What is the application of sheet metal perforated machine?

2025-05-26 12:00

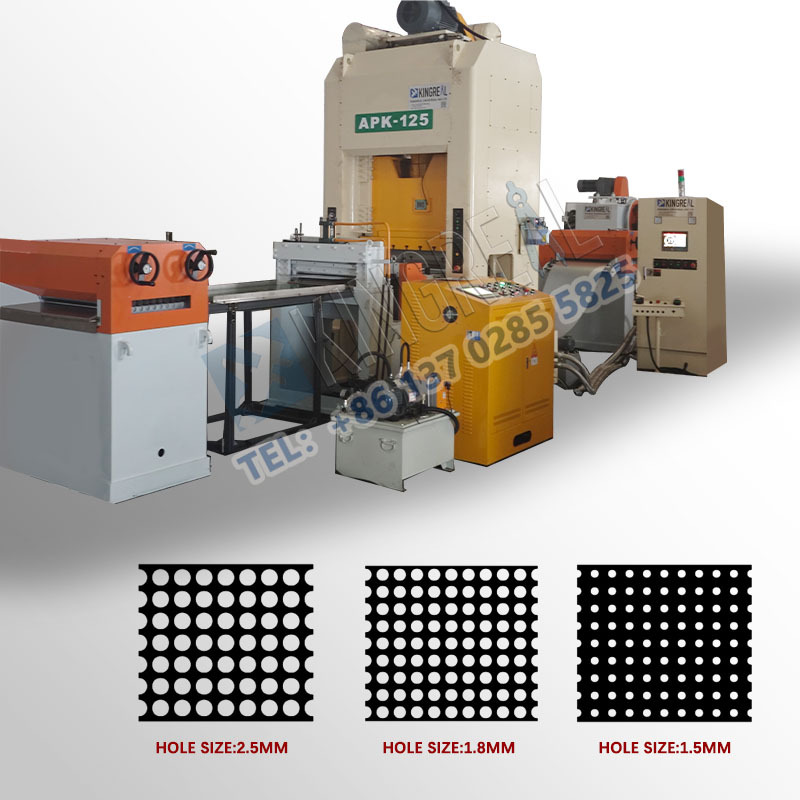

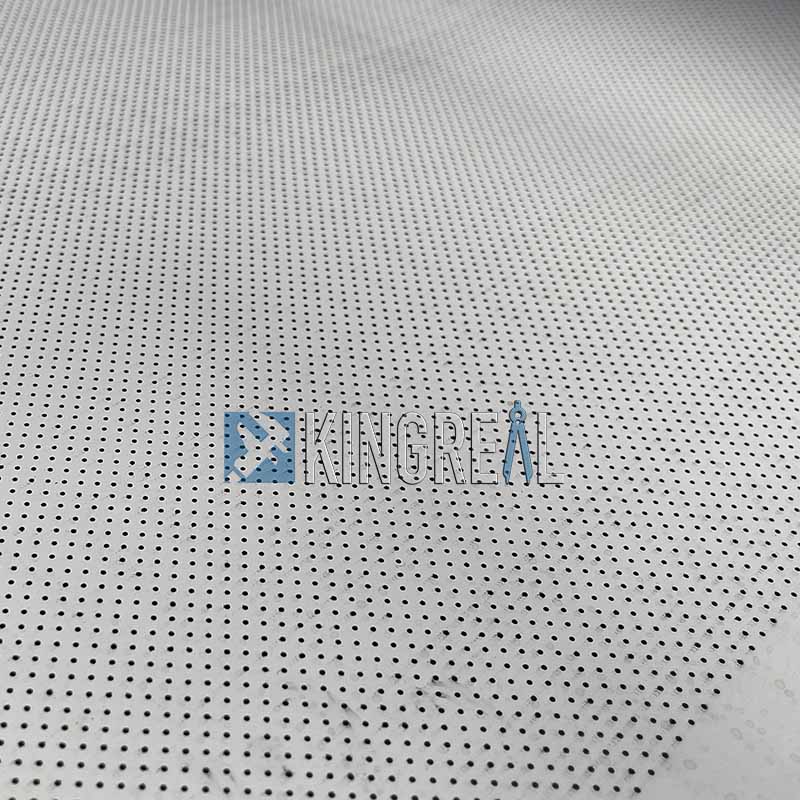

In modern manufacturing, sheet metal perforated machines play a vital role. This equipment can not only accurately punch holes on metal coils, but also accurately shear according to customer needs to produce high-quality, burr-free perforated metal sheets. With the continuous development of the global manufacturing industry, the demand for metal sheet perforation machines in Indonesia, Malaysia, the Philippines, Singapore and other countries is increasing. This article will explore the main components, application areas and significant advantages of sheet metal perforated machines to help you better understand the importance of this equipment.

Main Components of Sheet Metal Perforated Machines

Metal sheet perforation machines are composed of several core components, each of which plays an important role in the production process:

