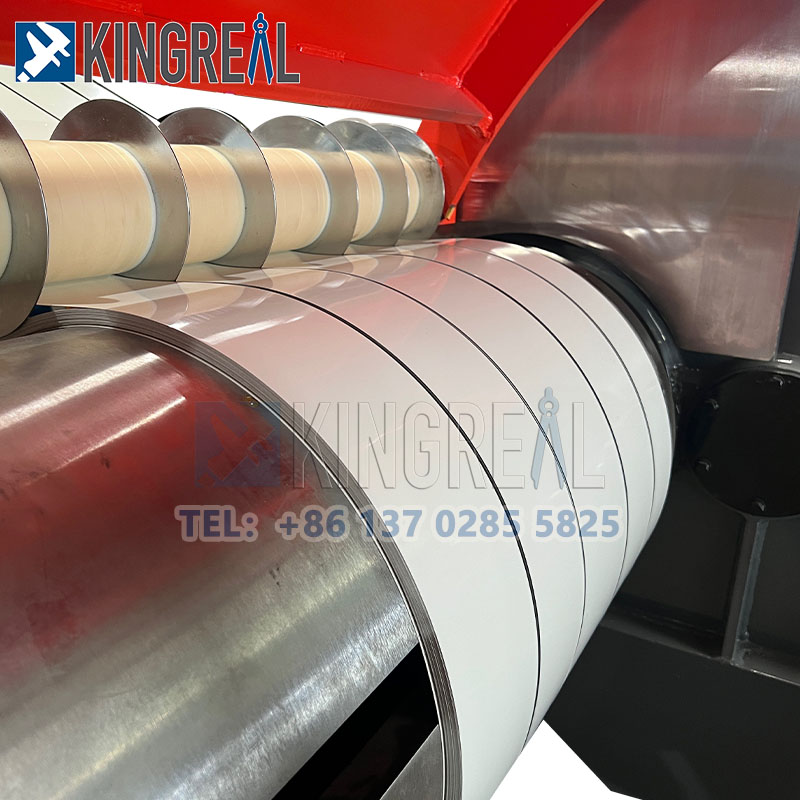

In addition, KINGREAL SLITTING has designed a steel slitting machine capable of cutting 40 narrow strips in a single pass. This design saves time and labor costs in mass production and effectively increases the overall output of the production line.

3.3 Finished Product requirements for steel slitting line

Regarding finished product quality, KINGREAL SLITTING belt tension coil slitting machine utilizes a belt tension design. The upper and lower belts press against the steel strip, generating friction to provide tension for the strip winding. This is suitable for customers with high requirements for material surface precision. This ensures that the finished product better meets the needs of various application scenarios.

4. Other Types of Steel Slitting Machines

Besides the types mentioned above, KINGREAL SLITTING offers many more types of steel slitting machines. KINGREAL SLITTING offers a diverse range of steel slitting line solutions tailored to different user needs, market conditions, and production targets.

▎Why are Steel Slitting Lines Important?

(1) Steel slitting machines employ advanced automated control systems, enabling fast and accurate slitting operations. They can cut and separate raw materials at high speeds, significantly shortening production cycles and improving efficiency. Compared to traditional manual slitting, steel slitting lines save considerable time and manpower.

(2) Steel slitting machines have high-precision cutting and separating capabilities. These steel slitting lines can slit raw materials to precise dimensions and lengths according to set parameters and requirements, ensuring consistent specifications and quality for each product. This not only improves manufacturing precision but also enhances the overall quality control level of the production line.

(3) Steel slitting machines are flexible and adjustable. These steel slitting lines can adjust parameters such as cutting speed, blade size, and slitting width according to different production needs and raw material characteristics to adapt to varying production requirements. This makes steel slitting lines perform exceptionally well in handling diverse production tasks, providing greater flexibility and adaptability.

(4) Steel slitting lines are widely used in metal processing, electronics manufacturing, and automotive parts industries. These steel slitting machines can separate various raw materials such as metal wires, sheets, and tubes to meet the production needs of different industries. Whether it's the manufacturing of electronic components or the processing of automotive parts, steel slitting lines can provide efficient and precise slitting solutions.

Customers need to provide drawings and specific production requirements. KINGREAL SLITTING professional engineering team will design and manufacture the most suitable steel slitting machine solution based on the customer's actual production needs. KINGREAL SLITTING is committed to helping customers achieve efficient production goals and creating more value for them.