Cable Tray Cover Machine

KINGREAL cable tray cover machine can be used in conjunction with the cable tray machine to provide customers with a complete cable tray system.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Cable Tray Cover Machine

Introduction to Cable Tray Cover Machine

KINGREAL Cable Tray Cover Machine is an efficient and intelligent machine that is specially designed for processing different metal materials such as aluminum and steel. The cable tray covers produced by this cable tray cover making machine can effectively protect products such as cables from sunlight, environmental factors, dust, debris and falling objects. Not only that, these cable tray covers also provide a safe, sturdy and non-slip walking surface, which greatly enhances the safety of the working environment.

The flexibility of the KINGREAL cable tray cover machine enables it to produce a variety of different sizes of cable tray covers to meet the diverse needs of customers for heavy duty cable trays, medium duty cable trays and light duty cable trays. Whether you need a standard size or a customized design, the KINGREAL cable tray cover making machine can provide you with the perfect solution. |  |

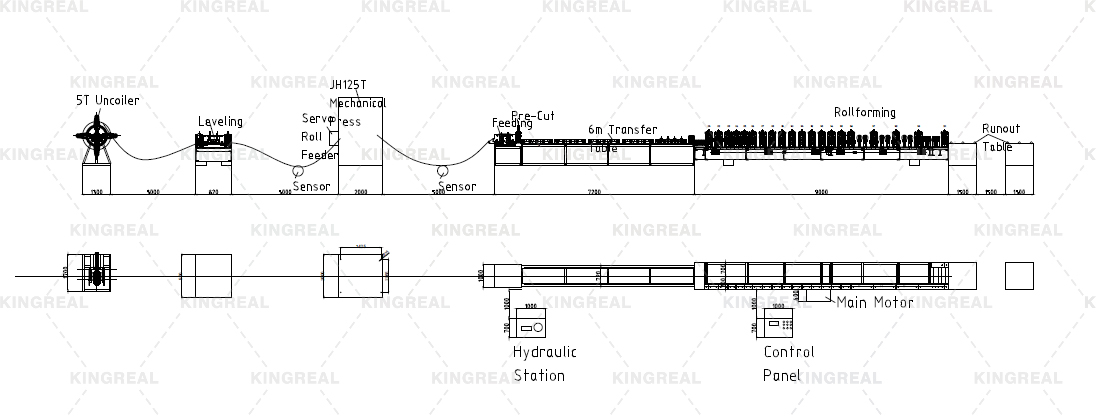

Workflow of Cable Tray Cover Machine

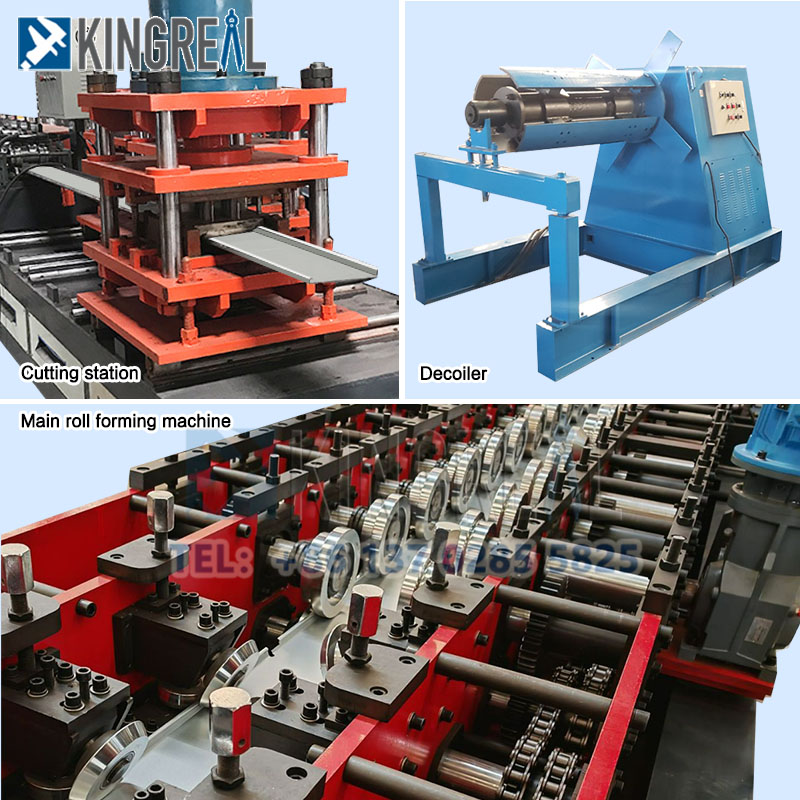

Decoiler

↓

Leveling Machine

↓

Punching Station

↓

Cutting Station

↓

Roll forming Machine

↓

Discharging Table

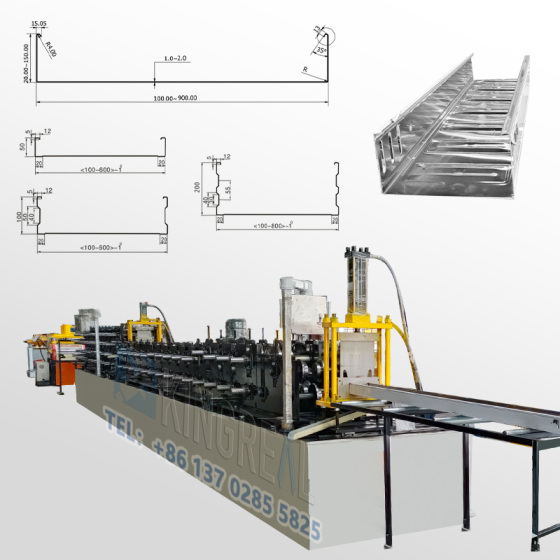

Parameters of Cable Tray Cover Making Machine

| Order number | Project | unit | numerical value |

| 1 | Material width | Mm | 60~430mm |

| 2 | Material thickness | Mm | 0.5~1.2mm |

| 3 | Material type | / | galvanized steel strip |

| 4 | Speed | m/min | 1-30m/min |

| 5 | Power | KW | 14KW |

Advantages of Cable Tray Cover Machine

(1)Intelligent automation system for cable tray cover machine Equipped with advanced automation technology, the KINGREAL cable tray cover machine delivers precision installation while offering user-friendly operation. Through an intuitive interface, operators can effortlessly adjust parameters to meet specific requirements. This smart design significantly enhances production efficiency while simplifying manual workflow complexity.

(2)High-Efficiency production capacity for cable tray cover machine The cable tray cover making machine's robust manufacturing capability enables rapid production of high-quality cable tray covers, effectively supporting both large-scale manufacturing and urgent project demands. KINGREAL cable tray cover machine ensures consistent output stability, making it suitable for both short-term tasks and long-term industrial partnerships. |  |

