HVAC Damper Frame Machine

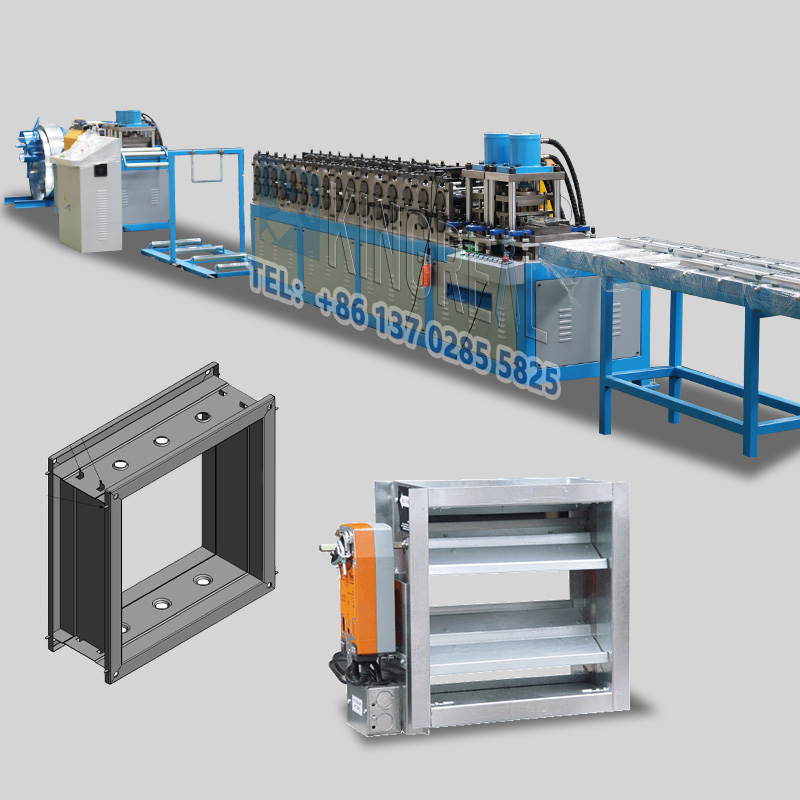

KINGREAL specializes in customizing various roll forming machines, including hvac damper frame machines, fire damper frame machines, fire damper blade making machines, and flange forming machines, to meet customer needs.

KINGREAL is committed to providing comprehensive air conditioning and heating system solutions, ensuring efficient and reliable system operation.

