Roof And Wall Panel Roll Forming Machine

KINGREAL Roof And Wall Panel Roll Forming Machine can provide customers with a variety of solutions for metal roof tile systems and wall panel systems.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Brief Introduction of Roof And Wall Panel Roll Forming Machine

With the improvement of living standards, people have higher requirements for building decoration, so when decorating, they put forward more requirements and ideas for the design of the wall and the design of metal roof tiles, so different types of metal roofing machines and metal wall cladding panel machines came into being, and they are exactly what customers need.

Metal roofing machines and metal wall cladding panel machines usually provide roof tiles to customers when customers have roof tile production needs, and provide wall panels when customers have wall panels.

Roof & Wall Panel Machines are designed to process flat metal coils into the required shape of roof tiles or wall panels. It consists of a series of rollers and dies that gradually form the metal coils as they pass through the machine. The rollers and dies are carefully configured to form the specific shape and size required for roof tiles or wall panels.

The process first puts the metal coil into the Roof & Wall Panel Machine, and when the coil passes through the machine, it undergoes a series of operations such as unwinding, forming and cutting. These operations are precisely controlled to ensure the precise formation of the wall panel or house tile profile.

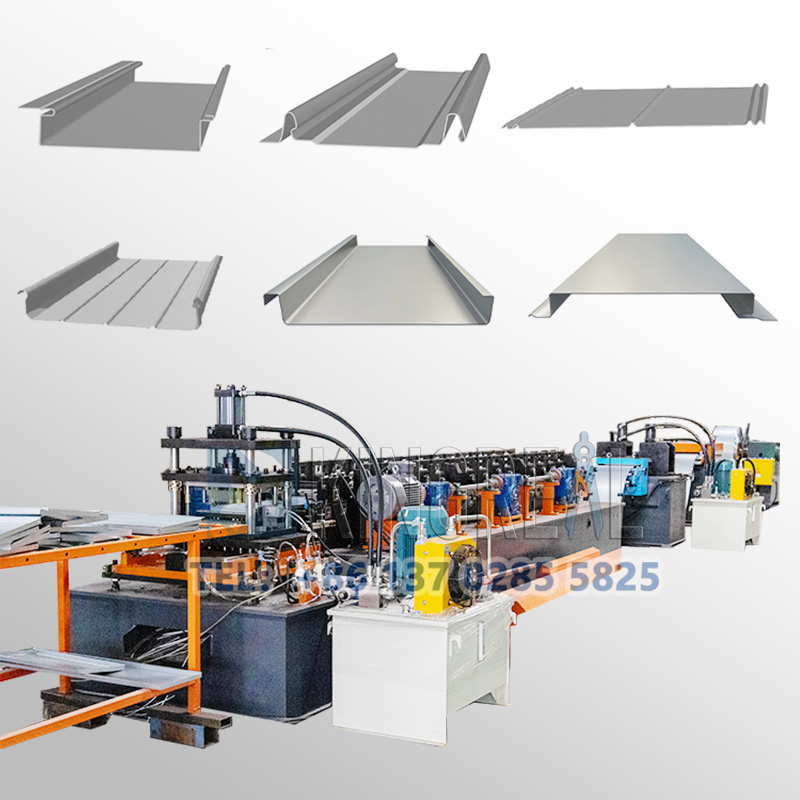

| The wall panels produced by the metal wall cladding panel machine provide beautiful and practical solutions for interior and exterior walls. The metal wall cladding panel machine is usually equipped with an advanced computer control system that allows easy setting and adjustment of the machine. This enables the operator to produce wall panels of different shapes and sizes with minimal effort, producing various types of wall panels required by customers, such as flat panels, small v ribs, clip relief, large v ribs, striations, small pencil ribs, beads and large pencil ribs, etc. |  |