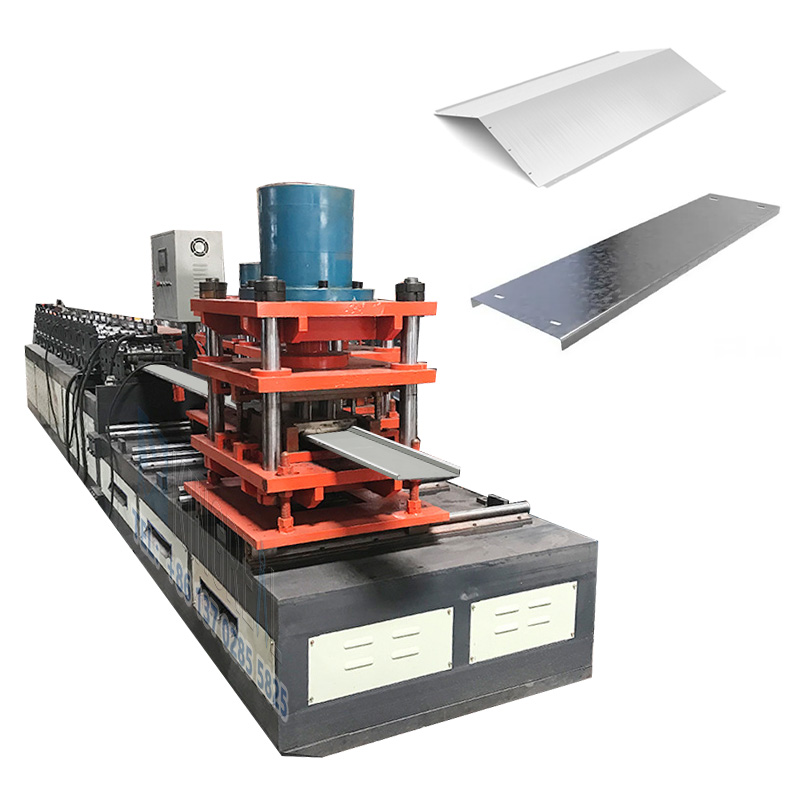

(3)Customizable Dimension System for cable tray cover making machine Featuring adjustable sizing options, this roll forming machine for cable tray cover making machine accommodates various cable tray specifications. Standard widths cover 6"-36" increments (6/12/18/24/36 inches), with customized solutions available through technical drawings submission. Our engineering team provides tailored manufacturing plans to meet unique project requirements.

(4)Comprehensive safety protocol for cable tray cover machine Prioritizing operational safety, the cable tray cover making machine integrates multiple protective mechanisms including emergency stop systems and sensor-based monitoring. These features not only safeguard operators but also minimize equipment failure risks, ensuring continuous production stability. The dual-protection design aligns safety compliance with operational reliability. |  |

Collaboration Between Cable Tray Cover Machine & Cable Tray Machine

The combination of cable tray cover making machine and cable tray machine can form a complete and efficient cable tray system, perfectly meeting customers' needs for overall cable tray solutions. This integrated system not only improves production efficiency, but also ensures product compatibility and stability. Customers who choose to purchase cable tray cover machine and cable tray machine from KINGREAL will enjoy significant advantages: the produced cable trays and covers can fit together perfectly, ensuring that each product can be perfectly matched, thereby improving the overall construction quality and safety. Through this efficient and collaborative approach, customers can better respond to market demand and achieve greater commercial value.

