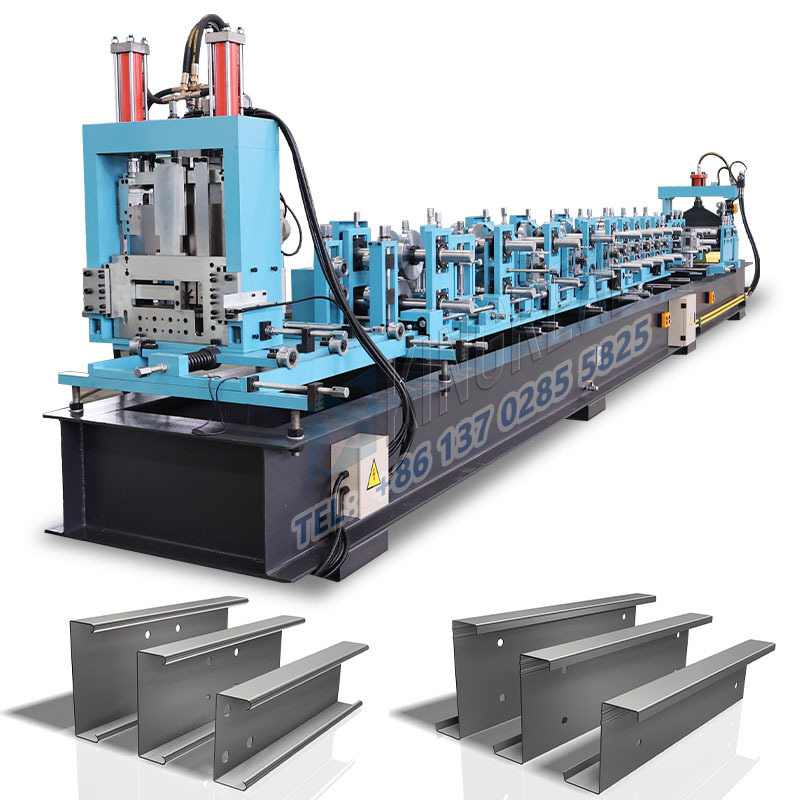

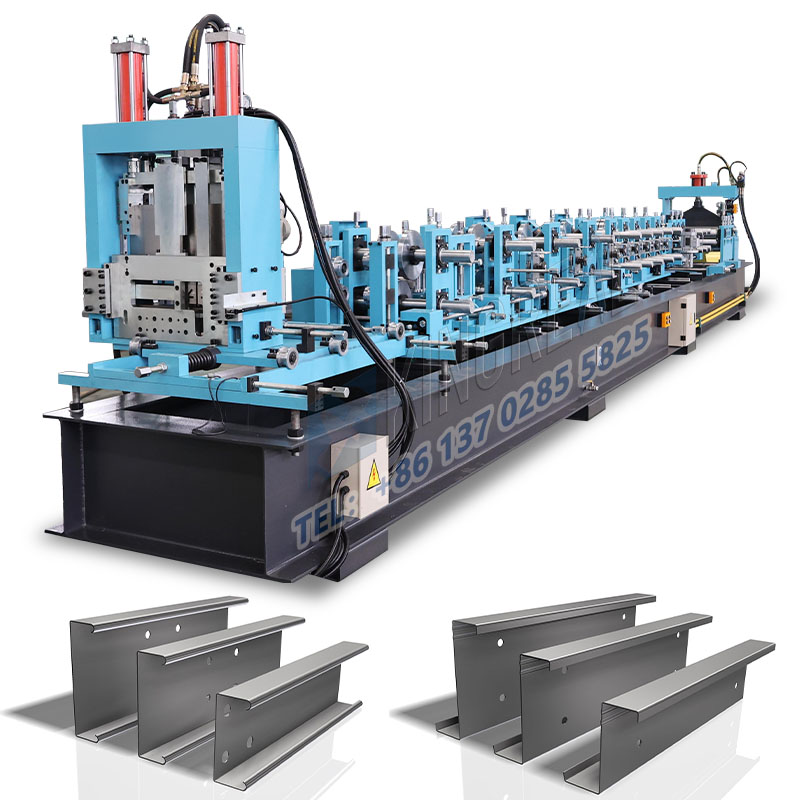

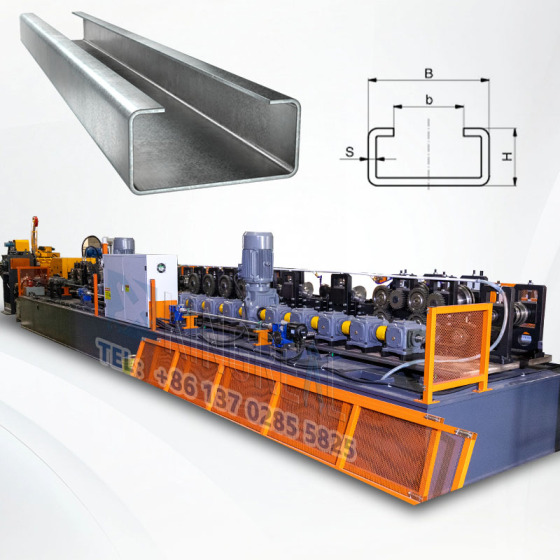

CZ Purlin Roll Forming Machine

KINGREAL CZ Purlin Roll Forming Machine can produce C purlin and Z purlin of different sizes (standard or non-standard Shape Profile) to meet the personalized needs of customers.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About CZ Purlin Roll Forming Machine

Introduction of CZ Purlin Roll Forming Machine

KINGREAL CZ Purlin Roll Forming Machine is a machine designed for the production of c purlins and z purlins of different sizes. These purlins are widely used in building structures to provide the necessary support and stability. The design of the CZ Purlin Machine ensures efficient production capacity and can complete the rapid change of size in a short time, usually within 3 to 5 minutes to achieve the conversion from c purlin to z purlin. In addition, the forming speed of KINGREAL CZ Purlin Roll Forming Machine is as high as 30 m/min, which greatly improves production efficiency.