- KINGREAL

- China

- Information

- Download

Video About HVAC Damper Frame Machine

Description of HVAC Damper Frame Machine

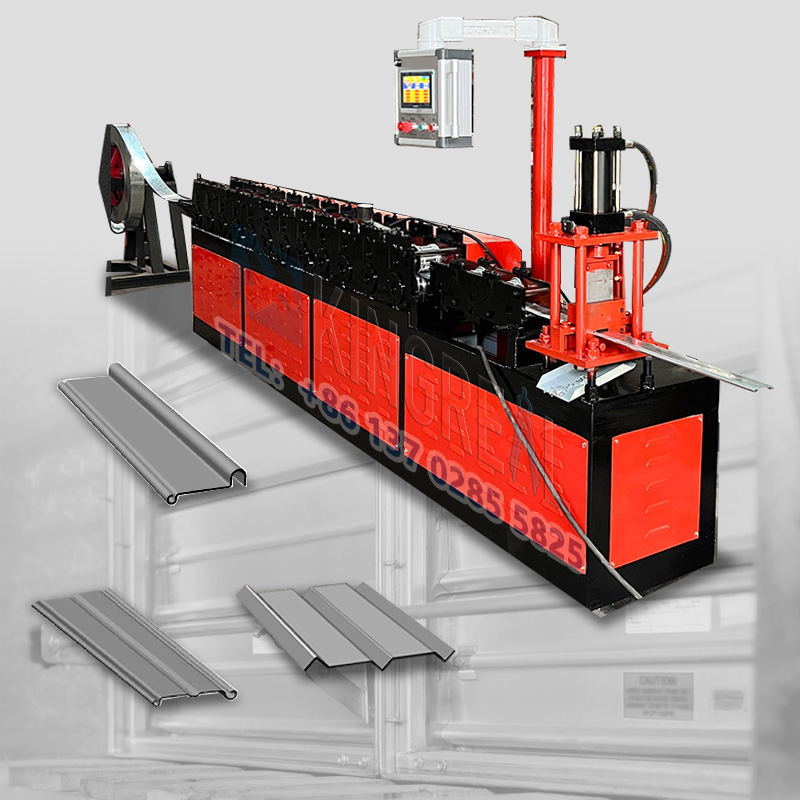

KINGREAL specializes in customizing various roll forming machines, including hvac damper frame machines, fire damper frame machines, fire damper blade making machines, and flange forming machines, to meet customer needs. KINGREAL is committed to providing comprehensive air conditioning and heating system solutions, ensuring efficient and reliable system operation. KINGREAL has successfully developed and manufactured a hvac damper frame making machine controlled by a PLC computer system, with adjustable production speeds of up to 15 m/min. This fully automated hvac damper frame machine ensures stable operation, significantly improving production efficiency and precision, and hvac damper frame making machine is suitable for producing a wide range of hvac damper frames. When used in conjunction with fire damper blade making machines and flange forming machines, even better production results can be achieved.

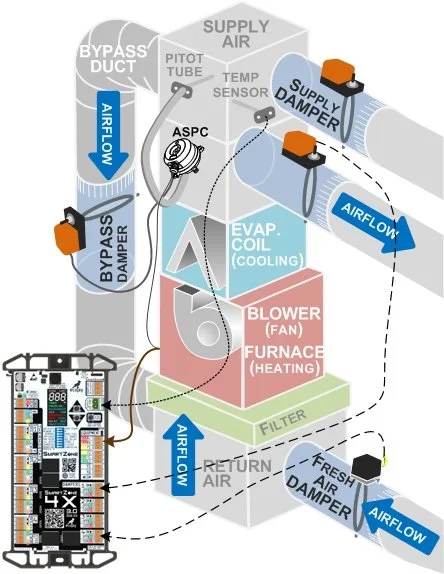

Damper frames produced by KINGREAL hvac damper frame machines are crucial components in air conditioning and heating systems, acting as air flow regulators within the system. They control airflow within ductwork, primarily balancing air, adjusting air volume, and maintaining the required airflow. Through optimized design and efficient production, KINGREAL ensures high-quality hvac damper frame making machines to meet the needs of diverse applications.

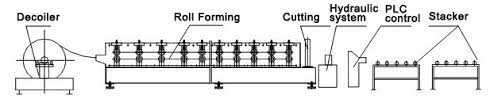

Workflow of HVAC Damper Frame Making Machine

Decoiler- Roll Forming Machine - Punching Machine- Cutting Station -Output Table

HVAC Damper Frame Machine Solution

HVAC Damper Frame Machine

Introduction to HVAC Damper Frame Machine:

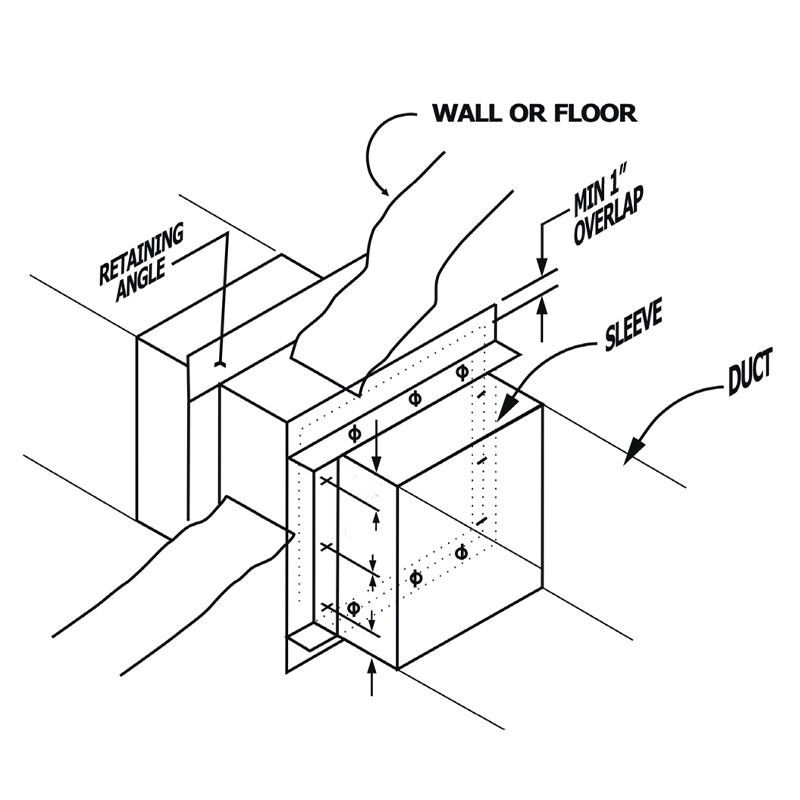

"HVAC damper frame making machines, also known as fire smoke damper machines, are primarily used to manufacture fire damper frames, a crucial passive fire protection measure in heating, ventilation, and air conditioning (HVAC) systems.

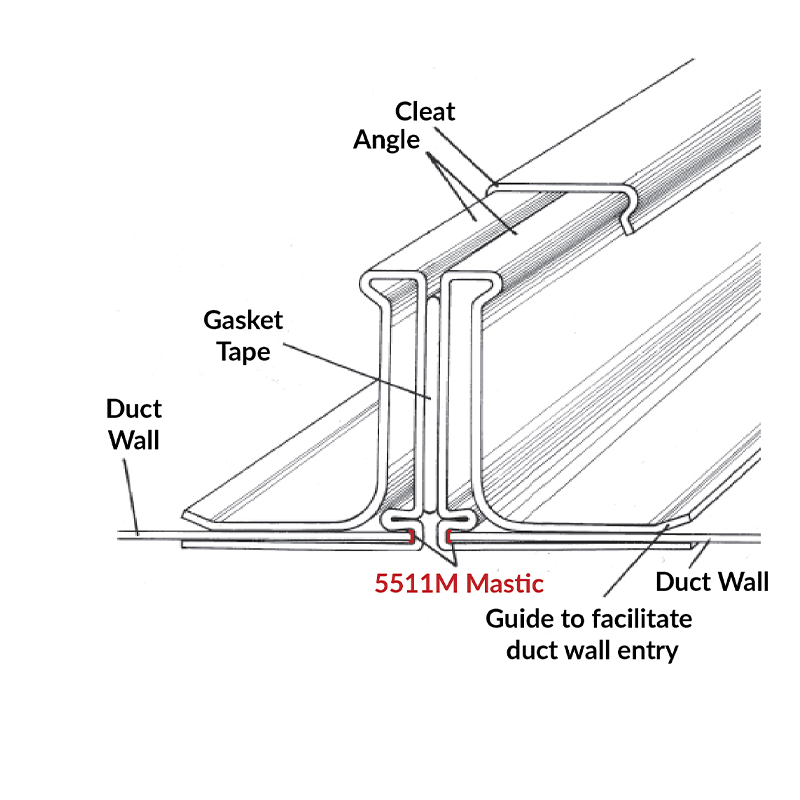

In modern building design, fire barriers are installed to limit the spread of flames within the building and ensure safety. HVAC ducts often penetrate these fire barriers, leaving a breach in their protective layer."

Under normal circumstances, fire damper frames remain open. When the smoke temperature within the duct reaches 70°C, the dampers automatically close, meeting smoke and fire protection integrity requirements. This mechanism effectively acts as a fire barrier, preventing the spread of fire.