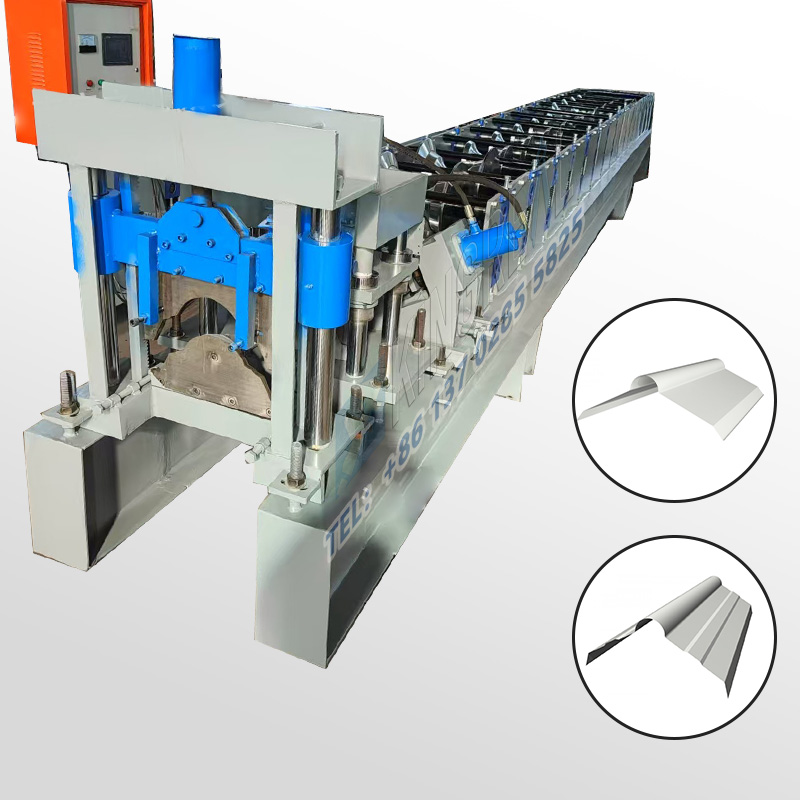

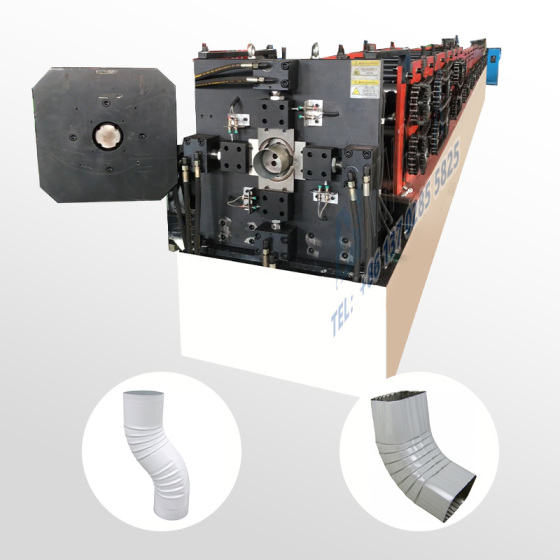

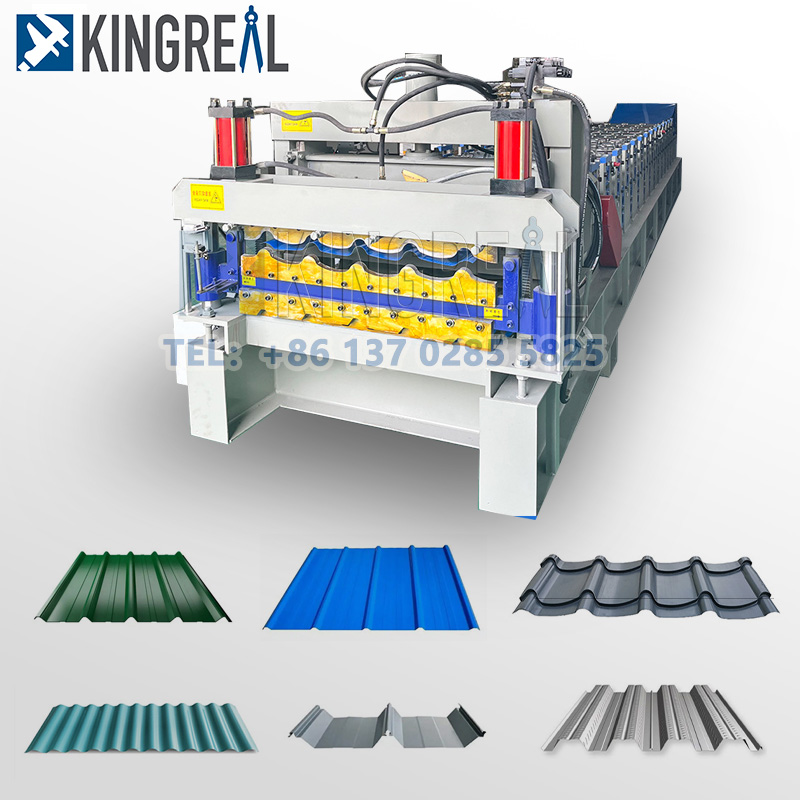

The metal roof tiles produced by the metal roofing machine provide a diverse solution for roof decoration projects. The metal roofing machine usually consists of three main components: decoiler, roll forming machine and shearing station. According to the actual needs of customers, different sizes and types of metal roof tiles can be produced, KINGREAL can provide glazed roof tile machine, ibr roof tile machine, corrugated tile machine,double layer roof tile machine, standing seam roof panel machine, etc. In addition, KINGREAL can also provide customers with downspout roll forming machine, gutter making machine, floor deck roll forming machine, which are closely related to the metal roof tile system. |  |

Video About Roof And Wall Panel Roll Forming Machine

Main Components of Roof And Wall Panel Roll Forming Machine

Decoiler Main Roll Forming Machine Cutting Station |  |

Decoiler Straightener Punching Station(Optional) Main Roll Forming Machine Cutting Station |  |

Advantages of Roof & Wall Panel Machine

① Advanced technology KINGREAL integrates cutting-edge production technologies. These advanced technologies not only improve the production efficiency of Roof & Wall Panel Machines, but also improve the precision and quality of products. For example, the use of intelligent control systems can monitor various parameters in the production process in real time to ensure the consistency and stability of products. At the same time, the operation interface design of the machine is simple and clear, which greatly reduces the difficulty of operation, and even novices can quickly get started. |  |

② Customizable design KINGREAL Roof & Wall Panel Machines are highly customizable and can adapt to different architectural needs and design styles. Whether it is traditional metal roof tile design or modern wall panel style, KINGREAL can provide corresponding solutions. In particular, while maintaining the strength and service life of metal materials, the Roof And Wall Panel Roll Forming Machine can achieve a variety of architectural styles and meet customers' dual needs for beauty and practicality. In response to customers' special needs in the production of perforated wall panels, KINGREAL