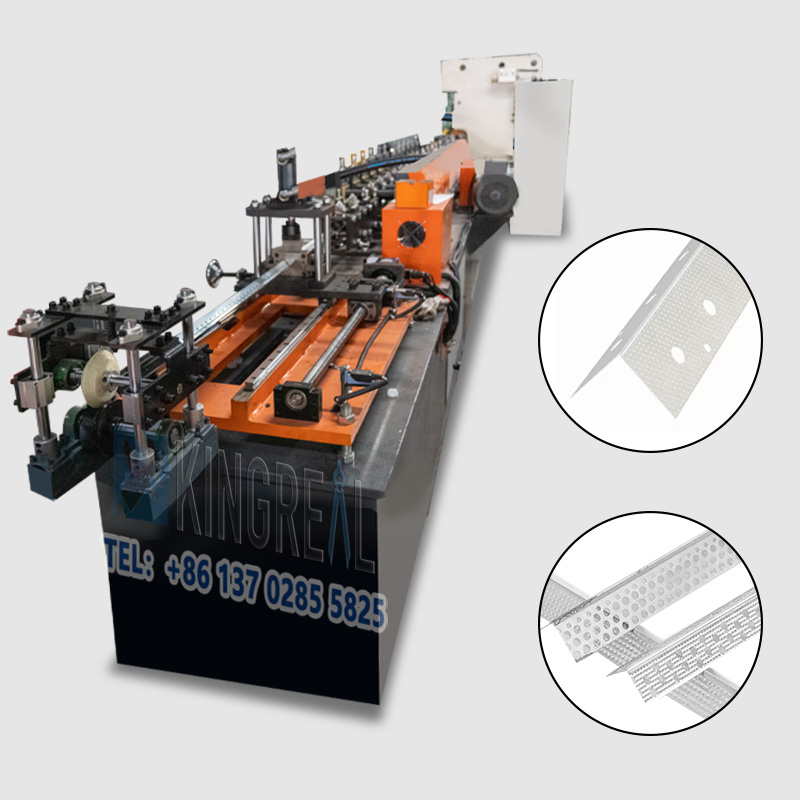

Plasterboard Corner Bead Machine for Stud and Track Installation

2025-08-21 12:00In modern architecture and interior decoration, gypsum board has become a widely used wall material. To ensure the strength, aesthetics, and construction efficiency of gypsum board walls, the use of plasterboard corner bead machines is particularly important. In particular, in partition systems used for installing studs and tracks, plasterboard corner bead making machines not only effectively enhance the structural stability of the wall but also optimize the construction process. This article will discuss in detail the functions, advantages, and applications of plasterboard corner bead machines in partition systems.

1/ What is a Plasterboard Corner Bead Making Machine?

A plasterboard corner bead machine is a type of equipment specifically designed for producing galvanized steel non-load-bearing partition walls. Its primary function is to produce the corner bead that form the basic metal frame of the gypsum board wall. These profiles, along with the studs (vertical studs) and tracks (horizontal studs), form the partition system and provide structural support.

Galvanized steel, stainless steel, aluminum, and several other materials may be used to create the plasterboard corner bead produced by plasterboard corner bead machines. Offering a range of length alternatives to lower material waste and the demand for splicing, KINGREAL plasterboard corner bead making machines can create corner bead ranging from 20mm to 30mm.

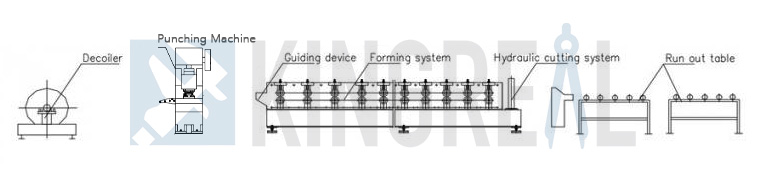

2/ Working Process of Plasterboard Corner Bead Machine

Decoiler- Leveling machine- Punching machine- Roll forming machine - Cutting station- Output table- Packaging machine(optional)