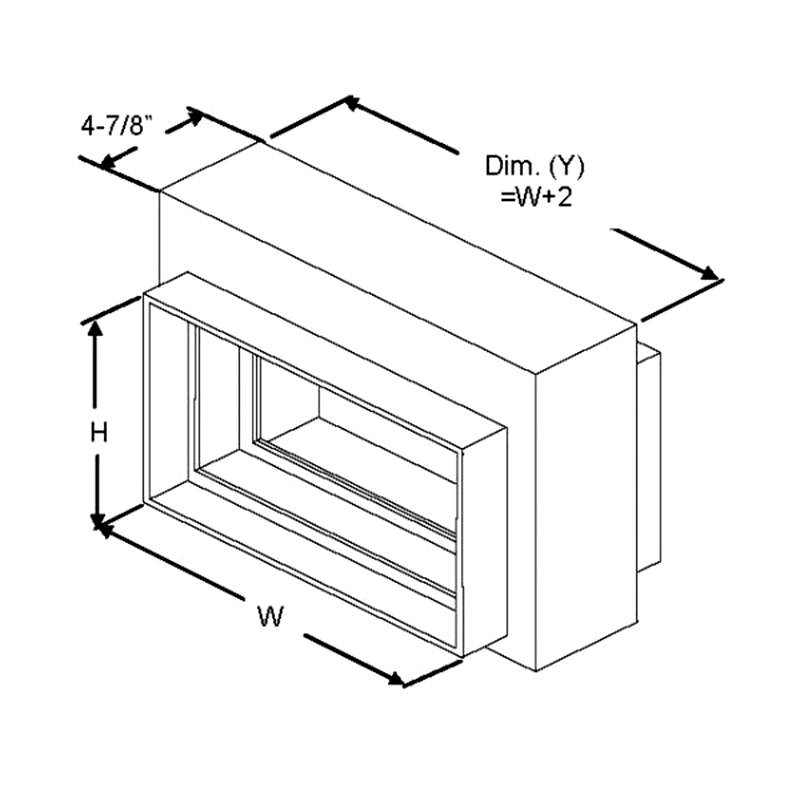

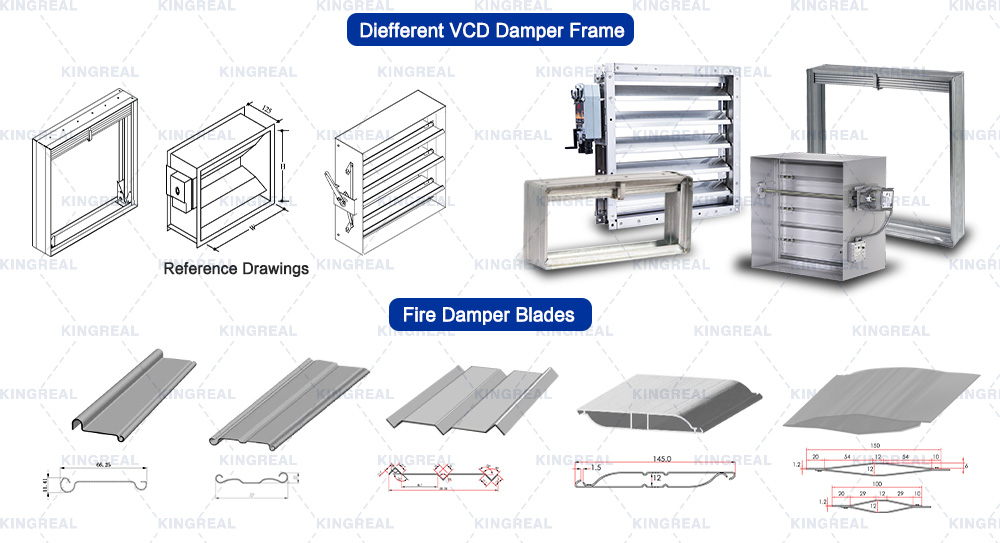

KINGREAL hvac damper frame making machines can produce three types of damper frames, depending on customer needs and applications: single-piece, two-piece, and three-piece. This flexible design allows the hvac damper frame machine to adapt to a variety of application scenarios and technical requirements.

KINGREAL hvac damper frame making machines are capable of producing a variety of fire damper frame styles, including L-shaped, slit-shaped, and sheet-shaped. These diverse frame designs can meet specific ventilation directions, flow requirements, installation space, and structural requirements, ensuring efficient and reliable system operation. Through customized hvac damper frame making machine manufacturing solutions, KINGREAL is committed to providing customers with the best product experience. |  |

Parameters of HVAC Damper Frame Machine:

| Item | Technology parameter | |

Material | Material | cold-rolled strip,galvanized steel strip |

| Thickness | 1.0-2.5mm | |

| Coil Inner | Ф360—Ф510 | |

| Process | Form Speed | 0-13m/min |

| Length | Not limit | |

Quality | Length Precision | L≤1000mm:±0.5㎜ |

Straight, Deflection | L≤1000mm,Bend no more than 1mm;Deflection no more than 2mm | |

| Forming size | As per design | |

Advantages of HVAC Damper Frame Machine

-Material Savings: The cutting-before-forming process ensures zero waste from commissioning to production.

-Excellent Forming Results: Specially designed rollers minimize wear on the zinc coating after forming the galvanized sheet.

