How Does the Warehouse Pallet Rack Machine Work?

2025-08-14 12:00Pallet racking is a material handling system used to store materials on pallets. There are many different types of pallet racks, all of which allow palletized materials to be stored in multiple layers in a horizontal arrangement. Pallet racking is an easy-to-manage storage system designed for quick construction, flexible adjustment, and reuse. Pallet racking system typically consists of box beams, step beams, uprights, shelf panels, and slotted angle.

KINGREAL can customize warehouse pallet rack machine to meet specific customer needs, providing customers with a complete pallet racking system solution.

KINGREAL warehouse pallet rack machine is compatible with a variety of metal materials, including galvanized steel, carbon steel, stainless steel, and copper. To date, KINGREAL has delivered satisfactory warehouse pallet rack machine manufacturing solutions to customers in countries including the United States, Russia, Nigeria, Qatar, and Brazil.

To learn more about this warehouse pallet rack machine, please feel free to email KINGREAL with your inquiries.

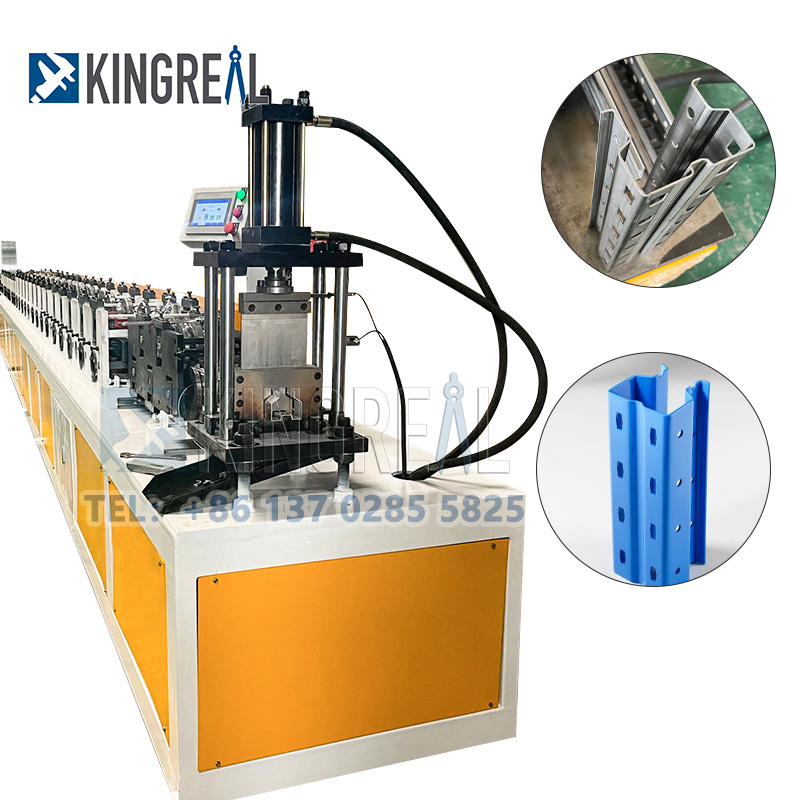

The pallet rack making machine, also known as the storage rack making machine or the omega rack upright machine, produces uprights in a series of steps to specific shapes and sizes. The forming process includes an decoiler, feeding and leveling machine, a punch/hydraulic punching unit, a main roll forming machine, and a hydraulic back cutter. A frequency converter controls motor speed, and a PLC system automatically controls length and quantity, enabling continuous, automated production. This pallet rack making machine is ideal for the cold roll forming industry. |  |

Workflow of Pallet Rack Making Machine

Manual decoiler → leveling → Mechanical press with punch die → roll forming machine → shape cutting → output table

Features of Pallet Rack Making Machine

①Can produce light, medium, and heavy-duty pallet racks for various pallet racking systems.

②The pallet rack making machine utilizes pre-punching, which involves punching holes or notches in the metal strip before forming. This is crucial for mounting components or accessories on storage racks.

③The pallet rack making machine is equipped with a high-speed shearing station, which cuts the metal strip into individual pieces at high speed, ensuring accuracy and speed during the manufacturing process.