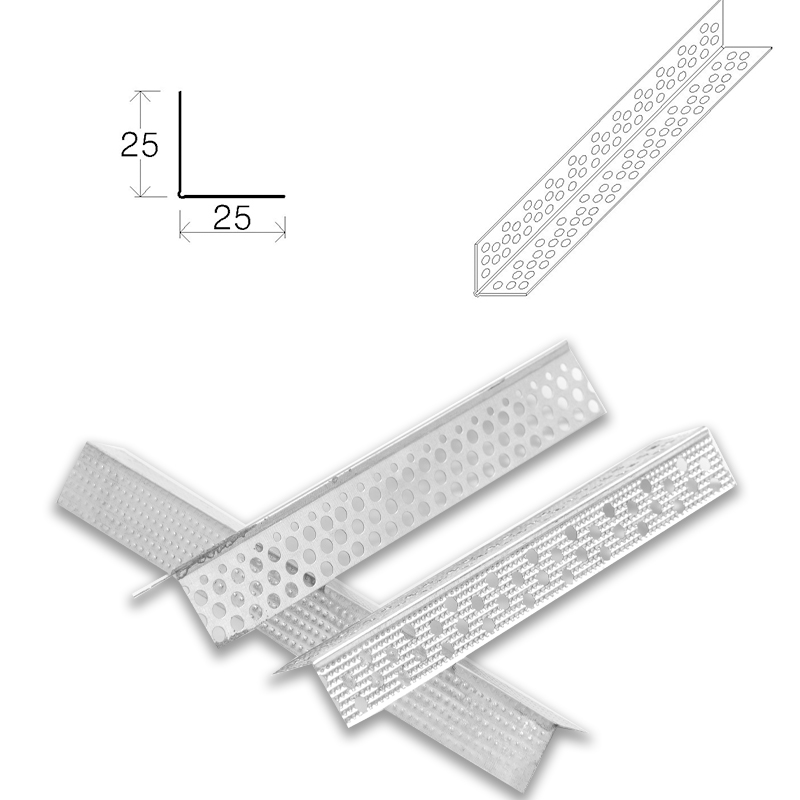

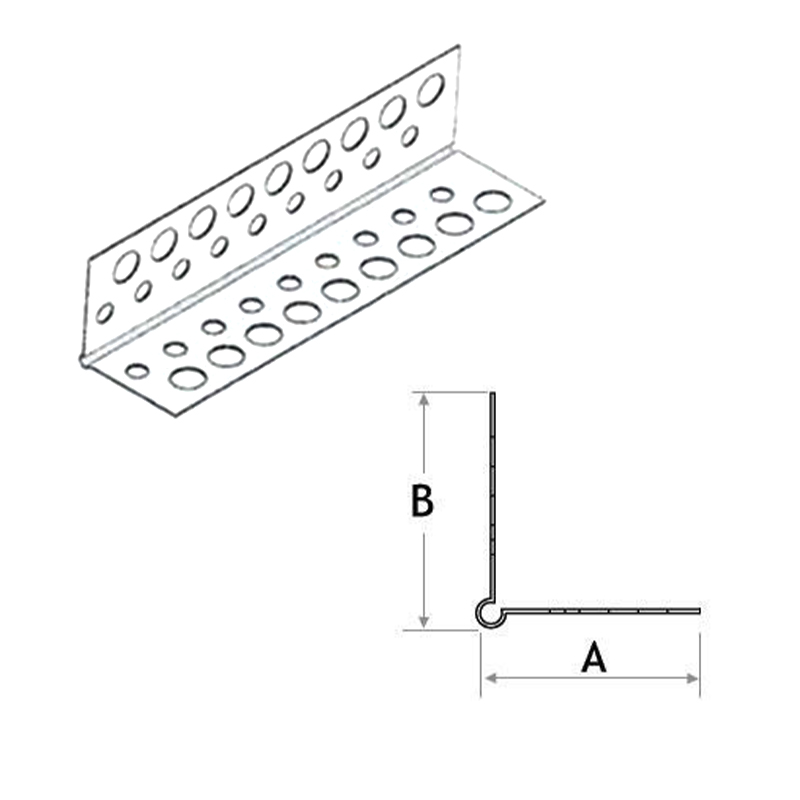

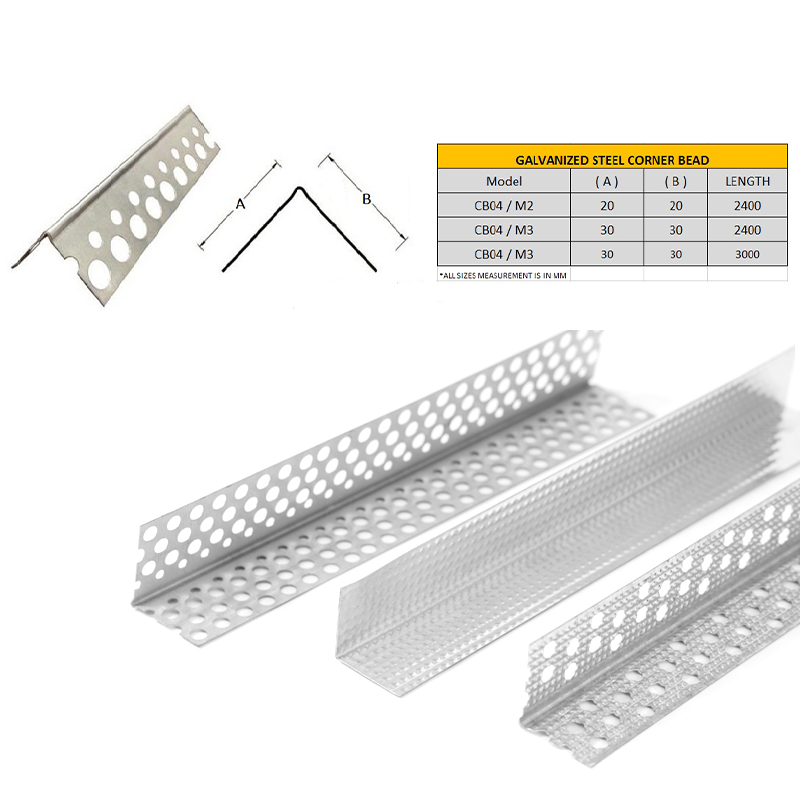

3/ Specifications of Plasterboard Corner Bead

KINGREAL plasterboard corner bead machines can produce a variety of plasterboard corner bead.

Key specifications include:

Material: Available in galvanized, stainless steel, and aluminum.

Sheet Thickness: Available in thicknesses from 0.2mm to 0.5mm.

Length: Standard lengths range from 2.4m to 3m, and custom lengths are available.

Aperture Diameter: Available in various aperture diameters (including frame): 5×15mm, 10×20mm, and 10×30mm.

Width: Corner bead widths can be selected from 20mm×20mm and 30mm×30mm.

These parameters enable KINGREAL plasterboard corner bead making machines to flexibly meet diverse market demands.

4/ Advantages of Plasterboard Corner Bead Machine

1. High speed plasterboard corner bead machine

Boasting an adjustable production rate of up to 120 m/min, KINGREAL plasterboard corner bead making machine are rather amazing. This adaptability lets consumers customize the plasterboard corner bead machine to their individual manufacturing needs for best possible efficiency.

2. Fully automatic plasterboard corner bead making machine

The plasterboard corner bead machine utilizes a PLC control panel for easy operation. Users only define production parameters—including the length and quantity of finished products—and the plasterboard corner bead making machine automatically runs, therefore obviating the need for human intervention from unwinding to discharge and even packaging. This completely automatic perforated corner bead making machine lowers labor costs and increases production efficiency greatly.

3. Customizable accessories for plasterboard corner bead making machine

To enhance the competitiveness of finished products, KINGREAL can also equip its perforated corner bead making machines with an inkjet device. During the forming process, custom text can be printed directly onto the plasterboard corner bead, facilitating subsequent differentiation and sorting of different models.

