- Home

- >

News

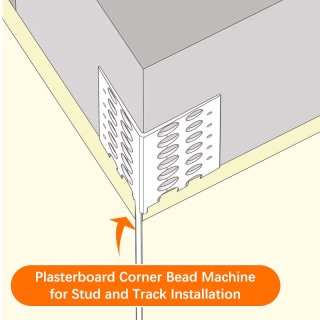

In modern architecture and interior decoration, gypsum board has become a widely used wall material. To ensure the strength, aesthetics, and construction efficiency of gypsum board walls, the use of plasterboard corner bead machines is particularly important. In particular, in partition systems used for installing studs and tracks, plasterboard corner bead making machines not only effectively enhance the structural stability of the wall but also optimize the construction process. This article will discuss in detail the functions, advantages, and applications of plasterboard corner bead machines in partition systems.

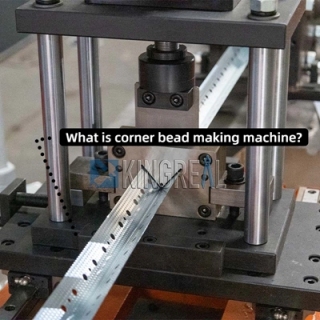

The corner bead making machine is used to produce corner bead of various sizes and types, typically using metal materials with a thickness ranging from 0.2-1.2mm. Punching, logo embossing, and other custom features can be customized to meet specific customer needs. This corner bead machine can be customized to your specific specifications, perfectly matching your project's requirements. Comprehensive safety features ensure peace of mind for operators. Furthermore, the low-noise corner bead making machine offers significant advantages in environments with strict noise requirements. The fully automated design allows for efficient production within the factory.