Wall Siding Panel Machine Shipped to Greece

2025-07-21 15:40"In the modern construction industry, the application of wall siding panel machine is becoming more and more extensive. As an efficient and flexible production equipment, the metal wall cladding panel machine not only improves production efficiency, but also reduces labor costs."

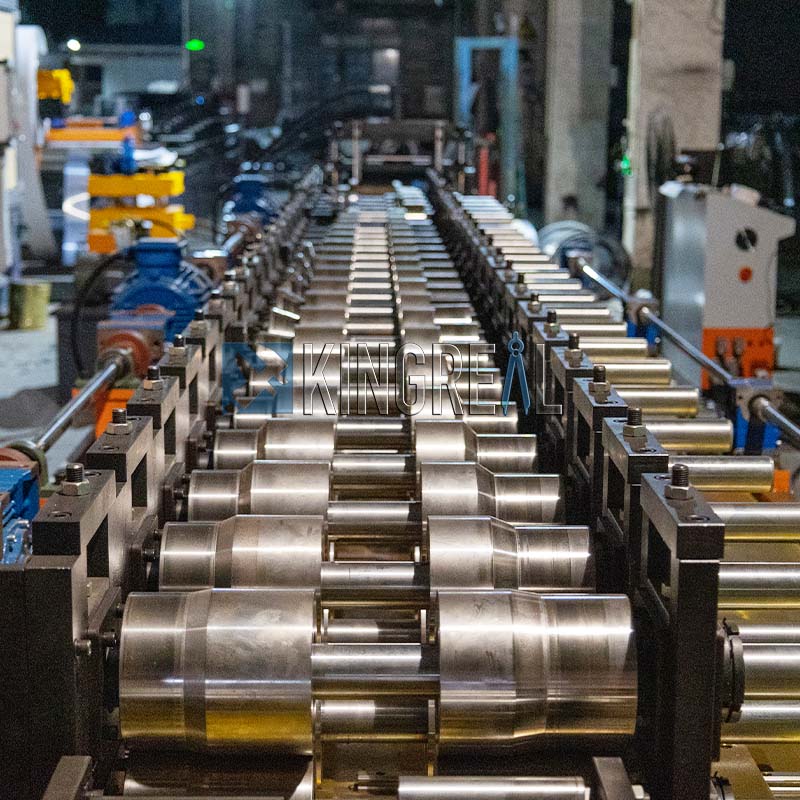

Two weeks ago, the KINGREAL wall siding panel machine completed manufacturing and machine testing in the factory and was rated as a qualified metal wall cladding panel machine. After obtaining the permission of the Greek customer, KINGREAL quickly contacted the freight company and started the process of shipping this wall siding panel machine to the Greek customer's factory. This article will introduce the process of shipping this metal wall cladding panel machine in detail, as well as the basic information and technical parameters of the KINGREAL wall siding panel machine. |  |

1/ Preparation for Shipment of Wall Siding Panel Machine

Machine testing & qualification assessment

Before shipment, KINGREAL engineers conducted rigorous tests on the metal wall cladding panel machine to ensure that its performance and quality meet international standards. The testing process includes checking the wall siding panel machine's production speed, ease of operation, automatic control system and other aspects to ensure that every detail can meet the expectations of Greek customers.

Packaging & transportation of wall siding panel machine

After confirming that the metal wall cladding panel machine is qualified, KINGREAL staff began to pack the machine. Each component of the metal wall cladding panel machine, including the decoiler, leveler, main roll forming machine, cutting station, receiving table, etc., was carefully packed to prevent damage during transportation. KINGREAL used a forklift to safely transport these components to the truck and checked the parts list of the wall siding panel machine one by one to ensure that all accessories were complete and correct.

After confirming that everything was correct, the KINGREAL staff tied all the items firmly, then closed the door and the truck drove to the dock. This process was very meticulous, and the KINGREAL team always remained efficient and professional to ensure the smooth delivery of the metal wall cladding panel machine.

Handling from truck to ship

After arriving at the dock, KINGREAL staff carefully moved the wall siding panel machine from the truck to the ship. During this process, KINGREAL ensured that each metal wall cladding panel machine was properly handled to avoid any potential damage. The staff also recorded the entire handling process and sent the progress to the Greek customers in real time through pictures and videos, so that the Greek customers could always keep abreast of the delivery dynamics.

2/ Basic Information of Wall Siding Panel Machine

Production speed and ease of operation of metal wall cladding panel machine

This metal wall cladding panel machine has a production speed of up to 20 m/min, and can flexibly adjust the production speed, cutting length and production quantity according to different parameters entered on the control panel. The operation of the wall siding panel machine is very simple, and workers can easily learn and master it, which greatly reduces training time and cost.

Safety device for metal wall cladding panel machine

In order to ensure safe operation, the wall siding panel machine is equipped with a variety of safety measures. When there is a problem with the wall siding panel machine, the system will automatically detect the specific fault location and push the alarm in time. In an emergency, the wall panel cladding machine will automatically stop to ensure the safety of the operator and the normal operation of the metal wall cladding panel machine.

3/ Parameters of Wall Siding Panel Machine

Decoiler: Manual decoiler

Inner diameter:480-520mm

Outer diameter:1250mm

Loading weight: 5TONs

Expansion: Manually

Forming speed:20m/min

Forming stations:14-18 stations

Machine base:welded with 36#Hbeam-steel

Material of Shafts: 45# high quality steel

Diameter of Shafts: 70mm

Material of Roller: high quality 45#steel coated with hard chrome 0.05mm

Thickness of Siding Plate:18mm

Transmission by Chain-brackets

Motor Power: 5.5 KW

Hydraulic Cutter of the roofing cladding sheet roll forming machine

Material of blade Crl2 with quenched treatment 48-50

Hydraulic Power: 4 KW

Cutting Length and Quantity Clients can set the required length and quantity on the PLc touch screen

Control System of roofing cladding sheet roll forming machine

Panasonic PLC Control, LCD screen, touch screen, frequency converter

Voltage 380v/50HZ/3phase

Automatically measure the length and quantity

4/ Follow-up After Machine is Shipped

After the wall siding panel machine is shipped, the KINGREAL team continues to communicate with Greek customers to ensure that they can get timely support and help when they have any questions about the machine. KINGREAL engineers also provided detailed operation manuals and maintenance guides to ensure that Greek customers can use the wall siding panel machine smoothly.

Through the delivery process of this wall siding panel machine, it not only demonstrates the professionalism and efficient execution of the KINGREAL team, but also reflects KINGREAL's attention and commitment to customer needs. In the future, KINGREAL will continue to be committed to providing more efficient and high-quality metal wall cladding panel machines and services to global customers, and promote innovation and development in the construction industry.