2025 Metal Ceiling Machine Project

2025-11-19 18:37As a professional metal ceiling machine manufacturer, KINGREAL achieved outstanding results in 2025, successfully completing several metal ceiling machine projects, including ●baffle ceiling making machines, linear strip ceiling machines, open cell ceiling machines, and metal ceiling tile production lines●, in collaboration with customers in Italy, Turkey, the UK, Ukraine, Russia, Greece, and other countries. To date, most of these metal ceiling machines are operating stably in the customers' factories, bringing them large quantities of high-precision finished products and generating substantial profits. A small number of metal ceiling machines have been inspected by customers at their factories, and with their approval, the equipment is awaiting shipment. Below, we will detail the various metal ceiling machine projects that KINGREAL collaborated on with customers in 2025.

1. Metal Ceiling Tile Production Line Project

The metal ceiling tile production line is KINGREAL flagship product. KINGREAL can provide fully automatic and semi-automatic metal ceiling tile production line solutions to meet customers' diverse production needs. In 2025, KINGREAL provided customized metal ceiling tile production line solutions for customers in Italy, Greece, Ukraine, and Turkey. During the metal ceiling tile production line design process, KINGREAL engineers fully considered the specific needs of the customers, including drawings, production processes, and cost-effectiveness. Meanwhile, taking into account the different climate conditions and policy requirements for equipment performance in various countries, KINGREAL ensures that the final metal ceiling tile production line can operate efficiently and stably in specific environments. For example, KINGREAL designed a metal ceiling tile production line with protective covers for an Italian customer to prevent unauthorized personnel from entering the metal ceiling tile production lines while they are operating, reducing safety hazards and improving production safety.

For a Greek customer, KINGREAL provided a fully automated metal ceiling tile production line, specially equipped with a metal sheet cleaning machine. The metal sheet cleaning machine cleans oil stains from the metal ceiling tile surfaces during production, allowing the finished products to be used or sold directly, significantly saving the customer's cleaning time and labor costs. Furthermore, a long-term customer in Turkey has been expanding its production scale in recent years and urgently needed to purchase a new metal ceiling tile production line. The KINGREAL team quickly communicated with them, looking forward to providing production assistance to the Turkish customer once again.