4. Precision cutting for plasterboard corner bead machine

The cutting station of the perforated corner bead making machine utilizes blades made of high-hardness material, enabling precise shearing and ensuring burr-free finished products. This high-precision cutting process not only improves the quality of the finished product but also reduces subsequent processing.

5/ Application in Partition Wall Systems

Partition wall systems are inseparable from the drywall profile machine and the plasterboard corner bead machine. The stud, track, and corner bead together form a complete wall structure. Specifically:

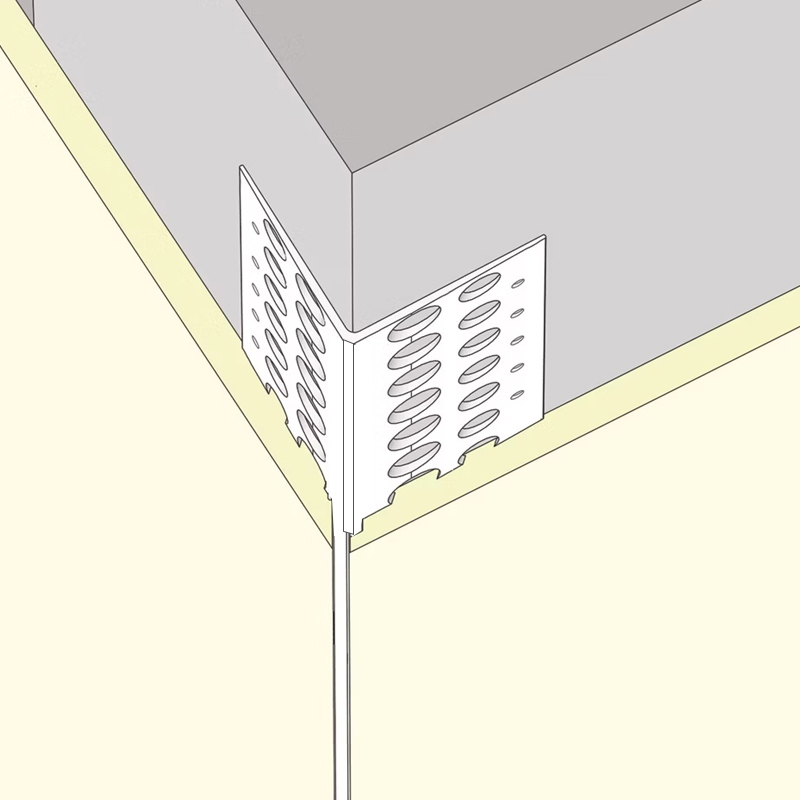

(1)Wall Structure Support

In partition wall systems, the studs produced by the drywall profile machine provide main support as vertical studs, while the track offers a steady bottom and top frame for the wall as horizontal studs. By adding strength to the corners and guaranteeing a perfect fit for the plasterboard, the corner bead generated by the plasterboard corner bead making machine reinforces them. In addition to increasing the wall's general stability, this mix very well shields the edges from damage.

(2)Aesthetics and Functionality

The corner bead produced by the perforated corner bead making machine perfectly complements the studs and track created during construction by the drywall profile machine, therefore creating a more fluid and visually appealing wall surface. The corner bead design enhances the visual flow of the wall while also improving its impact resistance and reducing wear and tear from daily use.

(3)Adaptable to Irregular Structures

The plasterboard corner bead created by plasterboard corner bead making machine can be tailored to the right mortar height and is appropriate for erratic frame constructions. This flexibility makes perforated corner bead making machines suited for use in a range of building contexts and especially valuable in projects calling for wall shape changes.

Modern building—especially partition systems, where their value is great—is using plasterboard corner bead making machine more and more. Customers not only get high-quality plasterboard corner bead but also increase production efficiency and save money with KINGREAL effective plasterboard corner bead machines. Plasterboard corner bead machines will keep a critical part in improving the appearance and structural stability of wall surfaces as the construction sector keeps developing. Choosing a KINGREAL plasterboard corner bead making machine will give you an advantage in the competitive market and achieve higher production efficiency.