-Small Bending Angles: Specially designed bending dies and pre-punched indentations on the small edges ensure a tight bending angle through two steps.

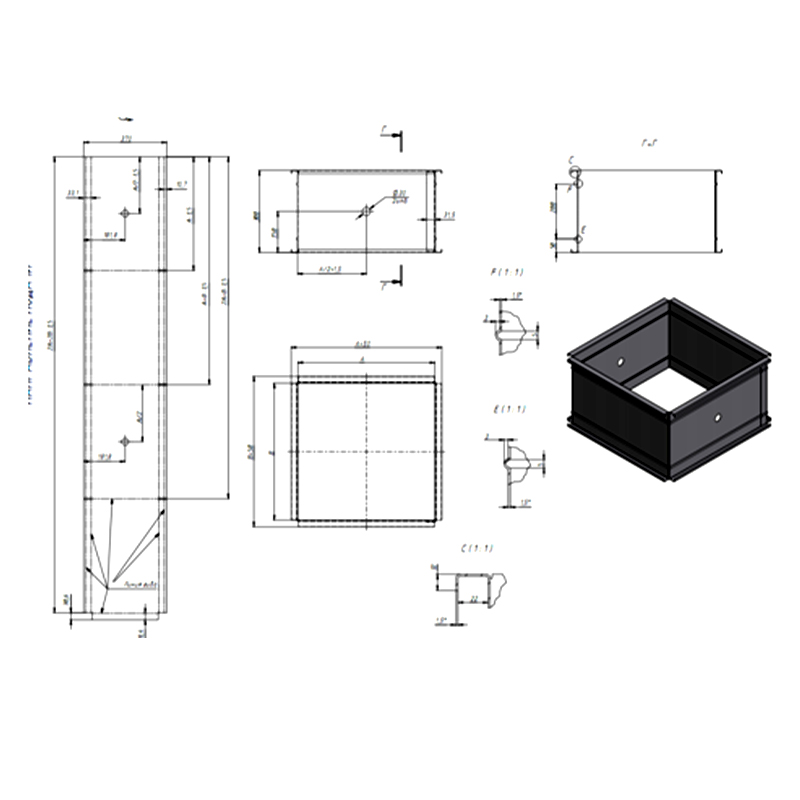

Drawing About HVAC Damper Frame:

Fire Damper Blade Making Machine

Introduction to Fire Damper Blade Making Machine :

The fire damper blade making machine is specifically designed to process metal coils and precisely shape them into the required profile for damper blades. This fire damper blade making machine utilizes a continuous manufacturing process, ensuring high product precision and consistency, which is crucial for meeting stringent fire safety standards.

The damper blades are designed to automatically close in the event of a fire, effectively sealing the duct and preventing the spread of fire. This mechanism not only enhances safety but also ensures overall system performance and reliability.

This fire damper blade making machine offers flexible operation, allowing it to customize any dimensions to meet specific requirements, allowing blades of varying widths to be manufactured on the same production line. Length tolerances can be controlled to within ±0.5 mm, and diagonal tolerances to within ±0.8 mm, further enhancing product precision.

Standard widths for fire damper blades range from 110 to 188 mm, and can be customized to meet specific customer requirements. This flexibility and high precision make KINGREAL fire damper blade making machines essential for meeting the fire safety demands of modern buildings, ensuring that every blade meets industry standards. |  |

Parameters of Fire Damper Blade Making Machine:

| Profile | Fire Damper Aerofoil Blade |

| Raw Material | GI Steel, DC51D+Z Thickness 1.5mm |

| Coil width | According to profile drawing |

| MAX Coil weight (KG) | 3000kg |

| Line speed | 0-15m/min |

Forming roller | CR12,After treatment, hardness HRC58-62 15 stations |

| Shaft diameter | 60mm, 40CR after treatment |

Driving system | By gearing box |

Dimension (mm) | 9500*1100*1200 |

Main motor power (KW) | 11KW |

Advantages of Fire Damper Blade Making Machine:

-High-Speed Production: These fire damper blade making machines can efficiently produce large quantities of highly precise blades.

-Customization Options: Depending on customer requirements, KINGREAL fire damper blade making machine designs may include automated cutting, punching, and slotting capabilities, allowing for customized dimensions and functional properties tailored to each application.