KINGREAL is committed to meeting the personalized needs of customers and provides a variety of customized CZ Purlin Machine manufacturing solutions. Among them, the fully automatic manufacturing solution for the interchange of c purlin and z purlin is particularly well received by customers. This flexibility enables KINGREAL CZ Purlin Roll Forming Machine to adapt to different production needs and meet market changes. |

|

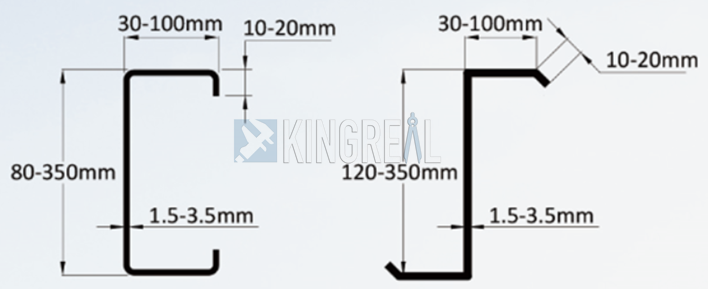

Standard Shape Profile (also can be customized) C purlin: A=80-300mm; B=35-80mm; C=10-25mm; T=1.5-3mm Z purlin: A=120-300mm; B=35-80mm; C=10-25mm; T=1.5-3mm

Usually, c purlins and z purlins produced by CZ Purlin Machines are used in: Industrial buildings, Hall and warehouse construction, Expansion and renovation projects, Agricultural projects. |  |

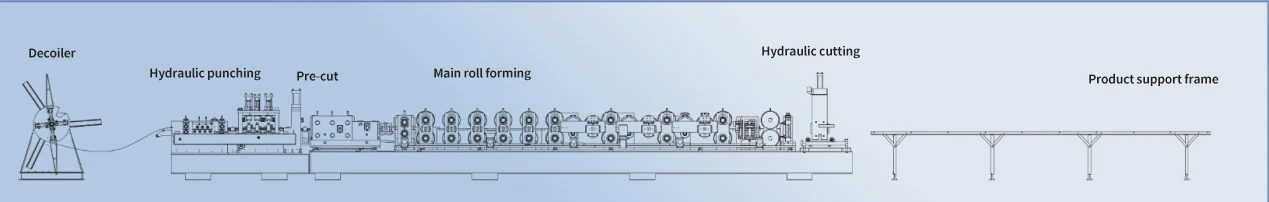

Workflow of CZ Purlin Roll Forming Machine

Decoiler -- Hydraulic Punching-- Pre-cutting -- Main Roll Forming Machine -- Hydraulic Cutting -- Output Table |  |

