What is mechanical press punch?

2025-08-17 12:00Video About Mechanical Punch Press

1/Description of Mechanical Punch Press

Mechanical press punch is an important production equipment in modern manufacturing and is widely used in various industries, especially in fields such as construction, automobiles, electronics, aerospace, etc.

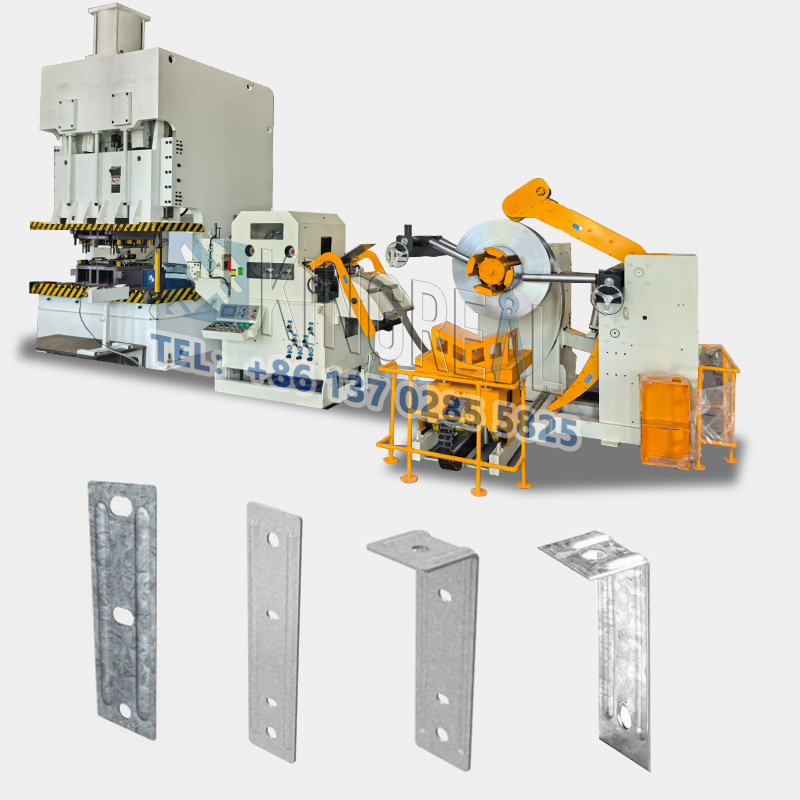

The mechanical punch press can achieve material bending, plastic deformation, punching and the production of reinforcing ribs by stamping metal raw materials such as stainless steel, aluminum, iron and copper, thereby manufacturing various metal mounting brackets of different shapes.

These connectors play a crucial role in the suspended ceiling system, providing reliable support for the installation and fixation of suspended ceiling panels.

In this regard, KINGREAL, as a professional manufacturer of mechanical press punches, not only offers high-quality mechanical punch presses but also provides customers with a complete set of suspended ceiling solutions, including suspended ceiling machines and metal ceiling channel machines, fully meeting the needs of customers.