-Quality Assurance: Fire damper blades produced by KINGREAL fire damper blade making machines are robust and reliable, essential for the effective operation of fire dampers within buildings.

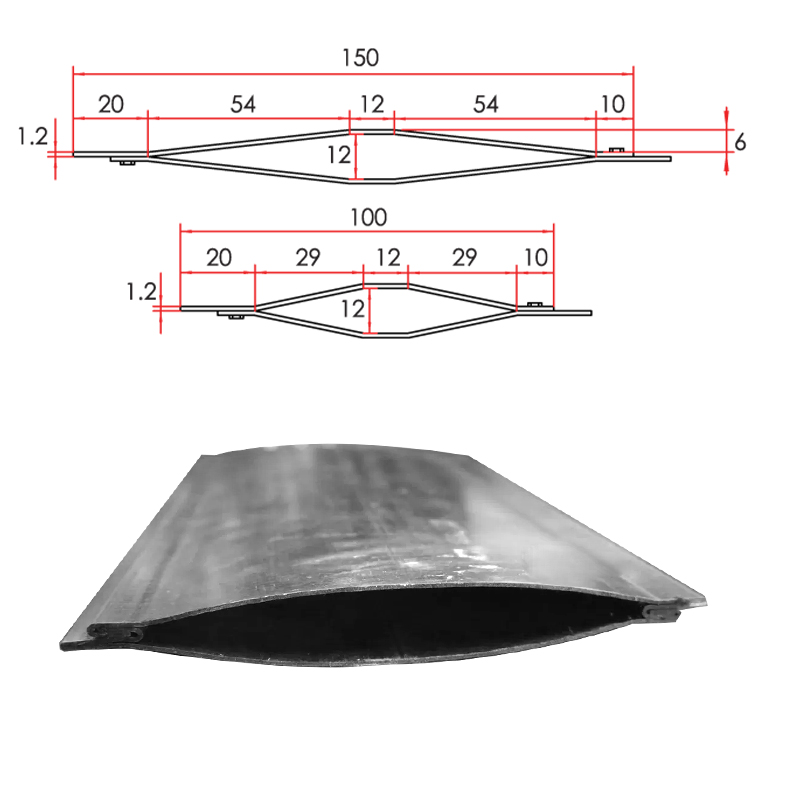

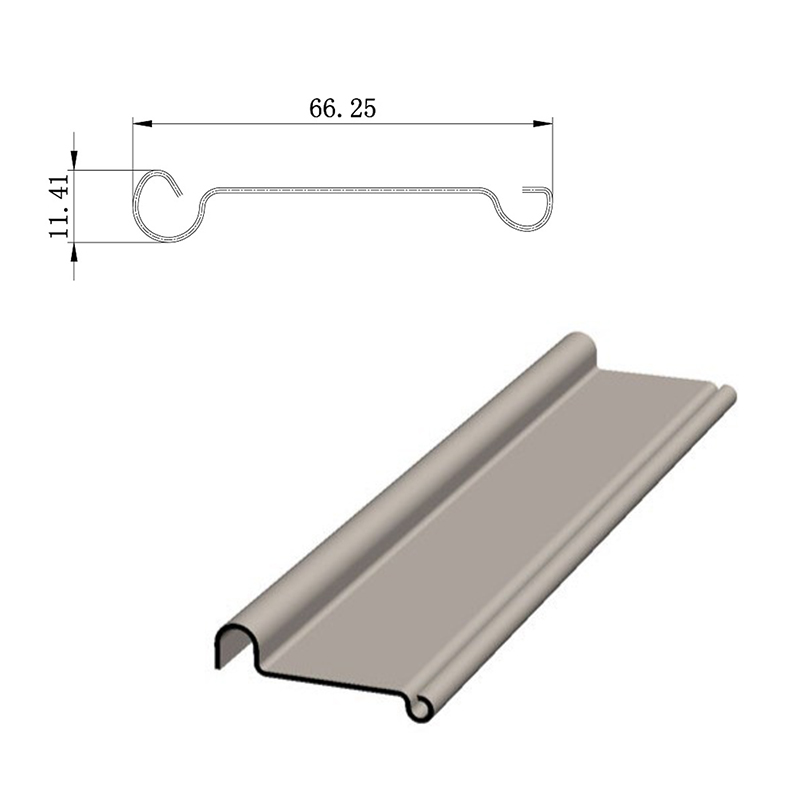

Drawing About Fire Damper Blade:

TDC Flange Forming Machine

Introduction to Flange Forming Machine:

Ducts are piping systems used for air transportation and distribution. Their flange cross-sectional shapes can be categorized as either TDC flanges or TDF flanges. KINGREAL offers two types of flange forming machines: tdc flange machine and tdf flange machine, to meet diverse production needs. To further enhance the customer customization experience, KINGREAL has also subdivided these two flange forming machines into several more targeted models designed to meet a wider range of production requirements. |  |

Parameter of Flange Forming Machine:

TDC flange machine:

| Model | Flange Height(mm) | Thickness(mm) | Power(kw) | Weight(KG) | Dimension(mm) |

| Model 1 | 20 | 0.6-0.8 | 3 | 2200 | 3800×600×1250 |

| Model 2 | 25 | 0.6-0.8 | 3 | 2500 | 3800×600×1250 |

| Model 3 | 30 | 1.0 | 3 | 2700 | 4300×600×1250 |

| Model 4 | 35 | 1.0 | 4 | 3100 | 4300×600×1250 |

| Model 5 | 40 | 1.0-1.2 | 4 | 3300 | 4300×600×1250 |

TDF flange machine:

| Model | Power(kW) | Sheet Thickness(mm) | Weight(kg) | Dimension L*W*H(mm) |

| T-12 | 3 | 0.5-1.2 | 840 | 2550*700*1100 |

| T-15 | 0.8-1.5 |

Advantages of Flange Forming Machine:

TDF Flange Machine:

KINGREAL categorizes its flange s into two types: single tdf flange machines and double tdf flange machines, depending on the job requirements:

Single tdf flange machine: Available in the T-12 and T-15 models, these tdf flange machines simultaneously form the flange shape on one side and the clip shape on the other. This design makes the production process more efficient and reduces changeover time.

Double tdf flange machine: Capable of forming flanges on both sides simultaneously, they significantly reduce production time and improve overall efficiency. This type of tdf flange machine is particularly suitable for high-volume production.

TDC Flange Machine:

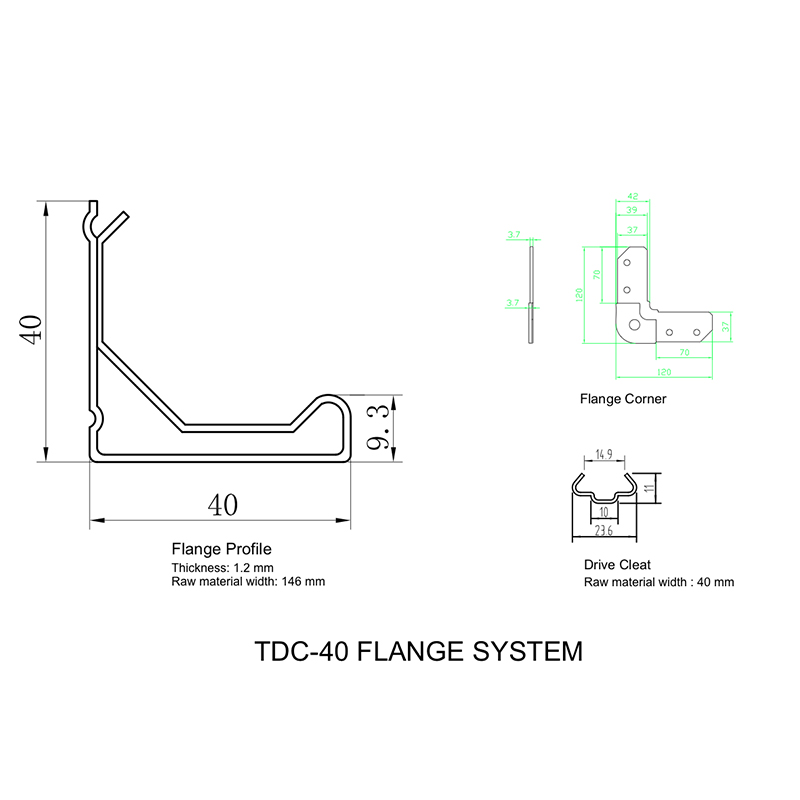

KINGREAL has designed five specialized TDC flange machines to meet the diverse processing requirements of our customers.