Parameters of CZ Purlin Machine

| No. | Item | Parameters | |

| Hydraulic drive | Servo drive | ||

| 1 | Main motor power | 22KW | 22KW +5.5 |

| 2 | Hydraulic pressure | 16mpa | |

| 3 | control system | PLC | PLC+Drive |

| 4 | Axis Material | 40CR Quality Treatment | |

| 5 | Roller | Gcr15 | |

| 6 | Shaping speed | 25m/min | 30m/min |

| 7 | Knife material | Cr 12Mov | |

| 8 | Forming group | 18 | |

| 9 | Size | 10200x1350x1750 | 10200x1350x1750 |

| 10 | Material quality | Rolling strip steel or galvanized strip steel | 1.5-3.0mm |

Advantages of CZ Purlin Roll Forming Machine

1. Highly automated cz purlin machine

KINGREAL CZ Purlin Machine realizes the fast switching between C purlin and Z purlin in a fully automated manner, and the entire process is automatically controlled by program settings. This high degree of automation simplifies the production process, reduces human intervention, and reduces the possibility of errors. The CZ Purlin Roll Forming Machine's control system uses advanced PLC technology, which can monitor and adjust the CZ Purlin Machine's operating status in real time.

During the switching process, the operator only needs to release the positioning pin, rotate 180 degrees, and then insert the positioning pin back. This design greatly improves production efficiency, and the size changeover can usually be completed within 3 to 5 minutes, significantly shortening the production cycle. The automation system is also equipped with fault detection and alarm functions, which can provide timely feedback when problems occur to ensure the smooth operation of the CZ Purlin Roll Forming Machine.

2. CZ purlin machine with a wide range of applications

The CZ Purlin Roll Forming Machine is capable of processing a variety of metal materials such as galvanized steel and aluminum alloy, with a thickness range of 1.2 to 3.2 mm. Its wide range of applications enables KINGREAL CZ Purlin Machine to meet the needs of different customers, whether it is standard or non-standard size, the CZ Purlin Roll Forming Machine can respond flexibly. By adjusting the CZ Purlin Machine’s settings, users can easily switch different types of materials for processing.

3. CZ purlin machine with high flexibility

The high flexibility of KINGREAL CZ Purlin Machine is reflected in its punching function. The CZ Purlin Roll Forming Machine can punch holes at any position of the purlin. Users only need to provide design drawings, and KINGREAL engineers can design customized punching dies according to the specific needs of customers. This feature allows customers more freedom in personalized design and can be flexibly adjusted according to the needs of the building structure.

4. Consistent cutting system for cz purlin machine

The CZ Purlin Roll Forming Machine does not need to change the tool when processing purlins of different sizes. This design ensures production efficiency and cutting consistency. Traditional cutting systems usually require frequent tool changes when facing different specifications, resulting in production stagnation and time waste. The consistent cutting system of KINGREAL CZ Purlin Machine makes the cutting process more efficient through advanced tool design.

Two Options for CZ Purlin Machine Parameters

1. Gearbox and chain box selection for cz purlin machine

Gearbox for CZ Purlin Roll Forming Machine: Suitable for applications with high precision, high stability and processing thicker materials (such as 5 mm). Although the initial cost is higher, it can effectively improve production and efficiency in long-term operation. Chain box for CZ Purlin Roll Forming Machine: Suitable for light material operations, limited budgets or applications that do not require high precision. Although the speed is slower, it performs superior in cost-effectiveness.

2. Fully automatic or semi-automatic cz purlin machine

Fully automatic cz purlin machine: PLC controlled, all operations can be completed via touch screen, size change and c purlin and z purlin interchange can be completed within 3-5 minutes.Semi-automatic cz purlin machine: Size change is controlled by buttons, c purlin and z purlin interchange needs to be done manually, usually completed within 10 minutes.

Application of CZ Purlin Roll Forming Machine

C purlins and Z purlins produced by KINGREAL CZ Purlin Machines are key materials for building steel structure frames, providing stability and support.

Widely used in:

(1) Warehouses and industrial facilities

Warehouses and industrial facilities benefit from using C purlins and Z purlins to build strong and durable roof and wall support systems.

(2) Agricultural buildings

C purlins and Z purlins are often used to build agricultural buildings where structural integrity is critical, such as barns and sheds.

(3) Commercial buildings

Commercial buildings often require the use of C purlins and Z purlins to build reliable support systems for a variety of building designs.

(4) Residential Construction

In residential construction, these purlins can be used to support the roof and provide structural stability for large homes.