What is light gauge frame machine?

2025-03-15 12:00Video About light gauge steel frame machine

Definition of light gauge frame machine

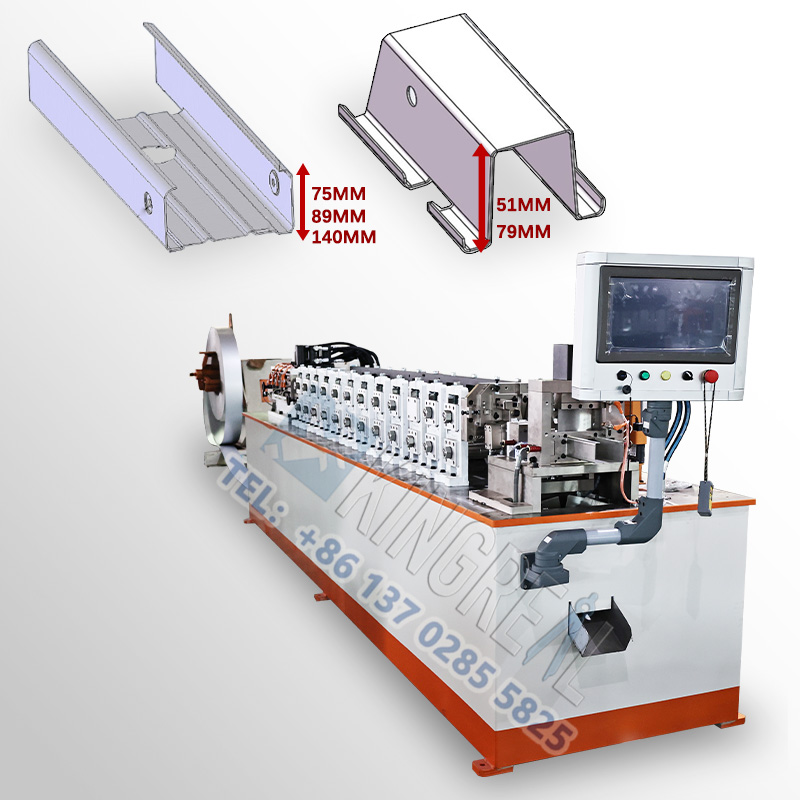

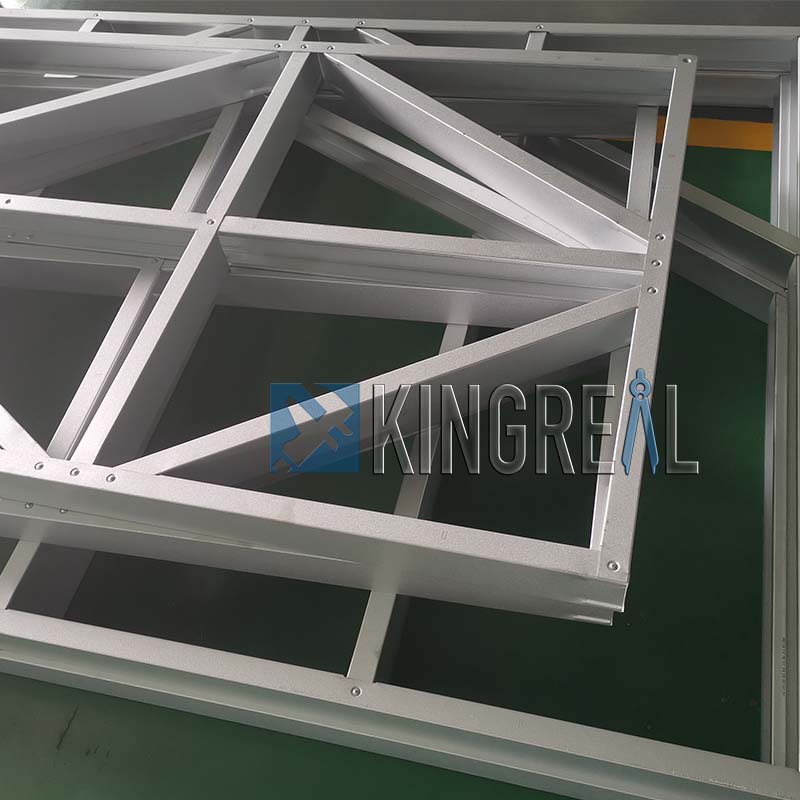

LGS machine, or Light Gauge Frame Machine, is an advanced equipment for manufacturing light steel structures. By placing metal coils into the light gauge steel frame making machine, after a series of process steps, including uncoiling, leveling, punching, forming, coding, cutting, etc., different types and sizes of finished products, such as C-type, U-type and top hat, are finally produced. These finished products are widely used in building structures such as houses, walls and floors. With the increasing demand for light steel structures in the construction industry, light gauge steel frame machines have become an indispensable equipment in modern construction. Its efficient production process and flexible product design make light gauge steel frame making machines widely used in the construction industry. |  |

Main workflow of light gauge steel frame machine

● Uncoiling for light gauge steel frame machine

In the first step of production, the metal coil is placed in the decoiler for flattening. The purpose of this step is to flatten the curled state of the coil to prepare for subsequent processing. The decoiler needs to have good stability and precision to ensure that the coil remains straight throughout the entire processing process.

