Case: Cable Tray Making Machine

2025-06-27 14:39

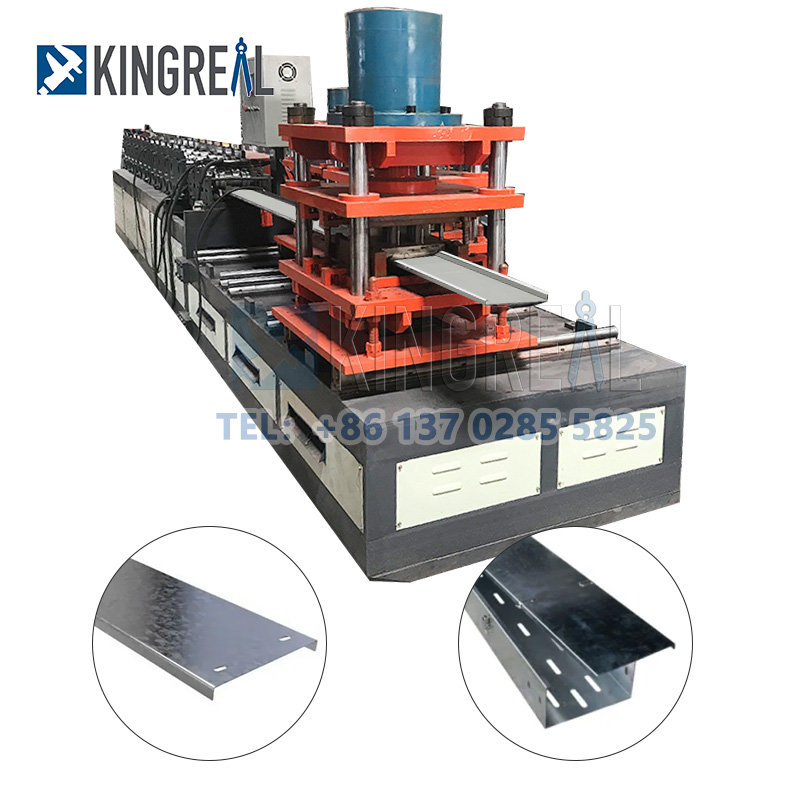

Last year, KINGREAL successfully sold a cable tray making machine to Brazil. This article aims to introduce this success story in detail, as well as the main features and advantages of this cable tray machine. If you need more information about this cable tray machine, please feel free to contact KINGREAL! |  |

Brazilian Customer Background

This Brazilian customer is a professional cable tray seller, dedicated to providing high-quality cable trays for various construction projects. With the rapid development of the power and communication industries, the demand for cable trays continues to increase, and the customer's business continues to expand. Cable trays are not only used to hang cables and signal lines, but also effectively protect them to ensure the safe operation of power facilities. In order to meet the needs of multiple construction projects, the Brazilian customer urgently needs a cable tray making machine that can mass-produce high-precision finished products.

In the early communication, the Brazilian customer provided detailed drawings and actual production needs. Based on this information, the KINGREAL team developed different cable tray machine solutions for the customer. These solutions include the feeding design of coils or sheets, and the configuration of different cable tray making machines. Finally, after inviting Brazilian customers to the KINGREAL factory for a field visit, the two sides confirmed the most suitable cable tray machine manufacturing plan. The plan fully considers the width, thickness and height of the cable tray required by Brazilian customers, ensuring the full adaptation of the cable tray making machine. |  |

Features of Cable Tray Machine

KINGREAL cable tray making machine consists of multiple precision components, including decoiler, punching station, roll forming machine, cutting station, etc., which can produce cable trays of different sizes according to customer needs. The following is a detailed introduction to each component:

Decoiler for cable tray machine This decoiler is specially designed to carry coils weighing up to 10 tons, with the ability to unwind quickly, which can efficiently meet production needs. The design of the decoiler fully considers the user's operating convenience to ensure smooth operation during the production process. |  |

Punching station for cable tray making machine With rich industry experience, KINGREAL provides customers with the best punching die solution. The die is independently built in the KINGREAL factory to ensure the best adaptation and accuracy of the punching effect. This design avoids potential problems caused by outsourcing and procurement, allowing Brazilian customers to easily obtain perfect punching effects on KINGREAL cable tray machine. |  |

Roll forming machine for cable tray machine The cable tray making machine provided by KINGREAL has the function of automatically adjusting the width and height. The operator only needs to enter the required finished product size on the control panel, and the roller of the roll forming machine will automatically adjust to the corresponding position. In addition, according to the production needs of Brazilian customers, KINGREAL also customized the cable tray machine to adapt to the number of stations and shaft diameters produced by customers. This flexibility enables Brazilian customers to efficiently produce cable trays that meet market needs. |  |

Cutting station for cable tray making machine The cutting station is equipped with high-strength blades that can perform precise cutting to ensure the consistency of the finished product and the flatness of the cross-section. This design not only improves production efficiency, but also minimizes the waste of metal materials. By optimizing the shearing process, KINGREAL cable tray machine effectively reduces production costs and creates higher economic value for Brazilian customers. |  |

Brazilian Customer Evaluation for Cable Tray Machine

After using KINGREAL cable tray making machine, Brazilian customers gave high praise to the performance of the machine. He mentioned that KINGREAL cable tray machine is highly flexible, not only can it adjust the production speed, but also can adjust the size of the finished product according to demand.

The Brazilian customer particularly praised the quality of the roll forming machine and the cutting station, saying that it provides a smooth and consistent forming and cutting process, which greatly improves production efficiency. In addition, the efficient design of the cable tray making machine minimizes the waste of metal materials and reduces production costs. This is achieved by optimizing the production process and accurately controlling the use of materials.

The Brazilian customer also said that as the business expands, he intends to expand the sales scope and plans to negotiate with KINGREAL for the purchase of other types of cable tray making machines in the future, including Cable Ladder Machine, Cable Tray Cover Machine and Din Rail Channel Machine, etc.

Through this successful case, KINGREAL has demonstrated its professional capabilities and technical strength in the field of cable tray machines. KINGREAL not only provides high-quality cable tray making machines, but also is committed to tailoring solutions for customers to meet their specific production needs. KINGREAL cable tray machines have won wide recognition from customers for their efficiency, flexibility and reliability.

If you are interested in cable tray machines or other equipment, please feel free to contact KINGREAL. KINGREAL will wholeheartedly provide you with professional consultation and services.