Parameters of Pallet Rack Making Machine

| Items | Details |

| Total power | 11-18kW (3 Phase,50Hz,380V) |

| Speed | 16-18m/min |

| Dimension (L*H*W) | (8-11)x(1.2-1.6)x1.6m |

| Weight of machine | 6-9tons |

| Roller station | 14-20 |

| Material thickness | 1.0-3.0mm(G300-G550) |

| Material width | 150-450mm |

| Transmission system | Hydraulic motor |

| Cutting system | Hydraulic cylinder (rear & front cutting) |

| Punching system | Hydraulic |

| Changing size | Manual with spacers |

| Control system | Automatic with inverter, PLC,HMI,hydraulic |

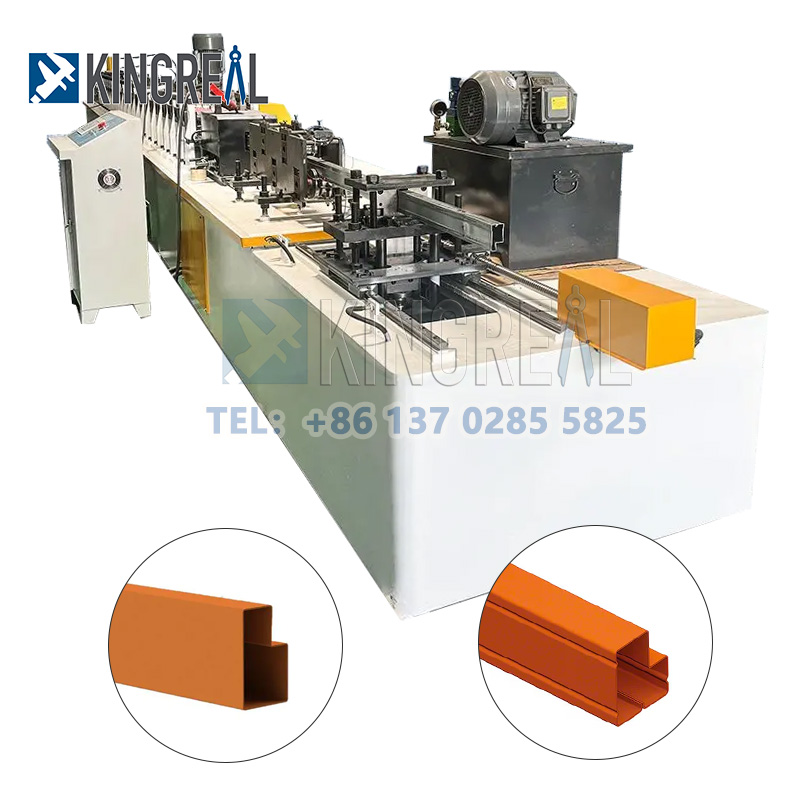

The box beam making machine, also known as the rack box beaming machine, is specialized equipment for producing box beams for warehouse racking. The box beam making machine continuously rolls galvanized steel strip using specially designed rollers to form a unique box-shaped cross-section. |  |

Workflow of Box Beam Making Machine

Uncoil → Continuously Cold Roll Forming → Follow Shearing →

Automatic Turning → Composite Station (Seaming Machine) → Product Output.

Features of Box Beam Making Machine

① This box beam making machine automatically and continuously adjusts product dimensions to accommodate various box beam specifications and shapes.

② Equipped with a seaming machine, the box beam making machine efficiently and securely joins two sections. The seaming rollers move on tracks to accommodate various box beam sizes. Customers only need one operator to control the PLC, eliminating the need for manual welding and the expense of additional welders.

Parameter of Box Beam Making Machine

Machinable Material : | A) Galvanized Coil | Thickness(MM):1.5-2.0 |

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Stainless Steel | ||

| E) Aluminum | ||

| F) Carbon steel | ||

| Yield strength : | 250 - 350 Mpa | |

| Tensile stress : | 350 Mpa-500 Mpa | |

Nominal forming speed(M/MIN) | 10-20 | * Or according to your requirement |

| Forming station : | 18-20 | |

Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Torri stands | * Cast iron stands (Optional) |

| Rollers’ material : | GCr 15 | * SKD-11 (Optional) |

| Cutting system : | Hydraulic cut | * Flying cut (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

Machine color : | According to your requirment | |

The pallet rack step beam machine, also known as a p beam making machine, primarily consists of a manual decoiler, a roll forming machine, a circular saw cutting device, an electrical control system, and an output table. The pallet rack step beam machine is widely used in the production of custom-sized and designed step beams, offering high production efficiency, high precision, and stable performance. |  |

Workflow of Pallet Rack Step Beam Machine

Material Coil → Decoiling → Feeding → Roll Forming → On-Line Spot Welding → Cutting Off → Finished Profile.