● Punching for light gauge steel frame machine

The flattened metal sheet will enter the punching stage. In this step, the machine will punch the required holes on the sheet according to the set drawings and parameters. The accuracy of this process directly affects the quality of subsequent forming and assembly.

● Forming for light gauge steel frame machine

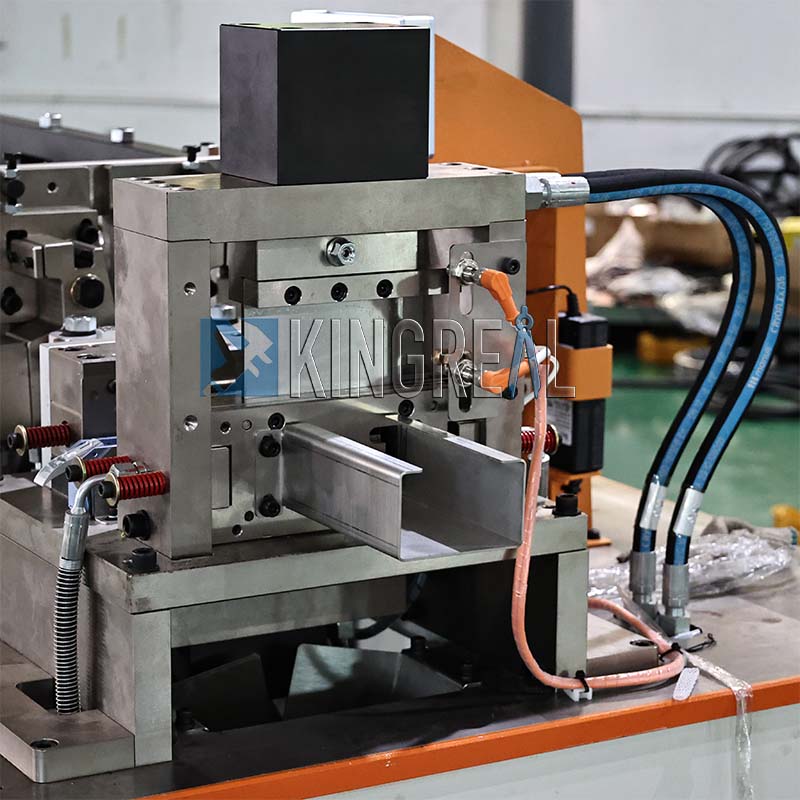

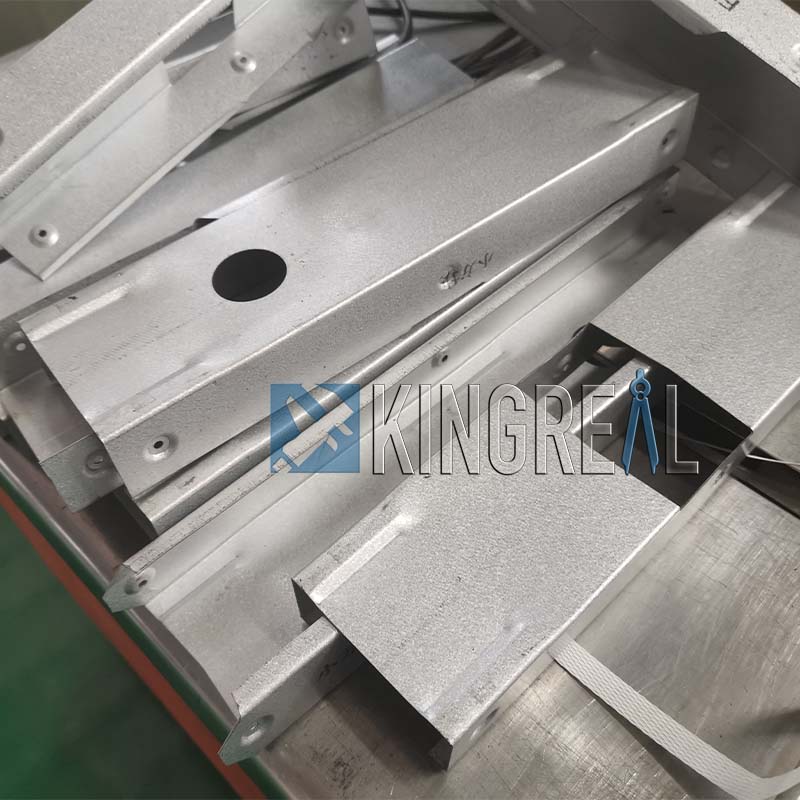

After the punching is completed, the metal sheet will enter the forming stage. At this time, the machine will process the metal sheet into the required C-type, U-type or other shapes through different molds and processes. Pressure and temperature control during the forming process is crucial to ensure the strength and stability of the finished product.

Cutting for light gauge steel frame machine

After the coding is completed, the finished product will enter the cutting stage. The machine will cut the finished product into specified lengths according to customer needs. This process requires a high degree of precision to ensure that the size of each component meets the requirements.