2/Working Principle of Mechanical Press Punch

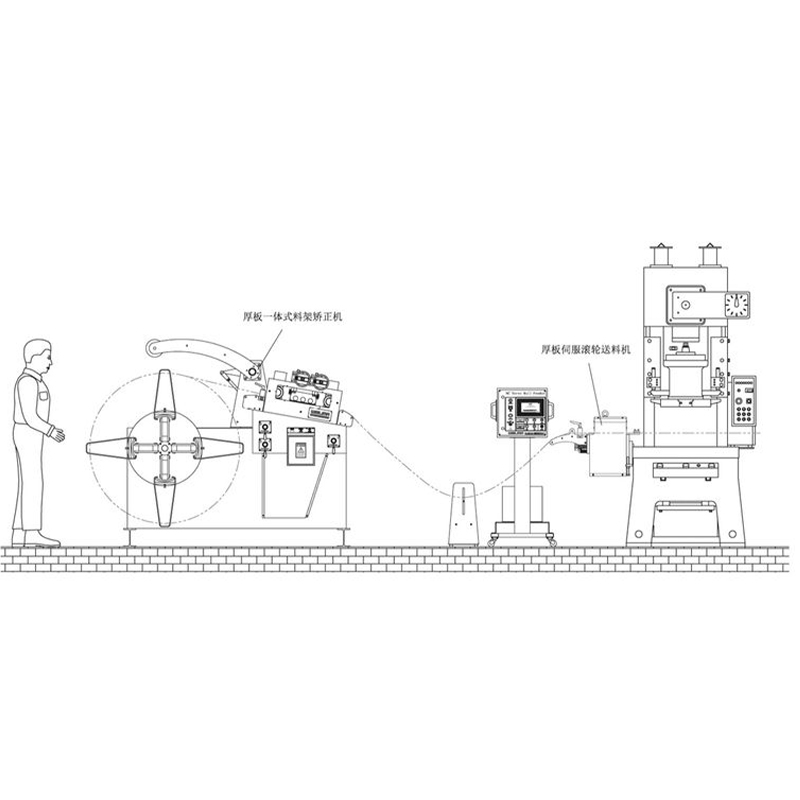

The basic working principle of a mechanical punch press is to utilize the power of a mechanical press to place metal materials in a die. Through processes such as stamping, cutting, and forming, the material is processed. The stamping process usually includes the following steps:

| Material preparation: Firstly, prepare the metal raw materials and ensure they meet the production requirements, such as thickness and strength. Mold installation: Install the required molds onto the press. The design of the molds is customized according to the shape of the parts to be produced. Stamping operation: Start the press, and the metal material undergoes impact, extrusion and other operations in the die to form the predetermined shape.

|

●Metal Mounting Brackets in the Suspended Ceiling System

In the suspended ceiling system, metal mounting brackets are indispensable parts. These metal brackets are used to fix the suspended ceiling panels to the false ceiling channel and connect the ceiling with other building structures or equipment.

Their materials and specifications need to be selected based on the ceiling panels and the installation environment to ensure the firmness and stability of the connection.

●Types of metal brackets in ceiling system

-Metal hooks: Used to fix the ceiling panels to the false ceiling channel, ensuring the stability of the ceiling.

-Connection clips: Used to connect different ceiling panels to form a complete ceiling structure.

-Support rods: Provide additional support and enhance the load-bearing capacity of the ceiling.