Features of Pallet Rack Step Beam Machine

①Applicable Materials: Carbon Steel Coil/Cold-Rolled Coil

②Material Thickness: 1.6 - 2.0 mm

③Profile Dimension Tolerance: ±0.5 mm

④Profile Twist and Linearity Tolerance: 1.0 mm‰

Parameters of Pallet Rack Step Beam Machine

Machinable Material : | A) Galvanized Coil | Thickness(MM):1.5-2.0 |

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Stainless Steel | ||

| E) Aluminum | ||

| F) Carbon steel | ||

Yield strength : | 250 - 350 Mpa | |

| Tensile stress : | 350 Mpa-500 Mpa | |

| Nominal forming speed(M/MIN) | 10-20 | * Or according to your requirement |

| Forming station : | 26 | * According to your profile drawings |

| Decoiler : | Hydraulic decoiler | * Double head decoiler (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Torri stands | * Cast iron stands (Optional) |

| Rollers’ material : | GCr 15 | * SKD-11 (Optional) |

| Cutting system : | Saw cut | * Flying cut (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | According to your requirment | |

This fully automatic storage shelf panel machine is easy and quick to operate, producing high-precision finished products with scratch-free and crack-free surfaces. This storage shelf panel machine is widely used in the shelf system industry. |  |

Workflow of Storage Shelf Panel Machine

Decoiling — Leveling — Pre-Punching — Roll Forming — Two-Side Bending — Cutting — Both-End Bending — Discharging

Features of Storage Shelf Panel Machine

①Customized punching dies based on customer drawings, capable of producing various hole shapes, including square and round.

②Encoder records signal feedback and displays the exact product length on the display.

③The hydraulic system is equipped with a cooling system to ensure continuous low temperatures throughout the day.

Parameter of Storage Shelf Panel Machine

| NO. | Item | Specification |

| 1 | Metal decoiler(with feeding trolley) | 3T/5T/8T/10T/15T/20T |

| 2 | Feeding device | 200mm-1500mm |

| 3 | Front shear | Automatic cutting/Manual |

| 4 | Roll forming machine | 8m/min -22m/min |

| 5 | Safety cover | Guardrail/Protective cover |

| 6 | Panel cutting | Fixed/Tracking |

| 7 | Output System | Manual supporter|Automatic palletizer |

| 8 | Panel stacking direction | Parallel/perpendicular |

| 9 | Lubricating system | Automatic bearing lubrication system |

| 10 | Hydraulic system | Powering the decoiler and cutting machine |

| 11 | Electric control system | PLC and HMI control panel |

Slotted angle making machine also known as Rack L Angle This machine is used to produce long steel strips with perpendicular sides. Slotted angle comes in both equal and unequal leg angles. These channels are typically available in a variety of sizes, with continuous punched holes on both flanges for connection or bolting. They can be produced in a variety of widths and nearly any length. The slotted angle making machine offers high forming accuracy and cut-to-length capabilities, significantly increasing customer production capacity. |  |

Workflow of Slotted Angle Making Machine

Decoiling – Leveling – Hole-Punching – Roll Forming – Hydraulic Cutting – Final Proliferation

Features of Slotted Angle Making Machine

① In addition to pneumatic punching, KINGREAL offers hydraulic punching options for the slotted angle making machine. The hydraulic punching station offers the advantage of expandable multi-station configurations, allowing for multiple punching requirements.

② It can process metal coils with a thickness range of 2-8mm and is widely used in both light-duty and heavy-duty pallet racking systems.

Parameters of Slotted Angle Making Machine

| Coil width (mm) | 250 to 450 |

| Coil thickness (mm) | Up to 0.5 |

| Roll Shaft Dia. (mm) | 50 |

| Horizontal distance b/w stations (mm) | 200 |

| Vertical distance b/w stations (mm) | 120 |

| Max. Profile Height (mm) | 50 |

| Required Power (H.P.) | 10 |

| Line Speed (mpm) | 20 |