These tdc flange machines automatically form TDC flanges and provide automatic feeding during the sheet metal processing process. Each tdc flange machine varies in flange height, processable metal thickness, and performance configuration, providing a more flexible solution to meet diverse production needs.

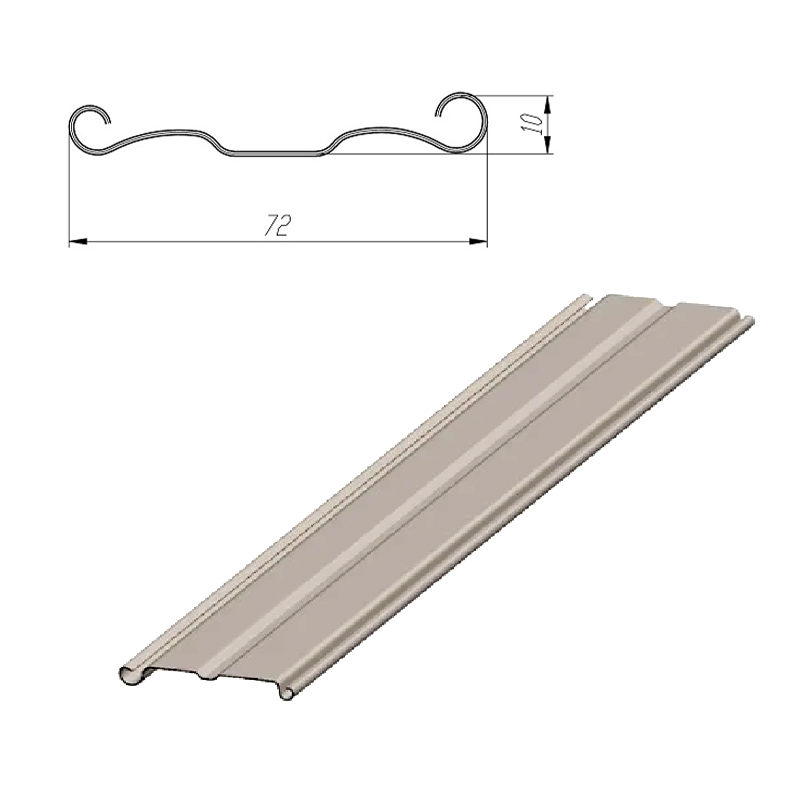

Drawing About TDC Flange & TDF Flange:

Applications of HVAC Damper Frame Making Machine

HVAC damper frames produced by the hvac damper frame machine are primarily used in the following areas:

1. Heating, Ventilation, and Air Conditioning (HVAC) Systems -Central Air Conditioning Systems: Used to adjust the supply air volume to each area for temperature zone control -Fresh Air Systems: Control the ratio of fresh air to return air to ensure indoor air quality -VAV (Variable Air Volume) Systems: Automatically adjust the supply air volume based on load changes to achieve energy savings -Smoke Exhaust Systems: Rapidly switch valve states during a fire to guide smoke exhaust 2. Industrial Production Systems -Chemical Industry: Reactor Ventilation and Exhaust Gas Treatment Systems -Pharmaceutical Industry: Cleanroom Pressure Control and Process Exhaust Systems -Food Processing: Drying System Air Volume Control and Odor Control -Electronics Manufacturing: Cleanroom Airflow Management and Static Control 3. Environmental Protection and Exhaust Gas Treatment Systems -Flue Gas Desulfurization and Denitrification Systems: Regulate Flue Gas Volume -Industrial Dust Removal Systems: Control Dust Collector Air Volume Distribution -VOCs Treatment Systems: Optimize Exhaust Gas Collection Efficiency -Waste Incineration: Regulate Incinerator Air Volume 4. Energy and Power Industry Systems -Power Plants: Boiler Combustion Air Conditioning and Flue Gas Recirculation -Nuclear Power Plants: Ventilation System Safety Control -New Energy: Process Air Control for Biomass and Waste-to-Energy Power Generation

5. Transportation Systems -Tunnel Ventilation Systems: Adjust Ventilation Volume Based on Traffic Flow -Subway Systems: Environmental Control for Platforms and Tunnels -Ship Ventilation: Cabin Air Conditioning |  |

If you want to know more information about hvac damper frame making machine, welcome to consult KINGREAL!