|  |

| Cable Tray Cover Machine | Cable Tray Machine |

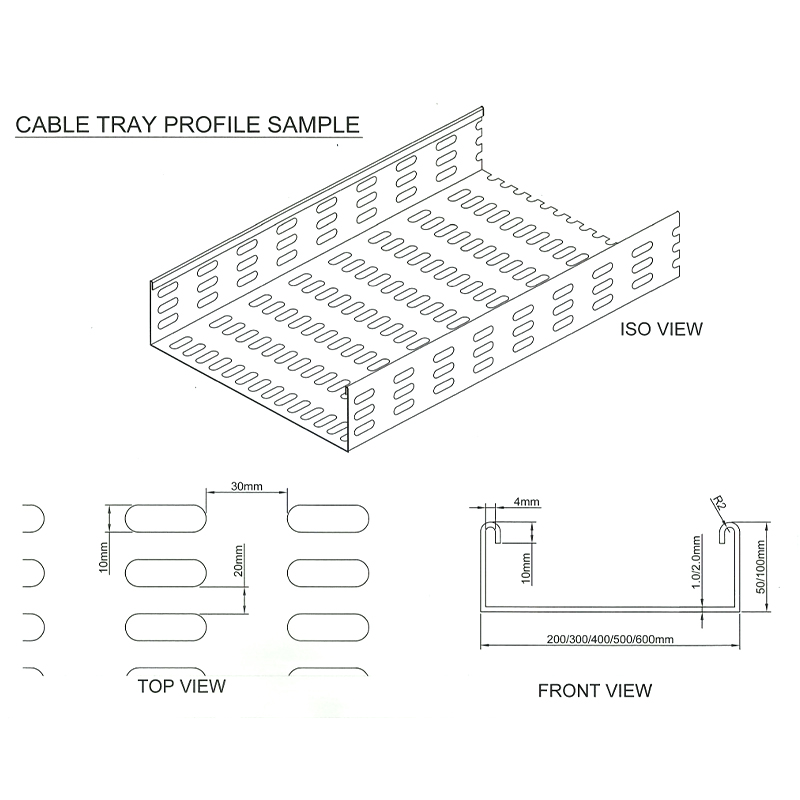

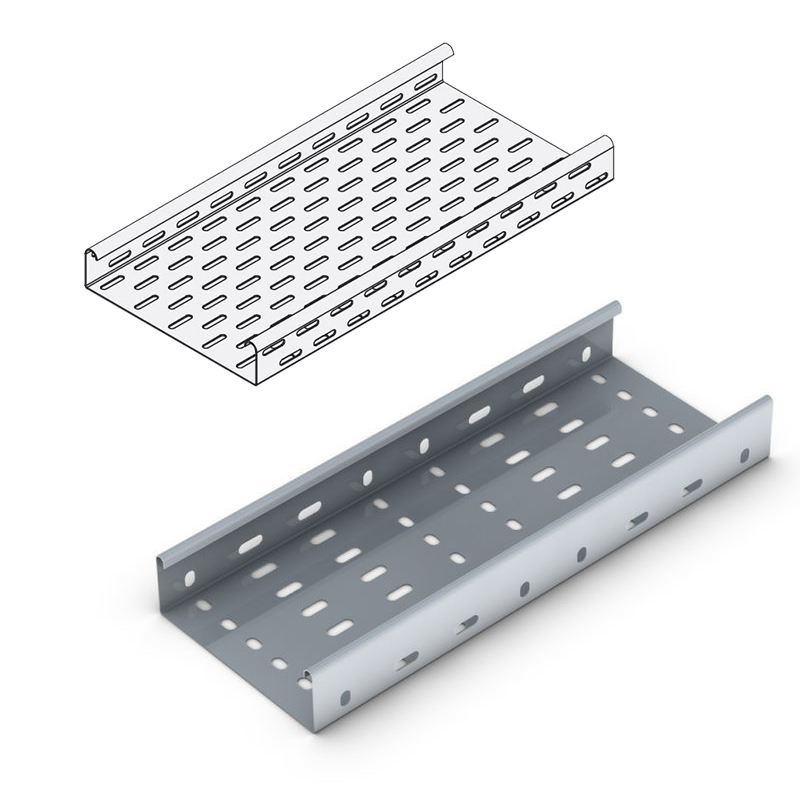

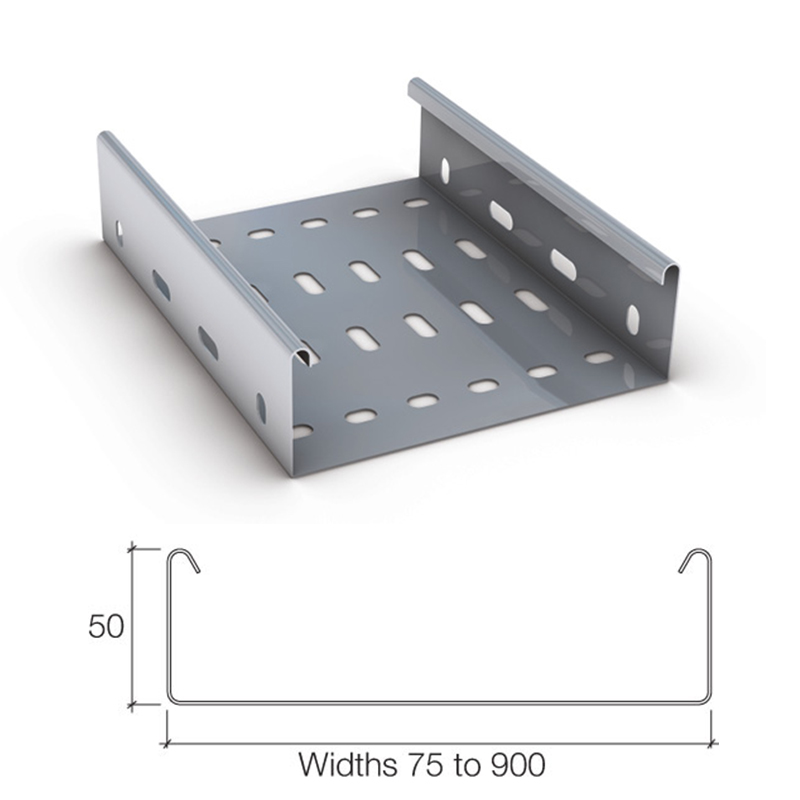

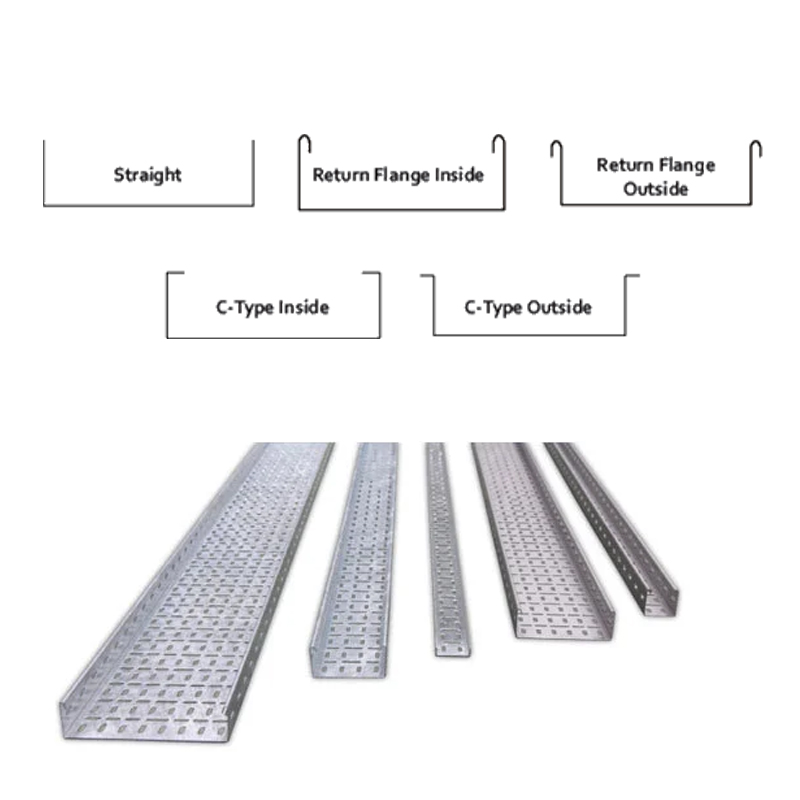

Drawing About Cable Tray

Application of Cable Tray Cover Making Machine

The produced Flat and Flat Flanged and Hat-Shaped types of cable tray covers have been widely used in cable tray systems. The main function of the cover is to protect the cables and wires in the cable tray from the external environment and provide additional safety and aesthetics. According to different scene requirements, the cable tray covers produced by KINGREAL cable tray cover machine can be selected for the following situations:

Electrical interference protection: When external electrical interference needs to be shielded, a non-porous metal tray with a solid cover should be selected to ensure the normal operation of the cable.

Combustible dust environment: In places with flammable dust, it is recommended to use ladder racks, and each layer of the bridge rack should be equipped with a solid cover to prevent fire hazards.