3/KINGREAL Offers a Complete Suspended Ceiling System Solution

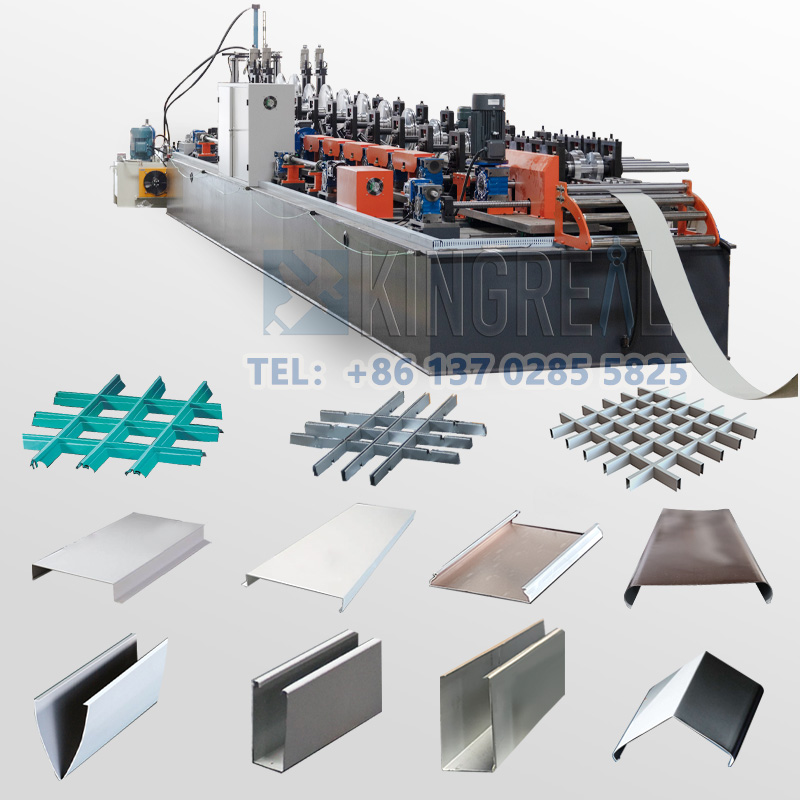

KINGREAL not only offers efficient mechanical press punches, but also provides customers with complete suspended ceiling solutions, including suspended ceiling machine and metal ceiling channel machine.

This entire system can achieve comprehensive production from suspended ceilings to supporting false ceiling channels and then to metal mounting brackets, meeting the diverse needs of customers.

| KINGREAL can provide mechanical press punches of different tonnages. The specific choice depends on the customer's requirements for the thickness, strength and elasticity of the product. The metal brackets produced by the mechanical punch press are used to fix the ceiling panels onto the false ceiling channel. The material and specifications of these connecting parts need to be selected based on the ceiling panels and the installation environment to ensure the firmness and stability of the connection.

●Features of mechanical press punch

-High-precision mechanical punch press: It can achieve ±0.004 inches of high-precision stamping forming, ensuring that the size and shape of each part meet the requirements. -Multi-functional mechanical punch press: It can be equipped with various molds and tools to perform operations such as cutting, punching, forming and bending. -High-safety mechanical punch press: Equipped with emergency braking system, protective cover and grating protection device to ensure the safety of operators. -Automated mechanical punch press: Through an automated system, semi-automatic or fully automatic operation can be achieved, reducing manual intervention and improving production efficiency. |

| 2. Metal ceiling channel machine KINGREAL offers a variety of false ceiling channel machines, including u channel machines, corner bead making machines, and hat channel machines. These false ceiling channels are the main components of the ceiling frame, responsible for supporting the entire ceiling structure and ensuring its flatness and stability.

●Features of false ceiling channel machine

-High speed machines: up to 120 meters per minute, enhancing production efficiency. -Multi-functional false ceiling channel machine: The 3-in-1 false ceiling channel machine can produce three types of profiles, namely hat channel, u channel and corner bead, by changing the mold. -High-efficiency cutting station for false ceiling channel machine: The main ceiling channel machine is equipped with a flying shear or swing shear system. It can process shearing without stopping the machine, featuring high speed and efficiency. |

| KINGREAL also offers a variety of suspended ceiling machines, including open cell ceiling machines, linear strip ceiling machines and baffle ceiling machines. Customers can choose different types of suspended ceilings according to their actual application scenarios and preferences.

●Features of suspended ceiling machine

-Flexible suspended ceiling machine: Equipped with a PLC control panel, production parameters can be freely adjusted to meet different production needs. -Automatic suspended ceiling machine: The rollers of the roll forming machine can automatically adjust their width, facilitating the production of ceiling panels of different sizes. -Reduce human labor: Fully automated production minimizes the demand for human labor to the greatest extent, thereby lowering production costs. |

Mechanical press punch is an indispensable equipment in modern manufacturing, especially playing an important role in the production of suspended ceiling systems. By using efficient mechanical press punches, manufacturers can produce a variety of specifications of metal connectors, ensuring the safety and stability of the ceiling structure.

KINGREAL not only offers professional mechanical press punches but also provides customers with a complete set of solutions ranging from suspended ceiling machine and mechanical press punch to false ceiling channel machines.

Through efficient equipment and integrated production processes, KINGREAL is committed to meeting the diverse needs of customers and promoting innovation and development in the construction industry. Whether it's large-scale construction projects or small-scale decoration projects, KINGREAL can provide outstanding products and services, helping customers achieve higher production efficiency and better product quality.