1. Decoiler for metal sheet perforated machine The decoiler is used to unwind the metal coil to ensure the flatness of the material when it enters the subsequent processing link. It can effectively control the tension of the coil to avoid wrinkles or deformation of the material during processing. |  |

2. Leveler for metal sheet perforation machine The main function of the leveler is to further adjust the flatness of the metal material. This link is crucial for the subsequent punching and shearing process, because only flat materials can ensure the accuracy of punching. |  |

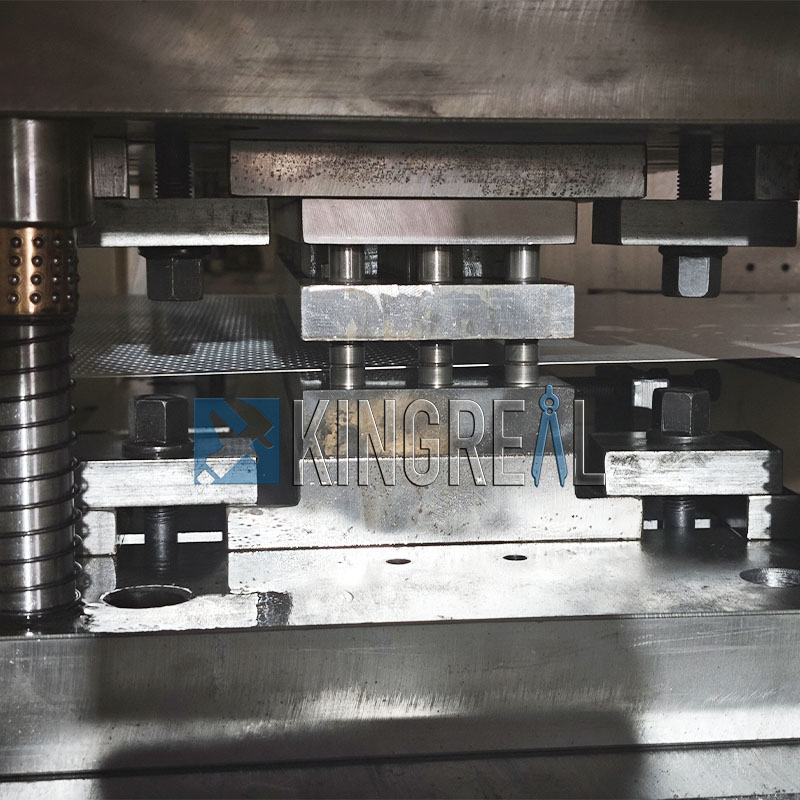

3. Punching machine for sheet metal perforated machine The punching machine is the core component of the metal sheet perforation machine. It uses a high-pressure punch to punch out the required hole shape and diameter on the metal surface. The accuracy of the punching machine directly affects the quality of the finished product, so it is crucial to choose a high-performance punching machine. |  |