provides metal wall cladding panel machines that can be equipped with punching stations. This design not only improves the flexibility of production, but also effectively liberates labor and improves production efficiency. In addition, in order to meet the market's requirements for automated production, KINGREAL has also equipped the metal roofing machine with an automatic packaging machine, further improving the overall intelligence level of the production line. Through the introduction of automated equipment, enterprises can not only reduce labor costs, but also improve the packaging quality of products and ensure the safety of finished products during transportation. |  |

③Flexible production capacity KINGREAL Roof & Wall Panel Machines are extremely flexible and can quickly adjust production parameters to produce finished products of different sizes and types according to the different needs of customers. No matter what specifications of metal roof tiles or wall panels the customer needs, KINGREAL can provide a variety of options. Through simple parameter input, users can easily adjust machine settings to meet specific production requirements. This flexibility enables customers to respond quickly to market changes and adjust production plans in a timely manner, thereby maintaining a competitive advantage. |  |

Application of Roof & Wall Panel Machines

Metal wall cladding panel machine: Metal wall cladding panel machines are often used in the cladding of houses, apartments and townhouses, the exterior walls of office buildings, shopping centers and hotels, the exterior walls of industrial facilities and agricultural buildings, and public infrastructure. It has the characteristics of improving aesthetics, heat insulation and windproof, and meeting energy-saving standards. |  |

Metal roofing machines are often used in any place with a roof in residential areas and industrial areas. They have the characteristics of smooth drainage and improving the consistency of house style. |  |

Related Roof And Wall Panel Roll Forming Machines

KINGREAL can provide metal roofing machines:

double layer roof tile machine,

standing seam roof panel machine,

...

KINGREAL can provide metal wall cladding panel machines:

Trapezoidal Wall Panel Roll Forming Machine,

Concealed fastener wall panel machine,

...