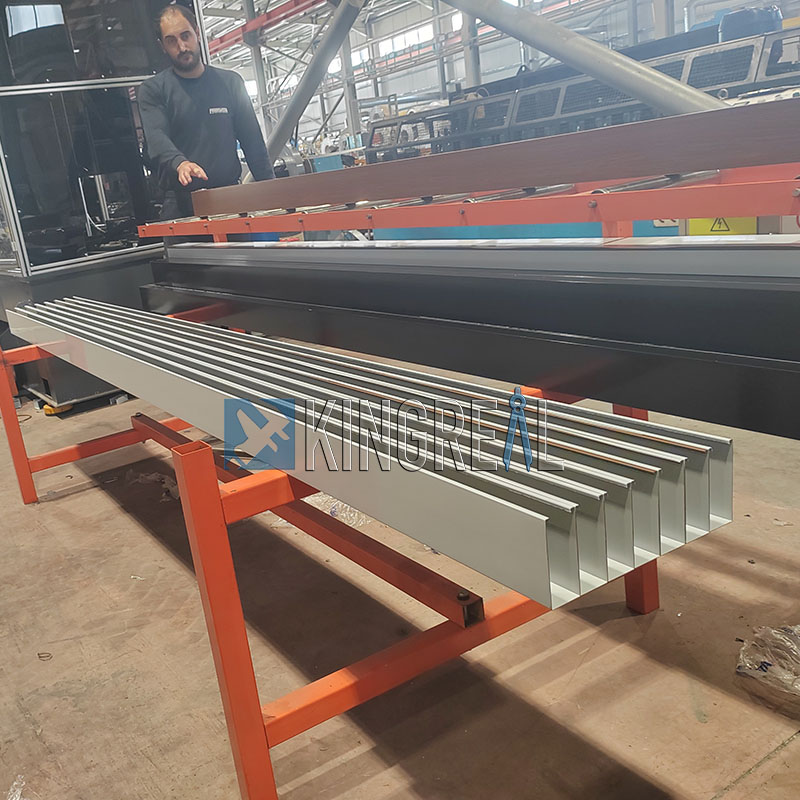

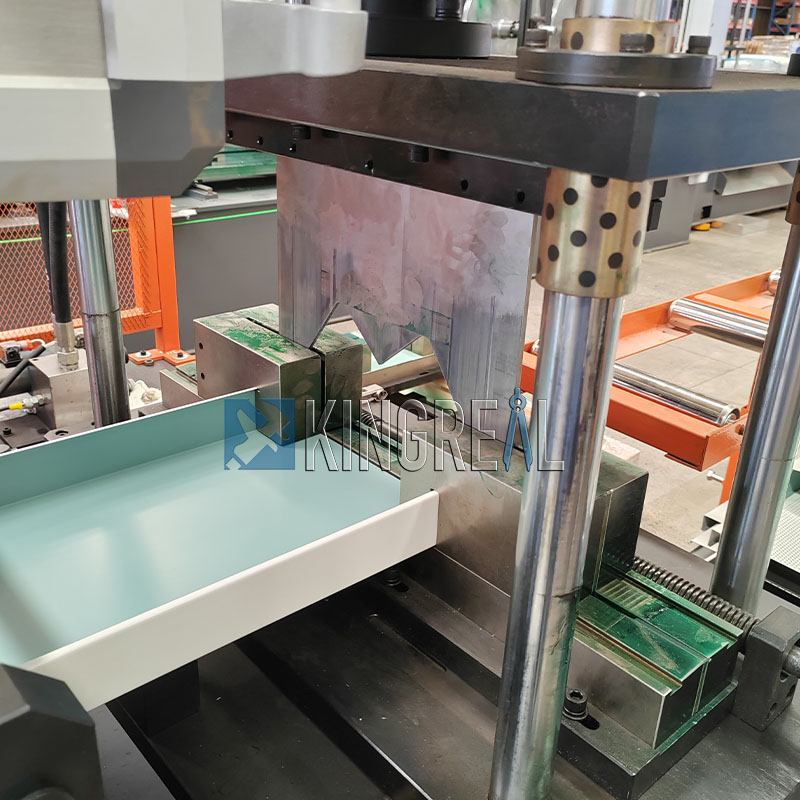

More importantly, to meet the needs of a Ukrainian customer, KINGREAL designed a metal ceiling tile production line equipped with a tiles flipping machine, an automatic tiles feeding machine, and an auto-bending forming press. This metal ceiling tile production line can automatically produce 600x600mm metal ceiling panels. It successfully passed quality inspection when a Ukrainian customer visited the factory for testing, and both parties have begun negotiating delivery arrangements.

2. Baffle Ceiling Making Machine Project

At the beginning of this year, KINGREAL engineers visited factories in Italy and Vietnam to install baffle ceiling making machines. For the Italian customer's specific needs, KINGREAL engineers also designed a baffle ceiling making machine equipped with a protective shield. This prevents workers from being injured by accidental contact with moving parts during baffle ceiling making machine operation, improving factory safety management. The protective shield can be opened at any time when the baffle ceiling making machine stops for easy daily cleaning and maintenance.

In collaboration with Vietnamese workers, the fully automatic baffle ceiling making machine was quickly installed. After testing with metal coils, KINGREAL engineers found that the baffle ceiling making machine maintained stable production at a speed of 30m/min, demonstrating excellent performance. Based on the Vietnamese customer's daily production needs, KINGREAL engineers repeatedly adjusted the production parameters to ensure the baffle ceiling making machine could accurately produce high-quality finished products, to which the Vietnamese customer expressed great satisfaction.

3. Open Cell Ceiling Machine Project

KINGREAL has provided various types of open cell ceiling machine solutions for customers in Vietnam, Ukraine, and Russia. These solutions fully consider the diverse needs of the market and the personalized requirements of customers. During the open cell ceiling machine acceptance phase, the Vietnamese customer personally visited the KINGREAL factory to participate in the open cell ceiling machine's operational testing. The customer not only participated in the splicing of the grilyato ceilings but also worked with KINGREAL staff to assess the precision of the finished products, ensuring everything met expectations.

To meet the Ukrainian customer's demand for different specifications of finished products, KINGREAL specially designed a multi-specification open cell ceiling machine. This open cell ceiling machine, through control panel settings, can automatically adjust the forming rollers, thereby producing grilyato ceilings of various specifications. This flexible design significantly improved the Ukrainian customer's production efficiency and adapted to changing market demands.

The cooperation process with the Russian customer was also very fruitful. In the first half of this year, KINGREAL sent professional engineers to the Russian customer's factory to conduct open cell ceiling machine installation and operation training. Through professional training, Russian workers gained a deep understanding of the open cell ceiling machine's use and acquired proficient operating skills. KINGREAL engineers ensured that each worker could operate the equipment independently before concluding the training. After the training, the workers spontaneously celebrated in the factory, expressing their joy and satisfaction with the open cell ceiling machine.

4. Linear Strip Ceiling Machine Project

In 2025, KINGREAL completed linear strip ceiling machine projects with customers in the UK and Vietnam. After the linear strip ceiling machine was manufactured, KINGREAL invited the UK customer to the factory for acceptance testing. The customer conducted a comprehensive and detailed evaluation of the linear strip ceiling machine's appearance and the performance of each component, including the decoiler, leveler, roll forming machine, and shearing station. During the linear strip ceiling machine tour, the UK customer also had in-depth discussions with KINGREAL engineers regarding the use of protective shields, exchanging valuable experience and insights.

For the linear strip ceiling machine design for the Vietnamese customer, KINGREAL fully considered maximum automation. The customer only needs to set the parameters (including finished product specifications, quantity, and operating speed) on the control panel, and the linear strip ceiling machine can automatically complete the uncoiling, leveling, forming, and precise shearing of metal coils, greatly reducing manual intervention and improving production efficiency. The Vietnamese customer expressed great satisfaction with the linear strip ceiling machine's performance, believing it perfectly met their production needs.

The metal ceiling machine projects undertaken in collaboration with KINGREAL customers have all received unanimous praise. Besides highly commending the high-quality metal ceiling machines provided by KINGREAL, customers also expressed satisfaction with KINGREAL one-stop service. They believe that KINGREAL not only excels in metal ceiling machine manufacturing but also provides excellent after-sales service and technical support. The KINGREAL team will continue to monitor the status of these metal ceiling machines to ensure smooth production operations for our customers and provide necessary after-sales support. When needed, KINGREAL will promptly assist customers with metal ceiling machine maintenance and spare parts supply to protect the normal operation of their production lines.