Dust-prone environment: In dust-prone environments and other environments that need to be covered or outdoor places, cable trays and cable ladders should be equipped with covers to keep the environment clean and safe.

High temperature and corrosive environment: In environments with high temperature and easy splashing of chemical liquids, cable tray covers can effectively prevent damage and corrosion.

Direct sunlight: In outdoor environments with direct sunlight, cable tray covers are suitable to provide additional protection for cables and extend their service life.

FAQ about Cable Tray Cover Making Machine

How to ensure the quality of the cable tray cover machine?

KINGREAL has a strict set of processes for cable tray cover making machine manufacturing, and must find high-quality materials in the screening of raw materials. Engineers will test the raw materials, and if they do not meet the standards, they will be returned and not used. And during the production process, there is an inspection team to supervise. After the cable tray cover machine is produced, metal coils will be put in for trial operation to test whether the cable tray cover making machine's running speed, finished product size, etc. meet customer needs. Only cable tray cover machines that pass the test will be sent to the customer's factory.

What after-sales services can KINGREAL provide?

KINGREAL can send professional engineers to the customer's factory to install the cable tray cover making machine and train workers on how to use the machine correctly. If the cable tray cover machine fails, KINGREAL can check for customers in the first time through offline visits or online video conferences, and provide solutions.

Can you provide a complete cable tray machine manufacturing solution?

Of course! KINGREAL is a professional cable tray machine manufacturer, and can provide different types of cable tray machines to meet the needs of customers in different scenarios. For example, Cable Tray Ladder Machine, Solid Bottom Cable Tray Machine, Cable Tray Cover Machine, Din Rail Channel Machine, Perforated Cable Tray Machine, Trough Cable Tray Machine and other machines.

In summary, KINGREAL cable tray cover making machine has become an indispensable and important equipment in the cable tray industry with its excellent performance and flexible application. Whether it is mass production or customized services for special needs, KINGREAL cable tray cover machine can provide customers with the best solutions and help customers achieve greater success in the field of cable protection.