Market demand for light gauge steel frame machine

The market demand for light gauge steel frame making machines is gradually increasing, especially in the following situations, its demand is particularly obvious:

1. Adding floors and renovating old houses With the acceleration of urbanization, many old houses need to be added and renovated. The light steel components produced by light gauge frame machines are ideal for adding floors to old houses because of their lightness and high strength.

2. Areas with building material shortages In some areas where building materials are scarce, light gauge steel frame making machines can quickly produce the required components, solving the problem of insufficient supply of building materials. This flexible production method greatly facilitates the development of construction projects. 3. Areas with inconvenient transportation For some areas with poor transportation conditions, light gauge steel frame machines can be produced on site, reducing transportation costs and time and improving the efficiency of the project.

4. Projects with tight schedules In some projects with tight schedules, the fast construction characteristics of light steel structures make light gauge steel frame making machines very popular. Its efficient production process can ensure that the project is completed on time and avoid economic losses caused by delays in construction. |  |

Popularity of light gauge frame machines in the international market

Light gauge steel frame making machines have been widely recognized worldwide, especially in the following countries and regions, where market demand continues to rise:

1. United States

As a leading country in the construction industry, the United States is at the forefront of the application of light steel structures. light gauge steel frame machines are widely used in the construction of residential, commercial and industrial buildings.

2. Canada

Canada is vast and sparsely populated, and construction resources are relatively scarce. The frequency of use of light gauge steel frame making machines in the country is gradually increasing, especially in construction projects in remote areas.

3. Australia

In Australia, light steel structures are favored by builders because of their wind and earthquake resistance. The application of light gauge steel frame machines provides efficient solutions for many construction projects.

4. New Zealand

The construction market in New Zealand is gradually transforming to light steel structures to meet the challenges of natural disasters. The market demand for light gauge frame machines in the country is rising.

5. Europe

In Europe, especially in the Nordic region, light steel structures are attracting more and more attention from builders because of their energy-saving and environmentally friendly characteristics, and the sales of light gauge steel frame making machines are also on the rise.

Advantages of light gauge frame machines

Light gauge steel frame machines have many significant advantages, making them highly respected in the construction industry:

High-precision punching, less waste

Light gauge steel frame making machines have high precision in the punching and forming process, which can ensure that the size and hole position of each component meet the requirements, reducing waste in the production process.

High-speed production

The production speed of light gauge steel frame machines can be as high as 900 meters/hour, which makes large-scale production possible, greatly improves production efficiency, and meets customers' needs for fast delivery.

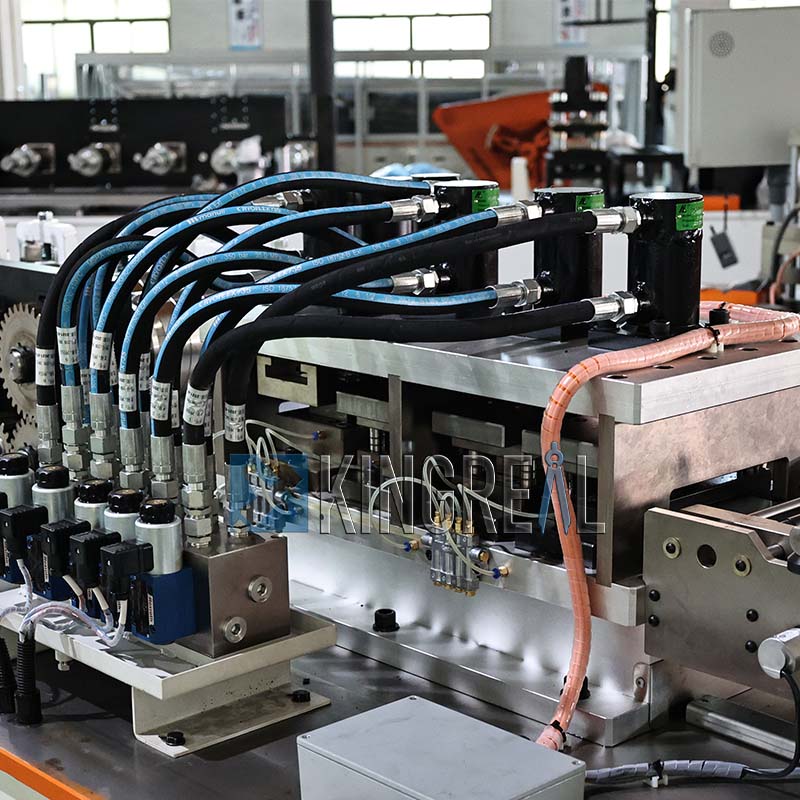

High-quality hydraulic accessories

KINGREAL's light gauge frame machines use high-quality hydraulic accessories to ensure the stability and reliability of the equipment. High-quality accessories can extend the service life of the machine and reduce the failure rate.

Fast drawing analysis

Light gauge steel frame making machines are equipped with advanced control systems that can quickly analyze drawings and flexibly adjust according to customer needs. This flexibility allows the machine to adapt to different production tasks and improve production efficiency.