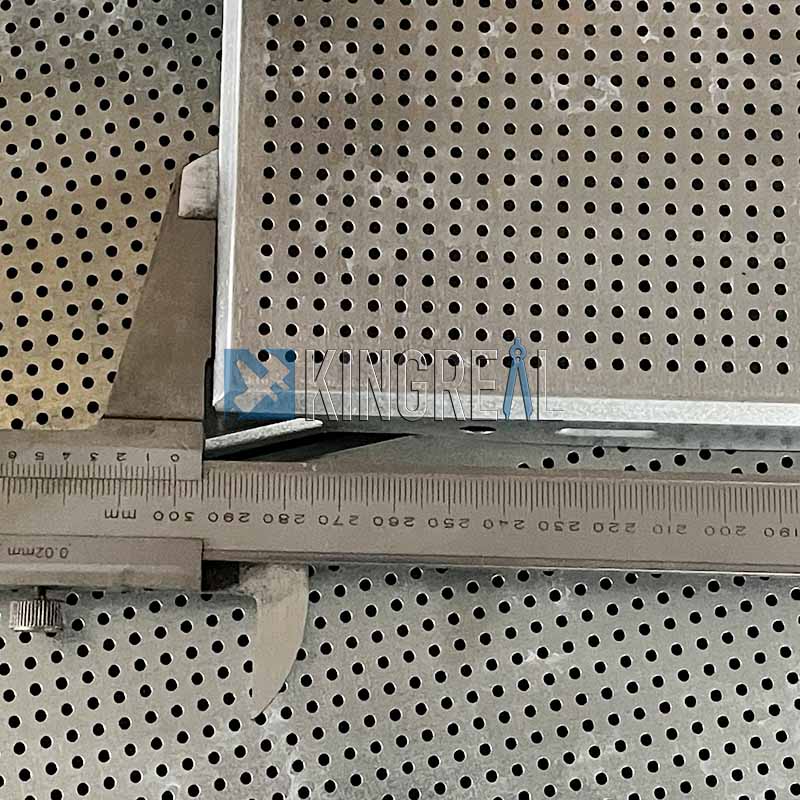

4. Shearing station for sheet metal perforated machine After the punching is completed, the shearing station will perform precise shearing according to the parameters set by the customer on the control panel. It can ensure that the size of each punched metal sheet is consistent and meet the specific requirements of the customer. |  |

Application Areas of Sheet Metal Perforated Machines

The application areas of metal sheet perforation machines are wide, and the following are its main applications in various industries:

1. Construction industry In the construction industry, sheet metal perforated machines are often used to produce perforated wall panels. These materials are not only beautiful, but also effectively improve the sound insulation effect of buildings. By using metal sheet perforation machines, builders can quickly produce sound insulation materials that meet design requirements and meet the high standards of acoustic performance in modern buildings. |  |

2. Home appliance industry Sheet metal perforated machines are also widely used in the home appliance industry. It is used to manufacture the outer shell and internal structural parts of home appliances to ensure product consistency and quality. Through precise punching and shearing, manufacturers can produce lighter and stronger home appliance parts, thereby improving the overall competitiveness of the product. | |

3. Automobile Industry In the automotive industry, metal sheet perforation machines are used to produce various automotive parts, such as mufflers and brackets. The lightness and strength of these parts directly affect the fuel efficiency and safety of the car. By using sheet metal perforated machines, automakers can quickly produce high-performance parts that meet strict standards. | |

4. Electronics Industry The electronics industry has extremely high precision requirements for metal parts, and the metal sheet perforation machine can meet this demand. It is widely used to manufacture electrical housings and other metal parts to ensure the perfect combination of product function and appearance. Through efficient punching and shearing processes, electronic product manufacturers can better meet market demand. |

Advantages of Sheet Metal Perforated Machines

The advantages of metal sheet perforation machines are obvious. The following are its main advantages:

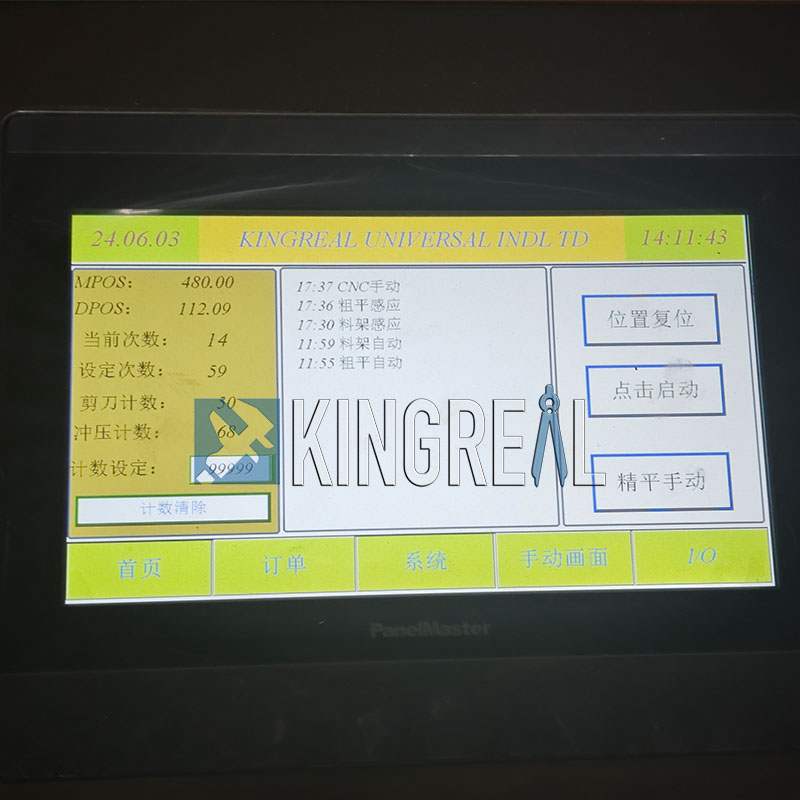

1. Intelligent control panel for sheet metal perforated machine

The modern metal sheet perforation machine is equipped with an intelligent control panel that supports multiple languages and is easy to operate. Users can complete complex punching and shearing processes with simple settings, greatly reducing the difficulty of operation. This user-friendly design allows operators with different language backgrounds to quickly get started, reducing training time and costs.

2. High degree of automation for sheet metal perforated machine

The high degree of automation of the metal sheet perforation machine makes the production process almost free of human intervention. The sheet metal perforated machine can automatically complete the entire punching and shearing process under the set program, greatly reducing the dependence on manpower. This not only reduces labor costs, but also reduces losses caused by human errors, and improves production efficiency and safety.

3. Reduce material waste for metal sheet perforation machine

Through precise punching and shearing, the sheet metal perforated machine can effectively reduce material waste. Compared with traditional manual operations, this metal sheet perforation machine has obvious advantages in material utilization, helping companies save production costs. Optimized material use not only helps to improve economic benefits, but also reduces environmental impact, meeting the requirements of sustainable development.

4. High production efficiency for metal sheet perforation machine

The sheet metal perforated machine can complete punching and shearing at extremely high speeds, significantly shortening the production cycle. Compared with traditional production methods, the metal sheet perforation machine can process more materials in a shorter time and improve overall production capacity. This is especially important for companies that need to respond quickly to market demand, which can help them stay ahead of the competition.

5. High-quality output for sheet metal perforated machine

The metal sheet perforation machine ensures that the size of each punched metal sheet is consistent and the quality is reliable. The high-precision punching and shearing technology of the sheet metal perforated machine reduces the defect rate of the finished product and improves customer satisfaction. Whether in appearance or function, the metal sheet perforation machine can provide high-standard products that meet the strict requirements of various industries.

6. Flexible production settings for sheet metal perforated machine

The metal sheet perforation machine can be flexibly set according to the different needs of customers and supports a variety of hole types and sizes. Users can freely adjust parameters according to specific production requirements to meet diverse market needs. This flexibility enables companies to quickly adapt to market changes and develop new products.

Conclusion

Thesheet metal perforated machinehas an irreplaceable position in modern manufacturing. Whether in the construction, home appliances, automobiles or electronics industries, it provides companies with efficient and precise production solutions. With the continuous growth of market demand, the application prospects of the metal sheet perforation machine will be broader. If you are considering introducing a sheet metal perforated machine, please contact us to learn more about our products and help you upgrade your production. By choosing a suitable metal sheet perforation machine, you will be able to significantly improve production efficiency, reduce costs, and achieve higher market competitiveness.